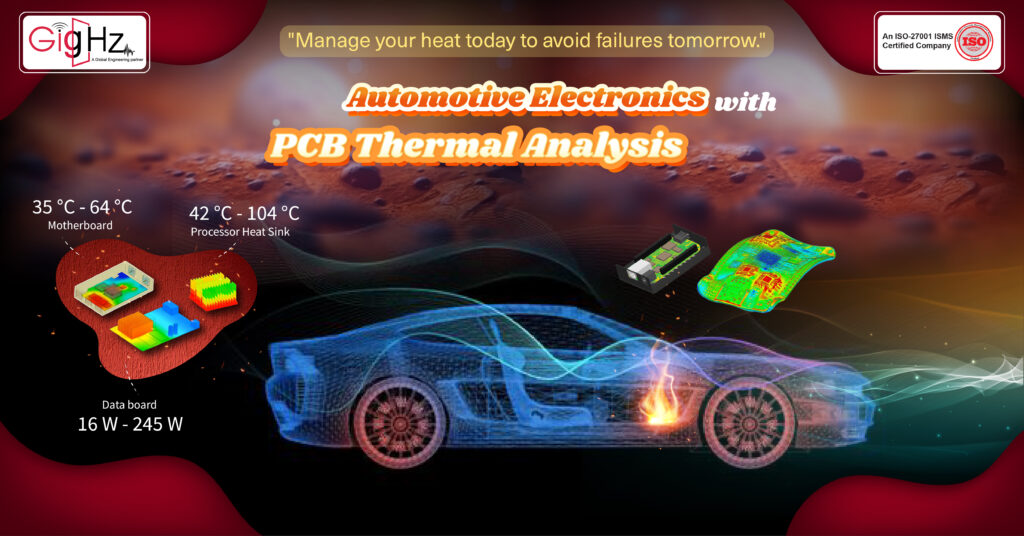

Keep Cool: Analyzing Automotive Electronics with PCB Thermal Analysis

- Posted On:

- July 10, 2024

- Category:

- Analysis & Simulation

PCB Thermal Analysis

Hey Readers!

When it comes to the world of electronics, especially in the realm of printed circuit boards (PCBs), there’s a hidden hero that often goes unnoticed but plays a critical role in the performance and longevity of electronic devices – PCB thermal analysis.

Imagine this: every time you use your smartphone, laptop, or even start your car, intricate electronic components are at work, generating heat as they operate.

This heat, if not managed effectively, can lead to performance degradation, premature component failure, or even safety hazards.

Here’s where PCB thermal analysis steps in as the unsung champion.

By delving deep into the thermal behavior of PCBs, engineers can optimize designs to enhance heat dissipation, ensure component reliability, and ultimately elevate the overall performance of electronic systems.

From optimizing the layout of components to selecting the right materials, PCB thermal analysis is the cornerstone of innovation in electronics.

It’s not just about cooling down; it’s about unlocking the full potential of electronic devices and pushing the boundaries of what’s possible in the world of technology.

So, the next time you hold a device in your hands, remember – behind its sleek exterior lies the meticulous work of PCB thermal analysis, shaping the way we experience and interact with electronics on a daily basis.

Let’s dive in for Automotive Electronics!

Keep Cool: Analyzing Automotive Electronics with PCB Thermal Analysis

Modern vehicles, especially electric ones, have complex systems with high-power electronics that require careful heat management for optimal performance.

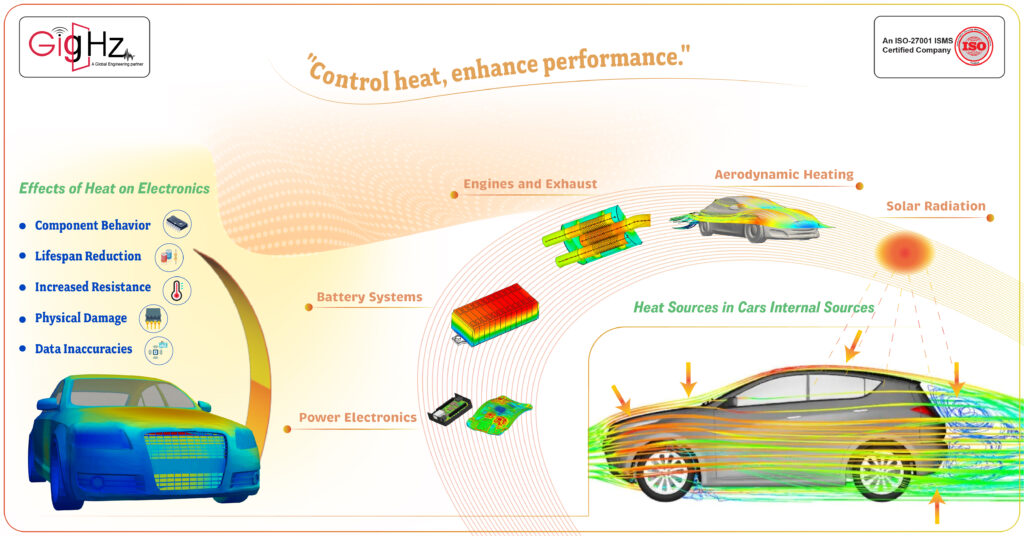

Heat Sources in Cars Internal Sources

- Power Electronics: Components like inverters in electric vehicles generate heat due to high current flows.

- Battery Systems: Batteries in EVs produce heat during charging and discharging cycles.

- Engines and Exhaust: Internal combustion engines release a lot of heat, which can affect nearby electronic parts. External Sources

- Ambient Temperature: Hot weather can add external heat to the vehicle.

- Solar Radiation: Direct sunlight can raise temperatures inside the vehicle.

- Aerodynamic Heating: Fast-moving vehicles can experience increased heat due to air friction.

Effects of Heat on Electronics

- Component Behavior: Electronic parts behave differently at varying temperatures.

- Lifespan Reduction: High temperatures can shorten the lifespan of components like capacitors and resistors.

- Increased Resistance: Materials can become less efficient as temperature rises, leading to thermal runaway.

- Physical Damage: Extreme temperatures can damage components like solder joints and cause failures.

- Data Inaccuracies: Sensors may give wrong readings if exposed to extreme temperatures, risking safety.

Thermal Challenges in Modern Automotive Systems

Miniaturization and High-Density Packaging

Modern cars face tough heat challenges as they strive for top performance, efficiency, and new features. The push for smaller sizes and more electric parts has made dealing with heat in cars even more important.

Small Size and Many Parts Limited Space: Cars today are designed to be compact, especially in cities. Packing lots of parts closely together can lead to hot spots where heat gets trapped.

More Parts, Less Room: As cars get more advanced, they need more electronic parts. These parts generate a lot of heat, especially when packed tightly together.

Material Issues: Some materials used in small parts may not handle heat well. This can create hot spots that are hard to cool without smart solutions.

Efficiency vs. Cooling: Smaller parts can work better but might struggle to get rid of heat effectively because they have less surface area.

Electric Cars and Strong Electronics Electric and Hybrid Cars: Electric vehicles (EVs) mainly produce heat from batteries, inverters, and motors, unlike traditional cars that make heat from burning fuel. When these parts work hard, they can get very hot, needing good cooling.

Powerful Electronics: Modern car electronics, especially in EVs, need a lot of power. Power inverters, which help convert battery power, can get hot because they handle high currents.

Battery Care: Batteries not only make heat during use but also need steady temperatures to last long and stay safe. If they get too hot, they can wear out faster or even catch fire.

To keep cars running safely and well, engineers are always looking for creative ways to handle the heat challenges brought by small sizes and electric technology. They explore new materials and smart cooling systems to ensure car electronics work efficiently and reliably.

Electrification and High-Power Components

Electric and High-Power Components Electric and Hybrid Cars: The switch from traditional engines to electric power has changed where heat comes from. In electric cars, heat mainly comes from batteries, inverters, and motors, while combustion engines create heat through burning fuel. These parts can produce a lot of heat, especially during fast charging or high speeds, requiring efficient cooling.

Powerful Electronics: Modern car electronics, particularly in electric vehicles, require significant power. Power inverters, which convert battery power for electric motors, can handle high currents, leading to substantial heat generation.

Managing Battery Heat: Batteries not only generate heat during use but are also sensitive to temperature changes. Maintaining the right battery temperatures is crucial for longevity, safety, and performance. Overheating can shorten battery life and, in extreme cases, lead to thermal runaway—a dangerous situation where the battery may catch fire or explode.

In modern vehicles, effective thermal management is vital due to the challenges of shrinking sizes and increased electrification. Engineers continuously seek innovative solutions, such as advanced materials and smart cooling systems, to ensure the safe, efficient, and reliable functioning of automotive electronics.

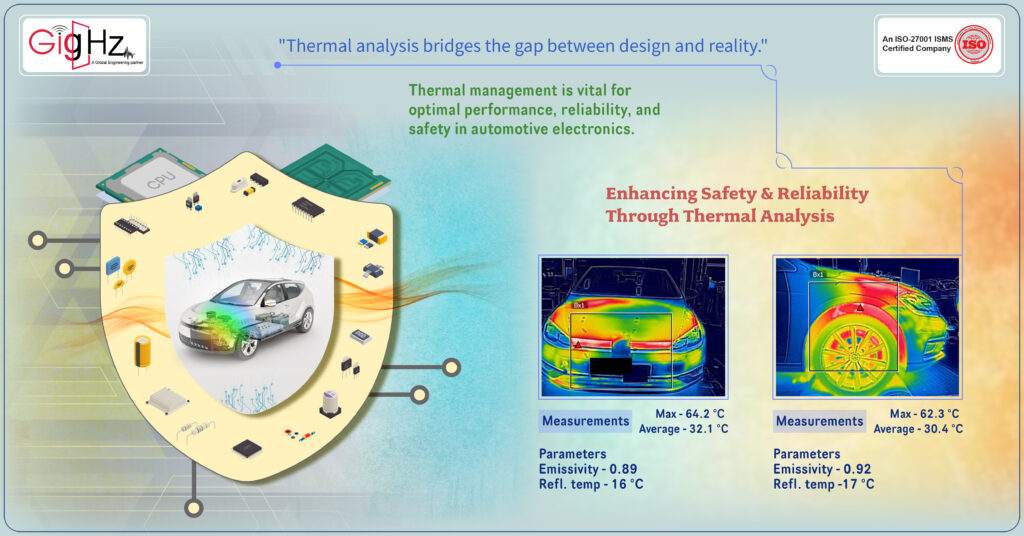

Enhancing Safety & Reliability Through Thermal Analysis

In vehicles, safety is crucial as electronics are used for important functions like braking and steering. Overheating can make these systems fail, putting the vehicle and passengers at risk.

For electric vehicles, managing batteries is essential to avoid issues like fires caused by overheating.

Reliability means electronics should work well in all conditions. Good thermal management ensures consistent performance, whether it’s hot or cold outside.

Managing heat helps electronics behave predictably, especially in systems that rely on feedback to work properly.

Preventing thermal runaway is important to stop components from getting too hot during operation, which can lead to inefficiency and damage.

Thermal management is vital for optimal performance, reliability, and safety in automotive electronics, especially as more electronics are used in vehicles each year.

Final Thoughts

Conducting thorough PCB thermal analysis is essential for ensuring the reliability, performance, and safety of automotive electronics.

By accurately assessing and managing heat dissipation within printed circuit boards, engineers can address potential hotspots, prevent thermal issues that may impact component lifespan, and optimize the overall efficiency of electronic systems in vehicles.

Effective thermal management strategies, informed by detailed PCB thermal analysis, play a critical role in enhancing the longevity and functionality of automotive electronics, particularly in the context of the increasing complexity and heat challenges presented by modern automotive systems.

Discover our Specialities. Visit our Services Page. https://gighz.net/thermal-analysis-services-in-pcb/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.