Expert EMC / EMI Simulation Analysis Solutions in PCB Design

Leaders in Electromagnetic Compatibility Testing, from Debugging to Full Compliance

In the rapidly advancing landscape of electronic design, ensuring electromagnetic compatibility (EMC) and mitigating electromagnetic interference (EMI) are paramount considerations. EMI and EMC testing provides a dependable means to anticipate product performance in various electromagnetic environments.

We provide pre-compliance lab testing services, enabling customers to conduct iterative tests and address any issues identified in the design. We promptly share all raw test results, allowing customers to review and devise alternatives or fixes to resolve identified issues.

GigHz analysis of radiated and conducted emissions from electronic products is conducted with precision to confirm adherence to applicable standards. This involves a thorough consideration of critical components, traces, and signal paths while simulating realistic operating conditions.

Leaders in Electromagnetic Compatibility Testing, from Debugging to Full Compliance

In the rapidly advancing landscape of electronic design, ensuring electromagnetic compatibility (EMC) and mitigating electromagnetic interference (EMI) are paramount considerations. EMI and EMC testing provides a dependable means to anticipate product performance in various electromagnetic environments.

We provide pre-compliance lab testing services, enabling customers to conduct iterative tests and address any issues identified in the design. We promptly share all raw test results, allowing customers to review and devise alternatives or fixes to resolve identified issues.

GigHz analysis of radiated and conducted emissions from electronic products is conducted with precision to confirm adherence to applicable standards. This involves a thorough consideration of critical components, traces, and signal paths while simulating realistic operating conditions.

What is EMC (Electromagnetic Compatibility)?

EMC, or Electromagnetic Compatibility, is characterized by the capacity of electronic and communication equipment to function effectively in the presence of interference while also refraining from being a source of interference to neighboring equipment.

EMC = EME + EMI

EME: Electromagnetic Emission (Interference),

EMI: Electromagnetic Immunity.

Effects of EME/EM Interference:

Equipment to Equipment

- Loss of data in digital systems or during data transmission

- Interference with TV and radio reception.

- Malfunction of medical electronic equipment.

- Disruption of automotive microprocessor control systems (e.g., braking) and navigation equipment.

- Malfunction of critical process control functions (e.g., in oil, chemicals, aircraft, railways).

Equipment to Human:

- According to IEEE C95.1 Standard, safety levels are defined concerning human exposure to radiofrequency electromagnetic fields within the range of 3 KHz to 300 GHz.

- ICNIRP Guidelines set limits for exposure to time-varying electric, magnetic, and electromagnetic fields up to 300 GHz.

We focus on the following industries product EMI / EMC testing:

- Industrial Electronics

- Consumer Electronics

- Telecommunications

- Medical

Our cutting-edge and high-speed simulation analysis solutions are designed to empower PCB designers in navigating the complexities of EMI / EMC problems.

Leaders in Electromagnetic Compatibility Testing, from Debugging to Full Compliance

In the rapidly advancing landscape of electronic design, ensuring electromagnetic compatibility (EMC) and mitigating electromagnetic interference (EMI) are paramount considerations. EMI and EMC testing provides a dependable means to anticipate product performance in various electromagnetic environments.

We provide pre-compliance lab testing services, enabling customers to conduct iterative tests and address any issues identified in the design. We promptly share all raw test results, allowing customers to review and devise alternatives or fixes to resolve identified issues.

GigHz analysis of radiated and conducted emissions from electronic products is conducted with precision to confirm adherence to applicable standards. This involves a thorough consideration of critical components, traces, and signal paths while simulating realistic operating conditions.

EMI and EMC Simulation and Analysis at the Product Design Phase

During the product design phase, EMI / EMC analysis & simulation are imperative for electronic products intended for commercial, residential, industrial, or military applications. Compliance with EMC (Electromagnetic Compatibility) and EMI(Electromagnetic interference) standards tests are mandatory. These products must operate effectively within their electromagnetic environment and ensure that their functionality does not compromise the performance of other devices. Incorporating EMI / EMC considerations early in the design process is crucial to meet regulatory standards and maintain overall product reliability

How to Avoid Potential Failures

EMI / EMC Pre-Compliance Testing is instrumental in managing common failures encountered during testing by:

- Minimizing RF noise.

- Ensuring cleanliness of power, ground, and static input/output signals.

- Recognizing and monitoring ESD testing locations.

- Calculating ESD levels.

- Selecting and testing the appropriate power adapter.

- Optimizing functional equipment, such as LCDs.

- Inspecting auxiliary equipment for compliance (often overlooked).

- Adhering to the appropriate protection rating.

- Safeguarding sensitive analog and RF circuitry.

In our tech-dependent world, where reliance on gadgets and devices is pervasive, EMC testing has become mandatory to uphold quality standards.

EMC Testing Routine

The EMC testing routine is tailored based on the device under evaluation, its intended application, and the regulatory standards governing its use. The electromagnetic phenomena replicated through EMC testing include:

- Electrostatic discharges associated with static electricity

- Magnetic fields, such as those emanating from electrical wires

- Electromagnetic surges resulting from a lightning strike

- Fast transients caused by electrical switches, relays, motors, and fluorescent lamp ballasts

- Conducted and radiated electromagnetic noise

- Voltage drops due to burnouts or other power interruptions

To simulate these conditions and assess a device’s capabilities, EMC testing labs employ a diverse range of equipment, including surge generators, power amplifiers, spectrum analyzers, and various other testing instruments.

List of EME and EMI Tests

- Radiated Emission

- Conducted Emissions

- Electromagnetic Coupling

- Radiated Immunity

- Conductive Immunity

- Electrostatic Discharge

- Fast Transient and Burst

- Surge

- Voltage Dips and Drops

- H-Fields

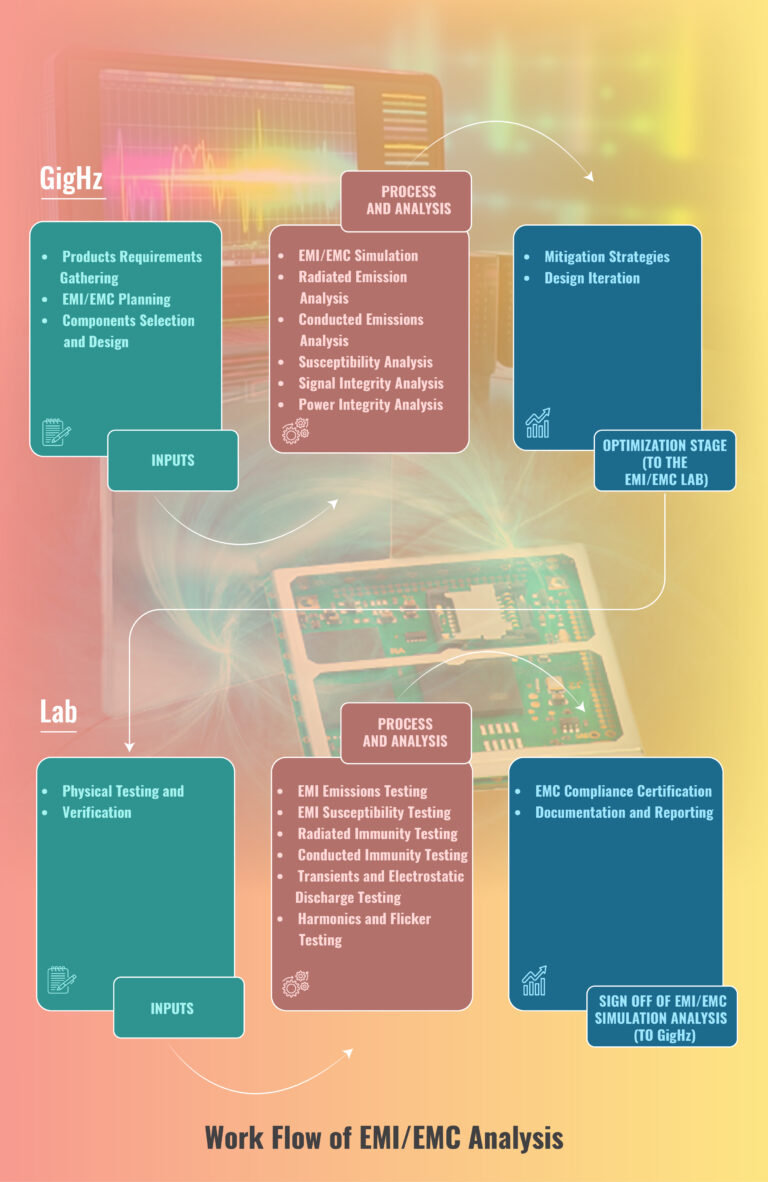

GigHz Electromagnetic Testing Process

To assess the exposure to electromagnetic fields (EMF), our experts conduct tests on physical quantities such as electric and magnetic field strength, magnetic flux density, power density, and contact current, comparing the results against established reference levels. If the measured quantities exceed these reference levels, a more detailed analysis is conducted to evaluate compliance with basic restrictions for physical quantities, including current density, internal electric field, and specific absorption rate (SAR).

We possess the expertise and equipment to measure:

- Magnetic field

- Electric field

- Electromagnetic field

- Induced current density due to the electric field (EMF for lighting equipment)

- Specific absorption rate (SAR) testing

How We Work at GigHz

At GigHz, our approach to EMI / EMC analysis and simulation in PCB design is characterized by a commitment to precision, innovation, and efficiency. Through our dedicated team and cutting-edge tools, we navigate the complexities of electromagnetic compatibility with meticulous attention to detail. By incorporating advanced simulation techniques, we proactively address potential issues, ensuring that our PCB designs not only meet but exceed industry standards.

Ensuring that transmissions adhere to regulations for sharing the available spectrum is equally crucial for the integration of multi-technology devices as traditional EMC tests. In the context of electronic devices coexisting with both humans and the broader living environment, electromagnetic field testing is essential for addressing safety concerns associated with emissions.

Click Here to Set-up a no Cost Consultation now.

Frequently Asked Questions

Q. What are the benefits of using EMI / EMC Analysis in PCB Designs?

A. Prevent EMI: EMC testing can help prevent electromagnetic interference (EMI) from disrupting the operation of electronic devices and equipment.

Reduce EMI: EMC can help determine a circuit’s ability to reduce or eliminate EMI while also reducing noise impact on other circuits.

Reduce the distance between components: Component placement is an important part of EMC and PCB design. It can shorten the distance between electronic components and reduce the risk of EMI.

Boost reliability: EMC testing can improve reliability.

Qualify a device: EMI analysis can determine whether a device is an intentional or unintentional radiator. It can also detect the amount of EMI emitted from a device via signal or power cables.

Q. When can you call a PCB design EMC compliant?

A: We can call a PCB design EMC compliant in the following cases:

It must avoid interference with other systems.

It must exhibit insensitivity to emissions from other systems.

Most importantly, it must prevent self-interference.

Q. How can GigHz-EaaS assist in EMI / EMC analysis services for startups to enterprise companies?

A: Customized Solutions: GigHz-EaaS provides tailored EMI / EMC analysis services, catering to the specific needs of startups and enterprise companies.

Comprehensive Analysis: GigHz-EaaS conducts thorough EMI / EMC analysis, ensuring that electronic products comply with electromagnetic compatibility standards, and mitigating interference risks.

Regulatory Compliance: The service helps companies navigate regulatory requirements, ensuring adherence to industry standards and norms in EMI / EMC analysis.

Performance Optimization: GigHz-EaaS aids in optimizing the performance of electronic systems, enhancing reliability and minimizing the risk of electromagnetic interference.

Early Integration: By incorporating EMI / EMC considerations early in the design process, GigHz-EaaS contributes to efficient and cost-effective solutions for startups and enterprises alike.

Q. What is electromagnetic compatibility (EMC) in the context of automotive electronics?

A. Electromagnetic compatibility (EMC) refers to the ability of electronic systems, such as those used in automobiles, to operate effectively in the presence of electromagnetic interference while also avoiding the production of electromagnetic interference that might affect other systems.

Q. What are the standards for automotive EMC testing?

A. The standards for automotive EMC testing include CISPR 25, CISPR 12, ISO 11452, and SAE standards. These standards outline the test methods, limits, and measurement procedures for ensuring the electromagnetic compatibility of automotive electronic components and systems.

Q. What are the common EMC issues in automotive electronics?

A. Disturbances from narrowband radiated electromagnetic energy, conducted and radiated emissions, and susceptibility to electromagnetic interference from external sources within the automotive environment are all common EMC issues in automotive electronics.