Top 9 reasons: Why PCB thermal analysis is important?

In today’s modern world, we have moved from a time of scarcity in basic needs like food and shelter to a time when everything is available at our fingertips, thanks to mobile phones. This has led to a huge improvement in how connected we are and how easily we can access information. Similarly, in every industry, including automotive, we see a similar move towards advanced technology.

In today’s modern world, we have moved from a time of scarcity in basic needs like food and shelter to a time when everything is available at our fingertips, thanks to mobile phones.

This has led to a huge improvement in how connected we are and how easily we can access information.

Similarly, in every industry, including automotive, we see a similar move towards advanced technology.

Category :

Published Date :

April 23, 2024

Category :

Published Date :

April 23, 2024

Category :

Published Date :

April 23, 2024

The automotive industry, known for its innovation, has embraced cutting-edge technologies to adapt to this era of rapid advancement.

We recently faced an interesting situation in the automotive industry that clearly shows the vital role of thermal analysis in modern engineering practices.

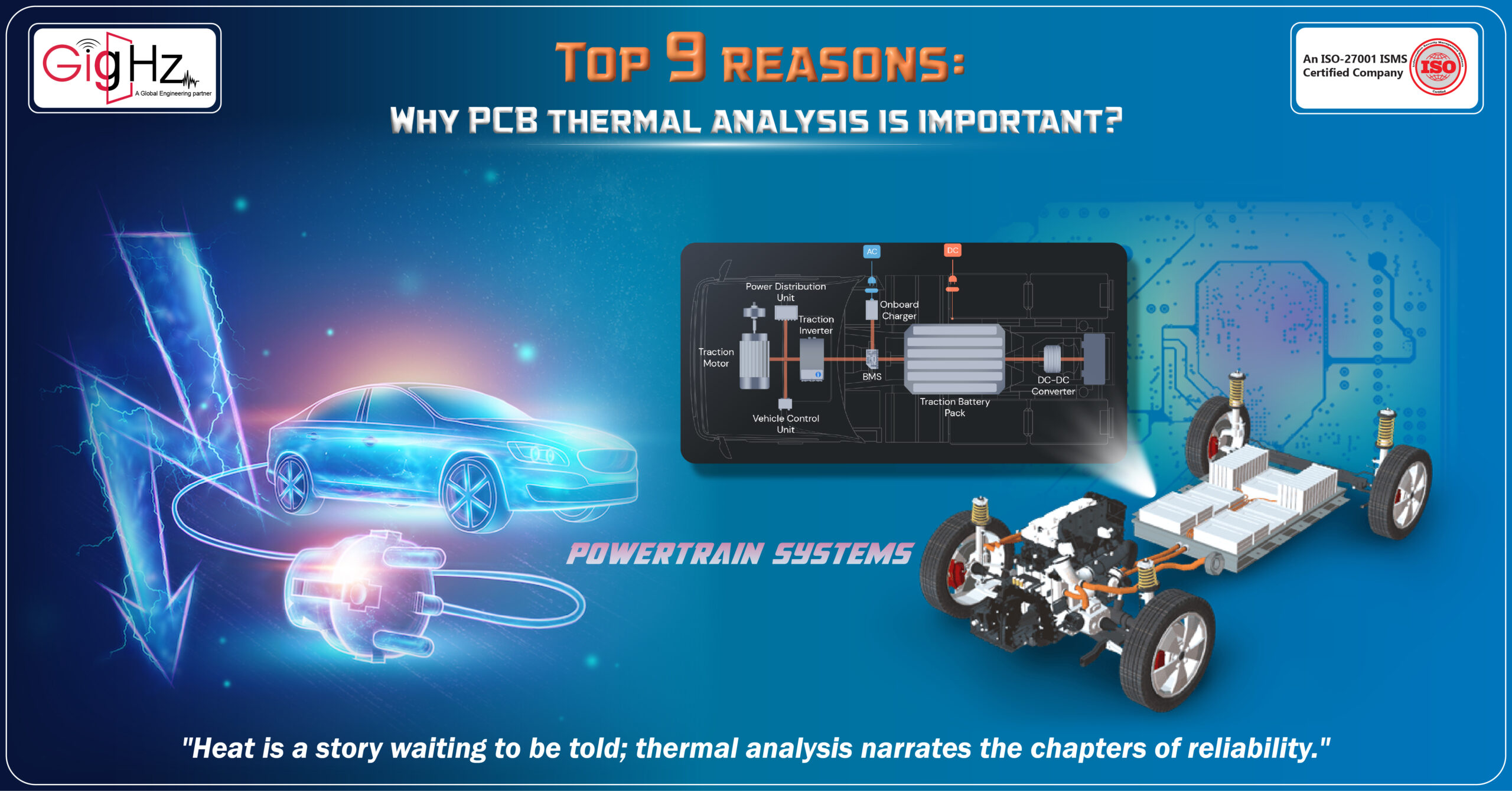

We were given the task of designing a highly advanced printed circuit board (PCB) layout for a client’s electric powertrain systems.

To ensure the PCB’s performance and reliability under tough conditions, we conducted detailed thermal analysis.

This wasn’t the end of the story.

Impressed by the successful results of the thermal analysis, the client came back to us with an even more challenging project that required extensive thermal analysis for another PCB design iteration.

Essentials of PCB Thermal Analysis

When it comes to PCB thermal analysis, we use simulation software to predict the temperature distribution on the board.

This helps us identify potential hot spots that could affect the performance and reliability of the PCB.

By analyzing factors such as component placement, power dissipation, and airflow, we optimize the design to ensure adequate cooling for all components.

Additionally, we perform thermal testing on prototypes to validate the simulation results and make any necessary adjustments.

This comprehensive approach to PCB thermal analysis allows us to deliver products that meet the required thermal specifications and perform reliably in real-world conditions.

Walk us through the execution of the Thermal Analysis

Advanced Simulation Software:

The process began with the utilization of advanced thermal analysis simulation software, such as Ansys, to calculate the temperature distribution and heat flux within the system.

The first step involved defining the material properties and boundary conditions of the components being analyzed.

This included specifying the thermal conductivity, specific heat, and density of each material, as well as the external temperatures and heat sources, renowned for its robust capabilities in thermal analysis.

We construct highly detailed models of thermal data of the PCB layout and its surrounding environment within the automotive powertrain system.

Model Creation:

We meticulously solved the heat transfer equations through the software to determine how heat flowed through the system and where temperature gradients occurred and craft models that precisely emulate real-world conditions.

This includes factors such as material properties, heat dissipation characteristics, and thermal boundary conditions, thereby ensuring a comprehensive representation of the thermal behavior of the PCB layout.

Operational Scenarios:

The sophisticated modeling and simulation tools are utilized to simulate and assess the thermal behavior of the components under varying operational scenarios.

Factors such as power dissipation, thermal conductivity, and heat generation are systematically studied to gain valuable insights into the thermal behavior performance of the PCB within the automotive powertrain system.

This information was then used to optimize the design and placement of thermal insulation, heat sinks, and cooling systems to ensure the system operated within safe temperature ranges.

Temperature Distribution Analysis:

Through the advanced simulations, we conduct an in-depth analysis of the temperature distribution across the layout.

This process enables us to pinpoint potential hotspots and areas for optimization within the PCB design.

Real-World Validation:

Our approach extends to real-world validation through physical testing and data correlation, ensuring that simulations closely align with the actual operational conditions experienced by the PCB within the powertrain system.

This comprehensive validation process validates the accuracy and reliability of thermal analyses conducted.

By leveraging the powerful capabilities, we are able to develop an in-depth understanding of the thermal behavior of PCB layouts within automotive systems, facilitating the optimization of designs for enhanced performance and reliability.

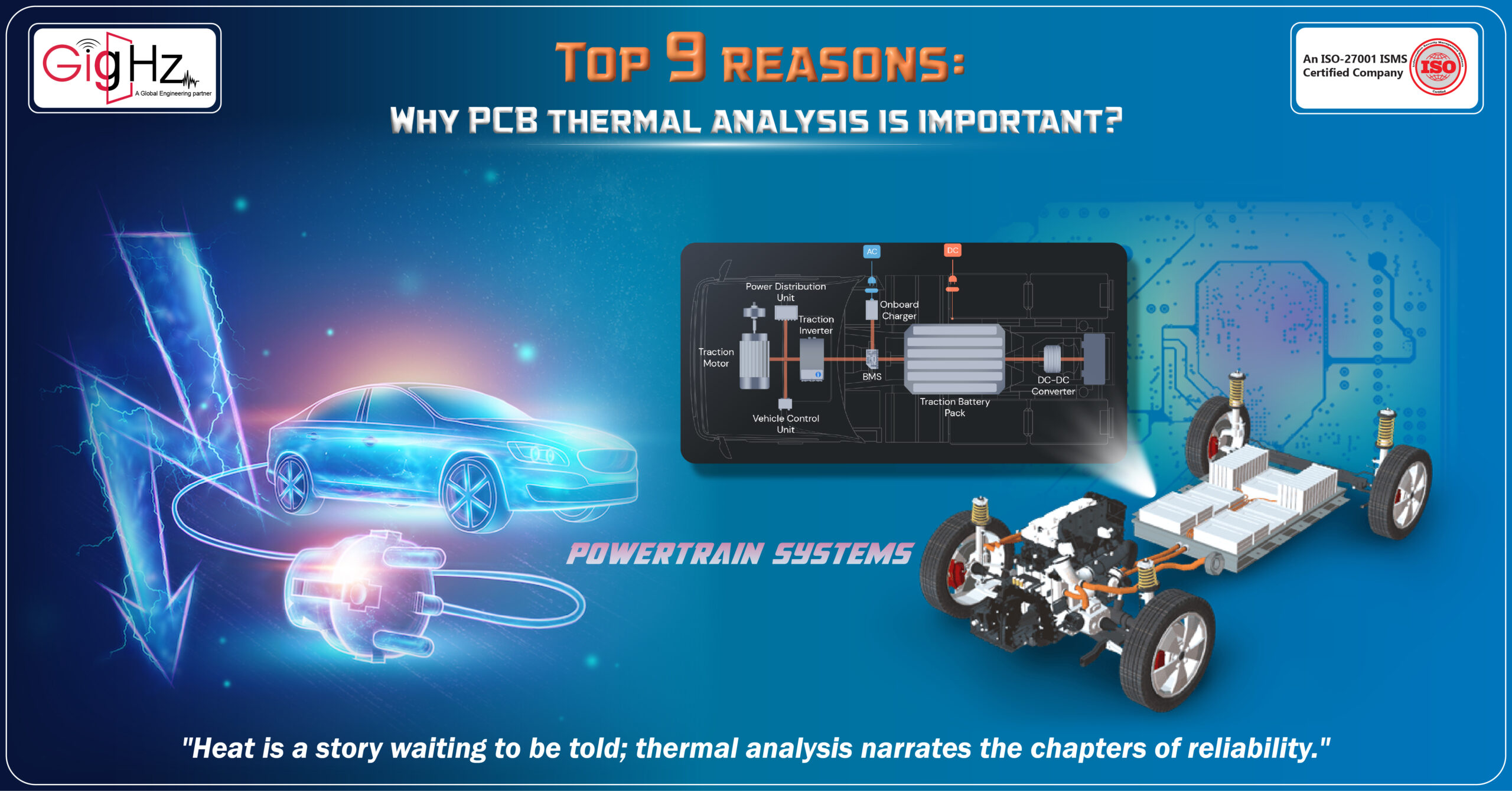

"The top 9 reasons of why the thermal analysis is important for pcb"

Here are the reasons why conducting thermal analysis holds significant importance for us:

Enhanced Reliability: Thermal analysis plays a crucial role in increasing the reliability of PCBs by allowing a deeper understanding of material behavior at various temperatures.

Influence on Design Aspects: The thermal conductivity of PCBs affects all design aspects, from stack-up and material choices to the layout of the board.

Impact of Temperature: Deficiencies in electrical systems, such as dust, vibration, and humidity, are greatly influenced by temperature, making thermal analysis essential for identifying and addressing potential issues.

Critical Factor in Performance: Thermal performance is one of the most critical factors in designing electronic products, and effective thermal management techniques are vital for reducing heating issues in PCBs.

Understanding Heat Generation: Thermal analysis enables a comprehensive understanding of the heat generated by various factors and the flow of heat throughout the entire system.

Tools for Improved Reliability: The availability of advanced PCB thermal analysis tools, including equivalent thermal circuits and expansive simulations, significantly improves the reliability of PCB designs.

Ensuring Operationality and Reliability: Thermal analysis of electronic components, such as amplifiers, is crucial for ensuring operationality and reliability in diverse applications.

Cost Reduction and Reliability Enhancement: Poor thermal design can lead to increased costs and reduced reliability, making thorough thermal analysis indispensable for all PCB designs.

Complete Understanding of Heat Generation: Circuit board thermal analysis involves power distribution analysis and a comprehensive understanding of heat generation within individual components, providing valuable insights for design optimization.

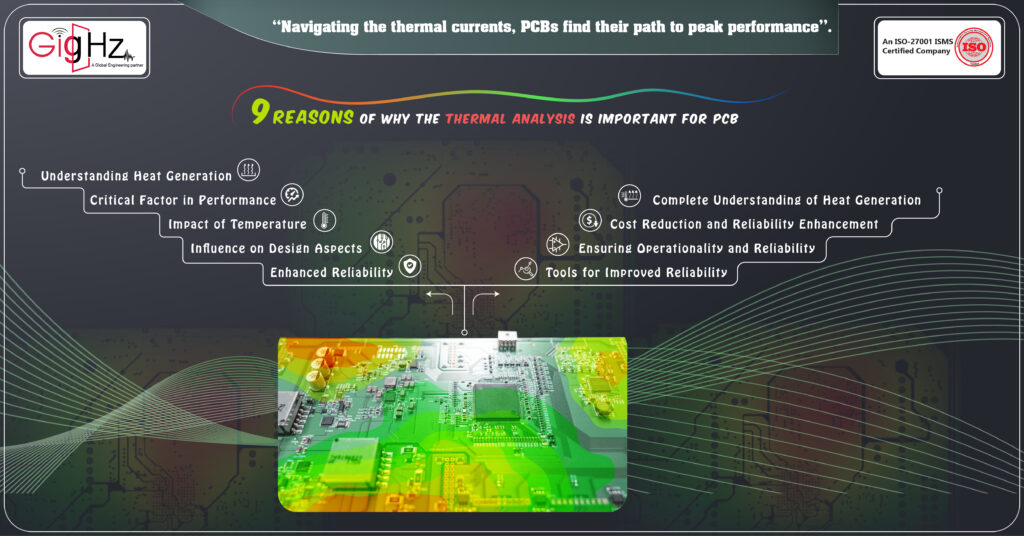

Our Notable Upgrade: Engineering as a Service (EaaS)

Absolutely!

The world of engineering is constantly evolving, and it’s fascinating to see how Engineering as a Service (EaaS) is keeping up with the demands of the industry.

By harnessing the power of ECAD, MCAD, and Analysis & Simulation, we’re able to provide comprehensive solutions that cover every aspect of the engineering process.

It’s really amazing how far we’ve come in terms of integrating different disciplines within engineering. With EaaS, we can seamlessly bring together electronic design, mechanical design, and analysis and simulation, all under one roof.

This not only saves time but also improves efficiency and collaboration among engineers.

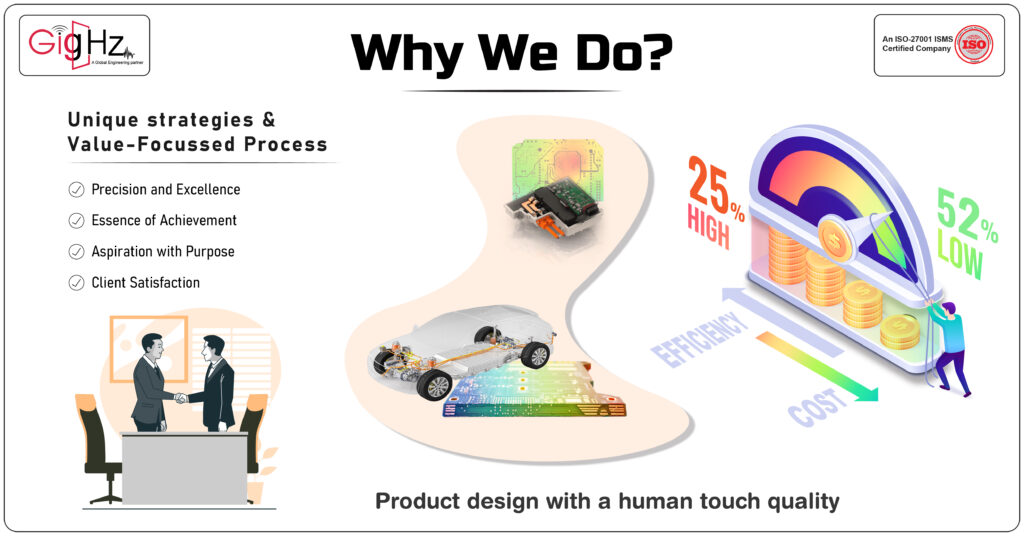

Why we Do?

We challenge our thermal analysis capabilities with emerging technologies of Powertrain systems to keep your time and cost in control, thereby transforming product design with human touch quality.

The rationale behind our commitment to performing thorough thermal analysis is rooted in our unwavering dedication to quality, reliability, and safety.

The harsh operating conditions experienced by automotive powertrain systems necessitate a proactive approach to understanding and addressing potential thermal issues within the PCB layout.

By conducting in-depth thermal analysis, we can preemptively identify thermal hotspots, optimize heat dissipation, and enhance the overall robustness of the PCB design.

Conclusion

Thermal analysis isn’t just a technical requirement—it’s a fundamental aspect of our commitment to excellence.

We take pride in our ability to delve into the intricate thermal intricacies of automotive PCB layouts, ensuring that our clients receive solutions that are not only innovative but also resilient in the face of thermal challenges.

In the fast-paced and ever-evolving automotive industry, our dedication to performing comprehensive thermal analysis stands as a testament to our unwavering pursuit of excellence and reliability.

We look forward to continuing our journey of delivering cutting-edge solutions that redefine the standards of quality and performance in automotive powertrain systems.

Your next adventure starts here – click to explore our specialized services and redefine your expectations!” https://gighz.net/services/