PCB Thermal Analysis Services

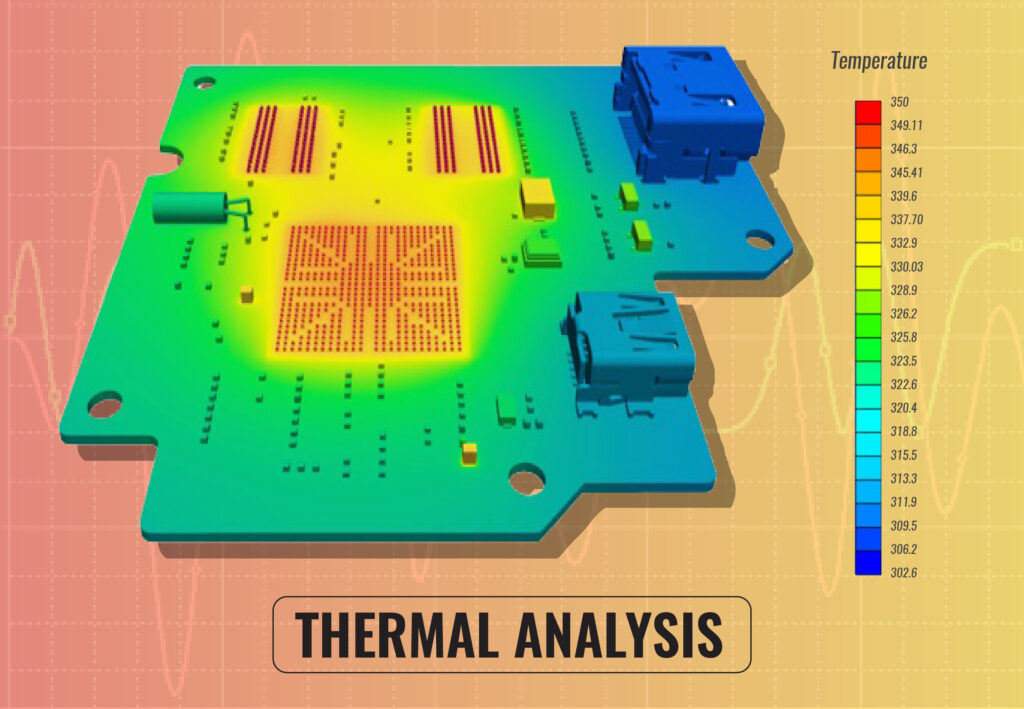

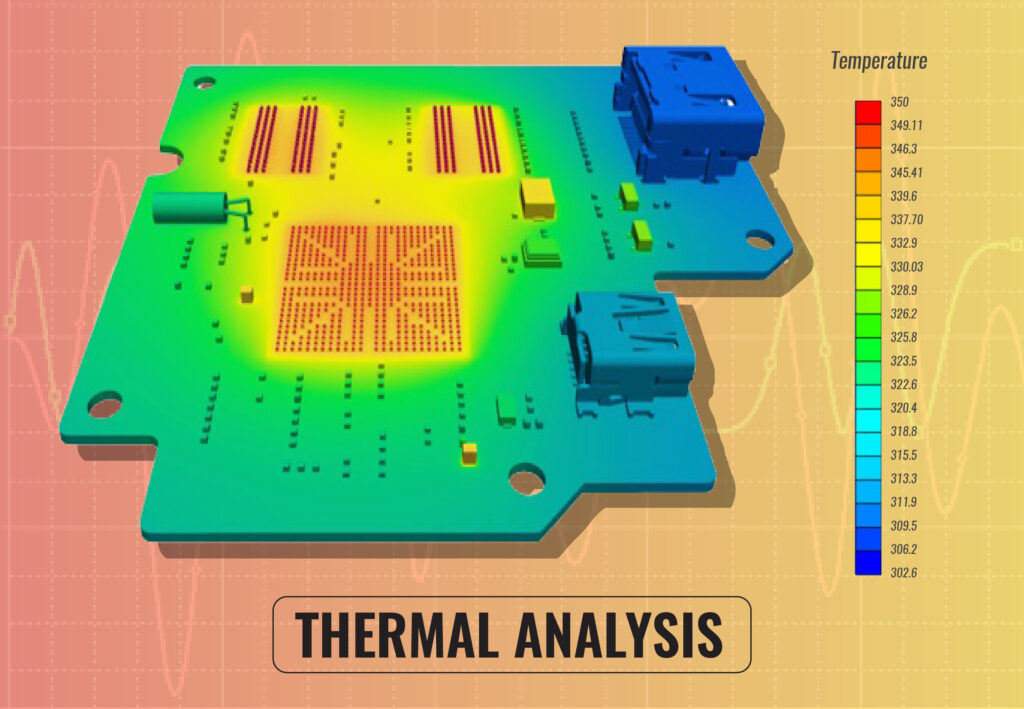

As Printed Circuit Boards become smaller, more powerful and packed with higher-density components, managing heat becomes a big challenge. The potential risk lies in excessive heat, which has the capacity to decrease the performance and reliability of your PCBs. Our Thermal Analysis services optimize PCB thermal design through advanced simulation of airflow, temperature mapping, and cooling for enhanced performance and reliability.

During PCB development, understanding a component’s heat dissipation is critical for layout and thermal management. However, repeatedly fabricating boards with different layouts, vias and heatsinks to test thermal performance is not practical.

PCB thermal simulation provides the solution by enabling the evaluation of various design variants through modeling. It allows observation of overall heat dissipation and identification of thermal issues before fabrication.

With PCB thermal simulation, engineers can:

- Pinpoint potential hotspots and high-temperature areas upfront, thus avoiding costly redesigns.

- Visualize airflow patterns, temperature distribution, and heat transfer across the board layout.

- Refine the design cost-effectively to integrate optimal thermal elements like vias and heatsinks.

As Printed Circuit Boards become smaller, more powerful and packed with higher-density components, managing heat becomes a big challenge. The potential risk lies in excessive heat, which has the capacity to decrease the performance and reliability of your PCBs. Our Thermal Analysis services optimize PCB thermal design through advanced simulation of airflow, temperature mapping, and cooling for enhanced performance and reliability.

During PCB development, understanding a component’s heat dissipation is critical for layout and thermal management. However, repeatedly fabricating boards with different layouts, vias and heatsinks to test thermal performance is not practical.

PCB thermal simulation provides the solution by enabling the evaluation of various design variants through modeling. It allows observation of overall heat dissipation and identification of thermal issues before fabrication.

With PCB thermal simulation, engineers can:

- Pinpoint potential hotspots and high-temperature areas upfront, thus avoiding costly redesigns.

- Visualize airflow patterns, temperature distribution, and heat transfer across the board layout.

- Refine the design cost-effectively to integrate optimal thermal elements like vias and heatsinks.

Why Choose GigHz For Thermal Analysis Services in PCB

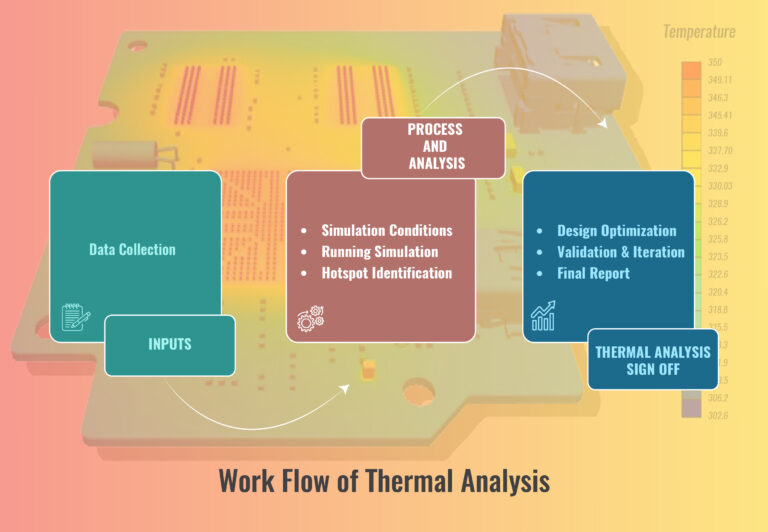

At GigHz , we optimize PCB thermal performance through advanced simulation and analysis. Our powerful CFD and thermal modeling tools allow comprehensive evaluation of airflow, temperature distribution, component placement, heat sinks, and other cooling elements.

With GigHz PCB thermal analysis, designers can:

- Visualize thermal behavior through detailed color mapping of the PCB layout

- Analyze design modifications like thermal vias and heatsinks for enhanced heat dissipation

- Compare temperature profiles of different design variants to choose the optimal thermal solution

- Identify and prevent hotspots across semiconductor devices and PCB tracks

By leveraging GigHz leading-edge simulation capabilities, engineers can refine PCB designs to meet stringent thermal limits and prevent issues like overheating components, electromagnetic interference, and reliability risks.

Key Highlights of our PCB Thermal Analysis Services

- Conduction based heat optimization

- Enhanced cooling through convection analysis

- Airflow consideration

- Enhancement and refinement areas identification

- Prolonged High Temperature analysis to monitor degradation over time

- Reliability Concerns

- Shortened Lifespan

- Performance Limitations

Click Here to Schedule a Free Consultation Now.

Benefits of PCB thermal Simulation

Predict Thermal Issues Early

Thermal simulation allows designers to foresee potential thermal problems in the layout before fabrication. This prevents expensive re-spins later in the development process. Simulation identifies issues that are very difficult to predict manually.

Optimize Layouts and Mitigation Strategies

Engineers can evaluate different layout arrangements and thermal management approaches like heat sinks in simulation. This enables data-driven decisions on optimal placement and thermal design.

Understand Airflow and Heat Transfer

Simulation provides unique insights into airflow paths, temperature distribution, and heat dissipation across the PCB. This level of thermal detail is not possible through manual calculations.

Accelerate Design Iterations

Simulating different design variants is faster and cheaper compared to physical PCB fabrication and testing. Thermal modeling enables quick design iterations.

Thus, PCB thermal simulation is a must-have tool for identifying and mitigating thermal issues early, optimizing designs, and making electronics more reliable.

For reliable, high-performance PCB thermal analysis, choose GigHz. Our expert solutions deliver design optimization, product quality, and cost savings.

Book a Call to Secure your Free Consultation Now.

Frequently Asked Questions

Q: What is Thermal Analysis in PCB Design?

A: Thermal analysis is crucial for advanced PCB’s with high density, power and smaller size. Increased component density and power, can lead to excessive heat, impacting overall electrical performance and reliability. To address potential issues, we perform thermal analysis in the design phase.

Q: Why is thermal analysis important for PCBs?

A: Thermal analysis identifies issues like component overheating early so that the design can be improved. This prevents field failures and ensures reliable performance.

Q: When should thermal analysis be done on a PCB?

A: Thermal simulations should be conducted in the pre-layout stage to guide the design. Additional analysis can be done post-layout to verify thermal performance before manufacturing.

Q: What techniques do you use for thermal analysis?

A: We utilize computational fluid dynamics (CFD) and thermal modeling to simulate conduction, convection, radiation and airflow. This provides detailed temperature mapping.

Q: Do you offer any other thermal analysis services?

A: Yes, we also provide thermal testing and measurement services to validate performance once prototypes are built.

Please contact us if you have any other questions! Our experts are happy to discuss how thermal integrity analysis can improve your PCB design.

Q: How can GigHz-EaaS help provide thermal integrity analysis services for companies ranging from startups to large enterprises?

A: GigHz-EaaS offers scalable thermal analysis capabilities to suit companies at any stage.

For startups, we provide rapid thermal integrity analysis at affordable rates to validate thermal designs fast. Our expertise allows startups to test concepts without delays.

SMBs can leverage our flexible service tiers, from individual thermal simulations to fully managed thermal analysis support. We scale to meet evolving needs.

Enterprises tap into our robust thermal engineering teams to augment in-house skills. Our global delivery model handles massive simulation workloads and complex multiphysics analysis.