Expert Reverse Engineering Services

Do you have a product or part you want to reverse engineer but find it too complicated? GigHz, a trusted Reverse Engineering Company, offers cutting-edge Reverse Engineering Services, enabling the digitization and transformation of almost any item into a precise 3D design CAD model. Through our expert CAD Reverse Engineering Solutions, we deliver highly accurate models that accelerate innovation and manufacturing.

Our MCAD services go beyond traditional PCB design, extending expertise to intricate reverse engineering. This process involves dissecting and extensively analyzing existing electronic products or PCB assemblies to extract valuable design insights.

Get in touch today to learn more about our Reverse Engineering Process.

Do you have a product or a part that you want to reverse engineer but find it too complicated? GigHz offers cutting-edge Reverse Engineering Services, enabling the digitization and transformation of almost any item into a precise 3D design CAD model.

Our MCAD services go beyond traditional PCB design, extending expertise to intricate reverse engineering. This process involves dissecting and extensively analyzing existing electronic products or PCB assemblies to extract valuable design insights.

Get in touch today to learn more about our Reverse Engineering Process.

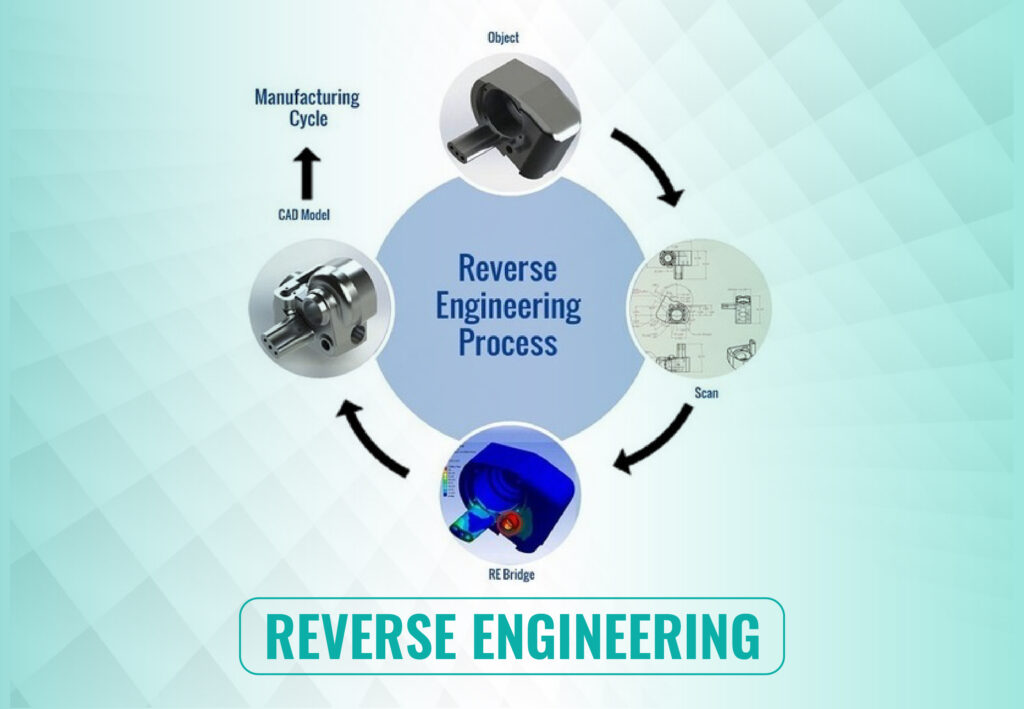

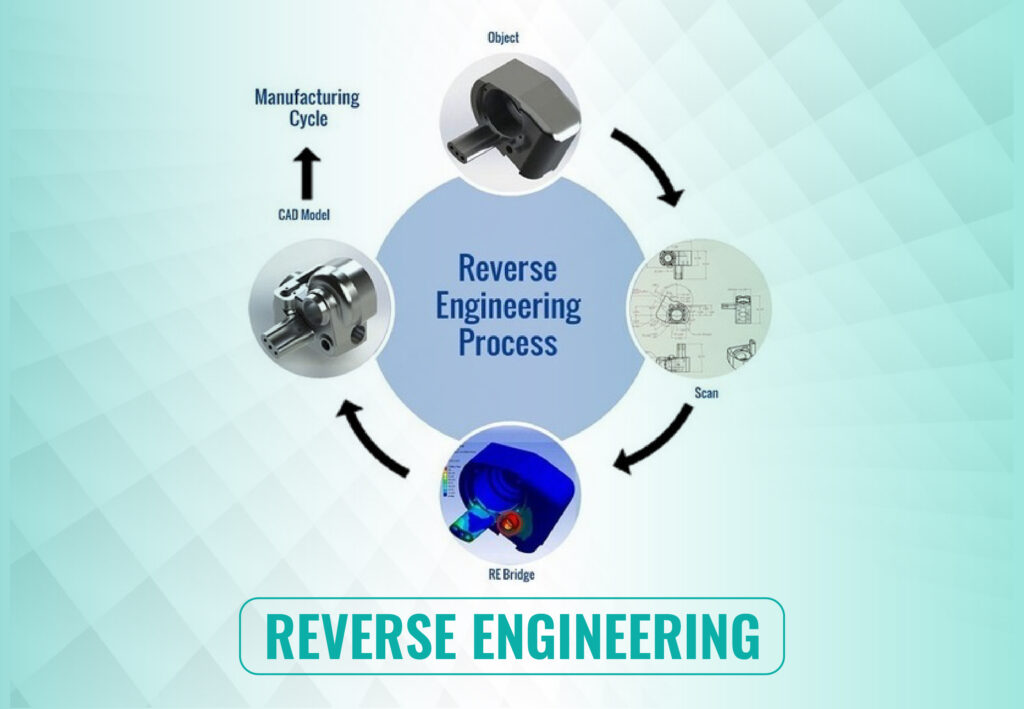

Our Reverse Engineering Process

Project Initiation / Object Identification

In the initial phase of the GigHz Reverse Engineering Services process, we identify the object of interest, which may require detailed analysis. As a trusted Reverse Engineering Company, we begin by understanding your specific requirements, including purpose, timelines, and constraints. Whether replicating, enhancing, or optimizing, we customize our approach to align with your project goals.

Scanning

We apply Design for Manufacturability (DFM) principles to define sheet metal dimensions and ensure quality. Simultaneously, we analyze designs for optimization. RFIs are issued promptly for collaboration where needed. In the selection phase, advanced scanning techniques such as laser or structured light capture physical geometry, forming a precise digital representation—critical for accurate CAD Reverse Engineering Solutions.

RE Bridge

The Reverse Engineering (RE) Bridge connects the physical object and its digital representation. It is the process of converting scanned data into a format that is compatible with computer-aided design (CAD) software. This step is crucial for further analysis and manipulation of the object’s digital model.

3D CAD Modeling

We convert gathered data into insights by creating 3D CAD models and a comprehensive Bill of Materials (BOM). The 3D model undergoes tolerance analysis using tools like FEA and CFD for stability assessment. After finalizing and quality-checking the model, detailed component and assembly drawings are seamlessly integrated into the 2D CAD schematic package.

Ensuring Quality and Swift Dispatch

After integrating your feedback, our manufacturing cycle’s deliverables, including models and drawings, undergo a detailed quality check. The finalized files, featuring a fully functional 3D model (native and .STP) and 2D drawings in PDF format, are promptly delivered. The drawings include detailed components with accurate GD&T annotations and custom notes as per your specifications.

How We Work at GigHz

Part Scanning

Using 3D scanning technologies, we recreate engineering design drawings by scanning entire products or individual parts. Using technologies such as Portable and Fixed CMM, 3D Laser Scanning, and CGI, our engineers replicate parts as the initial phase of the reverse engineering process.

Computer Aided Inspection (CAI) and Computer Aided Verification (CAV)

Post reverse engineering, our team employs CAI/CAV for final validation, ensuring perfect alignment of the recreated piece with the original. Utilizing a 3D scanner, CAI and CAV detect disparities between the recreated part and the computer design or original piece.

Benchmarking

Utilizing reverse engineering, our team identifies the strengths and weaknesses of a product. Subsequently, benchmarking is employed to pinpoint upgrades that optimize the final product. Taking reverse engineering to the next level, our team benchmarks methods to enhance the new product.

Detailed Part Specifications

Going beyond 3D designs and drawings of relevant parts, GigHz meticulously identifies how those parts align with existing commercially available or producible components. By specifying details such as nut and bolt measurements, we provide precise information on creating a product.

Drawing and Modeling Packages

Our reverse engineering teams possess extensive expertise in drawing and modeling software, along with proficiency in related modeling and drafting packages. This ensures the creation of comprehensive technical drawings essential for your reverse engineering project.

Parametric Modeling

In the process of reverse engineering, our teams utilize parametric modeling to create a 3D model that encapsulates the design intent of a product. This not only generates an ideal 3D model but also allows for predictions on how the product will evolve over its lifespan, adding substantial value to the design optimization process.

Hybrid Surface Modeling

Our project teams employ hybrid modeling, which involves using references from scans and integrating them with perfected and idealized geometry of products. This approach enhances accuracy, considers design intent, and minimizes the time and resources needed for each model.

Shrinkwrap Surface Modeling

Our team utilizes Shrinkwrap modeling, a technique that uses scanned surfaces to construct a product representation. This method reduces the data needed for models, particularly in cases of inner complexities, optimizing resources efficiently.

The Benefits of Our Reverse Engineering Services

Discover Cost-Saving Opportunities

Utilize our reverse engineering processes to pinpoint weaknesses and areas of expenditure in your current production process. This insight empowers you to replicate the product more efficiently, ultimately reducing costs and enabling a more budget-friendly production.

Replicate one-of-a-kind Parts

Encounter unique parts for which reverse engineering is the sole solution to understand how to recreate them. Rely on our expert teams for guidance and support in replicating such distinctive components.

Analyze Competitor Products

Utilizing reverse engineering is crucial for analyzing competitors’ products. Our process identifies flaws, defects, and areas for improvement, offering valuable insights for your company’s benefit.

Craft Engineering Drawings for Handmade Prototypes

In scenarios where a designer manually crafts a prototype without accompanying engineering drawings, the need arises to recreate the product using CAD data. Our adept reverse engineering team at GigHz is well-equipped to apply their skills and expertise for precisely this purpose.

Make Changes and Improvements to a Product’s Design

Utilize the expertise of our reverse engineering teams to evaluate your product’s design. Through meticulous analysis and modeling, we can pinpoint areas for improvement and recommend changes that will contribute to an optimal and enhanced design.

Preserve and Document Handmade Molds & Obsolete Parts

In engineering, coming across handmade molds, unique components, or outdated parts without documented drawings is common. With our reverse engineering expertise, GigHz systematically preserves and documents these designs, ensuring their availability and relevance for future reference.

Blueprint Parts for Government Certification

When seeking government or regulatory certification for any product, the submission of blueprints for the parts is often a requirement. In cases where the parts were created without initial blueprints, our engineering services can facilitate the creation of these essential blueprints, ensuring compliance with certification standards.

Get Your Reverse Engineering Process Started Today!

GigHz stands as a worldwide leader in comprehensive Reverse Engineering Services, offering unwavering support throughout the entire lifecycle of new engineering product development projects. As a trusted Reverse Engineering Company, we help organizations modernize designs, extend product lifecycles, and accelerate innovation.

Our team of experts specializes in creating 3D CAD models from existing objects (as-built). Using advanced CAD Reverse Engineering Solutions, we uncover original design intent, upgrade manufacturing processes, and design new parts that integrate seamlessly with legacy components.

Reach out to GigHz today for detailed insights on how we can optimize your design, employ reverse engineering strategies to minimize costs, and deliver a customized solution tailored specifically to your needs.

Book a Call : Schedule a Free Consultation now.