Custom Enclosure Design Services

For Electronics, Machinery & More

Discover unparalleled Enclosure Design Services with GigHz. We specialize in providing solutions for enclosures that harmoniously integrate your envisioned form with intended functionality. Our proficient team of designers and engineers collaborates seamlessly to transform your concepts into tangible, high-performance custom electronic enclosures. With a dedication to precision, durability, and aesthetic excellence, we take pride in delivering solutions that surpass expectations.

As a product design engineers company with a design-centric approach, we harness our design skills to create end-to-end product development enclosures and guide them through the entire development process up to manufacturing.

Explore our extensive range of enclosure design services and entrust us to bring your ideas into reality.

Book a Call to Schedule a Free Consultation Now.

Discover unparalleled Enclosure Design Services with GigHz. We specialize in providing solutions for enclosures that harmoniously integrate your envisioned form with intended functionality. Our proficient team of designers and engineers collaborates seamlessly to transform your concepts into tangible, high-performance custom electronic enclosures. With a dedication to precision, durability, and aesthetic excellence, we take pride in delivering solutions that surpass expectations.

As a product design engineers company with a design-centric approach, we harness our design skills to create end-to-end product development enclosures and guide them through the entire development process up to manufacturing.

Explore our extensive range of enclosure design services and entrust us to bring your ideas into reality.

Book a Call to Schedule a Free Consultation Now.

Industries We Serve

Electrical and Electronics Equipment

From control panels and panel boards to power distribution systems, our enclosure design services are customized for various domains. Whether you require a specialized solution for intricate control systems or durable enclosures for power distribution units, our expertise extends across a broad spectrum.

Industrial Equipment

Sheet metal enclosures are integral components in a wide range of industrial equipment and machinery, offering vital protection for internal components against challenges like debris, dust, and environmental elements. At GigHz, we provide a comprehensive and customized solution to meet your unique enclosure needs, showcasing our commitment to excellence across diverse domains.

Automotive Industry

Within automotive design, sheet metal enclosures stand out as indispensable components, fulfilling crucial functions across various automotive systems. These enclosures play a pivotal role in safeguarding internal automotive parts from the adverse effects of debris, dust, and environmental elements. Our dedicated team of designers and engineers brings versatility and proficiency to every project.

Industrial Equipment

Sheet metal enclosures are commonly employed in design for components such as batteries, electronic control units (ECUs), and other sensitive parts. These enclosures play a dual role, offering protection and contributing to the structural integrity of the overall design.

Medical Devices

Enclosures play a vital role as protective shields for a standard range of electro-mechanical medical instruments, providing a critical defense against potentially adverse conditions present in open environments. In the landscape of medical equipment, where precision and functionality are paramount, these enclosures play a pivotal role in ensuring the reliability and longevity of electro – mechanical engineering instruments.

Telecommunications Infrastructure

Building the intricate web of telecommunications infrastructure, which includes vital components like cell towers and communication cabinets, requires the integration of sheet metal enclosures. These enclosures play a crucial role in offering secure and protective housing for the essential hardware that forms the backbone of the seamless functionality of telecommunication networks.

Our Enclosure Development Project Stages

Within our company, we guide future devices and we assist you to design and develop, ensuring a comprehensive and seamless journey from conception to realization.

Define Requirements

We start by defining the enclosure’s purpose and then evaluate environmental requirements (temperature, humidity, dust, and water resistance). Determining the necessary size and shape follows, considering the components. We gather technical information about these components and account for relevant legal and compliance standards in the design process.

Designing

We create initial designs for the enclosure, integrating the provided information. Factors such as manufacturability, aesthetics, and ease of assembly are carefully considered. We conduct a comprehensive analysis of the pros and cons related to various enclosure materials. Using computer-aided design (CAD) tools, we develop accurate 3D modeling of the enclosure, keeping in mind the precise alignment of dimensions and tolerances with the specified requirements.

Testing

Following the design phase, our in-house engineers swiftly commence real-world scenario testing of your model using software like FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics). This rigorous testing is aimed at validating the concept under real-world conditions. If the results are unsatisfactory or reveal any issues, corrective action is taken. Necessary adjustments are implemented to ensure that the final design seamlessly aligns with your requirements.

Potential Feedback and Improvements

After the successful testing phase, our team of experts analyze your valuable feedback and incorporate it into the final design. Our goal is not just to meet but to surpass your expectations. We refine the design through iterative iterations and optimization to enhance its overall quality. The final product is then delivered to you in the file format of your preference, ensuring convenient accessibility at your convenience.

OUR KEY SERVICES

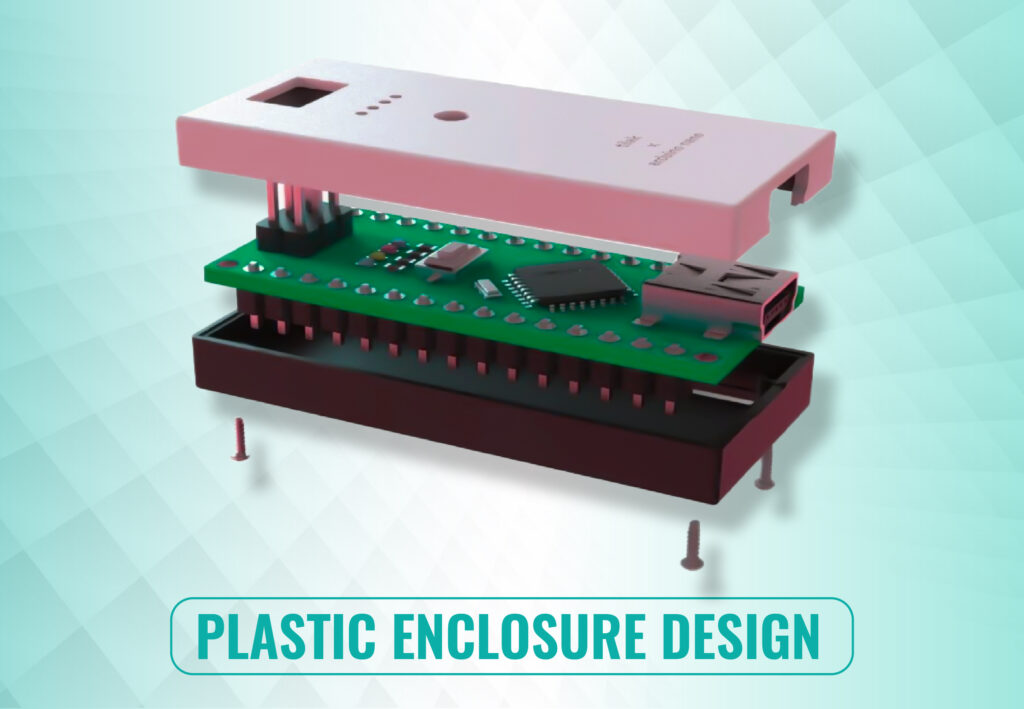

PLASTIC ENCLOSURE DESIGN

GigHz offers Customized Plastic injection Moulded Parts, Indoor and Outdoor Electronic Enclosure Design Services across various sectors, including Automotive Electronics, Consumer Electronics, IoT, Telecom, and Medical Products.

Our Offerings Include:

- Molding feasibility considerations during the design stage.

- Customized enclosure modifications as per customer specifications.

- Ensuring the balance of mass and rigidity.

SHEET METAL ENCLOSURE DESIGN

Our sheet metal enclosure designs turn flat sheets into 3D marvels, offering both protection and style for your electronic products.

Our Services Include:

- Support for metal fabricators and manufacturers in the design process.

- Efficient cooling design to enhance the performance of your electronic components.

- EMI shield is intricately shaped to match component tolerances and safeguard circuit components.

OUR KEY SERVICES

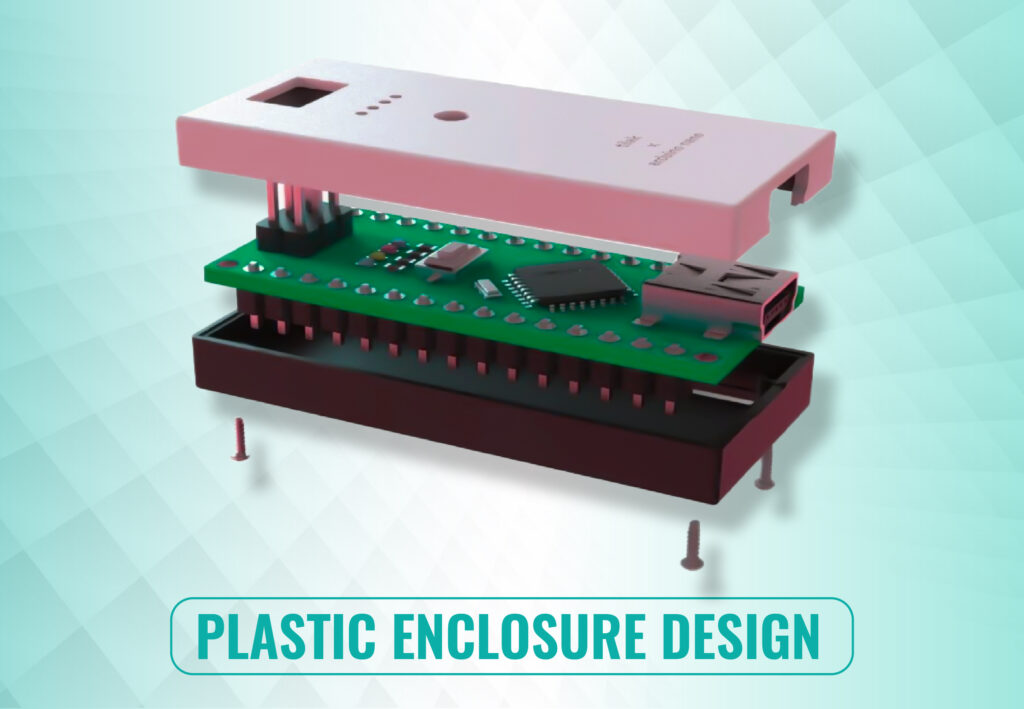

PLASTIC ENCLOSURE DESIGN

GigHz offers Customized Plastic injection Moulded Parts, Indoor and Outdoor Electronic Enclosure Design Services across various sectors, including Automotive Electronics, Consumer Electronics, IoT, Telecom, and Medical Products.

Our Offerings Include:

- Molding feasibility considerations during the design stage.

- Customized enclosure modifications as per customer specifications.

- Ensuring the balance of mass and rigidity.

SHEET METAL ENCLOSURE DESIGN

Our sheet metal enclosure designs turn flat sheets into 3D marvels, offering both protection and style for your electronic products.

Our Services Include:

- Support for metal fabricators and manufacturers in the design process.

- Efficient cooling design to enhance the performance of your electronic components.

- EMI shield is intricately shaped to match component tolerances and safeguard circuit components.

Why Choose Our Enclosure Design Services?

Comprehensive Design and Development

As a product development and design company, our experienced design team offers end-to-end services for the complete enclosure design and development of various products and machine enclosures to meet customers’ needs.

Streamlined and Manufacturable Design

Our skilled engineers and designers collaborate to achieve a sleek enclosure design that is not only aesthetically pleasing but also cost-effective to manufacture.

Diverse Industrial Design Applications

Our expertise extends to the design and development of metal and plastic enclosures, serving a diverse range of industries, including consumer, industrial, and medical sectors.

Materials for Electronics Enclosures

Thanks to our robust supply channels, we are equipped to collaborate with a wide range of materials:

- Various Plastics: ABS, ABS+PC, EK, PC, PE, PVC, PMMA, polyamide plastics, and more.

- Woods: Different wood species, including composite combinations like wood + plastic.

- Metals: Production of enclosure parts using stainless steel, aluminum, and aluminum-magnesium alloys, employing various technologies such as stamping, molding, milling, and extrusion molding.

In addition, we are flexible in incorporating other materials like rubber, ceramics, glass, etc., based on the customer’s preferences.

It’s important to note that selected materials for prototyping may not always be suitable for mass production. For instance, certain plastics used in commercial devices might not be feasible for prototyping. In such cases, we utilize analogs that closely replicate the original material’s characteristics during the prototyping stage.

Why Work With Us

Catering to a global clientele, we have collaborated with startups, entrepreneurs, and businesses, delivering the best enclosure design services tailored to their specific needs. Our design team is proficient in crafting enclosures based on various starting points, ranging from a basic description to detailed components and circuit boards.

Click Here! to Secure Your Free Consultation Now.

Frequently Asked Questions

Q: How do you create a custom electronics enclosure?

A: Initiate the process by compiling a comprehensive list of functional and design requirements for your electronics enclosure, covering aspects such as product usage, operating conditions, regulatory demands, and marketing/design preferences. Connect with a specialized product enclosure design firm like GigHz to obtain a quote for the design, development, and manufacturing phases. Upon project approval, an industrial designer brings the concepts to life, and an engineer translates them into 3D CAD files, primed for prototype manufacturing. The resulting prototype undergoes testing and evaluation. Upon finalizing the enclosure design, it undergoes further refinement to ensure optimal efficiency during mass production.

Q: What does the custom enclosure design service include?

A: At GigHz, our custom enclosure design service has four steps:

Research: Gathering technical, regulatory, functional, and design requirements.

Concept Design: Designing concepts for the product enclosure’s appearance and functionality.

Engineering: Utilizing 3D CAD and simulations to transform the concept into a reliable 3D CAD model ready for prototyping.

Prototyping: Creating physical prototypes based on the 3D CAD documentation.

Q: How Can GigHz-EaaS help in providing enclosure design requirements for startups to enterprise companies?

A: Tailored Solutions for Startups

GigHz-EaaS caters to startups’ specific enclosure design needs, providing customized solutions that meet their unique requirements and budget constraints.

Scalability in Enterprises

For enterprises, GigHz-EaaS provides scalability and flexibility to address complex enclosure design challenges, ensuring that solutions meet the rigorous standards associated with large-scale projects.

Comprehensive support

GigHz-EaaS provides quality enclosure design support across a wide range of business scales, from startups seeking agility to enterprises requiring robust capabilities.