Electronic Product Enclosure

Giving a cheerful welcome to the readers with smiles!

Have you come across the term “shelter” and its significance, dear readers?

I believe that every living thing requires a protective shelter.

Have you all heard about nests?

Nests are not always made by females. Among ‘weaver birds’, it is the duty of males for protective covering to make nests for females so that they can lay eggs.

Similarly, in today’s advancing electronic landscape, every electronic device requires a protective covering known as an “Enclosure.”

MCAD Enclosure is basically about designing protective coverings for electronic gadgets using special software.

It’s like giving these devices a sturdy home to keep them safe and working well.

It’s all about making sure your electronics stay happy and healthy in their little homes!

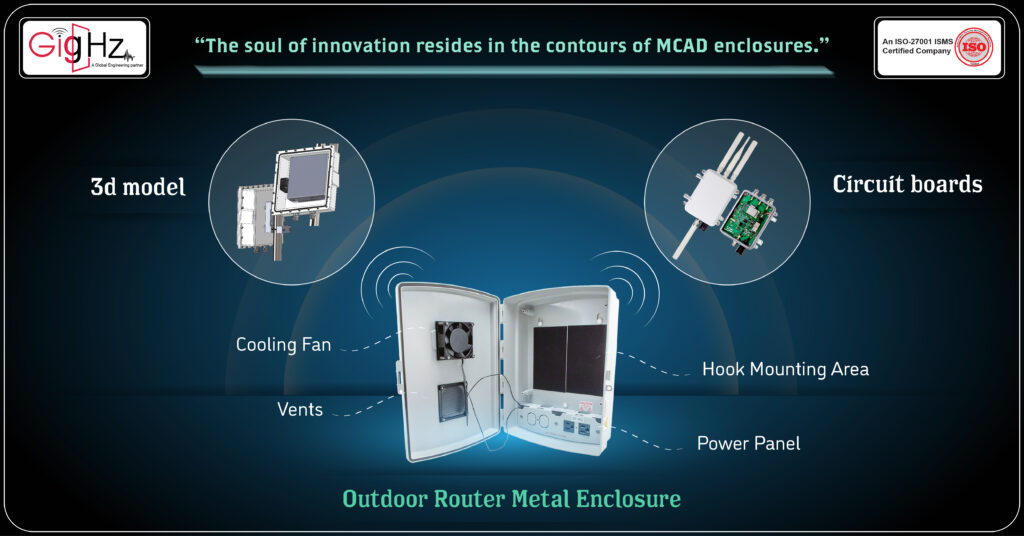

To help you grasp the concept of enclosure design, we’ll walk you through our experience of creating the enclosure for the Outdoor Router Waterproof Enclosure.

We followed standard procedures to ensure a robust and effective design.

Let’s look closer!

Before Design: Understanding Product Requirements

Before Design: Understanding Product, Requirements is a crucial step in the product development process.

Whether you are working on a hardware product or an electronics project, knowing the requirements for the enclosure design is key. Factors such as the weight of the product, the aesthetics of the design, and the corrosion resistance of the materials used all play a role in determining the right type of enclosure to use.

One option is a metal enclosure made of alloy or sheet metal. Another choice is a plastic enclosure created through injection molding. Both options have their advantages and disadvantages, depending on the specific needs of the project. Custom enclosures can also be designed to fit the specific dimensions and requirements of the electronic components inside the enclosure.

Before diving into the mechanical design and creating a 3d model of the enclosure, it is important to understand the functionality and limitations of the enclosure design.

This includes considering factors such as cutouts for circuit boards, fasteners for securing components, and the manufacturing process for the enclosure itself.

By taking the time to fully comprehend the requirements of the electronic enclosure, you can ensure a successful and efficient design process.

Exploring the Essentials Before Designing Our Electronic Design Product

Hey there!

Before diving into the nitty-gritty of designing your product, it’s crucial to lay down the groundwork by understanding a few key aspects.

Let’s take a closer look at what you need to consider:

Short Description of Product Functionality:

First things first, we outline a brief description of what our product will do. This summary sets the stage for the design process and helps keep the end goal in focus.

Ideas for Exterior Appearance:

Next up, we brainstorm some ideas for the external appearance of our product. Visualizing the outer shell can inspire the design direction and appeal to our target audience.

Customer Interaction Features:

Then, considering how our customers will interact with the product.

Then, we think about connectors, switch buttons, and any other interface elements that make using the product a seamless experience.

Aesthetic Vision:

Envision the final aesthetic of our product, including color schemes, textures, and overall visual appeal. Crafting a captivating design can elevate the product’s perceived value.

Operating Environment:

We consider the environment in which our product will be used or stored.

Understanding the operating conditions helps tailor the design for durability and performance.

Compliance with Standards:

Listing out any standards our product needs to meet, such as UL, FCC, or other industry-specific certifications. Ensuring compliance is essential for market acceptance and legal requirements.

Design Tolerances:

Defining the required tolerances for our design. Precision is key to ensuring functionality and compatibility with other components.

IP Rating Consideration:

We specify the IP rating requirements, like IP31, to determine the product’s protection against dust and moisture. This rating impacts where and how the product can be used.

By addressing these points early on, we set a solid foundation for the design process and pave the way for creating a successful and user-centered product.

Now, let’s bring your vision to life by incorporating these essential elements into your product design journey!

5 procedures to design electronic product enclosure

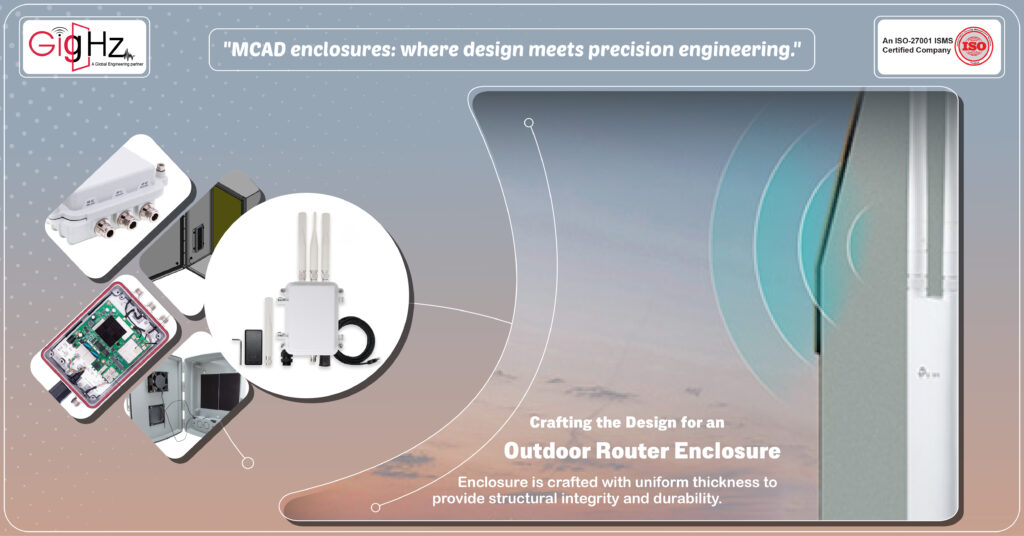

Crafting the Design for an Outdoor Router Waterproof Enclosure

Embarking on the journey of mechanical enclosure design, by designing an Outdoor Router Waterproof Enclosure requires meticulous attention to detail and a seamless blend of technical precision and creative vision.

Let’s tailor the content above to showcase the application in designing this specific enclosure:

Defining Model Requirements for the Enclosure:

In designing the Outdoor Router Waterproof Enclosure, we meticulously outline the model requirements to accommodate essential components such as circuit boards, antennas, and power supply units.

Each element is strategically positioned to optimize functionality and ensure a compact yet efficient design.

Precision Internal Component Modeling with Tolerance Consideration:

Within the enclosure, internal components are modeled with utmost precision, taking tolerance into account.

By understanding how these components may vary, we design with exacting detail to guarantee a perfect fit and seamless integration, enhancing the enclosure’s performance and longevity.

Structural Integrity through Rough Shell Construction:

The rough shell of the enclosure is crafted with uniform thickness to provide structural integrity and durability.

This foundational structure not only shields the internal components from external elements but also sets the stage for further refinement, ensuring a robust and reliable end product.

Thoughtful Cutouts for Connectors

Openings Reinforcing Support with Ribs and Component Holders:

Incorporating cutouts for connectors, LED indicators, and other openings is a key aspect of the design process.

These strategic openings not only facilitate user interaction but also enhance the aesthetic appeal of the enclosure, striking a balance between functionality and visual appeal.

To fortify the internal components within the enclosure, support ribs and holders are strategically placed. These structural features provide stability and security, safeguarding the components against external forces and environmental conditions, thereby ensuring the longevity and efficiency of the enclosure.

By weaving together technical expertise with a keen eye for design aesthetics, we embark on a journey of innovation and functionality to create the perfect Outdoor Router Waterproof Enclosure. Let’s continue this design exploration with a focus on excellence and ingenuity as we shape the future of your product.

Key Tips

Electronic enclosure design is a crucial aspect of electrical and electronic product development.

When designing an electronic enclosure for our new electronic product, there are several procedures to follow.

Firstly, it is important to design the enclosure with the pcb in mind, ensuring that there is enough space for all components. Utilizing cad design software can help with creating a prototype of the enclosure before fabrication begins.

Consider the enclosure size, wall thickness, and enclosure type for your electronic product. Additionally, using 3d printed metallic enclosures can be ideal for sheet metal enclosures due to their high temperature resistance.

Another important thing to consider when designing an electronic enclosure is the proper enclosure design for electronics enclosure and sheet metal parts. Different enclosures and sheet metal parts may require different machines for fabrication.

Consulting with expertise in electrical enclosure design, can help you create an enclosure that meets all necessary specifications for your electronic product design.

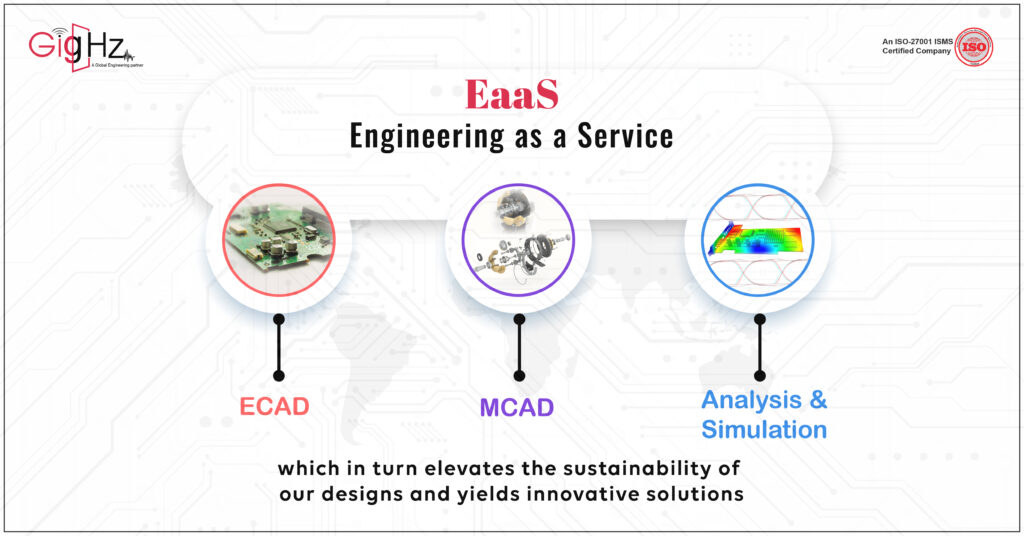

Our Notable Upgrade: Engineering as a Service (EaaS)

Absolutely! As the demand for advanced engineering solutions keeps growing, our Engineering as a Service (EaaS) is really stepping up its game.

We’re tapping into the power of ECAD, MCAD, and Analysis & Simulation, which positions us as frontrunners in the industry.

The fact that we offer a full package, covering every single step of the engineering process, is what makes our approach so exciting.

It’s this kind of forward-thinking approach that’s going to shape the future of our engineering,

It’s truly thrilling!

Conclusion

When it comes to the design of an enclosure for your electronic equipment, the process can be quite complex.

With so many factors to consider, such as size and shape, specific design features, and the needs of the application, designing an enclosure requires careful planning.

From choosing the right design to selecting the appropriate materials for the enclosure, each step plays a crucial role in the final product. In some cases, you may need to add RF shielding or design around other electronic parts to ensure the functionality and safety of your electronics.

Designing a Basic Enclosure: For indoor applications, a metal sheet enclosure is a popular choice for many. The cost-effectiveness and versatility of metal enclosures like RF enclosures make them ideal for a wide range of electronic equipment.

By following the steps for designing an enclosure and creating a detailed bill of materials, you can ensure that your product looks and functions exactly as intended.

Happy Designing!

To know more details, follow our founder on the LinkedIn page https://www.linkedin.com/in/chandra-thimma/recent-activity/all/