Importance of worst-case circuit analysis in Aerospace Industry

- Posted On:

- July 16, 2024

- Category:

- Analysis & Simulation

Worst-Case Circuit Analysis in Aerospace Industry

Aerospace world is in the news a lot lately!

By Highlighting notable advancements in autonomous technology, space exploration, requirements amidst global conflicts, and the progress in clean technology, particularly in power sources and fuels.

Alongside these positive narratives, there have been discussions surrounding industry challenges, including equipment malfunctions and security lapses.

This spotlight on the sector is expected to endure given its critical importance not only to the economy but also to national security, commercial and leisure travel, space exploration, technological innovation across industries, among other domains.

Within Aerospace lie core sectors encompassing aircraft manufacturing, guided missiles, space vehicles, explosives, ammunition, military vehicles, and their intricate systems.

Moreover, the industry includes a network of related supply chain sectors such as metals, plastics, composites, electronics, information technology, and professional services like engineering and research and development (R&D).

In the aerospace industry, worst-case circuit analysis is essential for Unmanned Aerial Vehicles (UAVs) or drones used for reconnaissance, surveillance, and targeted operations.

Let’s start by exploring the latest trends in the Aerospace industry before delving into its significance,

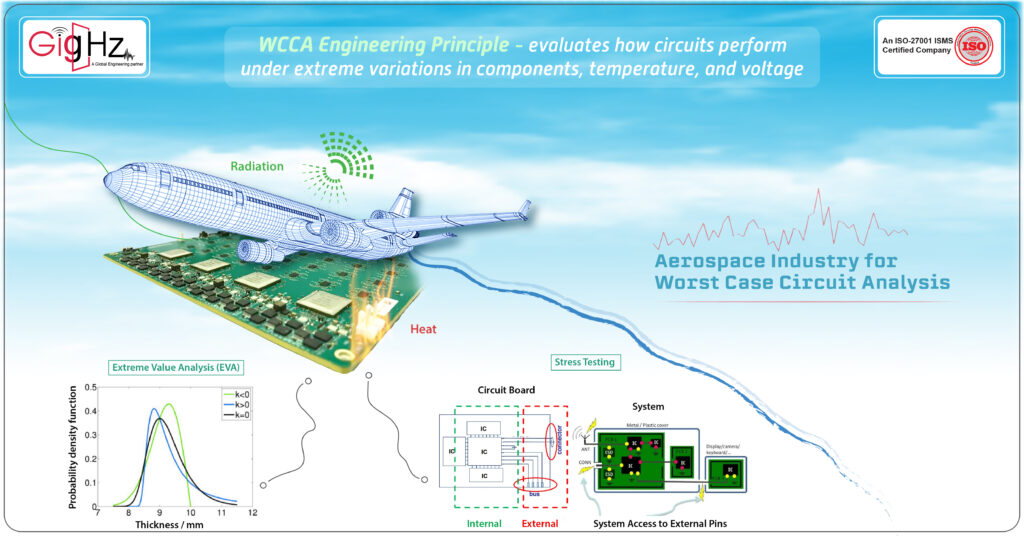

Current Trends in Aerospace Industry for Worst Case Circuit Analysis

The aerospace industry is constantly evolving, with new technologies and innovations shaping the way aircraft are designed and built.

One current trend in the industry is the increased use of worst case circuit analysis (WCCA) to ensure the reliability and performance of electronic circuits in aerospace applications.

WCCA involves performing a series of digital analysis simulations to analyze the extreme condition in which a circuit might operate.

By using extreme value analysis (EVA) and spice software to properly analyze hardware components, engineers can provide a more efficient circuit analysis and reduce the risk of failure in worst case circuit operation.

This method of stress testing is crucial in the aerospace industry, where reliability and performance are of utmost importance.

Continued advancements in modeling and simulation techniques allow for more accurate predictions of how electronic circuits will perform in environmental conditions such as radiation and heat.

Importance of worst-case circuit analysis in Aerospace Industry

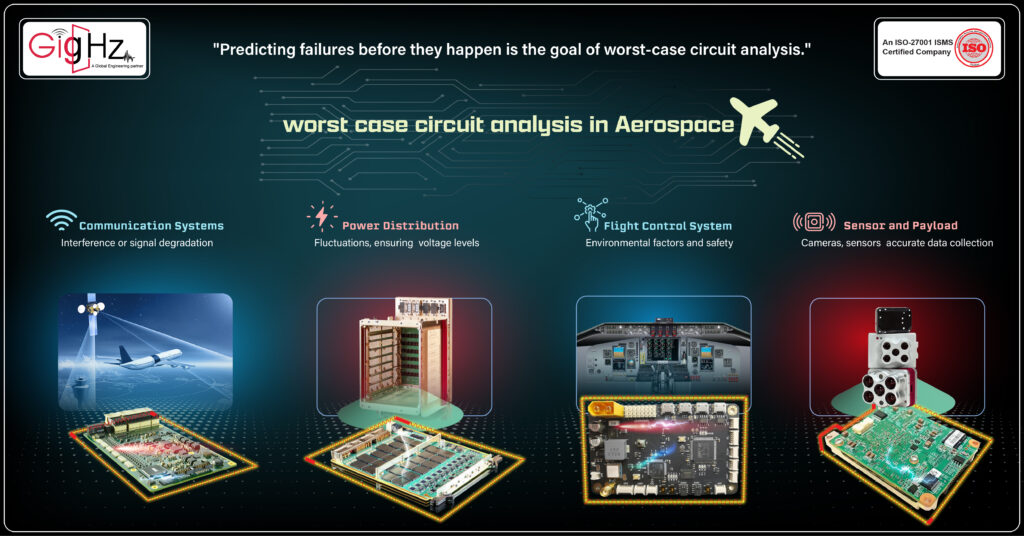

For UAVs used in reconnaissance, surveillance, and targeted operations in the aerospace industry, worst-case circuit analysis is technically essential in several critical aspects:

Communication Systems Analysis: UAVs heavily rely on communication systems to transmit data and receive commands. Worst-case circuit analysis is crucial to ensure that the communication circuits remain functional under extreme conditions, such as interference or signal degradation, to maintain reliable connectivity between the UAV and ground control stations.

Power Distribution and Management: UAVs have intricated power distribution circuits to supply various components onboard. Analyzing worst-case scenarios helps in identifying potential power fluctuations, ensuring stable voltage levels across the system to prevent component failures and operational disruptions.

Flight Control System Validation: The flight control system of a UAV consists of complex electronic circuits responsible for stability, navigation, and control. Worst-case circuit analysis is vital to validate these circuits’ performance under varying environmental factors, ensuring precise flight maneuvers and safe operations.

Sensor and Payload Integration: UAVs often carry sensors and payloads for reconnaissance and surveillance tasks. Conducting worst-case circuit analysis for integration circuits ensures seamless operation of sensors, cameras, or other equipment, guaranteeing accurate data collection and mission success.

Redundancy and Fail-Safe Mechanisms: In critical operations, UAVs may require redundant systems and fail-safe mechanisms. Worst-case analysis helps in identifying potential points of failure in redundancy circuits and ensuring that fail-safe measures activate reliably in emergency situations to prevent mission disruption.

Environmental Stress Testing: UAVs operate in diverse environments with varying temperatures, altitudes, and weather conditions. Worst-case circuit analysis involves stress testing circuits to simulate extreme environmental factors and verify their performance, durability, and resilience in real-world scenarios.

By rigorously conducting worst-case circuit analysis in these technical areas, aerospace engineers can enhance the reliability, safety, and performance of UAVs used in reconnaissance, surveillance, and targeted operations, ensuring mission success and operational efficiency in demanding and high-stakes scenarios.

Our Worst-Case Circuit Analysis Services

Enhancing Product Reliability

WCCA plays a pivotal role in enhancing product reliability. Our approach involves robust mathematical models, simulation-based methods, and hardware correlation. These correlated models help establish part stress margins and End-of-Life/Beginning-of-Life (EOL/BOL) product operating specifications. The impact of a single over-stressed component can result in significant financial losses for your company. A comprehensive Worst-Case Analysis serves as a preventive measure against such potential setbacks.

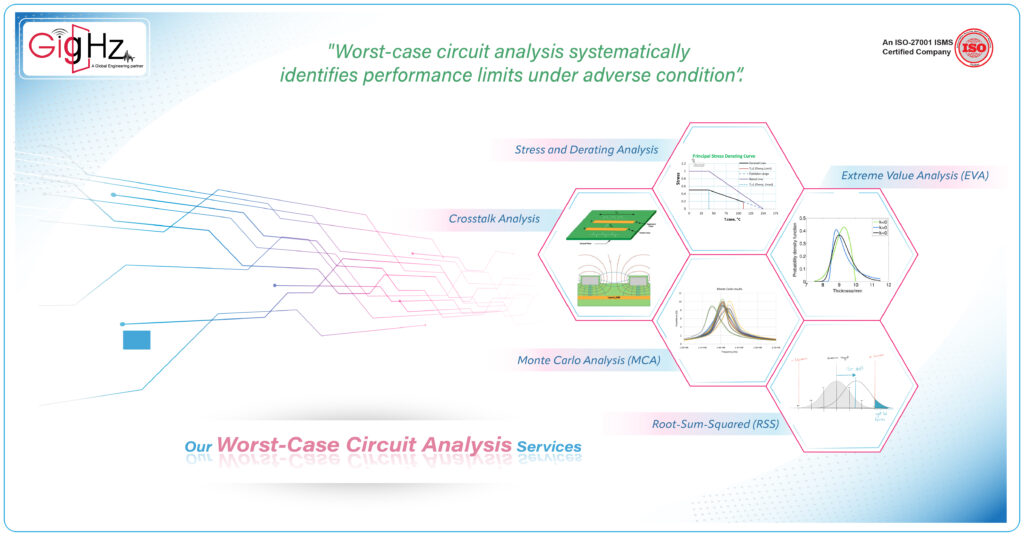

Crosstalk Analysis

GigHz analysis and simulation aim to identify and quantify the extent of crosstalk, considering factors such as signal frequency, distance between conductors, and the overall circuit layout. It is a critical process in electronics and telecommunications that involves the evaluation and mitigation of unwanted electromagnetic interference between adjacent conductors or components.

Stress and Derating Analysis

GigHz performs Stress and derating analysis to reduce the maximum rated values to enhance reliability and prevent premature failure. This analysis is crucial for designing circuits that can withstand challenging conditions and comply with safety and reliability standards.

Provide Acceptance Test Procedure (ATP) Limits

In WCCA, the ATP Limits are vital for assessing if the circuit meets reliability, safety, and functionality criteria. GigHz’s testing validates the circuit’s ability to operate within acceptable parameters under extreme conditions. Successful operation within ATP Limits demonstrates the circuit’s reliability in real-world scenarios, instilling confidence in its design and functionality.

Monte Carlo Analysis (MCA)

GigHz delivers the most realistic estimate of worst-case performance and provides supplementary information for risk assessment. Nevertheless, it is essential to note that this method can be complex and time-consuming

Extreme Value Analysis (EVA)

GigHz ensures the acceptable operation of products throughout their entire life cycle, even under the most challenging combination of expected conditions.

Root-Sum-Squared (RSS)

GigHz offers a more realistic estimation of worst-case performance, providing insights into the expected percentage of units that may pass or fail. It’s important to note that the RSS method, while widely used, makes certain assumptions about circuits that may result in inaccuracies in specific situations.

Ready To Improve Your Tolerance Analysis?

- Static and Kinematic System Analysis

- Optimize individual or combinations of functional criteria

- Run Monte Carlo, worst case, or RSS tolerance analysis

- Combine dimensional, geometric, and physical variation analysis

Conclusion

The significance of worst-case circuit analysis in the Aerospace industry cannot be overstated. This critical process ensures the reliability and safety of electronic systems in mission-critical applications.

By meticulously evaluating circuits under extreme conditions, potential risks are mitigated, and failures are preemptively addressed, ultimately safeguarding the integrity and performance of vital aerospace technologies.

Embracing worst-case circuit analysis is not just a best practice; it is a fundamental necessity to uphold the stringent standards of quality, resilience, and precision demanded by this high-stakes industry.

Discover our Specialities. Visit our Services Page. https://gighz.net/worst-case-circuit-analysis-in-embedded-systems/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.