What we have done for Overvoltage Protection Circuit Modification in Battery Management System (BMS)?

Imagine you’re driving your electric car, powered by the Battery Management System (BMS) that orchestrates the flow of energy within the vehicle’s battery pack. In particular, let’s focus on the Jumper (Overvoltage) Recognition section of the BMS. This is where precision is key, as it carefully distinguishes genuine overvoltage signals from background noise in real time.

Imagine you’re driving your electric car, powered by the Battery Management System (BMS) that orchestrates the flow of energy within the vehicle’s battery pack.

In particular, let’s focus on the Jumper (Overvoltage) Recognition section of the BMS.

This is where precision is key, as it carefully distinguishes genuine overvoltage signals from background noise in real time.

Category :

Published Date :

March 21, 2024

Category :

Published Date :

March 21, 2024

Category :

Published Date :

March 21, 2024

This essential function ensures that your electric vehicle operates reliably, providing you with peace of mind mile after mile.

But wait, there’s more!

The BMS doesn’t just spot overvoltage situations – it also jumps into action, tweaking the charging and discharging processes to avoid potential issues.

This not only keeps the battery system safe but also amps up energy efficiency, giving your electric ride an extra boost in performance and range.

And here’s the genius part: the BMS talks to the car’s other systems, so if an overvoltage hiccup happens, it can immediately take protective steps like isolating problem areas or rerouting energy.

This clever tech ensures that your electric vehicle stays safe and sound, making every drive a worry-free experience.

The bottom line?

The spot-on accuracy and quick reflexes of the Jumper (Overvoltage) Recognition section prove how cutting-edge tech keeps your electric vehicle running seamlessly and securely, letting you hit the road with total confidence.

Let’s dive into our Experience!

"Revolutionizing Safety: Our Breakthrough Overvoltage Protection Enhancements in Advanced Battery Management Systems (BMS)"

Dealing with the BMS Obstacles: What We Bring to the Table to balance

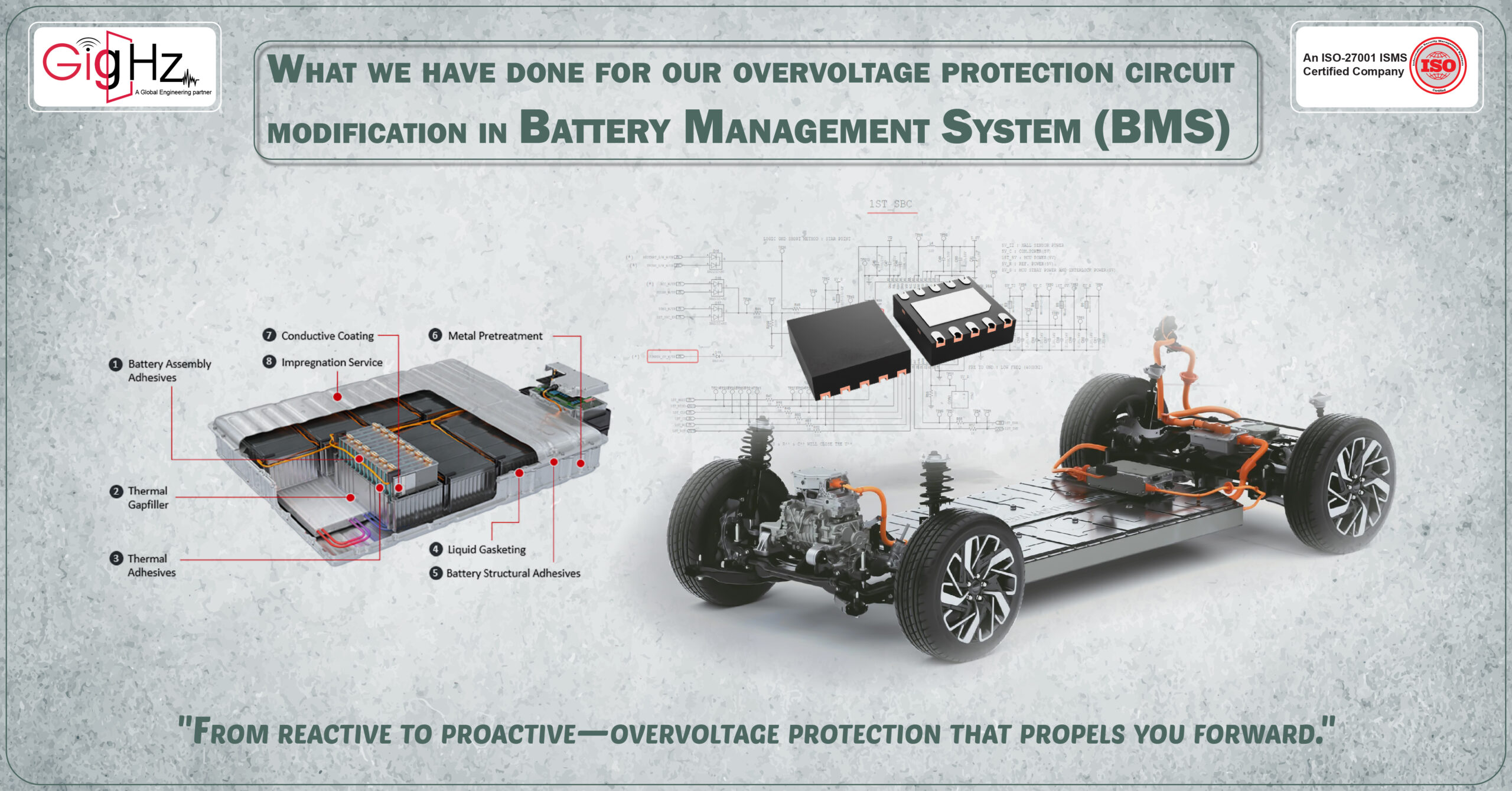

The effective management of rechargeable batteries heavily relies on the crucial hardware circuit design of a Battery Management System (BMS).

Considered the central intelligence of electric vehicles, the BMS ensures seamless operation.

In particular, our focus lies in the hardware design of the Jumper (Overvoltage) Recognition section, where precision is essential.

This section is tasked with recognizing overvoltage conditions, necessitating the accurate detection of press signals while filtering out sudden noise to prevent unintended execution of programmed tasks.

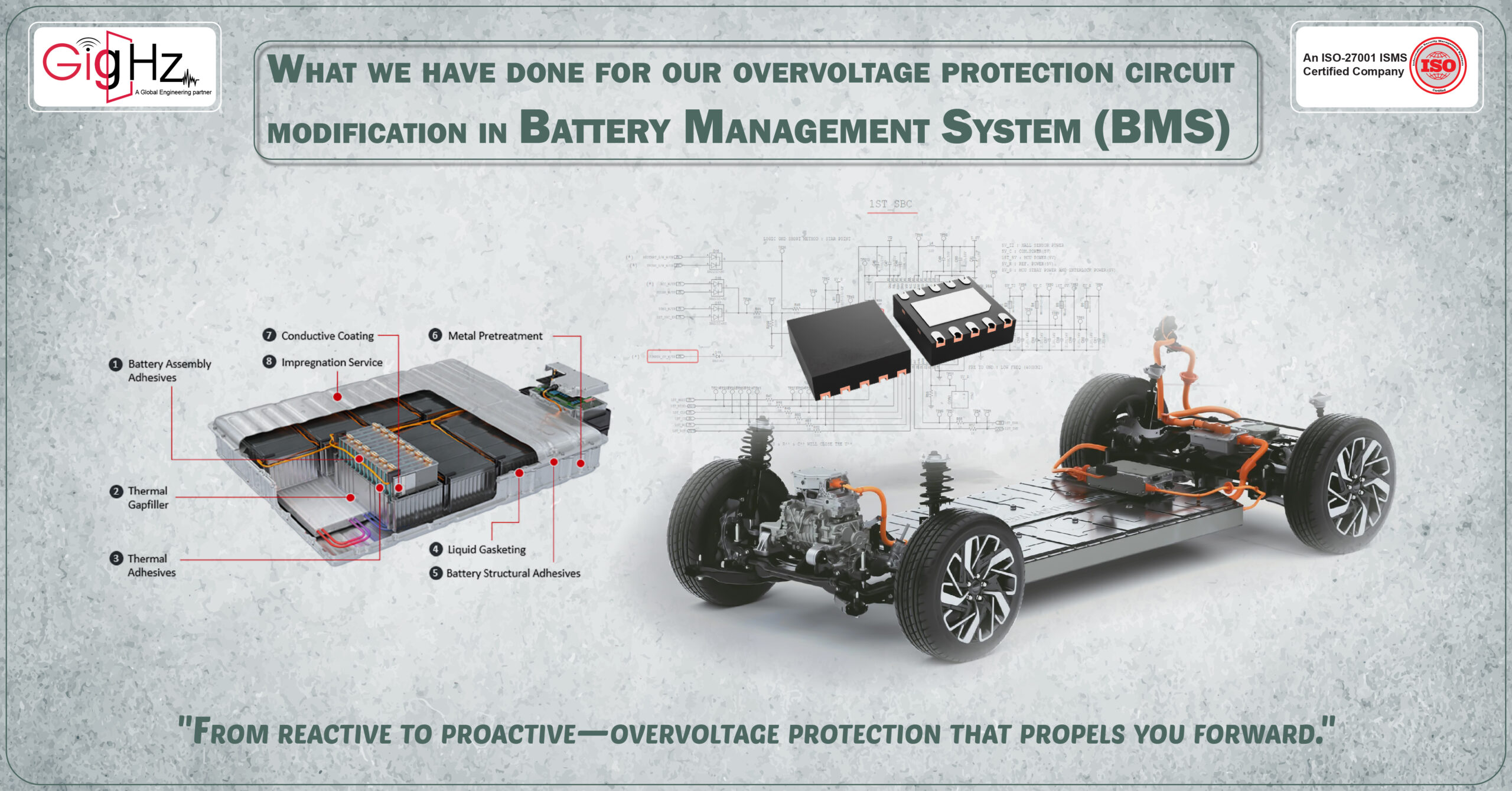

The client faced challenges in the wake-up recognition for Jumper (Overcharge), the design intent, and identifying the reasons for failure in the existing schematic.

So, the client is facing some hurdles with wake-up recognition, especially related to the Jumper (Overcharge) section.

What we’re aiming for in the design is the capability to split the internal pattern using the B+_LDC power pin, which will guarantee precise wake-up recognition.

we’ve got some specific requirements too – we want the wake-up recognition to kick in right before the voltage hits 14.5V, and also to register as “off” for voltages up to 14V.

On top of that, we’re really keen on examining the hysteresis characteristics for the wake-up recognition voltage to ensure everything performs at its best.

Navigating Overvoltage Protection and battery protection Challenges: Our Winning Formula

Now delver deeper insights of our work,

Design Intent

The Jumper Circuit Design is like a smart guard for the battery system. Its main job is to recognize when the voltage gets too high. When the input voltage is between 14 to 14.5V, it sends a signal to the system to manage the power properly.

This signal change helps the System Base Chip (SBC) to control the Power Management Integrated Circuit (PMIC) in the battery system.

This makes sure that the system can handle high voltages without causing any problems, keeping everything safe and working well.

So, by carefully designing this circuit, we’re making sure that the battery system can stay safe and work smoothly, even when the voltage goes up.

It’s like having a smart guard that keeps an eye on the power and makes sure everything stays under control.

Identifying Reasons for Failure – Existing Schematic

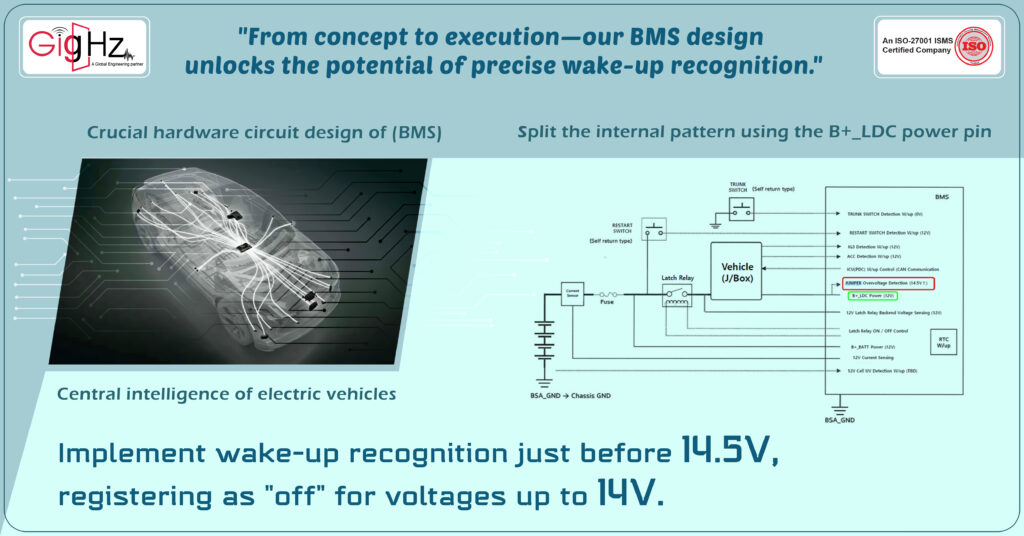

So, the existing design seems to have hit a roadblock with SBC1 not effectively using the jumper output signal for overvoltage detection.

It’s like trying to use a tool for a specific job, but it’s just not fitting right.

This emphasizes the importance of ensuring that all the parts and signals in the circuit work together smoothly to do their jobs properly.

Proposed Solution

The proposed solution is pretty interesting.

We want to move away from using separate components and instead opt for an integrated chip.

This shift aims to tackle the limitations of the current design.

By teaming up with well-known manufacturers like TI, Analog Devices, and RoHM, we’ve chosen the IC-TPS37AA90122DSKRQ1 from TI.

This chip shows real promise by being able to trigger a reset output when the voltage goes above 14V.

It’s like bringing in a high-tech, all-in-one solution to fix the problem.

Circuit Design Phase

Creating a rough schematic based on the application diagram is like sketching out a blueprint before building a house.

It lets our team to get a rough idea, of what we’re aiming for and allows for an initial assessment and analysis of the proposed design.

This phase is like laying the groundwork before diving into the nitty-gritty details.

Proposed Design Analysis

By simulating the overvoltage circuit with the configuration in the IC (TPS37AA90122DSKRQ1), we gain valuable insights into how the proposed design might behave.

This analysis helps us understand how the integrated chip works within the circuit and how it detects overvoltage conditions.

It’s like a sneak peek into how things might work before actually putting everything together.

Proposed Design Result

The simulation results show that the TPS37AA90122DSKRQ1 seems to be effective in responding to overvoltage scenarios of battery energy storage system.

When the input signal exceeds 14V, the reset output transitions from high to low, showing that the chip does its job by detecting and responding to overvoltage conditions.

This information is crucial for confirming that the proposed solution is on the right track.

By thoroughly exploring, we gain a comprehensive understanding of the over-voltage protection challenges, proposed solutions, design phases, analysis, and expected outcomes, which collectively contribute to informed decision-making and successful implementation.

This journey from identifying issues to proposing solutions and testing them out is a critical part of making sure that the circuit functions as intended.

It’s like solving a puzzle where every piece needs to fit perfectly to achieve success.

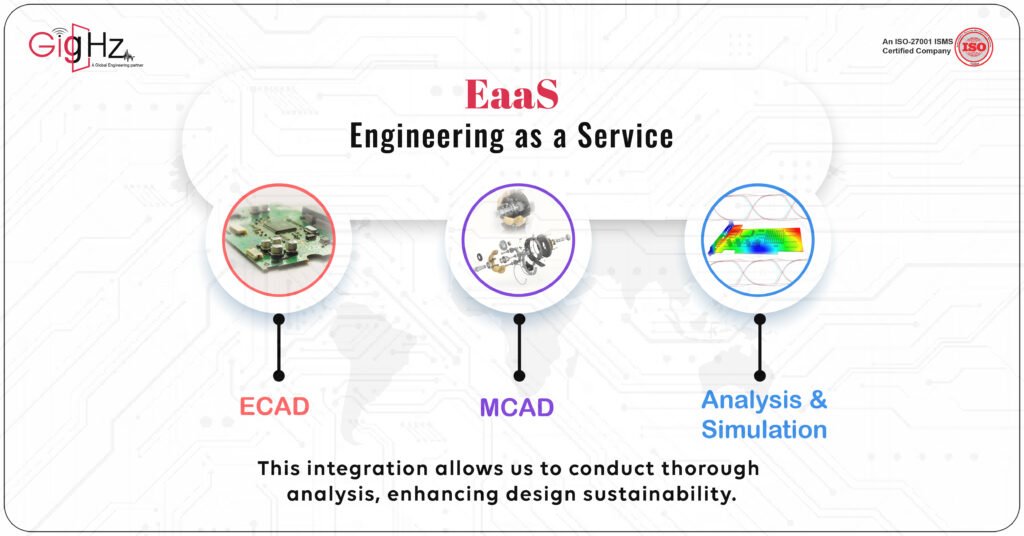

"Our Memorable Advancement": Engineering as a Service(EaaS)

Absolutely! As the demand for advanced engineering solutions keeps growing, our Engineering as a Service (EaaS) is really stepping up its game.

We’re tapping into the power of ECAD, MCAD, and Analysis & Simulation, which positions us as frontrunners in the industry.

The fact that we offer a full package, covering every single step of the engineering process, is what makes our approach so exciting.

It’s this kind of forward-thinking approach that’s going to shape the future of our engineering,

It’s truly thrilling!

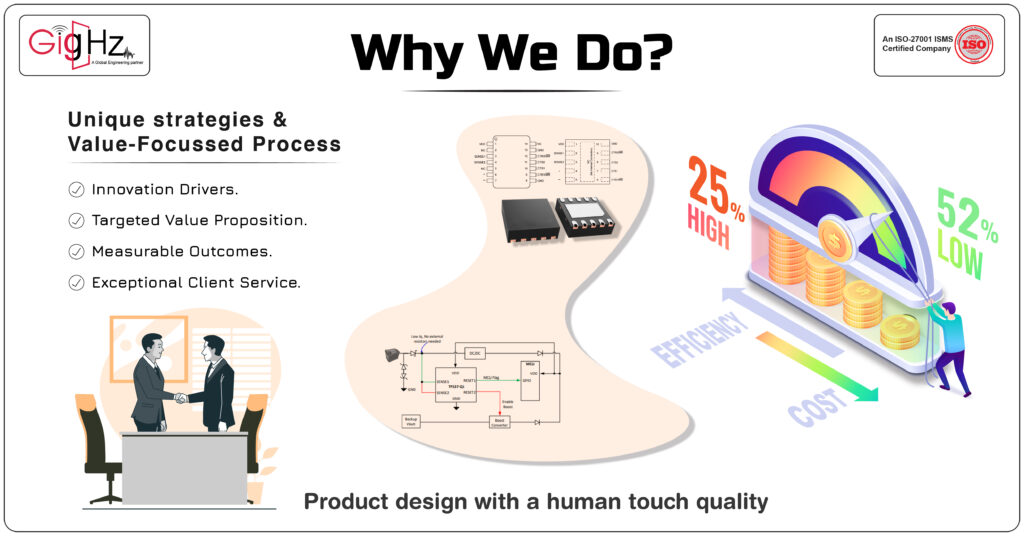

Why we Do?

Our inspiration arises from the intricate design of Battery Management System within the Automotive Industry.

Despite these complexities, we distinguish ourselves through the implementation of unique strategies and a value-centered process.

This distinct approach results in a remarkable 52% reduction in costs, concurrently enhancing operational efficiency by 25%.

Conclusion

In our pursuit of enhancing the overvoltage protection circuit within our Battery Management System (BMS), we have diligently incorporated an array of advanced safety measures and cutting-edge technologies.

By addressing the critical aspects of voltage regulation, overvoltage protection, and battery safety, our modifications have fortified the BMS with comprehensive safeguards. These measures extend to overcurrent protection, fire protection, and meticulous attention to battery charging and discharging dynamics.

Moreover, our upgraded BMS solution incorporates state-of-the-art features such as thermal management systems, cell voltage balancing, and advanced protection limits to ensure the optimal performance and longevity of the battery pack.

By integrating the latest advancements in BMS technology, we have mitigated potential hazards, enhanced operational efficiency, and bolstered the overall safety of the battery system.

Schedule a Call. Book a Free Consultation Now. https://calendly.com/gighz/30min

Our commitment to refining the overvoltage protection circuit underscores our dedication to delivering reliable, efficient, and secure BMS solutions for diverse applications and industries.

Discover our Specialities. Visit our Services Page. https://gighz.net/services/