The value of Reverse Engineering: Is it Justifiable?

Hello, everyone!

I think everything looks good.

Imagine a day where everything happens in reverse, that’s back of your present to past.

For some, it might bring good surprises, for others, it could be just okay, and for some, it might not turn out so well.

Hey there!

Welcome to Everyone,

So, when it comes to PCB design, the schematic capture process is super important for a few reasons.

First off, it’s like the foundation for designing the electronic circuitry within the PCB design software.

This part allows us to see how all the electrical connections will work in the circuit board design.

Category :

Published Date :

April 16, 2024

Category :

Published Date :

April 16, 2024

Category :

Published Date :

April 16, 2024

However, in a way, it’s miraculous, isn’t it?

In the advanced engineering world, we have the opportunity to reverse the product to concept through the process of reverse engineering.

Reverse engineering enables the breakdown of ideas so we could earn the right to duplicate to learn where people left-off & build it from there, develop, optimize, and then innovate!

People can tell you what you can & can’t do, but they can’t tell you what you can or can’t be…

Be the change that you want to see around you!

So, what exactly it is?

Reverse engineering is the process of analyzing and understanding the design, structure, and functionality of a product or system by dismantling and inspecting its components.

It involves measuring physical objects and reconstructing them 3D Models as well as analyzing information flow within software or hardware to gain knowledge about its inner workings.

This practice is often utilized to gain insights into existing products, systems, or technologies, enabling to understand, improve, or replicate them.

Let’s consider to enhance the design and performance to reproduce a rare or obsolete part for a vintage vehicle, this will help us to understand the value of Reverse Engineering and it is Justifiable, or not.

Importance of the value of Reverse Engineering

Got it!

The quick pace of technological advancement is driven by various factors, and one fascinating contributor to this progress is reverse engineering.

It involves taking apart machines, aircraft, cars, and other objects to understand how they work from the inside out.

This process gives manufacturers and designers a deep understanding that can lead to creating even better products.

Let’s find its importance,

Exploring What’s Out There: Ever thought about digging into existing products to find cool new ideas? Reverse engineering lets you do just that!

Getting Creative with Recreating: Want to bring back an old favorite or make a budget-friendly version of a product? Reverse engineering can help companies do just that, no blueprints needed!

Fixing Up the Classics: Using reverse engineering, businesses can give a tune-up to existing products, spot design blunders, and get understanding for future projects.

Spotting Weaknesses: By reverse engineering new products, companies can play detective, uncover any flaws, and amp up the overall quality.

Fueling Fresh Ideas: Reverse engineering isn’t just about looking back – it’s about using past smarts to come up with brand-new innovations!

Learning from Mistakes: Wondering why a product flopped? With reverse engineering, you can dive in, figure out what went wrong, and set it right.

Keeping an Eye on the Competition: Ever peeked at a competitor’s product and thought, “Hmm, what makes this tick?” Reverse engineering lets companies do just that, comparing and contrasting like a pro!

Role of the value of Reverse Engineering in Automotive Sector

In the automotive world, every product is a result of engineering, and the constant push for creativity and innovation often traces back to the practice of reverse engineering.

However, when it comes to analyzing and reverse engineering industrial automotive parts, it can be quite a challenge due to the complex materials used and the need for precision in processing image data.

Reverse engineering plays a pivotal role in the redesign, restructuring, and concept evaluation of various components.

It proves invaluable when extracting designs from models, such as efficient cars, discontinued parts, or old designs lacking a 3D model for reference. Additionally, it can be utilized to analyze competitors’ cars, bikes, and more.

The primary objective of employing reverse engineering services is to generate a 3D model that accurately reflects the functional design of the actual model across all aspects, including visual and aerodynamics.

The key considerations revolve around precisely and efficiently obtaining information through laser scanning and subsequently leveraging Mechanical Design Services to produce a flawless CAD file that eliminates imperfections from the original body.

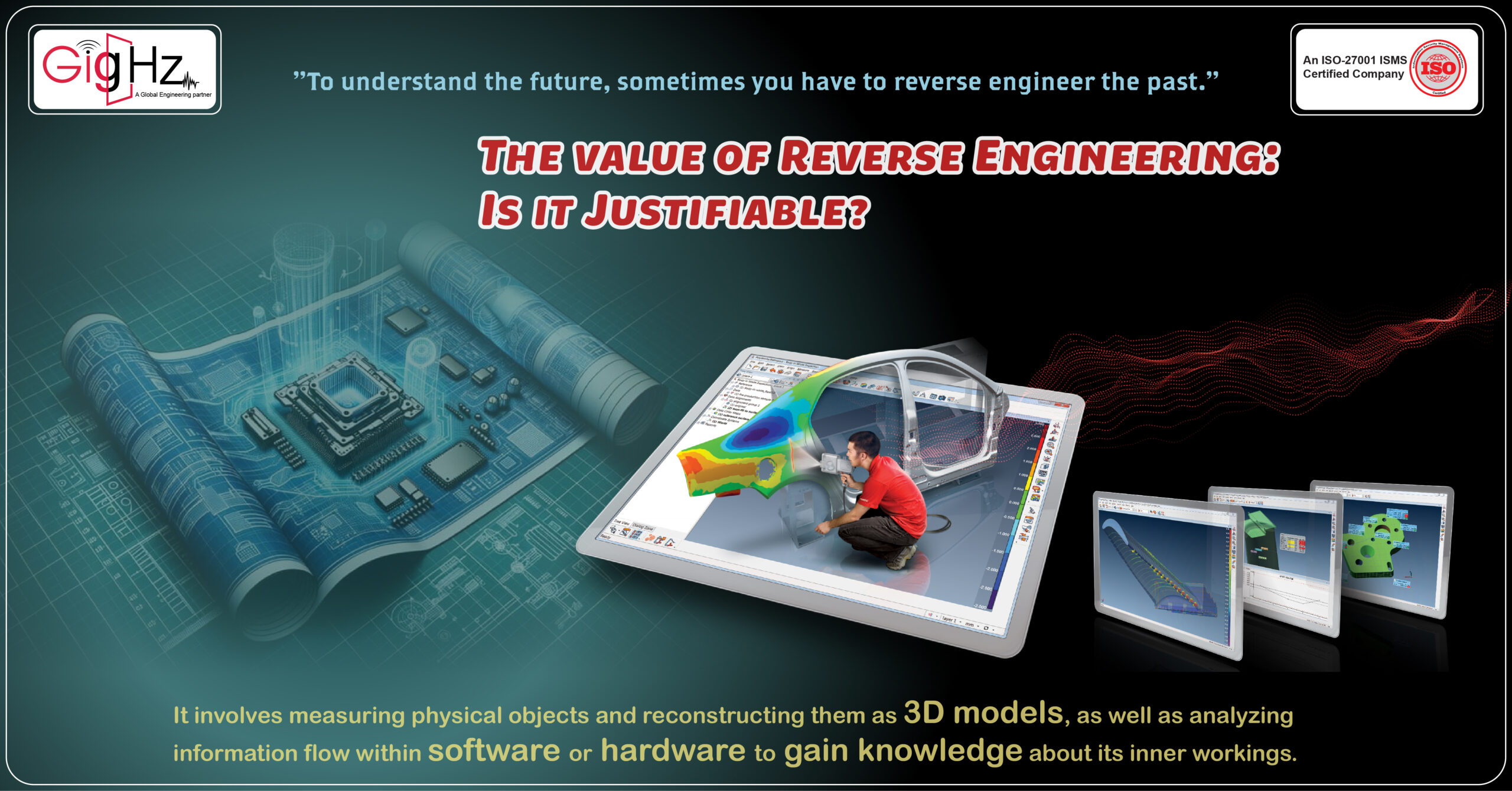

How the Reverse Engineering works?

Here’s a more detailed breakdown of the reverse engineering process for reproducing rare or obsolete parts for vintage vehicles:

Identification of the Specific Component:

The first step involves identifying the particular rare or obsolete part that needs to be reproduced for the vintage vehicle. This could be a complex mechanical gear, a unique component, or any part that is no longer in production.

Through careful inspection and analysis of the vehicle, manufacturers

pinpoint the exact part that requires replication. This step is crucial as it sets the stage for the subsequent reverse engineering process.

Reverse Engineering Process:

Once the specific component has been identified, the process of reverse engineering can be used. This involves meticulously dismantling the original part to gain a comprehensive understanding of its design, structure, and functionality.

Advanced tools such as 3D laser scanners and coordinate measuring machines are utilized to capture precise measurements and dimensions of the part. These tools create a highly detailed digital representation of the part, essentially creating a digital blueprint that serves as the basis for further steps.

CAD Model Creation:

With the digital data obtained from the scanning and measurement processes, move on to crafting a detailed CAD (Computer-Aided Design) model that accurately represents the original part.

This CAD model is created using specialized software, ensuring that all intricate details, geometries, and features of the original part are faithfully captured. It accounts for tolerances, material properties, and functional characteristics to produce an accurate virtual representation.

Manufacturing Replicas:

- Once the CAD model is finalized, modern manufacturing methods come into play to produce replicas of the rare or obsolete part.

- CNC machining, a subtractive manufacturing process, involves using computer-controlled machinery to precisely cut, mill, or shape the part from a solid block of material based on the CAD model.

- Alternatively, 3D printing, also known as additive manufacturing, can be employed to build the part layer by layer from the digital model.

- This method allows for the creation of complex geometries and customized designs, offering flexibility in manufacturing.

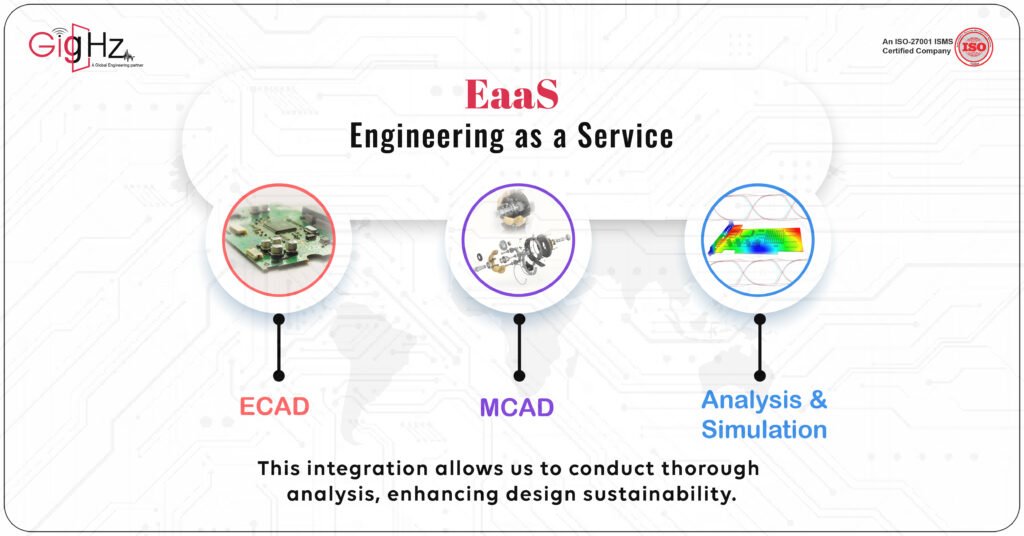

Our Notable Upgrade: Engineering as a Service (EaaS)

Definitely!

As complex engineering challenges become more prevalent, our Engineering as a Service (EaaS) offering is truly elevating its presence.

We are leveraging the combined strengths of ECAD, MCAD, and Analysis & Simulation, which establishes us as leaders in the field.

What’s particularly exciting is that we provide a comprehensive solution, encompassing the entire engineering workflow.

It’s genuinely exhilarating.

Conclusion

In conclusion, the value of Reverse Engineering can be justifiable in certain situations.

While it may raise ethical concerns and legal implications, it has proven to be a valuable tool for problem-solving, innovation, and enhancing product design.

On one hand, reverse engineering may be seen as a valuable tool for understanding and improving existing technologies.

Software developers may use reverse engineering to learn from others’ work and enhance their own skills.

However, reverse engineering can also be used to copy or circumvent patent protections, leading to copyright infringement and infringement of trade secrets. The legality of reverse engineering is further complicated by proprietary software code and encryption, which may be used to protect against reverse engineering. Reverse engineering that violates license agreements or terms of service can result in legal issues and potential lawsuits from the software developers or companies involved.

“The value of Reverse Engineering: Is Justifiable!”

Discover our Specialities. Visit our Services Page. https://gighz.net/services/