The ECAD Library Database in Our Electronic Design Journey

The ECAD Library Database is the backbone of electronic design, housing crucial components like schematic symbols, PCB footprints, and Manufacturer Part Numbers (MPN). Managing this repository via Components Library Management ensures smooth access to up-to-date component information, streamlining design processes.

Meet the challenging partner of modern cars – the ECU in ADAS! You can call it the ‘smart controller.’ It’s like the boss of all the information from sensors, helping your car stay safe and work better. This little brain acts as a super-smart traffic helper, listening to signals from all over the car.

Category :

Published Date :

December 15, 2023

Category :

Published Date :

December 15, 2023

Category :

Published Date :

December 15, 2023

This collaboration between design and procurement teams optimizes operations, ensuring a seamless flow of components from concept to reality.

Exploring our project detailing this dynamic Components Library Management.

Current Scenario

Initially, the client adopted a strategy of utilizing multiple library files, each adhering to distinct standards, to accommodate the diverse needs of various design teams.

Concurrently, they maintained several spreadsheets for documenting the specifics of each part and its associated parameters.

This approach seamlessly supported the different teams involved, such as components engineering and procurement, without encountering any significant issues in the initial stages.

However, as time progressed, the management of this multifaceted library system became increasingly daunting. The proliferation of files and spreadsheets presented a significant challenge, making collaborative efforts across multiple teams more intricate.

The mounting number of these data repositories led to operational challenges for each team, impeding their ability to efficiently handle this expanding volume of information.

Pros:

- Versatility: The approach allowed for flexibility in accommodating diverse design requirements.

- Adaptability: The system could adapt to different team preferences and needs.

- Customization: Tailoring the libraries to specific team requirements facilitated efficient workflow.

- Detailed Information: The comprehensive nature of documentation provided thorough insights into each part and its parameters.

Cons:

- Risk of Inconsistency: Varied standards and multiple sources increased the likelihood of conflicting or inconsistent information.

- Complexity Over Time: The growing number of files and spreadsheets escalated the complexity of managing the system.

- Coordination Challenges: Coordinating efforts across diverse teams became increasingly challenging.

- Increased Overhead: The expanded scope of data repositories required additional effort and resources to manage effectively.

Addressing Challenges and Meeting Requirements

Considering the challenges ahead of implementing Library Database Management is crucial for a successful transition.

Here we highlighted some of them below:

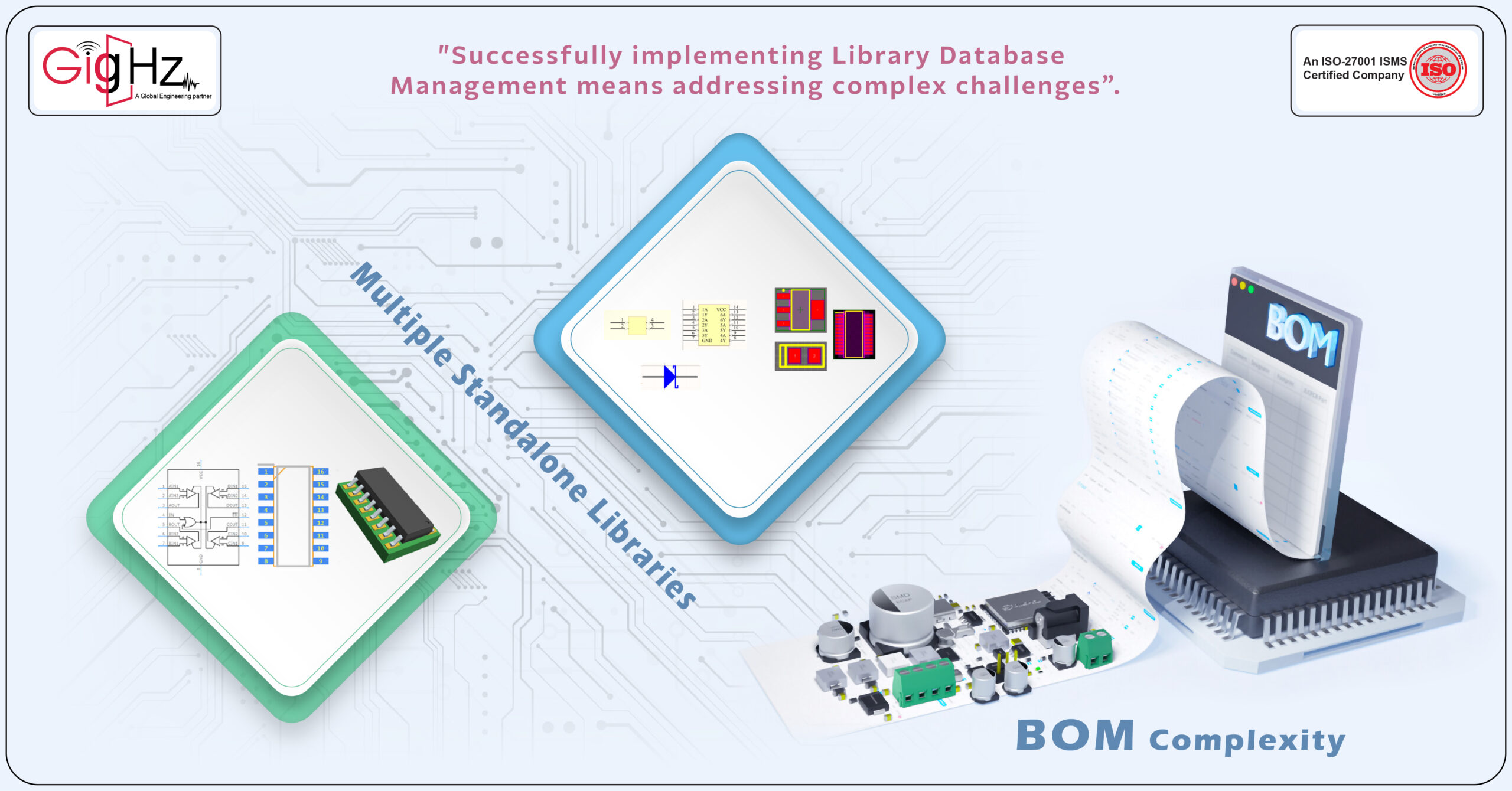

Multiple Standalone Libraries: Confrontation with disparate library files complicates design cohesion.

Spreadsheet Dependency: Scattered component details across multiple spreadsheets hinders streamlined management.

Diverse Library Standards: Operating under varied design standards complicates consistency.

BOM Complexity: Managing Bill of Materials (BOM) becomes challenging amidst complexity.

Part Duplication: Identifying and rectifying duplicated parts consumes resources.

Unapproved or Obsolete Parts: Handling unapproved or outdated components poses risks.

Team Collaboration: Inter-team collaboration barriers impede seamless workflow.

Vendor Data Management: Overseeing vendor part data and relationships requires a structured approach.

To effectively tackle these challenges, we must define specific requirements that cater to streamlined Library Database Management.

Centralized Database Library: Establish a unified platform for seamless data access and management.

Simultaneous Team Access: Enable concurrent access for diverse design teams to foster collaboration.

Inter-Team Relationships: Establish connections between teams to enhance synergy and efficiency.

Multi-Location Design Centers: Facilitate access to design resources across varied locations.

Consistency Assurance: Implement measures ensuring uniformity in design standards and data management.

How We Executed?

In executing this transformation, our focus began with verifying existing library standards to ensure conformity and compatibility across the board and of merging the multiple disparate libraries into a singular, well-organized repository.

Identifying and addressing redundancy became a priority as we go through the libraries, systematically removing duplicate parts. Simultaneously, a stringent culling process was implemented, swiftly removing unapproved or obsolete components, ensuring a leaner, more relevant inventory.

To enhance accessibility and usability, components were intelligently categorized into types—capacitors, resistors, ICs, and others—allowing for easier navigation and utilization.

Additionally, a framework of common and specific parameters was introduced, facilitating comprehensive component characterization.

Integrating PLM Part Numbers offers a standardized and efficient means of recognizing and referencing components. Moreover, the migration of component details from spreadsheet format to Access Tables bolstered accessibility and streamlined data management.

Database Library Connection in Altium

We established a vital connection between the Access database (.mdb) and Altium, enabling seamless integration and access to the refined component repository.

Leveraging sophisticated linkages and foreign keys facilitates smooth data flow and retrieval.

Precise and updated field mappings were implemented, ensuring consistency and accuracy in data transfer between the databases.

Design needs were met with ease through the components panel, where the required components were seamlessly fetched from the integrated database library.

Centralized Cloud-Based Database Library

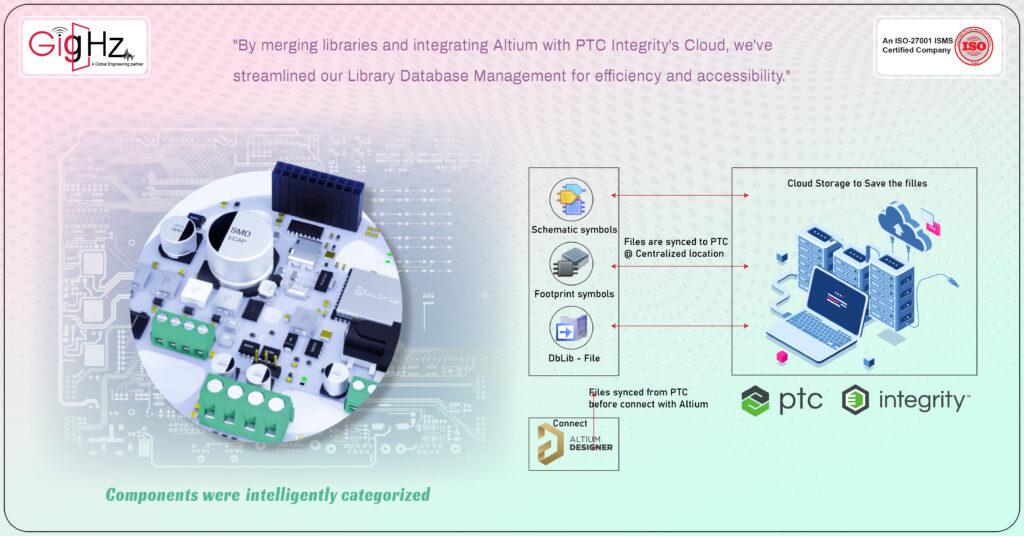

To optimize accessibility and usability, we centralized the Database Library on a Cloud Server, specifically utilizing a cost-effective solution like cloud-based PTC Integrity.

This move ensured universal access for all teams, promoting seamless usage and application across locations.

We initiated the transfer of Library and Access files, as well as the Database Library files, into the PTC Integrity platform, laying the groundwork for collaborative and synchronized work.

To maintain relevancy and accuracy, regular updates were performed on the library files based on the specific usage patterns of each team.

Prior to application, synchronization became a crucial preparatory step, ensuring that all files were up-to-date and in harmony across teams to optimize its utility for each project undertaken.

Component Library Management with Cloud Integration

The integration with PTC Integrity’s Cloud streamlined our Database Library, enabling efficient data management.

This integration drastically reduced duplication of work, saved time, and ensured consistency throughout the Component Library Management.

This setup not only facilitated a unified database but also offered a structured environment seamlessly integrated with Altium’s DbLib and Components Panel.

Altium’s integration within this setup allowed for intuitive access to the Database Library, further enhancing the design process efficiency.

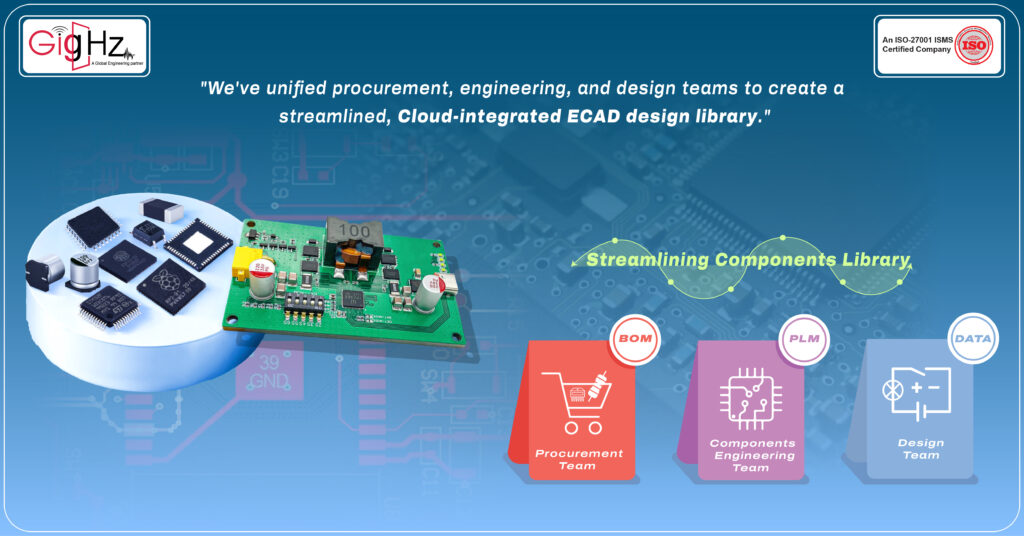

Streamlining Components Library Management across Teams

The streamlined steps ensure a cohesive and synchronized approach to managing components, enhancing collaboration and efficiency across teams.

Procurement Team

BOM-Based Availability Check: Ensure the component availability aligns with the Bill of Materials (BOM), ensuring seamless procurement planning.

New PLM Part Number Generation: Facilitate adaptation by generating PLM Part Numbers for components not present in the existing database, ensuring a comprehensive inventory.

Stock Information Updates: Maintain an up-to-date record of stock details, fostering informed decision-making and efficient stock management.

Vendor Relationship Management: Foster strong vendor ties, managing part data effectively and ensuring robust relationships to optimize procurement avenues.

Components Engineering Team

Review PLM Part Numbers: Scrutinize and validate newly created PLM Part Numbers, ensuring accuracy and relevance to uphold database integrity.

Alternate Component Suggestions: Offer alternative component options, promoting flexibility and resilience in component selection.

Parameter Addition: Enhance database depth by incorporating vital component parameters, enriching the database’s comprehensiveness.

Library Creation Request: Collaborate with the Design Team for seamless Library file generation, ensuring updated information availability.

Tracking Component Status: Monitor the component status to address any issues, ensuring database reliability.

Design Team

Symbol and Footprint Mapping: Match requested components with existing Symbol and Footprint data, minimizing redundancy and optimizing resource utilization.

Library File Creation: Craft the design of Symbol and Footprint Library files, adhering to stringent standards for consistency and accuracy.

Standards Adherence: Uphold Industrial Library design standards, ensuring uniformity and compatibility across the design ecosystem.

Library Sharing: Foster collaboration by sharing Library details and files, facilitating seamless integration and utilization.

Data Consistency: Maintain data uniformity across diverse ECAD tools, ensuring smooth operations and compatibility.

Upon successfully streamlining processes across teams, we integrated the ECAD design library with the cloud to make it suitable for all applications.

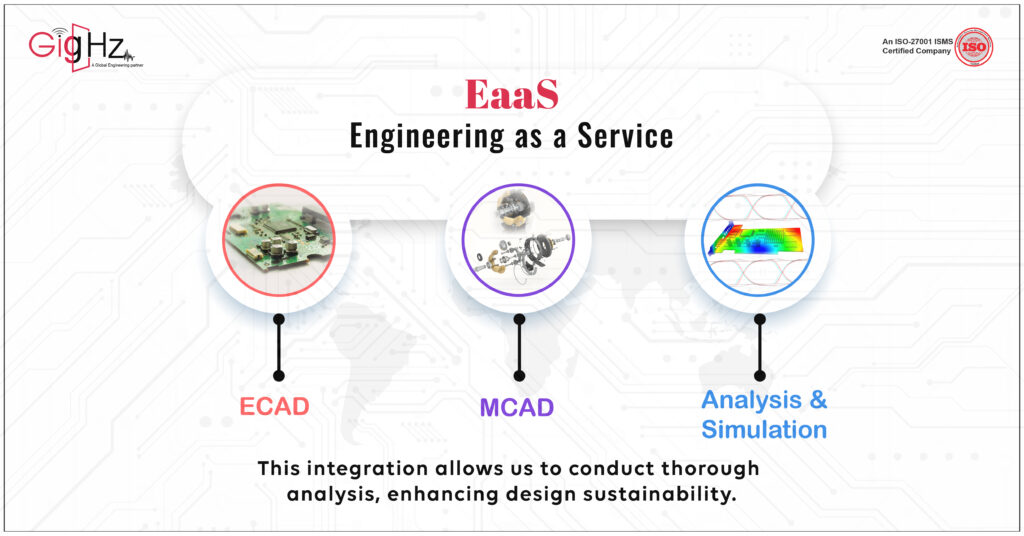

Engineering as a Service

Our commitment to electronics is showcased through the integration of ECAD, MCAD, Analysis & Simulation into a singular platform, streamlining design, production, and operations for heightened efficiency.

This cohesive integration enables comprehensive analysis, bolstering design sustainability and delivering innovative, cost-effective solutions, all accomplished within efficient timelines

Why We Do?

Even in the face of challenges posed by the ECAD Library Database, our distinction lies in pioneering methods and a process centered on value.

This strategy enables us to achieve a significant 52% cost reduction while concurrently boosting operational efficiency by 25%.

Conclusion

Our delivery of a precisely tailored Library Database (DbLib) showcases not only our commitment to delivering excellence but also our technical prowess.

Our collaboration extends beyond technicalities, aiming to streamline Library Management by melding expertise with a profound grasp of the client’s needs.

At our core, we are dedicated to providing unparalleled Library Management services, proving our proficiency and reliability in delivering exceptional results.

Trust us to optimize your library needs.

Let’s elevate your projects together. Contact us today for unmatched Library Management solutions https://calendly.com/gighz/30min