Designing PCBs with ECAD

Ever wondered how your gadgets work? Well, they have a little-known wizard inside called a PCB, short for Printed Circuit Board. These boards may seem plain, but they hold the magic that powers your smartphone, computer, and more. They’re like the secret architects of the electronic world. Our journey begins here, where we’ll explore the world of PCBs and how they work their magic.

Imagine the creation of an extraordinary autonomous vehicle, a technological marvel poised to revolutionize transportation. This cutting-edge innovation must navigate a wide spectrum of environmental challenges, from scorching desert heat to freezing arctic conditions. In the quest for unparalleled reliability and performance, engineers harness the power of Worst-Case Circuit Analysis (WCCA) during the design phase.

Category :

Published Date :

November 2, 2023

Category :

Published Date :

November 2, 2023

Category :

Published Date :

November 2, 2023

We’ll break down the complex stuff into easy-to-understand pieces.

Think of it as a treasure hunt for knowledge, where each step takes us closer to understanding the hidden world of electronics.

So, let’s dive in and unveil the mysteries of PCB design, where creativity and precision come together to create wonders.

Hold on to your curiosity because we’re about to embark on a fascinating adventure through the heart of electronic design, where imagination knows no bounds, and innovation has endless possibilities.

Before we dive into the fascinating world of PCB design, let’s outline our plan.

We’ll start by understanding what PCBs are, explore the software we’ll use, learn how to design them step by step, and then see how to bring our designs to life.

- Understanding PCBs (Printed Circuit Boards)

- Introduction to what PCBs are and their fundamental role in electronics.

- ECAD (Electronic Computer-Aided Design) Software: Your Magic Wand

- Exploring the tools and software that make PCB design possible.

- Designing PCBs: From Idea to Blueprint

- A step-by-step journey through the PCB design process.

- Mastering the Art of Component Placement and Routing

- How to strategically place components and create efficient electronic pathways.

- Prototyping, Testing, and Beyond

- Bringing your design to life, testing it, and preparing for mass production.

Think of this as our map for the exciting journey ahead.

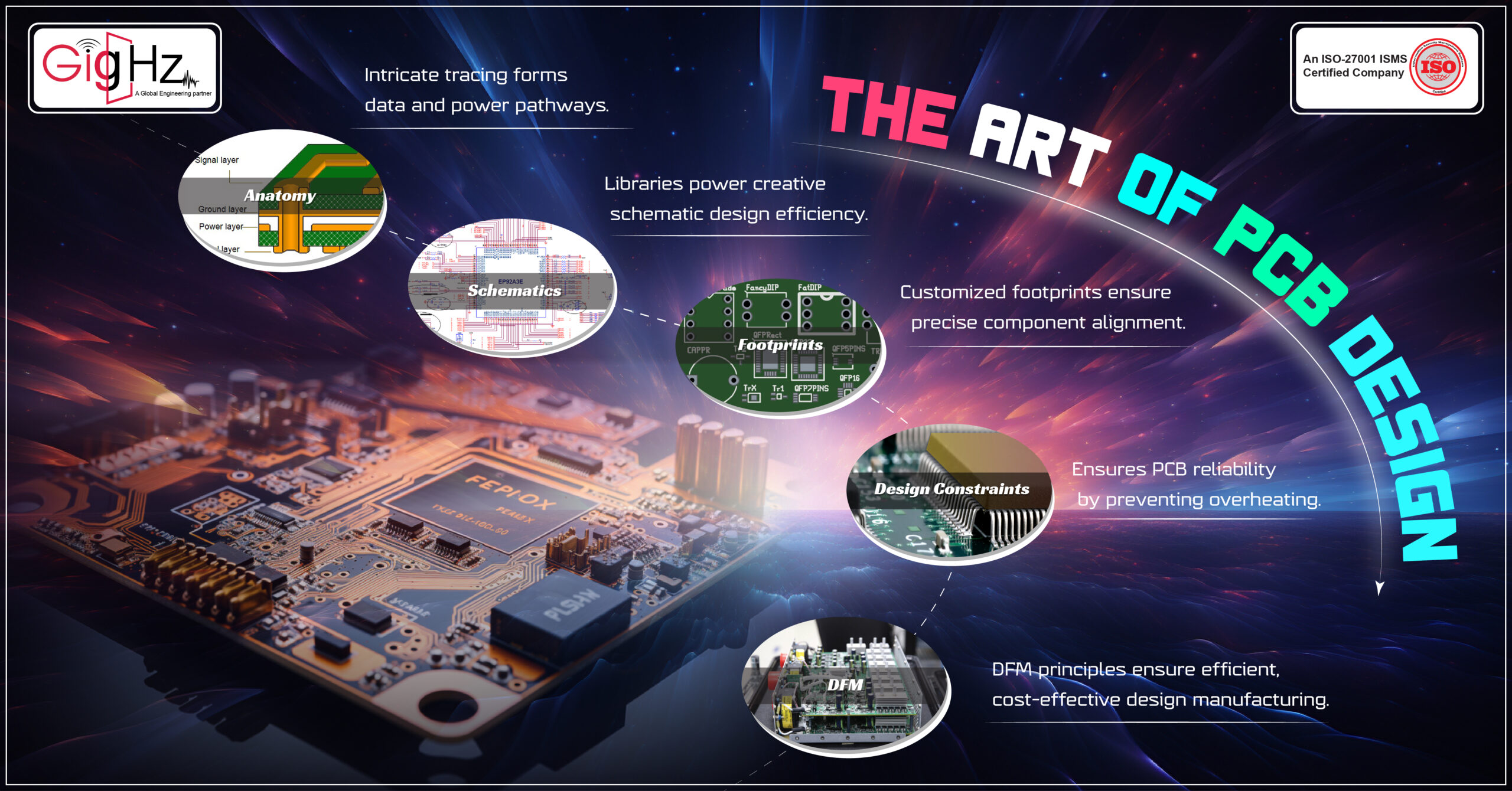

1. The Art of PCB Design

In this section, we’ll start at the beginning, explaining what PCBs are and why they’re so essential in the world of electronics. We’ll demystify these seemingly plain boards and highlight their crucial role.

1.1 The Anatomy of a PCB

- PCBs consist of multiple layers, with each layer serving a unique purpose. We’ll delve into how these layers, including the signal, power, and ground layers, work together to bring your electronics to life.

- Understanding the role of traces and components in creating the intricate pathways that allow data and power to flow.

1.2 Schematics: Blueprint for Brilliance

- Learn how to translate your ideas into actionable schematics. We’ll cover the basics of symbol creation and selection, helping you build the foundation for your PCB design.

- Discover the power of symbol libraries, which serve as your creative toolkit for efficient schematic design.

1.3 PCB Footprints: Where Components Find Their Home

- Dive into the world of PCB footprints and understand how these representations of physical components are crucial for accurate component placement.

- Explore methods for defining and customizing footprints to match the specific components you’re working with, ensuring precision in your design.

- Design Constraints: Balancing Act

- Explore the delicate balance of design constraints, where you’ll consider factors like timing, power, and signal integrity.

- Discover the importance of thermal management in preventing components from overheating and maintaining the reliability of your PCB.

- DFM (Design for Manufacturability): From Design to Reality

- Understand the transition from design to manufacturing and how DFM principles play a critical role in ensuring your design can be manufactured efficiently and cost-effectively.

- Discover eco-friendly practices in PCB design, aligning your electronic creations with sustainable design principles.

2.Mastering ECAD Software

Introduction to Statistical Analysis: Gain insights into the role of statistical methods in WCCA, enabling the capture of variability and providing a robust analysis approach.

Probability Distributions: Explore common probability distributions like normal and uniform distributions, which aid in modelling uncertainties in component values.

Monte Carlo Simulation: Learn about the utilization of Monte Carlo simulation to generate random variables and simulate a range of component values and operating conditions.

Statistical Metrics: Understand key statistical measures such as mean, standard deviation, and percentiles, enabling the analysis of Monte Carlo simulation results.

Confidence Intervals: Discover how confidence intervals provide a range of possible outcomes, aiding in estimating the likelihood of worst-case scenarios and their associated risks.

Also Read: Mastering Advanced ECAD Techniques

Temperature Variations Analysis

Temperature Effects on Components: Investigate the impact of temperature on component characteristics and its influence on overall circuit performance.

Thermal Analysis: Understand the evaluation of circuit behaviour under varying thermal conditions to identify worst-case scenarios.

Temperature Coefficients: Learn about temperature coefficients, which quantify the change in component parameters with temperature variations, aiding in worst-case analysis.

Thermal Simulation Tools: Explore software tools used to simulate temperature variations and assess their impact on circuit performance.

Worst Case Temperature Scenarios: Identify critical temperature extremes such as high and low limits, enabling analysis of their effect on circuit functionality.

Sensitivity Analysis

Sensitivity Analysis Basics: Gain an understanding of sensitivity analysis and its role in assessing the impact of parameter variations on circuit behaviour.

Parameter Variation: Explore the evaluation of how small variations in component values affect circuit performance by systematically varying each parameter while keeping others constant.

Sensitivity Metrics: Discover key metrics such as voltage transfer function sensitivity and impedance sensitivity, quantifying the relationship between parameter variations and circuit response.

Sensitivity Analysis Tools: Learn about software tools that facilitate sensitivity analysis, streamlining the evaluation of parameter sensitivities.

Design Optimization: Understand how sensitivity analysis results can be leveraged to optimize the circuit design by identifying critical parameters for component selection and design modifications.

Worst Case Combination Analysis

Definition and Purpose: Gain insight into worst case combination analysis, which involves identifying the most severe combination of parameters for worst-case scenarios.

Identifying Critical Scenarios: Explore the process of determining the combinations of parameters that lead to worst-case scenarios by considering their cumulative effects on circuit performance.

Worst Case Analysis Tools: Discover software tools used for efficient worst case combination analysis, enabling exploration of the parameter space and identification of critical scenarios.

Failure Modes and Effects Analysis (FMEA): Learn how to incorporate FMEA into worst case combination analysis, assessing potential failure modes and their impact on circuit functionality.

Mitigation Strategies: Explore approaches for mitigating risks identified through worst-case combination analysis, such as redesigning critical components or introducing redundancy to improve overall reliability.

Specialized Expertise in Outsourced WCCA Services

By outsourcing WCCA to specialized providers, companies can leverage their industry experience, access comprehensive testing capabilities, ensure compliance with regulations, utilize advanced simulation tools, and receive customized reporting.

This specialized content ensures accurate and reliable worst-case scenario analysis, contributing to the overall success and reliability of electronic designs.

Industry Experience: Specialized WCCA service providers bring industry-specific knowledge and experience, enabling them to understand the unique challenges and requirements of different sectors such as automotive, aerospace, medical devices, or telecommunications.

Comprehensive Testing and Analysis: Outsourcing WCCA includes access to advanced testing equipment and specialized laboratories.

Service providers can perform comprehensive analysis, including thermal testing, voltage and current stress testing, signal integrity analysis, and other specific tests required for accurate worst-case scenario evaluation.

Compliance Standards and Regulations: Specialized WCCA providers are well-versed in industry compliance standards and regulations.

They can ensure that the analysis and documentation meet the required criteria, such as ISO 9001, IEC 61508, DO-254, or MIL-STD-882, depending on the industry and application.

Advanced Simulation Tools: Outsourcing WCCA provides access to cutting-edge simulation tools and software that accurately model and simulate worst-case scenarios.

Service providers can employ specialized software for thermal analysis, circuit simulation, signal integrity analysis, and other specific applications.

Customized Reporting and Documentation: Specialized WCCA service providers offer customized reporting and documentation that meets the specific requirements of the client.

This includes detailed analysis reports, risk assessment documents, and recommendations for design improvements or modifications.

Conclusion

Worst Case Circuit Analysis (WCCA) plays a vital role in ensuring the reliability and performance of electronic circuits. By subjecting circuits to extreme conditions, WCCA identifies vulnerabilities, mitigates risks, and optimizes designs for robust operation.

Whether conducted in-house or outsourced, WCCA requires specialized expertise, accurate component characterization, analysis of environmental factors, sensitivity analysis techniques, and advanced simulation tools.

Outsourcing WCCA offers the benefits of accessing specialized knowledge, cost savings, time efficiency, enhanced accuracy, and effective risk mitigation.

Embracing WCCA as an integral part of the design process contributes to the development of reliable and resilient electronic systems.

Join us on this exploration of WCCA methodologies, where precision, foresight, and innovation converge to forge a path towards the future of reliable electronic design.

For more details, please reach us @ info@gighz.net.