How Copper Surface Roughness Affects Signal Integrity?

Imagine you’re at a party, and you’re trying to have a conversation with someone across the room. The noise in the room from other guests talking can make it difficult for your words to reach their destination intact.

This is similar to how signal integrity can be affected by copper surface roughness in printed circuit boards (PCBs).

Imagine you’re at a party, and you’re trying to have a conversation with someone across the room. The noise in the room from other guests talking can make it difficult for your words to reach their destination intact.

This is similar to how signal integrity can be affected by copper surface roughness in printed circuit boards (PCBs).

Category :

Published Date :

February 15, 2024

Category :

Published Date :

February 15, 2024

Category :

Published Date :

February 15, 2024

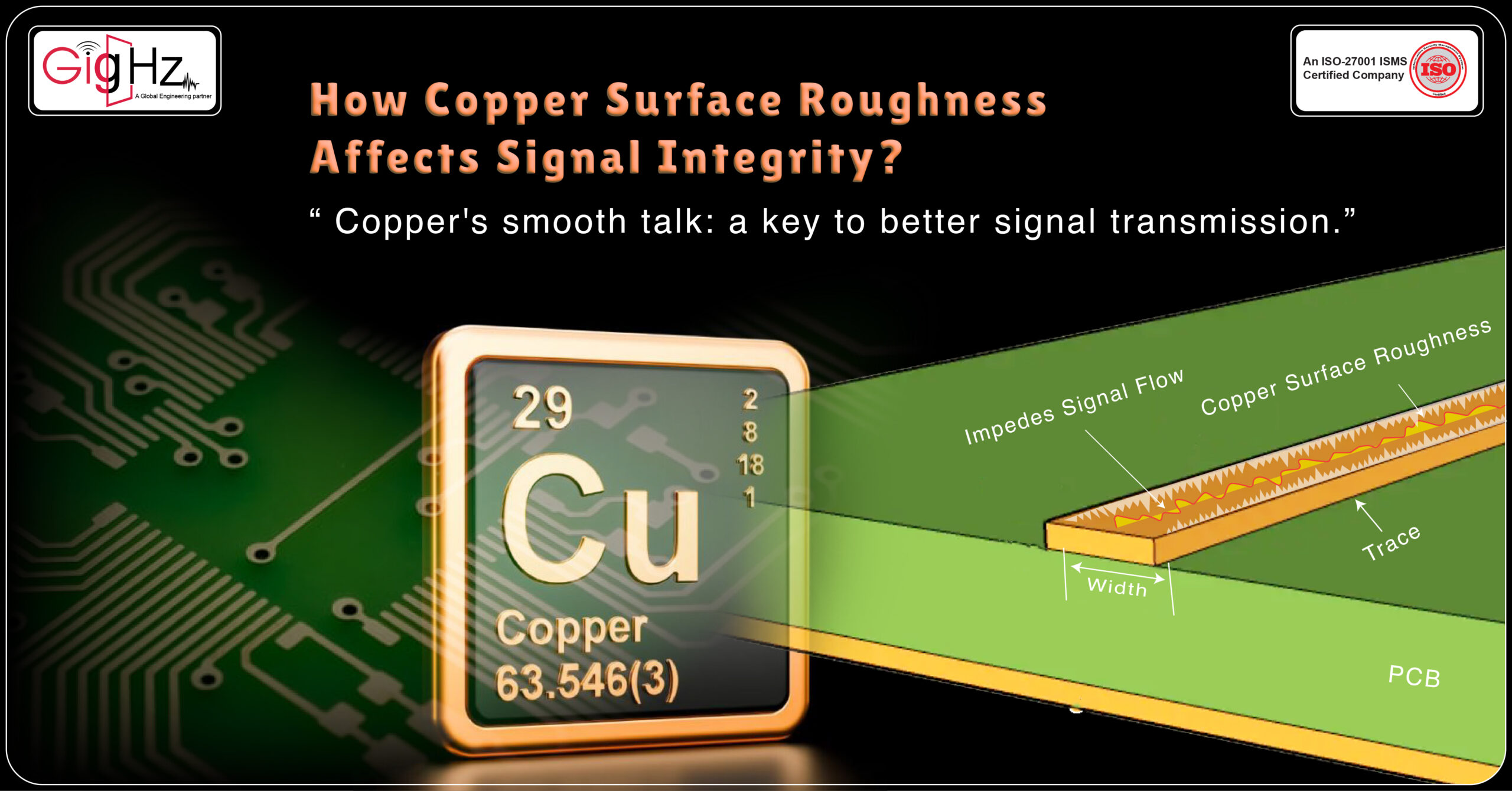

First, let’s understand what we mean by ‘copper surface roughness.’

In PCBs, copper is used due to its excellent electrical conductivity.

However, the microscopic irregularities on its surface, known as ‘roughness,’ can create a form of ‘electrical friction’ that impedes signal flow.

Signal integrity, on the other hand, refers to the quality of the electrical signal.

It’s about ensuring that the signal reaches its destination without being distorted or degraded.

Let we’ll delve into the technical aspects of how copper surface roughness affects signal integrity,

What is Copper Surface Roughness and How Does it Affect Signal Integrity?

Copper surface roughness refers to the degree of irregularity on the surface of a copper substrate. This characteristic has a pivotal role in determining the signal integrity of the signal transmission method. So, how does this happen?

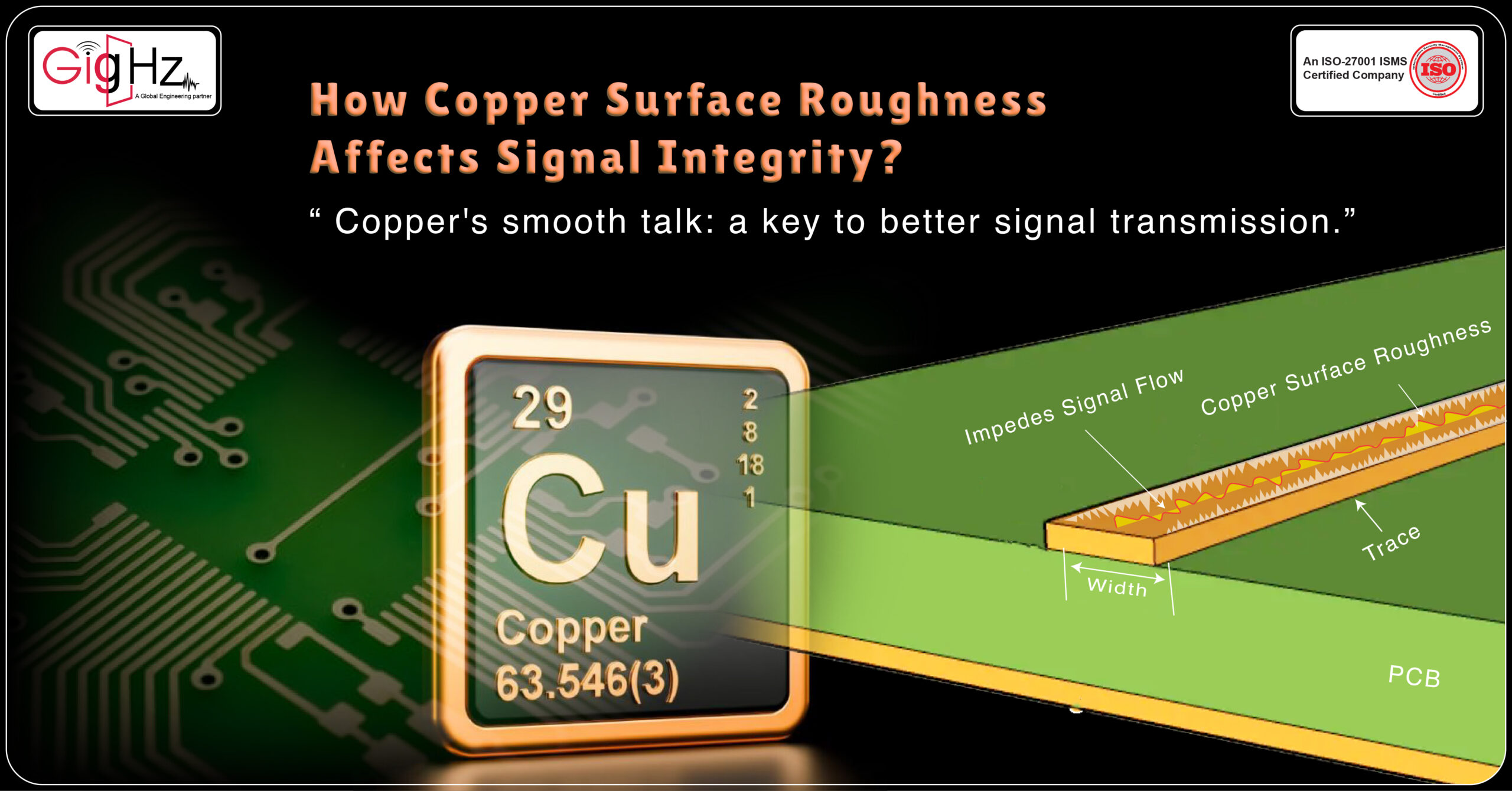

When we talk about the surface roughness of copper, we’re discussing how smooth or coarse the material is.

This isn’t just an aesthetic detail – it has a significant impact on signal transmission.

If the copper’s surface is too rough, it can cause signal attenuation.

Essentially, the signal weakens as it travels across the rough surface. It’s a bit like losing cell service when you’re far from the tower.

The roughness can also lead to signal reflection. That’s when the signal bounces back towards its source and interferes with the original signal. This can result in signal loss and additional noise.

Keeping the copper surface smooth is crucial for clear and accurate signal transmission. It reduces signal attenuation and reflection, ensuring the integrity of the signal.

Now, let’s bring in some more in detail- conductor loss and dielectric loss.

Conductor loss refers to the resistance an electrical signal encounters as it travels along a conductive path. Dielectric loss, on the other hand, pertains to the energy absorbed and then released by a non-conductive, or dielectric, material.

Surface roughness can increase both types of losses, especially in high-frequency applications. At higher frequencies, the current tends to flow near the surface of the conductor, a phenomenon known as the skin effect. Therefore, managing copper surface roughness becomes even more critical for high-speed signal integrity.

How Copper Surface Roughness Can Impact Electrical Performance?

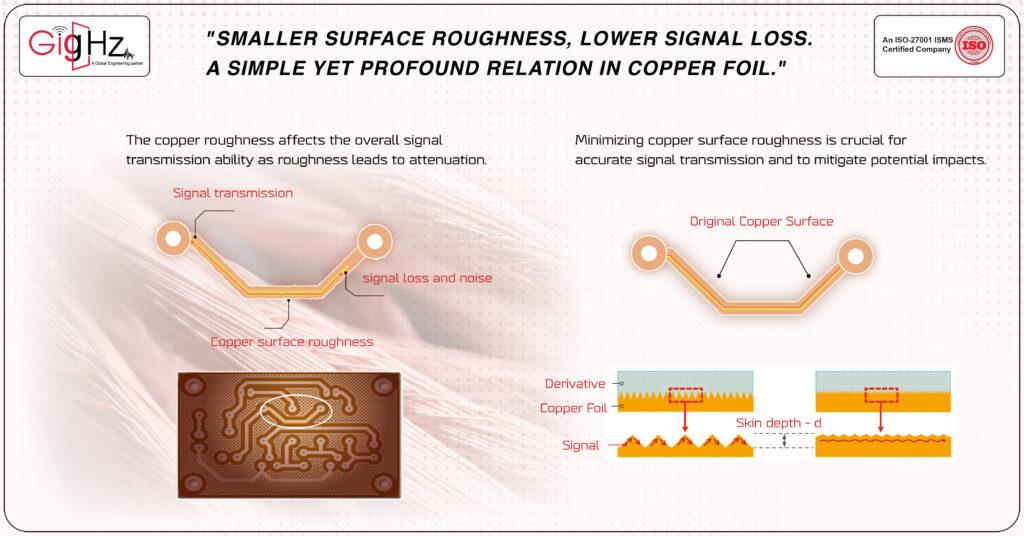

You see, when a conductor like copper has a rough surface, there’s actually a 10-50% higher loss compared to if it were smooth.

This is mainly because of what we call the skin effect and impedance mismatch.

The skin effect is this interesting phenomenon where alternating current tends to stay on the outer layer of a conductor, especially at high frequencies.

Now, when you have a rough copper surface, it tends to exaggerate this effect.

The current ends up taking a longer path due to the surface irregularities, which means more resistance and, consequently, more power loss.

Then there’s impedance mismatch – another issue caused by a rough copper surface.

This mismatch can lead to what we call signal reflection, which might result in distorted data or even data loss.

But that’s not all.

A rougher surface also increases the electric field strength and capacitance because it effectively enlarges the surface area. This can mess with the performance of high-speed circuits by slowing down signal rise times.

Even the phase of the network can be influenced by a rough copper surface.

It can make a trace electrically longer, causing a phase shift that could affect digital signal timing and the resonant frequency of RF circuits.

However, it’s not all doom and gloom.

We can take certain measures to mitigate these effects. For example, we can deposit a layer of silver on the copper surfaces. Silver is known for its high electrical conductivity and can protect the copper surface while enhancing its electrical performance.

So, in a nutshell, if you’re dealing with high-frequency and high-speed applications, you really need to pay attention to the surface roughness of your copper conductors.

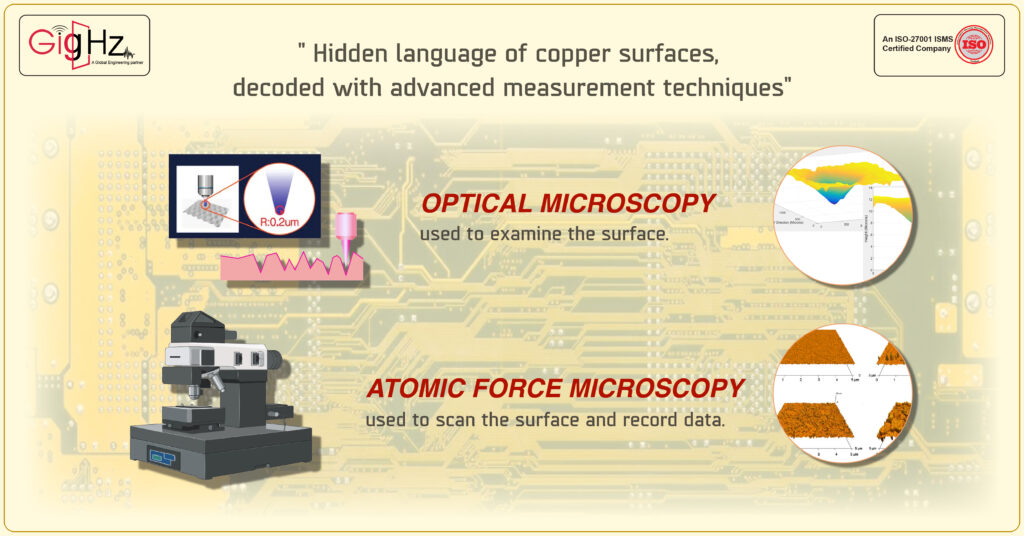

Types of Measurement Techniques to Determine Copper Surface Roughness

The determination of copper surface roughness is an important step in many industrial processes. To achieve accurate measurements, several techniques have been developed.

One such method is optical microscopy where a microscope is used to examine the surface.

Another is atomic force microscopy where a microscopic probe is used to scan the surface and record data. Another popular technique is stylus profiling where a stylus is used to measure the depth of the surface features.

Finally, X-ray diffraction is used as a non-contact method to measure the roughness of the surface. Each of these techniques has its strengths and weaknesses, and it is up to the user to select the most appropriate method depending on the application.

Strategies to Minimize Copper Surface Roughness for Optimal Signal Integrity

When it comes to optimizing signal integrity, surface roughness on copper can be a major hindrance. Fortunately, implementing the right strategies can help minimize roughness and improve signal performance.

One strategy involves using controlled impedance, where the traces on the printed circuit board are routed to maintain a constant resistance and prevent signal reflection.

Another effective tactic is to use a smooth copper surface finish, such as ENIG (electroless nickel immersion gold), which creates a uniform surface that minimizes roughness.

Lastly, it’s essential to control the etching process during PCB fabrication in order to achieve a consistent surface finish and prevent excess roughness.

By using these strategies, you can minimize copper surface roughness and achieve optimal signal integrity.

Tips on Troubleshooting Poor Signal Integrity Due to High Copper Surface Roughness

As electronic components get smaller and more complex, maintaining optimal signal integrity has become increasingly challenging.

If you’re experiencing poor signal reception due to high copper surface roughness, the problem may lie in the quality of your copper plating process.

When copper is deposited unevenly, it can cause signal irregularities that affect device performance.

To troubleshoot this issue, consider adjusting your plating methodology or investing in new equipment that offers more precision.

By taking a proactive approach, you can stay ahead of potential issues and ensure your electronic devices operate at their best.

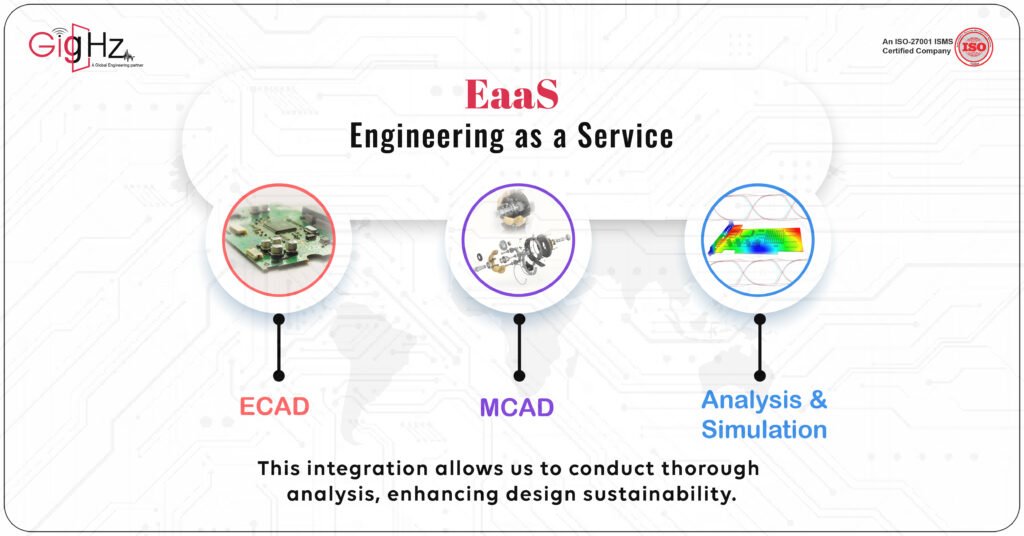

Our Notable Upgrade: Engineering as a Service (EaaS)

At GigHz, we take pride in offering comprehensive services that include ECAD, MCAD, analysis, and simulation.

These elements are vital parts of what we do, allowing us to provide exceptional value to our clients.

We harness the power of advanced technologies and simulation tools to enhance our design processes.

By following industry best practices and leveraging our extensive expertise, we ensure that our outcomes meet the highest standards of quality and performance.

Thorough analysis is at the core of our approach, enabling us to deliver designs that surpass expectations.

now, as the need for advanced and integrated engineering solutions keeps soaring, our Engineering as a Service (EaaS) are really stepping up the game.

We’re harnessing the power of ECAD, MCAD, and Analysis & Simulation. This gives us a great position to be frontrunners in this industry.

What’s really cool is that we offer a full package covering every single step of the engineering process.

And honestly, it’s this kind of approach that’s going to shape the future of our engineering.

It’s exciting stuff!

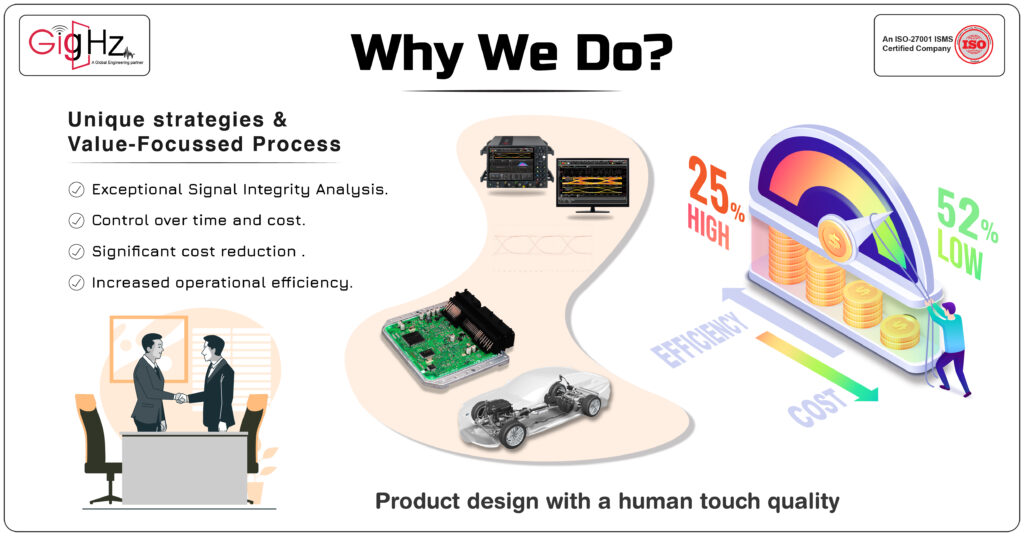

Why we do?

We embrace the challenge of providing exceptional Signal Integrity Analysis capabilities.

Our goal is to help you maintain control over both time and cost, all while elevating the quality of your product design with a human touch.

Despite the challenges in technology, we stand out from the competition due to our innovative methods and value-driven process.

This approach enables us to achieve a significant cost reduction of 52% while simultaneously increasing operational efficiency by 25%.

Conclusion

It is important for any designer of integrated circuits to consider copper surface roughness in order to maximize signal integrity.

It’s easy for even the most intricate designs to be degraded by the excess copper surface roughness, leading to poor electrical performances.

To minimize the chance of subpar performance due to high copper surface roughness, designers should use standard measurement techniques to assess the aluminum or copper material they use.

Additionally, considering external factors such as temperature and manufacturing processes can help reduce signal errors and improve electrical performance.

Now that we understand how copper surface roughness affects integrated circuit design, let’s put our knowledge into action!

Book a Demo call. Schedule a Free Consultation Now. https://calendly.com/gighz/30min

By adhering to signal integrity best practices and leveraging simulation tools, designers can mitigate potential signal integrity issues and improve the overall quality of their PCB designs.

“Ready to take your designs to the next level? Explore our in-depth services now.” https://gighz.net/services/