How Can You Conduct Power Integrity Measurements for Your Prototype Board?

Let’s consider you’re working on developing a prototype board for a leading-edge Electric Vehicle of (EV) charging system in Automobiles. This EV charging system requires a robust and efficient power delivery network to ensure fast and reliable charging for electric vehicles. In this scenario, power integrity measurements play a critical role in optimizing the performance of the prototype board.

Here at GigHz, we’re in the business of turning “impossible” into “done.”

We thrive on tackling complex challenges and transforming them into innovative solutions.

Recently, we had the chance to flex our problem-solving muscles when a client came to us with a tricky situation involving a hosted payload sensor data collection in their spacecraft.

Category :

Published Date :

January 26, 2024

Category :

Published Date :

January 26, 2024

Category :

Published Date :

January 26, 2024

Welcome to our blog post on conducting power integrity measurements for your prototype board! Developing a prototype board is an exciting endeavour, but ensuring its power integrity is absolutely crucial.

Without proper power delivery and regulation, your board’s performance, reliability, and overall functionality may be compromised.

Power integrity measurements involve assessing various aspects of your board’s power delivery system, from voltage ripple and noise levels to impedance analysis and load transients.

We’ll explain what these terms mean, why they matter, and most importantly, how to measure and address them effectively.

But we won’t just stop at theory.

We understand that real-world applications are what truly matter. That’s why we’ll provide practical tips, techniques, and examples to help you apply these concepts to your own prototype board.

From selecting the right measurement equipment to analyzing the effectiveness of decoupling capacitors, we’ll cover it all.

You know, during high-power charging sessions for electric vehicles, the charging system experiences these fluctuations in the current. It’s like the flow of electricity is not completely steady.

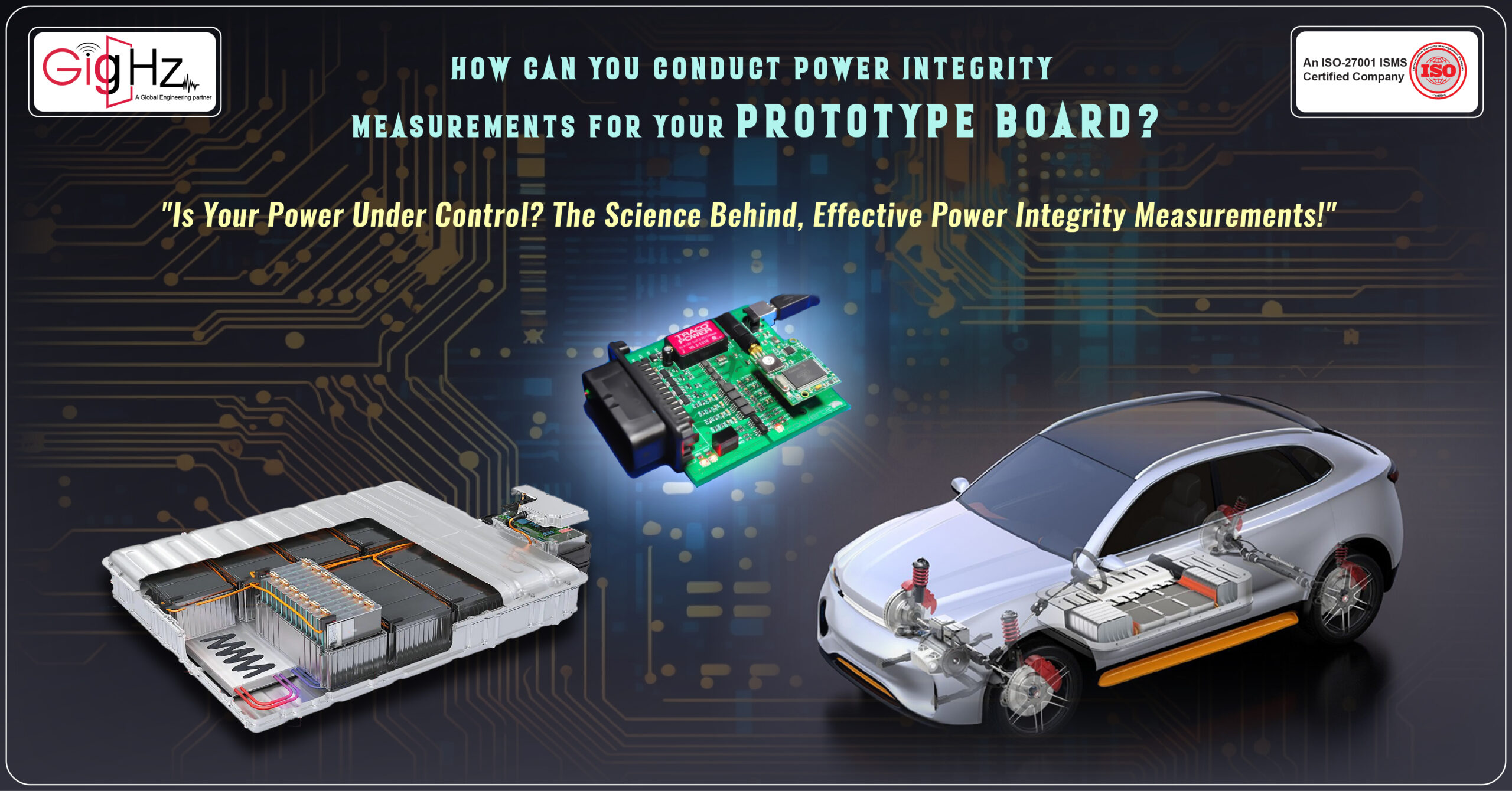

So, to make sure that everything runs smoothly and doesn’t cause any damage to the vehicle’s battery, engineers use something called power integrity measurements. Basically, they analyze the levels of voltage ripple and noise during these charging cycles.

Let’s dive in!

Why is it important to manage voltage ripple and noise?

In power integrity measurements for EV charging systems, it is better to analyze voltage ripple and noise to ensure a stable and efficient charging process.

We consider factors such as ripple frequency and harmonic distortion, which can affect the charging process and introduce unwanted components at multiples of the fundamental frequency.

By carefully selecting and placing capacitors, we can mitigate voltage ripple. They also employ filtering techniques, such as inductors, resistors, and active filters, to attenuate specific frequency components and reduce noise.

Power integrity measurements help assess the electromagnetic compatibility (EMC) of the system, ensuring compliance with standards and preventing electromagnetic interference (EMI) with other devices. Furthermore, by managing voltage fluctuations, we can protect the health and extend the lifespan of EV batteries.

By considering these technical points, we can optimize the performance and reliability of electric vehicle charging systems.

Evaluating Load Transients

To evaluate load transients in electric vehicle charging, we need to consider various technical aspects. One important factor is the response time of the charging system to sudden changes in charging current. Power integrity measurements play a crucial role in assessing this response.

By utilizing specialized power analyzers, we can measure and analyze voltage droops or spikes that occur during load transients.

These measurements provide valuable insights into how well the prototype board handles rapid changes in current demand. We can then make necessary adjustments to ensure the charging system maintains a stable output voltage, even during these dynamic load conditions.

Another technical consideration is the design and implementation of power management components, such as voltage regulators and capacitors. These components play a vital role in maintaining stability and mitigating voltage fluctuations during load variations.

Through power integrity measurements, we can evaluate the effectiveness of these components and identify any areas for improvement.

Additionally, it’s crucial to consider the impact of load transients on the overall efficiency of the charging system.

Rapid changes in charging current can lead to power losses or energy wastage if not properly managed.

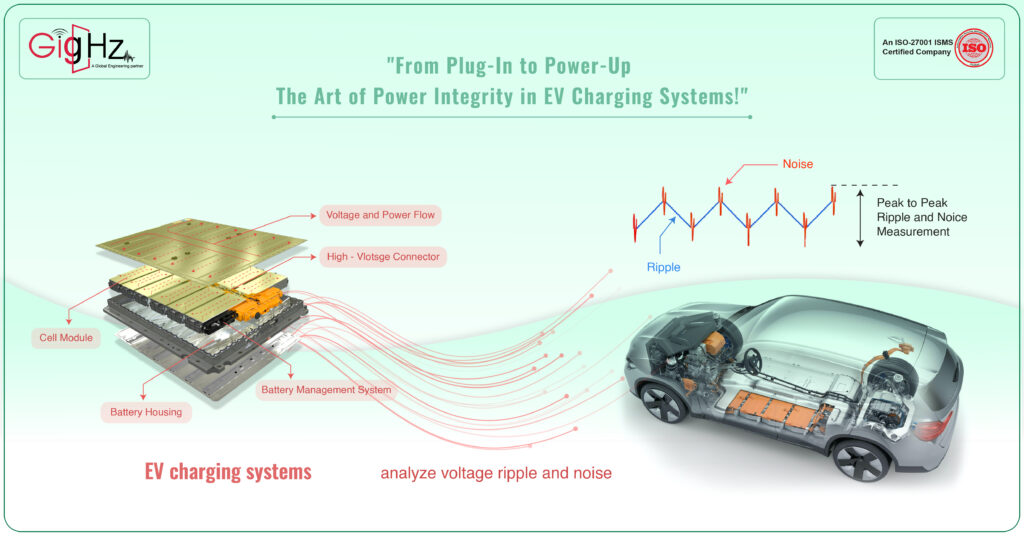

Assessing Decoupling Capacitor Effectiveness

By assessing the effectiveness of decoupling capacitors in EV charging systems, we can rely on power integrity measurements.

These measurements help evaluate how well the decoupling capacitors are performing in terms of suppressing high-frequency noise and maintaining stable voltage levels.

To get a clear picture of the noise levels in the power supply, engineers use real-time spectrum analyzers. These analyzers provide detailed information about the frequency components present in the power supply, allowing engineers to identify any areas where the decoupling may be insufficient.

By pinpointing these areas, we can take corrective actions.

This might involve adding or adjusting decoupling capacitors at specific points in the charging system to improve their effectiveness in reducing noise and fluctuations. This ensures that clean and stable power is delivered to the charging system, enhancing its efficiency and protecting the sensitive electronics within.

In technical terms, decoupling capacitors act as local energy reservoirs. They store and release charge as needed, effectively reducing the output impedance of the power delivery network.

This helps to smooth out any AC waveforms and provide a stable and reliable DC power supply.

Iterating and Validating Improvements

The iterative approach and continuous validation are essential in developing a robust EV charging system prototype board.

By conducting power integrity measurements at various stages of development and comparing the results against established benchmarks, you can identify any deviations or anomalies that might impact the charging system’s performance.

This iterative process allows you to make design modifications, optimize the power delivery system, and validate the improvements made, ensuring reliable and efficient charging for electric vehicles.

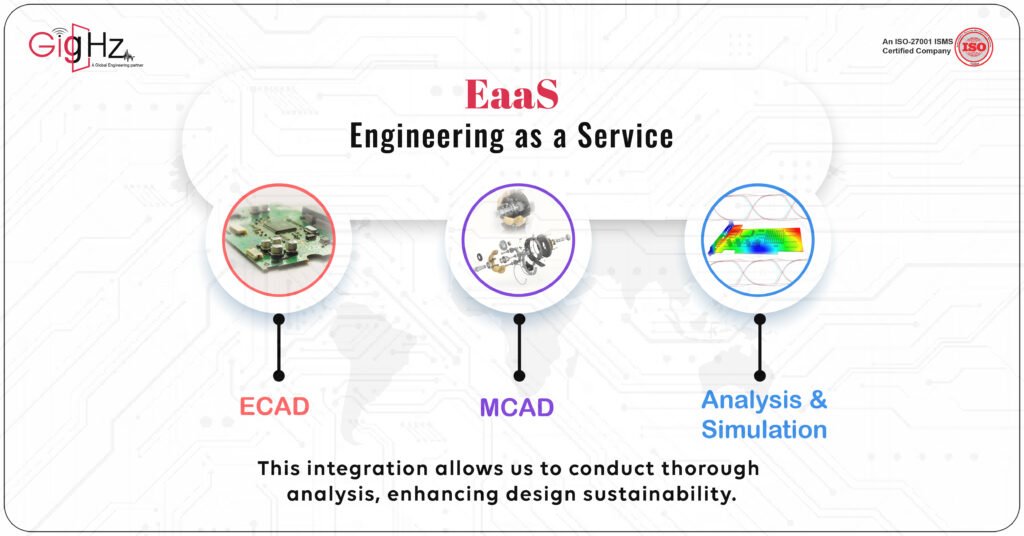

Engineering as a Service(EaaS)

At the heart of our expertise in electronics, we focus on seamlessly integrating ECAD (Electronic Computer-Aided Design), MCAD (Mechanical Computer-Aided Design), and Analysis & Simulation as EaaS.

This unique integration optimizes design, production, and operational workflows, ensuring efficiency at every step.

By combining these disciplines, we conduct comprehensive analyses that enhance the reliability of our designs while fostering creative problem-solving.

This approach consistently yields top-notch results in a cost-effective manner, even when faced with tight timelines. It is the perfect combination of innovation and durability.

At our core, we prioritize the seamless integration of ECAD, MCAD, and Analysis & Simulation to deliver high-quality outcomes that meet and exceed expectations.

With a focus on optimization, reliability, and efficiency, we drive forward-thinking solutions in the field of electronics.

Why we do?

We challenge our Engineering capabilities with emerging technologies to keep your time and cost in control, thereby transforming product design with human touch quality.

Conclusion

Power integrity measurements allow you to observe the power distribution networks and ensure they perform properly for your prototype board. With the right equipment and know-how, designing successful prototypes is achievable.

While tracking power integrity issues may seem daunting, it doesn’t have to be—what matters is the accuracy of your data and understanding what goes into making a reliable, low noise and efficient design.

Making sure your account for all possible sources of interference will help ensure your prototype boards are optimized for production quality and performance throughout its lifecycle.

Use these tips as a guide and start leveraging power integrity measurements in your prototypes today to stay ahead of the curve!

Ready to take your power integrity testing even further?

Reach our website to know more about us! https://gighz.net/