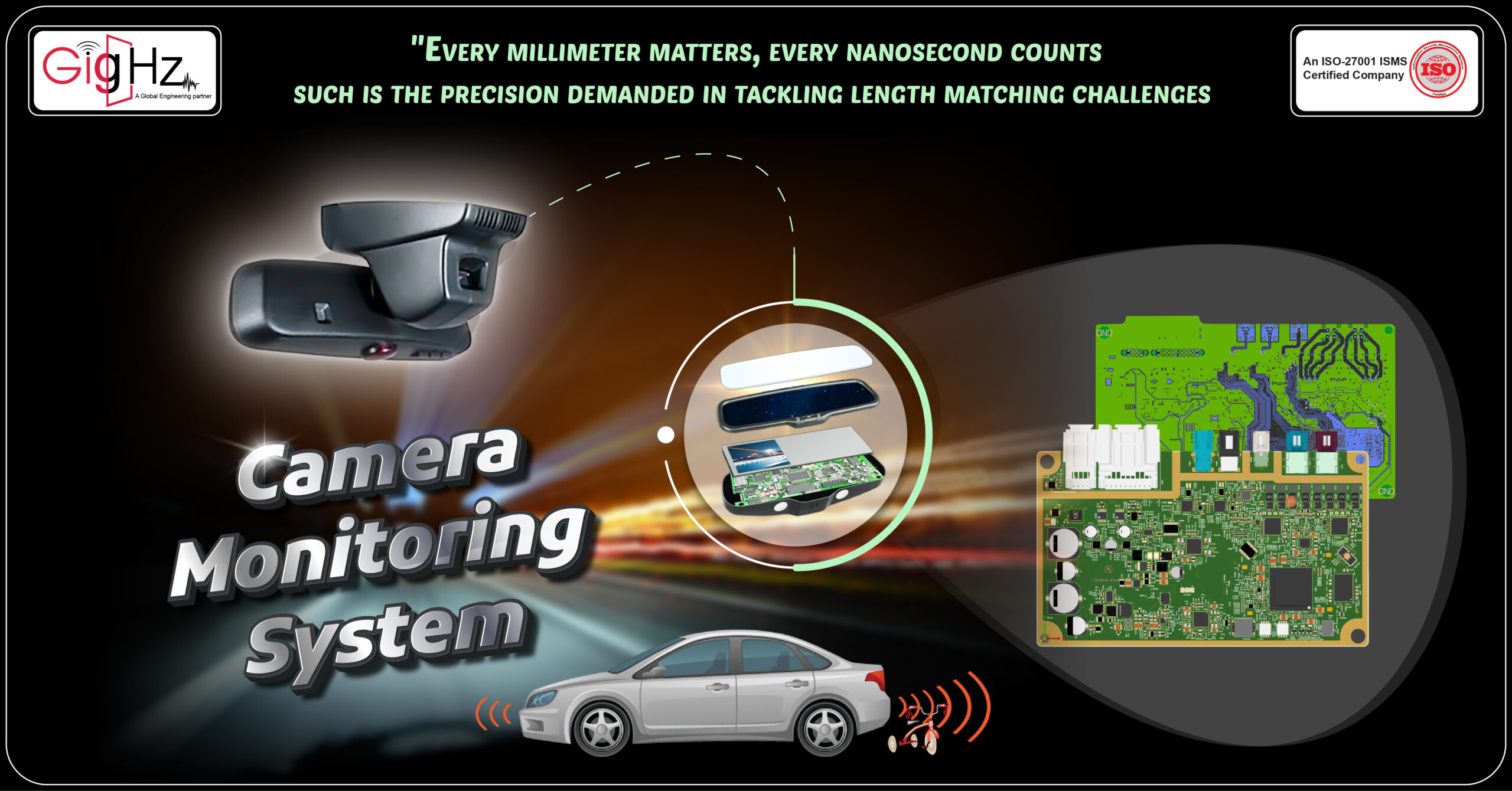

How about Overcoming Length Matching Hurdles in Automotive CMS PCB Design?

In the exciting Automotive world of Advanced Driver Assistance Systems (ADAS), there’s one crucial player that takes center stage: the Camera Monitoring System (CMS). This innovative technology is at the forefront of enhancing vehicle safety by utilizing cameras to monitor the surroundings and provide valuable information to the driver.

In the exciting Automotive world of Advanced Driver Assistance Systems (ADAS), there’s one crucial player that takes center stage: the Camera Monitoring System (CMS).

This innovative technology is at the forefront of enhancing vehicle safety by utilizing cameras to monitor the surroundings and provide valuable information to the driver.

Category :

Published Date :

February 29, 2024

Category :

Published Date :

February 29, 2024

Category :

Published Date :

February 29, 2024

From helping with lane-keeping assistance to recognizing traffic signs, the CMS is a game-changer in making our journeys safer and more efficient.

But behind the scenes, there’s a fascinating project that has been undertaken to take the performance of the CMS to the next level.

It involves tackling the intricate challenge of precision length matching for high-speed signal groups on the CMS circuit board design.

Length matching refers to ensuring that signals within a group travel the same distance to maintain timing integrity and minimize signal degradation.

In the context of the CMS, design and layout, this becomes even more critical due to the high data rates and stringent performance requirements involved.

Sounds complex, right?

Well, it is!

But fear not, because in this blog, we’re going to dive deep into this project, unravelling the challenges faced and the solutions implemented along the way for our CMS pcb design.

Conquering Length Matching Challenges in our Automotive Camera Monitoring System (CMS) PCB Design.

Challenges faced in Automotive CMS PCB Design

When our client embarked on the project of achieving length matching for high-speed signal groups on their PCB board, they encountered several challenges that required both technical expertise and innovative solutions.

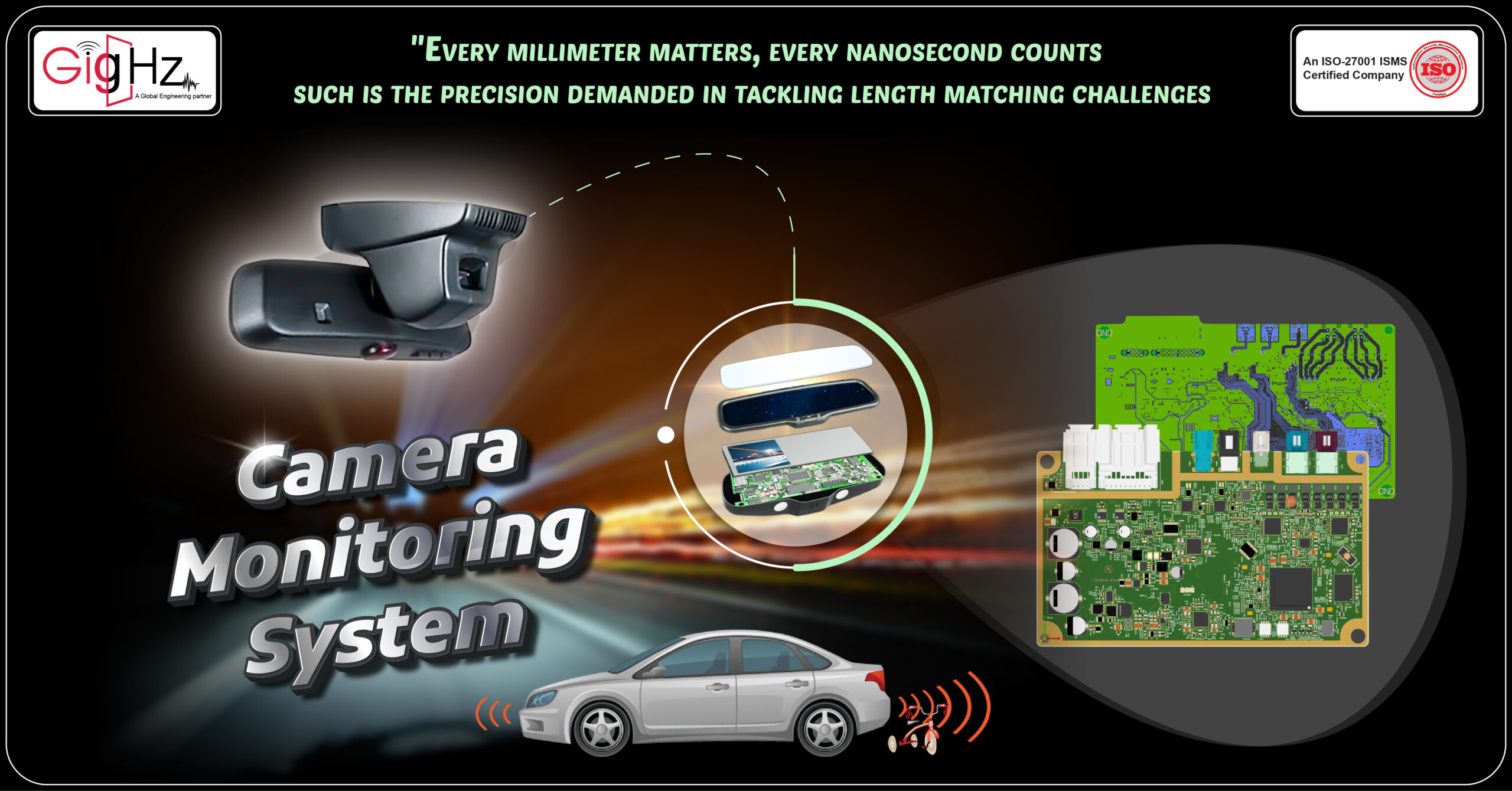

High-Speed Signal Groups

One of the primary hurdles they faced was dealing with the 11 high-speed signal groups present on the CMS board. These groups demanded precise length matching to ensure optimal performance.

Each signal had to travel the same distance to avoid timing discrepancies and maintain data integrity.

Skew Length Matching

Additionally, achieving length matching while considering the sandwich ground/power reference posed a unique challenge.

The presence of multiple reference planes and the need to account for the different paths taken by signals within this structure made it a complex task. We had to carefully analyze the design and develop strategies to overcome the skew length matching issue.

Differential Signal Groups

Furthermore, the CMS board included differential signal groups, which required exact length matching within each pair. Differential signals are utilized to improve signal integrity by transmitting data over two complementary paths.

Achieving precise length matching in these pairs was crucial to minimize common-mode noise and maintain signal integrity.

Single Ended Signal Groups

On top of that, the project involved single-ended signal groups, where a maximum allowable difference of 5mil was permitted.

Single-ended signals are more susceptible to noise, so maintaining consistent lengths helps reduce signal degradation.

However, achieving the required length matching while also considering other design constraints presented a notable challenge.

Our Workflow for our CMS Circuit Board Design

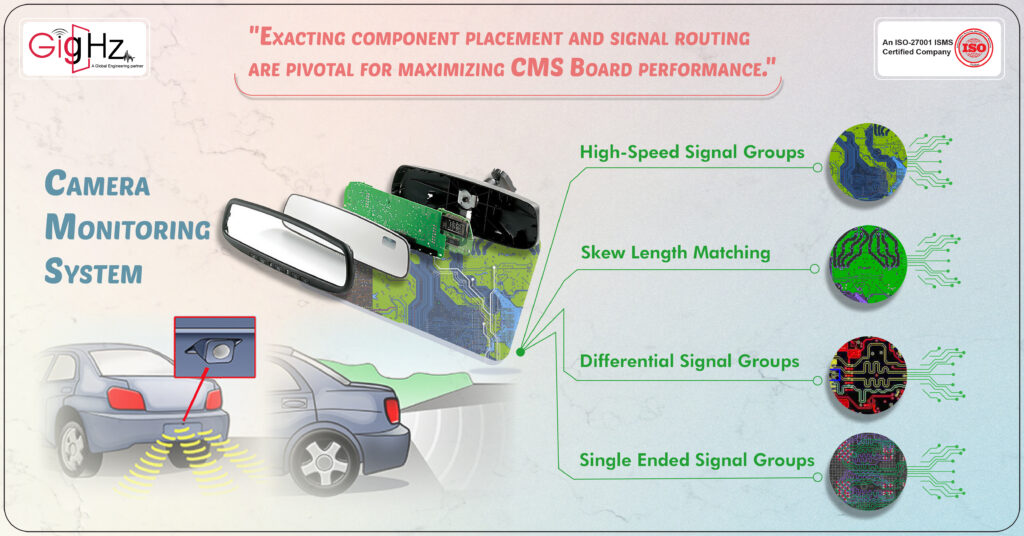

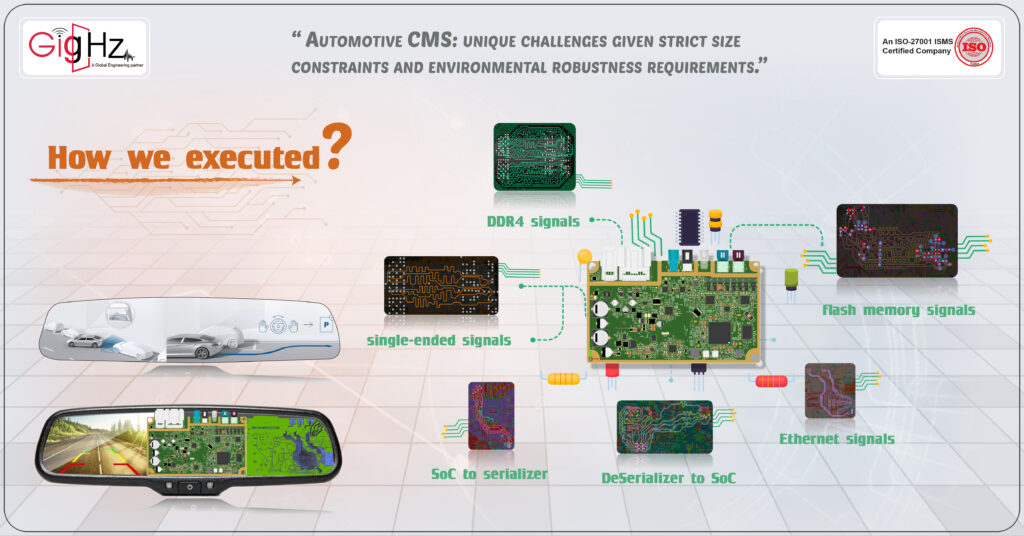

How we executed?

To tackle the challenges of achieving length matching for high-speed signal groups in the CMS board, we followed a methodical and structured approach.

Here’s an overview of the execution process we implemented:

Input Analysis:

We began by thoroughly analyzing the provided board design and identifying the different high-speed signal groups present. This included single-ended signals, DDR4 signals, Ethernet signals, and flash memory signals. Understanding the composition and requirements of each signal group was crucial for the subsequent steps.

Brainstorming and Planning:

Through collaborative brainstorming sessions, our team of experts devised a comprehensive plan for signal layer allocation. We carefully considered the sandwich ground/reference structure and determined the optimal routing strategy for each high-speed signal group. This planning phase ensured that we had a clear roadmap to follow during the implementation stage.

Route and Length Matching:

Armed with our plan, we proceeded to meticulously route and length match the high-speed signals on the CMS board. Our experienced designers paid close attention to critical areas, such as under fine pitch BGA components, SoC connections, and DDR4 clock rates. By following best practices and utilizing advanced routing techniques, we aimed to achieve precise length matching across all signal groups.

Iterative Testing and Refinement:

Throughout the execution process, we conducted iterative testing to validate the length matching and ensure signal integrity. This involved utilizing simulation tools, signal integrity analysis, and thorough impedance control. Any deviations or inconsistencies were identified and addressed promptly to refine the design further.

Deliverables:

Once the length matching goals were achieved, we provided the client with the necessary board files showcasing the completed design. Additionally, we developed a comprehensive length matching spreadsheet, detailing the achieved results for each signal group. This documentation served as a valuable reference for the client and demonstrated the successful execution of the project.

By adhering to this structured execution process, we were able to overcome the length matching challenges in the CMS board and deliver a robust solution to our client.

Our technical expertise, meticulous planning, and dedication to achieving precise signal lengths contributed to the overall success of the project.

Results we Achieved

Our dedicated efforts in addressing the length matching challenges in the CMS board resulted in significant improvements and value additions to its overall performance.

Here are the key outcomes we achieved:

Single Ended Signals:

We successfully routed and length matched the high-speed single-ended signal groups, ensuring that they met the specified requirements.

By maintaining consistent signal lengths, we minimized signal degradation and improved the overall reliability of the CMS circuit board.

Differential Signals:

Achieving exact length matching within pairs for the differential signal groups was a critical objective. Through meticulous routing and precise length adjustments, we successfully achieved the desired length matching, enhancing the signal integrity and reducing common-mode noise.

Signal Integrity Analysis:

As part of our comprehensive approach, we conducted thorough signal integrity analysis for all high-speed signal groups on the CMS board. This analysis revealed overshoots and undershoots in the data signal DQ-7 within the DDR4 Byte group-1. Identifying these issues allowed us to further optimize the design and improve the overall system-level signal quality.

Precision Length Matching:

To address the signal integrity concerns identified in the signal integrity analysis, we implemented precision length matching specifically for DQ-7 within the corresponding groups. This precise length matching helped mitigate both overshoots and undershoots, resulting in improved signal quality and reduced data transmission errors.

By achieving these results, we not only resolved the length matching challenges but also added significant value to the CMS board’s performance. The improved signal integrity, reduced noise, and enhanced data transmission capabilities contribute to a more reliable and efficient Camera Monitoring System.

Our technical expertise, thorough analysis, and precision implementation played a pivotal role in delivering these positive outcomes. The successful execution of the project underscores our commitment to pushing boundaries, optimizing designs, and delivering cutting-edge solutions in the realm of advanced driver assistance systems.

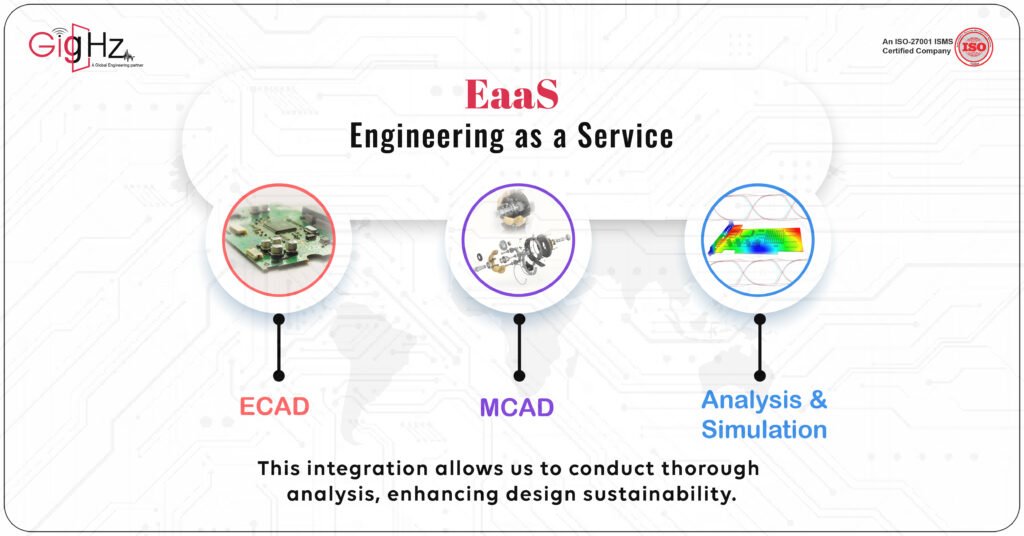

Our Notable Upgrade: Engineering as a Service (EaaS)

Absolutely!

The world of engineering is constantly evolving, and it’s fascinating to see how Engineering as a Service (EaaS) is keeping up with the demands of the industry.

By harnessing the power of ECAD, MCAD, and Analysis & Simulation, we’re able to provide comprehensive solutions that cover every aspect of the engineering process.

It’s really amazing how far we’ve come in terms of integrating different disciplines within engineering. With EaaS, we can seamlessly bring together electronic design, mechanical design, and analysis and simulation, all under one roof.

This not only saves time but also improves efficiency and collaboration among engineers.

Why we do?

Amidst the ever-evolving technological landscape, we distinguish ourselves from the competition by embracing innovation and leveraging our value-driven process.

This unique approach empowers us to achieve remarkable results, including a substantial 52% reduction in costs and a notable 25% improvement in operational efficiency.

We continually challenge our engineering ECAD capabilities by embracing emerging technologies, ensuring that we keep your time and costs under control.

Through this commitment, we are able to transform product design with a touch of human quality that sets us apart from the rest.

Conclusion

By effectively providing a PCB design that met the client’s specific requirements, we demonstrated our dedication to excellence and technical proficiency.

Beyond the technical aspects, our partnership highlighted personalized service, combining proficiency with understanding.

To discover our Specialities. Visit our Services Page. https://gighz.net/services/

Our commitment is to deliver top-tier PCB design services, serving as evidence of our capability and reliability in consistently achieving outstanding results.

Schedule a call. Book a free consultation now. https://calendly.com/gighz/30min

#ecad #pcbdesign #lengthmatching #signalintegrity #circuitboarddesign