Game-Changing Redesign of Restart and Trunk Circuits of Battery Management System (BMS) for Enhanced Performance

The world of electric vehicles and high-tech gadgets is buzzing with excitement over some pretty cool upgrades in the Battery Management System (BMS). Imagine the BMS as the brain behind your battery’s operations, making sure everything runs smoothly and safely.

Now, get this:

The world of electric vehicles and high-tech gadgets is buzzing with excitement over some pretty cool upgrades in the Battery Management System (BMS).

Imagine the BMS as the brain behind your battery’s operations, making sure everything runs smoothly and safely.

Now, get this:

Category :

Published Date :

March 19, 2024

Category :

Published Date :

March 19, 2024

Category :

Published Date :

March 19, 2024

Innovators out there are working on some amazing redesigns that are total game-changers for these BMS brains,

Particularly focusing on the restart and trunk circuits.

Let’s break it down into simple terms and see why this is such a big deal.

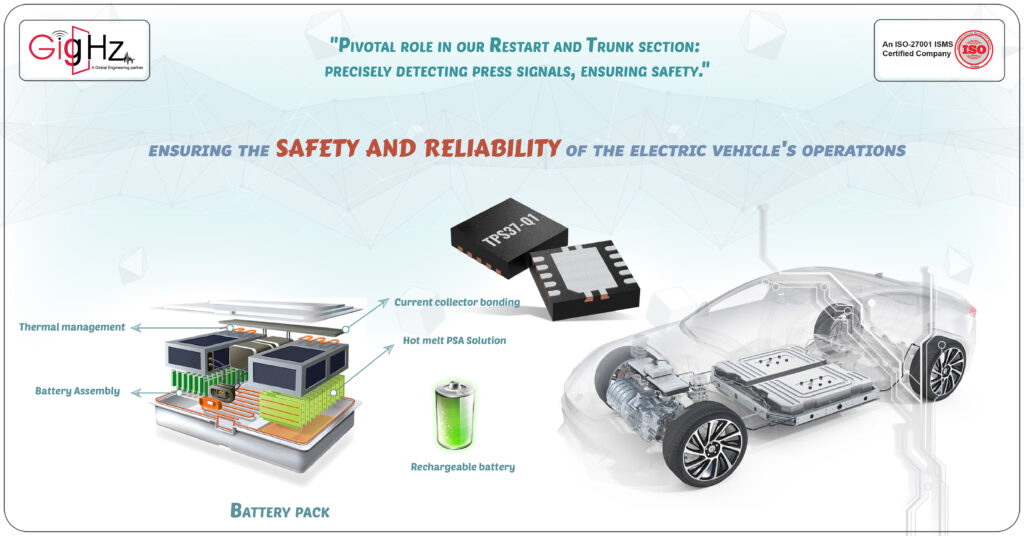

The hardware circuit design of the Battery Management System (BMS) plays a critical role in ensuring the endurance and performance of rechargeable batteries,

Particularly in the context of electric vehicles with high energy density.

The placement of battery protection circuit-breakers is also an important consideration in the design of a BMS.

Generally, these circuits are implemented with N-channel MOSFETs, and it’s essential to choose a topology appropriate for pack size, cost, complexity, and scalability needs.

Various vital components, such as the Battery Management Unit (BMU), play a key role in a typical BMS design continuously monitoring the state of the battery pack which is the energy storage device to ensure safety and reliability.

Additionally, sourcing components from reputable manufacturers like TI, Analog Devices, and RoHM, and identifying the ideal solution based on internal voltage divider configuration and dual adjustable time delay, such as TI’s TPS37-Q1, are crucial steps in the hardware circuit design process.

Ultimately, the hardware circuit design of a BMS is akin to the brains of electric vehicles, intricately managing the safety, stability, and performance of rechargeable batteries, ensuring the smooth operation and endurance of electric vehicles.

"Our Journey for Game-Changing Redesign of Restart and Trunk Circuits of Battery Management System (BMS) for Enhanced Performance"

What we Analyzed?

The hardware circuit design of the BMS is fundamental to the longevity and efficiency of rechargeable batteries, especially in the context of electric vehicles.

Serving as the “brains” of electric vehicles, this intricate circuit ensures seamless functionality by managing the rechargeable batteries.

In Restart and Trunk section, the hardware circuit design plays a pivotal role in precisely detecting press signals while effectively filtering out sudden noise. This capability is crucial for preventing unintended actions during specific programmed tasks, ensuring the safety and reliability of the electric vehicle’s operations.

By integrating advanced circuitry and sophisticated signal processing, we ensure that the heart of electric vehicles continues to beat strong, contributing to the overall endurance and performance of rechargeable batteries.

How We Do: Tackling Challenges with Precision and Innovation

The challenge at hand emerged when our client encountered functionality issues with the existing circuit design, specifically within the BMS module on SBC1, failing to meet updated requirements.

Here’s an insight into the intricate details of our approach to addressing these challenges with precision and innovation.

Wake-Up Recognition

For Restart:

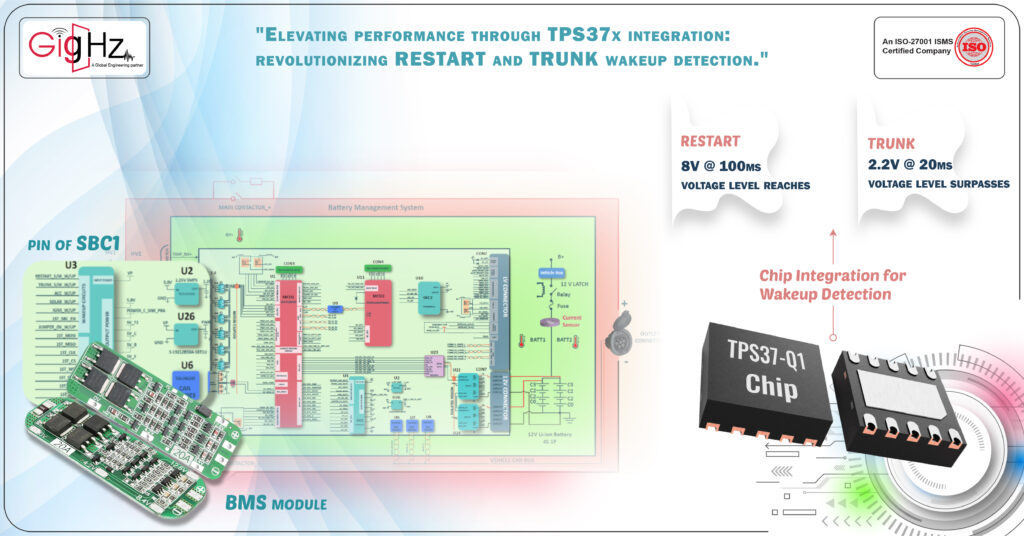

The circuit must accurately identify signals of at least 8V @ 100ms as High, prompting a wake-up response.

This entails the implementation of a latch circuit for pulse input signal and digital input for the signal at the end of the latch circuit.

For Trunk:

It is essential for the circuit to recognize signals as LOW from a minimum value of 2.2V or higher, requiring wake-up initiation. Only pulse signals longer than 20ms should activate recognition. Similar to the Restart phase, this involves implementing a latch circuit and digital input for the signal.

Approach and Methodology

Our Statement of Work (SOW) encompasses a multi-faceted approach, including.

Identifying Reason for Failure

This involves an exhaustive analysis of the existing design, comprehensive results discussion, and meticulous component sourcing.

Circuit Design Phase

This phase encompasses an in-depth exploration of the proposed circuit design, detailed analysis & calculation, and thorough documentation.

Existing Design Analysis

The existing circuit design relies on discrete components to regulate the voltage usable by the pin of SBC1. Notably, there is no introduction of delay by the programmed SBC1, resulting in functional limitations.

Result & Discussion

After meticulous analysis, it was discerned that the SBC1 encounters challenges in creating a delay when the input signal is analog and experiences a sudden rise in voltage.

Component Sourcing

Our component sourcing process involved careful selection from reputable suppliers such as TI, Analog Devices, and RoHM, culminating in the identification of TI’s TPS37-Q1 as the ideal solution due to its internal voltage divider configuration and dual adjustable time delay.

Proposed Circuit Design

TPS37x Chip Integration for RESTART Wakeup Detection

The TPS37x chip plays a pivotal role in enabling the generation of RESET when the voltage level reaches 8V @ 100ms, aligning seamlessly with the stringent RESTART wakeup detection requirement. This feature represents a significant advancement in circuit design, elevating the performance and responsiveness of the system.

Furthermore, the integration of the TPS37x chip empowers the circuit to reset the latch through the GPIO signal from the MCU1-RESTART_LATCH, ushering in a streamlined and synchronized operation that underscores the efficacy of the revamped design.

TPS37x Chip Integration for TRUNK Wakeup Detection

Elevating the standards of TRUNK wakeup detection, the TPS37x chip facilitates the generation of RESET when the voltage level surpasses 2.2V @ 20ms, aligning flawlessly with the requisite functionality on SBC1. This integration represents a paradigm shift in circuit design, fortifying the system’s ability to detect TRUNK signals with unparalleled precision and reliability.

Moreover, the circuit’s ability to reset the latch through the GPIO signal from the MCU1-TRUNK_LATCH underscores the seamless synergy between hardware and software components, culminating in a harmonized and responsive system architecture.

Proposed Design Calculations and Analysis Setup

The analysis involved simulating the circuit at three distinct voltages (8V,

9V, and 16V) while maintaining a consistent delay configuration within

The integrated circuit (IC).

Proposed Design Validation Result and Value Add

In-depth simulations were conducted across varied voltage levels to validate the proposed design, resulting in a robust and reliable solution that surpasses the existing design.

Value Adds

This particular output not only meets their specific requirements for the circuit and delay, but also exceeds the capabilities of the existing design, thereby significantly enhancing the overall value of the Battery Management System (BMS).

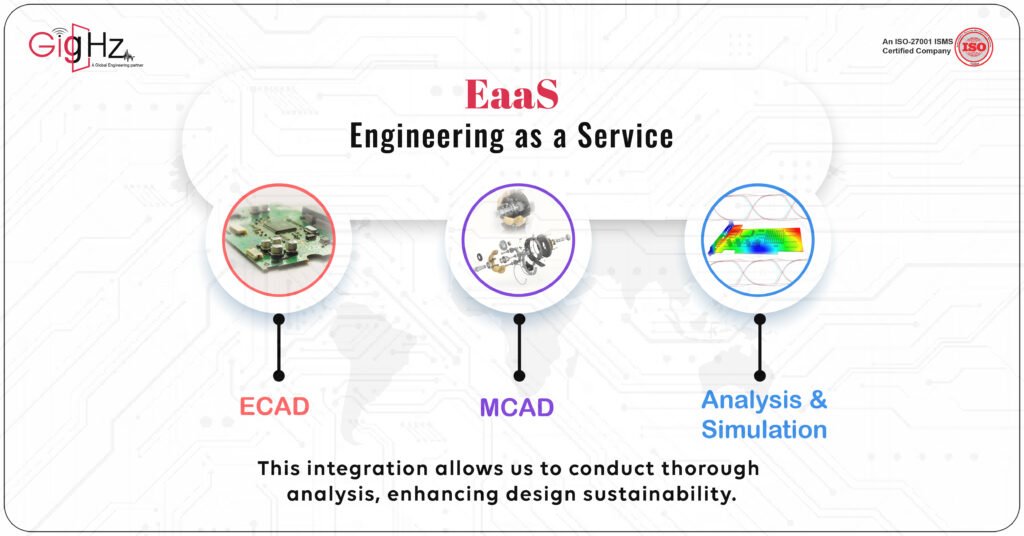

Our Significant Evolution: Engineering as a Service (EaaS)

The demand for advanced and integrated engineering solutions is soaring, and our Engineering as a Service (EaaS) is truly stepping up its game.

By harnessing the power of ECAD, MCAD, and Analysis & Simulation, we’ve positioned ourselves as frontrunners in this industry.

What’s really cool is that we offer a full package, covering every single step of the engineering process.

It’s this kind of approach that’s going to shape the future of our engineering, and honestly,

it’s super exciting stuff!

Why we Do?

Our drive originates from the ECAD Capabilities within the emerging technologies of the Battery Management System.

Despite these intricacies, we set ourselves apart by employing distinctive strategies and a process centered on value.

This unique approach leads to a significant 52% reduction in costs, while simultaneously improving operational efficiency by 25%.

Conclusion

In summary, despite the challenges in hardware design, we successfully developed a comprehensive circuit design and conducted analysis for the most demanding circuit voltages.

Our cost-effective design prioritizes performance, aligning seamlessly with the client’s requirements and positioning the product as an optimal solution.

Schedule a Free Consultation. Book a Demo call. https://calendly.com/gighz/30min

The efficient completion of this design marks a noteworthy milestone in our journey.

Discover our Specialities. Visit our Services Page. https://gighz.net/services/