Future of printed circuit boards: Supporter and Challenger

We all encounter both supportive and challenging phases in our daily lives, across various situations.

What do you tend to be, a supporter or a challenger? Think of. As the electronics industry continues to evolve, the role of printed circuit board (PCB) design will shape its future as either a force for support and a catalyst for change.

Hey there!

Welcome to Everyone,

So, when it comes to PCB design, the schematic capture process is super important for a few reasons.

First off, it’s like the foundation for designing the electronic circuitry within the PCB design software.

This part allows us to see how all the electrical connections will work in the circuit board design.

Category :

Published Date :

April 2, 2024

Category :

Published Date :

April 2, 2024

Category :

Published Date :

April 2, 2024

Let’s talk about the future of printed circuit boards (PCBs) – it’s not just about supporting the devices we rely on every day; it’s about stepping up to challenge the norms and drive innovation in the electronic world.

Imagine PCBs as the unsung heroes, quietly laying the groundwork for our gadgets while simultaneously shaking things up in the name of progress.

PCBs are gearing up to support the next wave of high-speed, ultra-efficient electronic wonders.

They’re mastering the art of packing more power into smaller spaces, optimizing signal pathways, and embracing eco–friendly materials to keep our devices humming along smoothly.

At the same time, they’re not afraid to challenge the old ways of doing things, diving into sustainable manufacturing techniques and flexing their creative muscles with new, flexible PCB designs.

So, what does this mean for all of us?

Quietly keeping our electronics running while fearlessly pushing the boundaries of what’s possible.

They’re the ones ensuring reliability and stability, all while sparking new ideas and setting the stage for a future where technology is not just powerful but also sustainable and adaptable.

In this blog, we are sharing our research findings to provide valuable insights for you.

Let’s dig in!

In-Demand Innovations of Printed Circuit Board

The field of electronics is witnessing unprecedented advancements, propelled by the soaring demand for cutting-edge devices.

Key among these innovations is Printed Circuit Boards (PCBs), which serve as the backbone of modern electronics.

Let’s delve into the remarkable features shaping the PCB landscape,

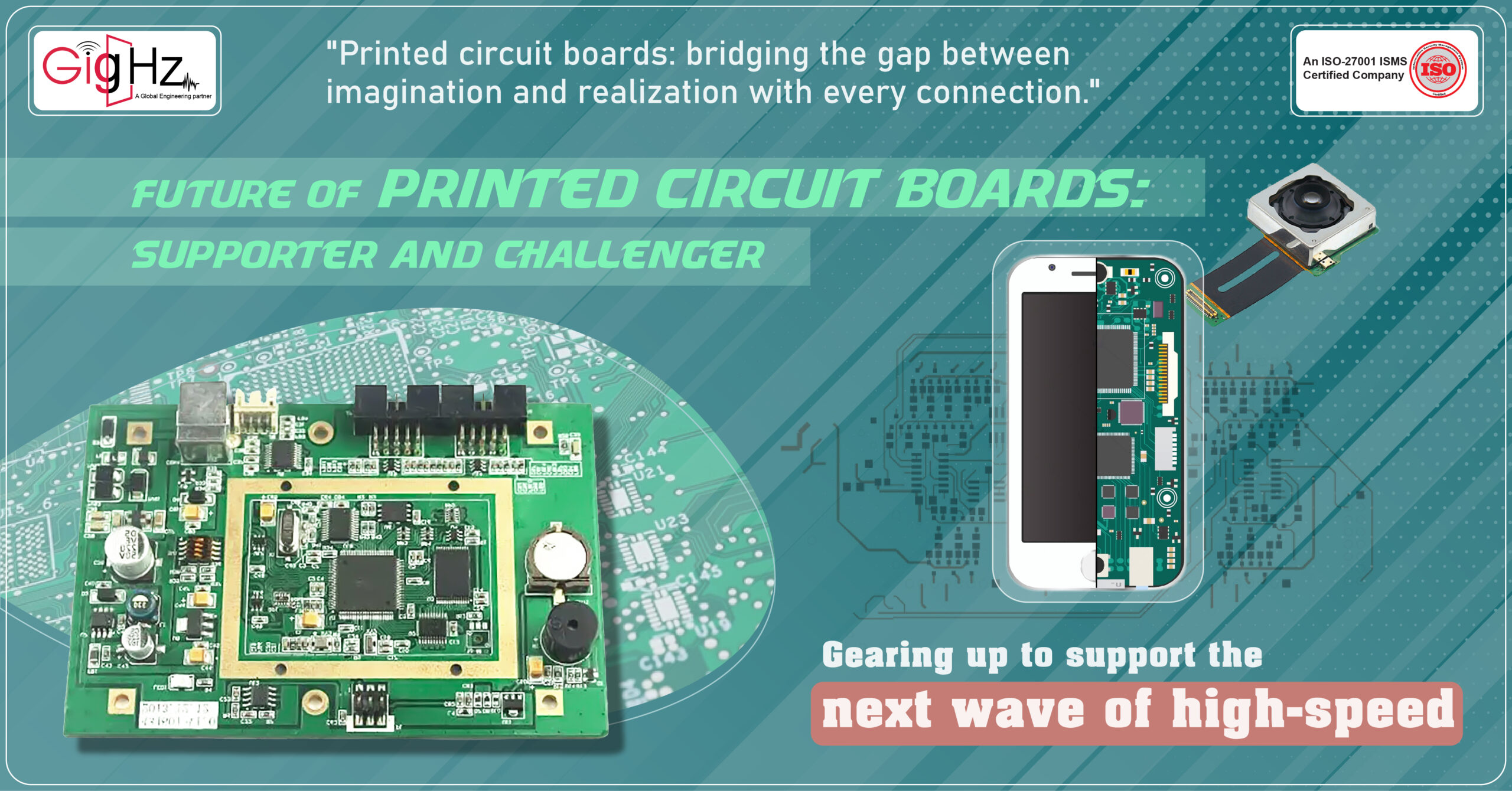

Compact PCB Cameras

The integration of high-quality imaging capabilities into compact PCBs has revolutionized various industries.

From smartphones to medical equipment and surveillance technology, the demand for PCB cameras continues to surge.

These miniaturized marvels have redefined visual communication and image capture, ushering in a new era of portable, high–performance imaging solutions.

High-Speed PCBs

As the need for speed in device development intensifies, high-speed PCBs have emerged as an indispensable component.

These advanced PCBs play a pivotal role in minimizing signal integrity problems, ensuring seamless data transmission, and facilitating the rapid evolution of electronic devices. Their significance is expected to remain paramount as the pace of technological innovation accelerates.

Rapidly Growing Flexible PCBs

The rapid rise in popularity of flexible PCBs underscores their potential to reshape the electronics market.

With their compact size and remarkable flexibility, these PCBs are predicted to exert a significant impact on the industry in 2023. Their adaptability and reliability make them ideal for applications in medical devices, wearable electronics, and other compact electronic systems.

Revolutionary 3D Printed PCBs

The advent of 3D printed PCBs has unlocked a new realm of possibilities in manufacturing. This innovative approach streamlines fabrication processes, reduces material waste, and enables the production of intricate designs.

Furthermore, the use of environmentally friendly materials adds a sustainable dimension to PCB manufacturing, reflecting the industry’s commitment to eco-conscious practices.

"The future of printed circuit boards Supporter and Challenger"

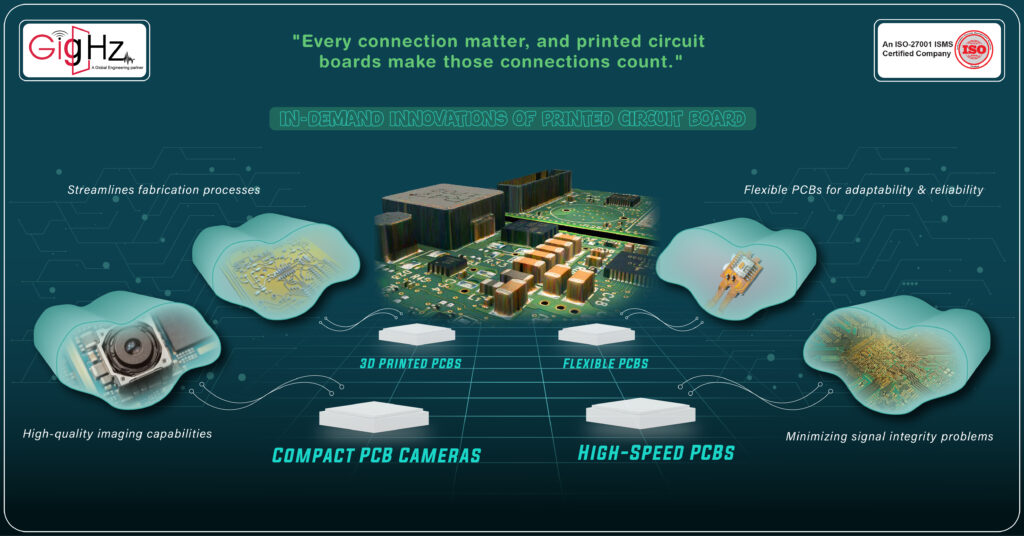

High-Speed Designs

The future of PCBs is all about high-speed designs. As electronic systems keep getting faster and more efficient, there’s a growing need for PCBs that can keep up.

This has pushed the development of new materials and design techniques focused on reducing signal loss, managing electromagnetic interference, and ensuring smooth high-speed data transfer.

Supporter: The increasing demand for faster and more efficient electronic systems is driving the need for high-speed PCB designs. This presents opportunities for advancements in materials and design techniques to meet these requirements.

Additionally, the adoption of high-speed PCBs allows for the development of cutting-edge technologies such as 5G networks, high-performance computing, and advanced medical devices.

FR-4 PCBs

FR-4 PCBs are looking strong in the market thanks to the increasing demand for electronic devices across different industries. With improvements in materials and manufacturing, FR-4 PCBs are set to meet the high performance and reliability standards expected in next-gen electronic systems.

Their adaptability to various applications makes them a solid choice in the ever-changing world of PCB technology.

Supporter: FR-4 PCBs are well-positioned to meet the rising performance and reliability standards in next-generation electronic systems due to their adaptability to diverse applications and continuous improvements in material science and manufacturing processes.

Furthermore, the widespread availability and cost-effectiveness of FR-4 materials contribute to their sustained market relevance, providing a dependable foundation for various electronic applications.

PCB Embedding Technology

This is a game-changer in PCB design and manufacturing. By embedding active and passive components within the PCB itself, this technology allows for super small designs, improved performance, and easier assembly.

The potential applications of embedded PCB tech cover industries like aerospace, automotive, and consumer electronics, marking the start of a new era for compact and efficient electronic systems.

Supporter: PCB embedding technology represents a significant leap forward in PCB design and manufacturing, offering miniaturization, enhanced performance, and streamlined assembly processes, which can benefit industries such as aerospace, automotive, and consumer electronics.

Moreover, the integration of components directly into the PCB substrate enhances system reliability by minimizing interconnect complexity and reducing signal propagation delays, thus paving the way for more robust and compact electronic systems.

Lighter, Thinner, and Flexible PCBs

These innovative PCBs are bringing a wave of change to electronic device design.

From wearable tech to bendable displays, their flexibility opens doors to new form factors and applications. While creating these PCBs comes with unique challenges in fabrication and assembly, innovative solutions are propelling this technology into the spotlight of future electronic design trends.

Challenger: While lighter, thinner, and flexible PCBs enable innovative electronic device designs, the unique challenges in fabrication and assembly require ongoing innovative solutions to fully capitalize on their potential.

However, the growing demand for wearable technology, IoT devices, and portable consumer electronics underscores the increasing importance of these PCBs in enabling a new generation of compact and versatile electronic products.

Paper-Based PCBs

In response to the growing focus on sustainability in manufacturing, researchers and manufacturers are exploring the potential of paper-based PCBs. By using materials based on cellulose, they’re aiming to create eco-friendly PCBs without sacrificing performance and reliability.

This sustainable approach to PCB fabrication aligns with the broader trend towards eco-conscious practices in the electronics industry.

Supporter: The development of paper-based PCBs aligns with the growing emphasis on sustainability and eco-conscious manufacturing in the electronics industry, offering the potential to create environmentally friendly PCBs without compromising performance and reliability. Additionally, the use of paper-based materials opens avenues for biodegradable electronics, disposable medical devices, and environmentally sustainable IoT applications, contributing to the advancement of green technology and circular economy initiatives.

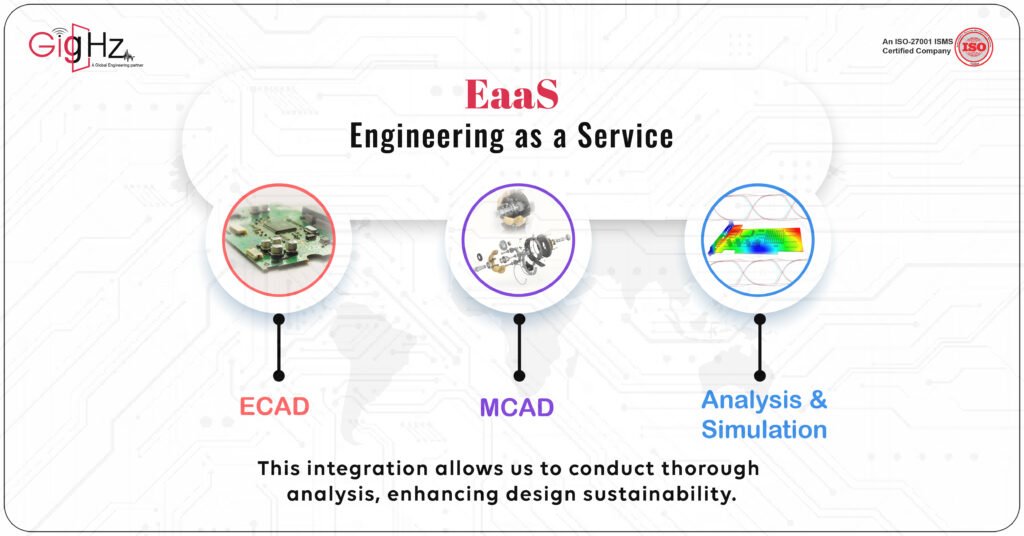

Our Notable Upgrade: Engineering as a Service (EaaS)

Our electronics specialization is all about bringing together ECAD, MCAD, and Analysis & Simulation to create a seamless integration.

This integration is crucial for optimizing our design, production, and operational workflows, making everything run more efficiently.

When we combine these different disciplines, we can conduct thorough analyses that really strengthen the reliability and resilience of our designs. It also helps us come up with innovative solutions to any challenges we face along the way.

And the best part is, we consistently achieve high-quality results without breaking the bank, even when we’re working on tight timelines.

This approach allows us to drive both innovation and durability at the same time, pushing the boundaries of what’s possible in the field of electronic systems.

Conclusion

The future of printed circuit boards (PCBs) is all about balancing steady support with bold innovation.

This reflects the industry’s dedication to progress and pushing boundaries. Whether it’s creating high-speed designs or developing eco-friendly solutions, the evolution of PCB technology has the potential to transform the core of modern electronic devices.

It serves as a dependable ally while also daring to challenge.

Moreover, the increasing demand for high-speed functionality underscores the pivotal role of PCB innovations focusing on high-speed designs. This trend aligns with the industry’s commitment to pushing the boundaries of performance and efficiency in electronic devices.

As we look ahead, the emergence of flexible and rigid-flex PCBs, along with the potential of 3D printed circuit boards, presents a glimpse into the future of PCB fabrication.

The miniaturization of circuits and the adoption of high-density interconnects further underscore the industry’s trajectory toward compact, efficient, and powerful PCB solutions.

Furthermore, the prospect of paper PCBs and the ongoing quest for sustainable and environmentally friendly materials foretell an era of responsible and forward-thinking PCB manufacturing.

Schedule a Call. Book a Free Consultation Now.https://calendly.com/gighz/30min

Discover Our Specialities. Visit our Services Page. https://gighz.net/services/