Driving into Tomorrow: The Clearview Mirror Revolution!

Welcome to the Future of Driving: Clearview Mirror – ECU! Take a moment to rethink what a rearview mirror can do. The Clearview Mirror isn’t just about reflection; it’s the brains behind a seamless driving experience. Ever experienced auto-dimming that adapts to your surroundings? That’s the magic it weaves.

Welcome to the Future of Driving: Clearview Mirror – ECU! Take a moment to rethink what a rearview mirror can do. The Clearview Mirror isn’t just about reflection; it’s the brains behind a seamless driving experience. Ever experienced auto-dimming that adapts to your surroundings? That’s the magic it weaves.

Category :

Published Date :

December 8, 2023

Category :

Published Date :

December 8, 2023

Category :

Published Date :

December 8, 2023

Step into the tech-packed world of Clearview Mirror. Cameras and sensors work in harmony, offering more than just a view behind you.

From rearview cameras capturing real-time action to intelligent lane-keeping and blind spot monitoring, it’s your vehicle’s watchful eye.

Versatility at its finest. The Clearview Mirror effortlessly switches between reflective elegance and camera-based displays.

Gain not just a rearview but a 360° perspective, giving you the confidence to navigate every turn.

Ready to explore the Clearview Mirror – ECU?

Your journey into the future of driving starts here!

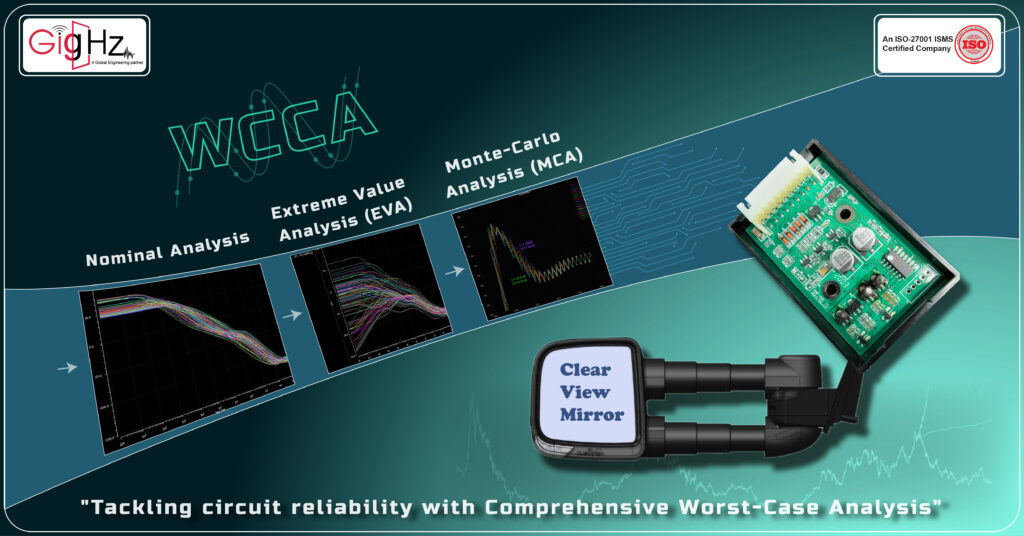

Here we discuss with you our project journey of doing WCCA analysis of the power circuits of clear view mirror in ECUs.

Fixing Up The Power Circuits

While analyzing the circuit, we came to know only 30% Power board has unexpected output voltage issues. But the real cause of the problem is unknown.

Then we try to find a solution, with improving the power circuit. Our board consists of totally 16 circuits including PMIC, Buck converter, Boost converter and LDO.

In the circuit board we worked, the total number of components used are 368. We determine these by WCCA analysis using Pspice Model. The main advantage of this Pspice model is it has most of the components inbuilt. Hence it is quite easy to use it for complex circuits.

The circuit under our study is also the similar one. Even it has more number of components, it can be easily analyzed using this tool.

Why we need to analyze a circuit?

Analyzing a circuit allows us to find the unknown elements of a circuit, such as voltage, current, resistance, impedance, power, among others, across its component.

It is able to design, synthesize and evaluate the performance of the electric circuits through the analysis.

In our project, first we do manual calculation based on the design requirements and check whether it meet out the expected results or not.

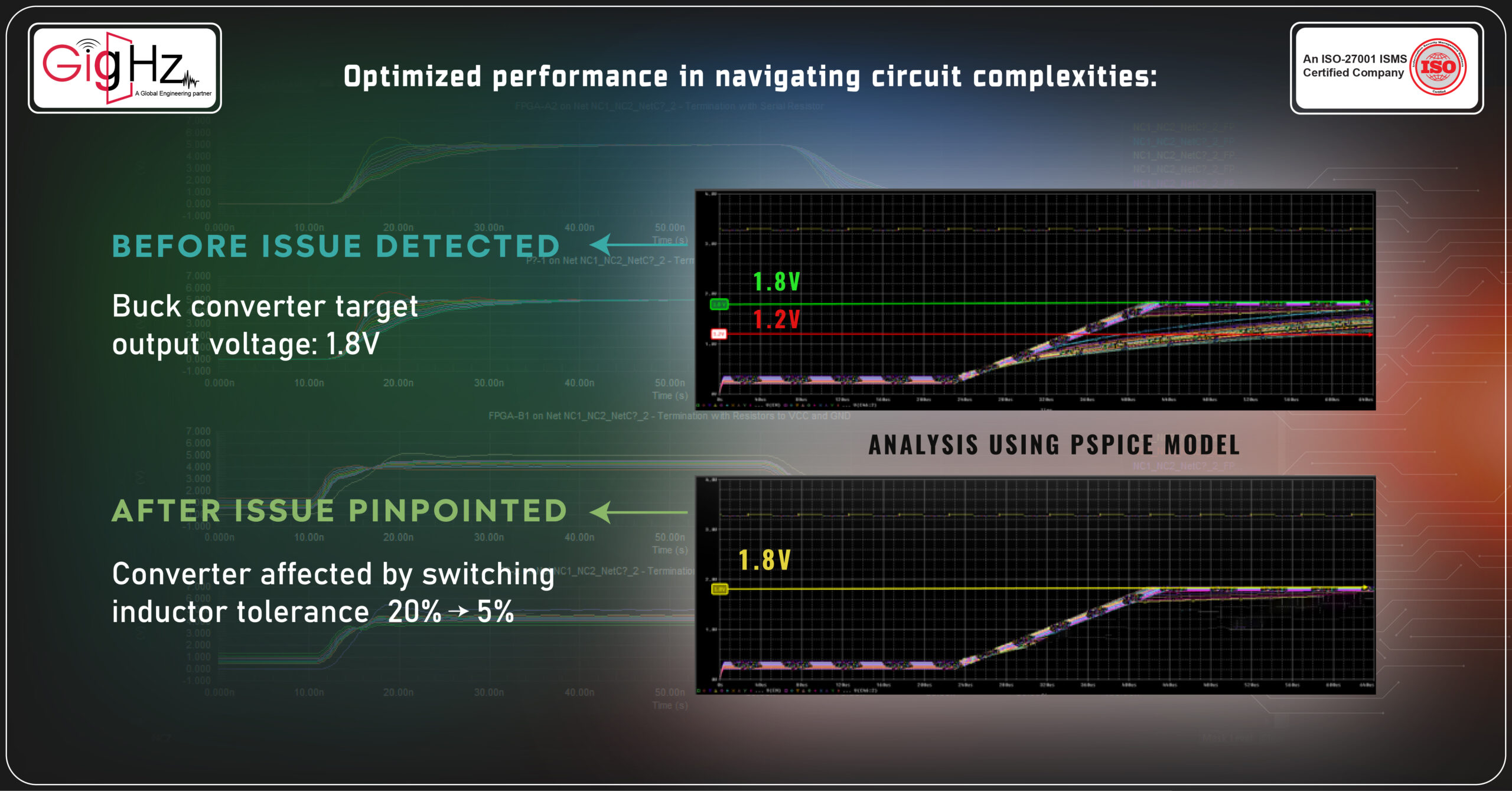

The buck converter in the board we do Monte-Carlo analysis and we find out that it does not meet the desired voltage level of 1.8v. We took up that as challenge and work on that to get the desired output.

You may think how it can be done?

We use pspice model for our analysis to find out the exact reason for the power issues and to modify the circuit to get the exact voltage of 1.8v.

What is a pspice? Why it is to be used?

PSpice is a computer-aided simulation Software that models the behaviour of a circuit containing any mix of analog and digital devices.

PSpice is a virtual SPICE simulation environment with the largest model library that allows you to prototype the designs using the analog, mixed-signal, and advanced analysis engines to deliver a complete circuit simulation and verification.

It is a great tool to be used for Worst Case Circuit Analysis (WCCA) and it is far better than other analysis as it takes into consideration of the significant factors such as life span and tolerance of the components.

How WCCA differentiate from other Analysis?

A Worst-Case Circuit Analysis is a cost-effective means of screening a design to ensure with a high degree of confidence that potential defects and deficiencies are identified and eliminated PRIOR TO and DURING test, production, and delivery.

It is a quantitative assessment of a circuit performance affected with worst condition of manufacturing, environmental, aging (in the case of Space applications, radiation tolerances) tolerances of a component.

Worst case circuit analysis (WCCA) is a method for determining circuit’s performance under extreme conditions by accounting for component variability.

It is carried out under three circumstances,

- Nominal Analysis

- Extreme Value Analysis (EVA)

- Monte-Carlo Analysis (MCA)

Nominal Analysis

It is the testing of the circuit and components under normal working conditions.

It is used to find out the faults that the circuit may encounter in normal operating conditions.

Extreme Value Analysis (EVA)

Extreme Value Analysis (EVA) is an estimate of the most extreme limits of the circuit’s components and function.

Extreme Value Analysis (EVA) is a process in which the behaviour of a circuit is simulated for every permutation of extreme component parameters – that is, a resistor of 5 ± 5% is simulated at 4.75 and 5.25, in combination with every permutation of extreme values for all other components.

EVA allows the designer to be highly confident that the circuit will function as required.

EVA simultaneously implements the worst-case extremes of all components for the circuit parameter under evaluation. Once the circuit extremes have been applied, the component parameter is evaluated using standard circuit analysis techniques.

The conclusions of the analysis are then compared to expected results.

The main advantage of using this EVA analysis as it does not require statistical inputs for circuit parameters.

Monte-Carlo Analysis

The last method of worst-case circuit analysis is Monte Carlo Analysis (MCA). The MCA technique uses actual part tolerance distributions.

Monte Carlo analysis, in which parameters are randomly selected from a distribution, and the circuit simulated, anywhere from 1000 to 100000 times. The results of the MCA are typically displayed using a histogram for the circuit parameter under analysis.

The Project Execution

Here in the buck converter, we faced the problem of not getting the desired 1.8v. Out of the three analysis, we preferred to use Monte-carlo analysis as it is accurate in finding out the voltages at each end point.

We have done MCA analysis for the circuit and find out the fault is in the switching inductor.

The difference in output is due to the tolerance and wide range of the switching inductor and it is adjusted from 20% to 5%, so as to get the required output.

Our project highlights are,

- Effectively using pspice model where most of the components are inbuilt and easy to use.

- The significant factors such as tolerance and life span of components are taken into consideration.

- Power fault in buck converter was rectified

- Three types of analysis were performed in pspice to analyze the working of circuit under all circumstances. In our project we have done Monte-carlo analysis for WCCA.

- Manual calculations were done for design requirements and to sort out whether the desired outputs met or not

- Cross-verification of simulation outputs with manually calculated results and compared with design requirements

- Evaluated the failure factors to rectify the circuit issues and to attain the expected result

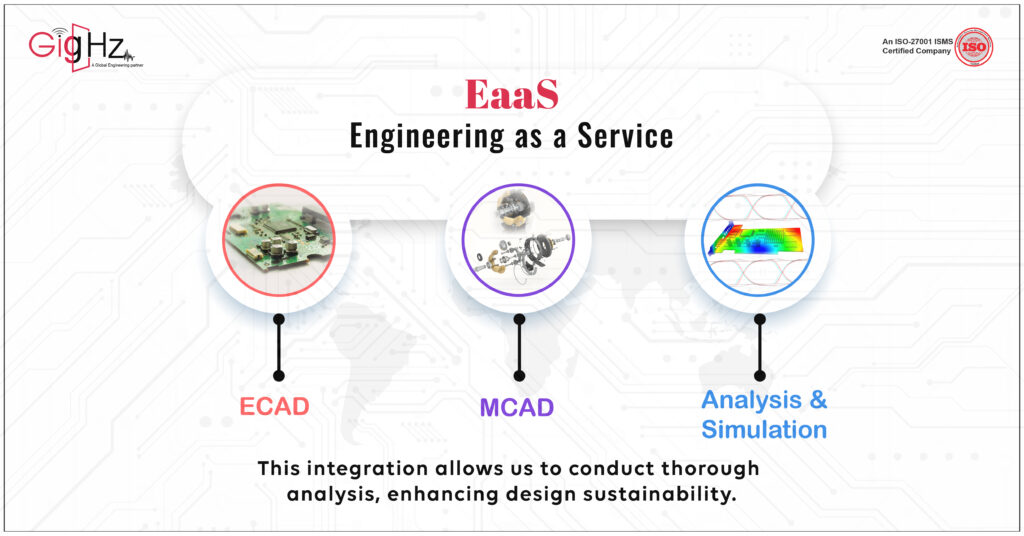

Engineering as a Service

Our dedicated focus on electronics encompasses the fusion of ECAD (Electronic Computer-Aided Design), MCAD (Mechanical Computer-Aided Design), and Analysis & Simulation. This fusion aims to optimize the effectiveness of design, production, and operational workflows.

This unified approach enables us to conduct thorough analyses, thereby enhancing the durability of our designs and fostering innovative solutions. The result is the attainment of cost-effective, top-notch results within accelerated timelines

Why We Do?

Our motivation arises from the complexities posed by power circuits within clear view mirrors in ECUs tailored for ADAS applications. Despite these challenges, we set ourselves apart by leveraging innovative methodologies and a process centered on value.

This unique approach allows us to realize a significant 52% reduction in costs while concurrently enhancing operational efficiency by 25%.

Conclusion

Wrapping up our project, we’ve diligently conducted a WCCA analysis aimed at pinpointing power defects within the buck converter of the clear view mirror’s power circuits, integral to the ECUs designed for ADAS applications.

Our focus on problem-solving and quality assurance has not only addressed specific power-related concerns but also emphasized our dedication to ensuring the utmost reliability and performance in these critical components.

We proved our strong dedication by delivering analysis results that perfectly matched what the client needed. Besides being skilled, our teamwork means we offer personalized service with expertise.

Our promise is to provide top-notch analysis services, showcasing our reliability and proficiency.

Ready to innovate?

Schedule a free consultation now https://calendly.com/gighz/30min