Inside the Circuit: 7 PCB Design Challenges in Medical devices

- Posted On:

- August 29, 2024

- Category:

- Ecad

PCB design challenges

In the critical realm of medical field, where every second can impact a patient’s life, technological advancements are revolutionizing how we monitor and manage health.

Smartwatches have become a key player in this transformation, offering invaluable real-time data on vital signs such as heart rate, ECG, oxygen levels, and physical activity.

These devices are not just accessories; they’re integral tools in modern medical care and personal health management.

But what makes these smartwatches function so effectively?

PCB is the backbone of the smartwatch, serving as the central hub that connects and powers all the critical electronic components.

It’s responsible for integrating sensors, managing power distribution, and ensuring smooth data transmission between various parts of the device.

A well-designed PCB ensures that smartwatches operate accurately and reliably, providing users with precise health monitoring capabilities.

It handles everything from maintaining signal integrity to managing heat dissipation, all while fitting within the compact space of a wrist-worn device.

In this blog, we’ll dive into the seven key challenges faced in designing PCBs for smartwatches used in the medical field.

We’ll explore how these challenges impact the functionality of the devices and how innovative PCB design techniques help overcome them.

Understanding these challenges and solutions is crucial for creating smartwatches that continue to push the boundaries of health technology and improve patient care.

Printed Circuit Board (PCBs) for Medical Applications

As medical technology advances, the reliance on printed circuit boards (PCBs) has grown, as these boards support smaller, high-density circuits packed with numerous connections.

These high-tech features are crucial for ensuring the reliability and accuracy of medical devices.

The medical industry insists on the utmost quality, precision, and dependability in their circuit board requirements.

The applications below are designed to drive innovation, improve product quality, and enhance the overall effectiveness and cost-efficiency of the medical industry,

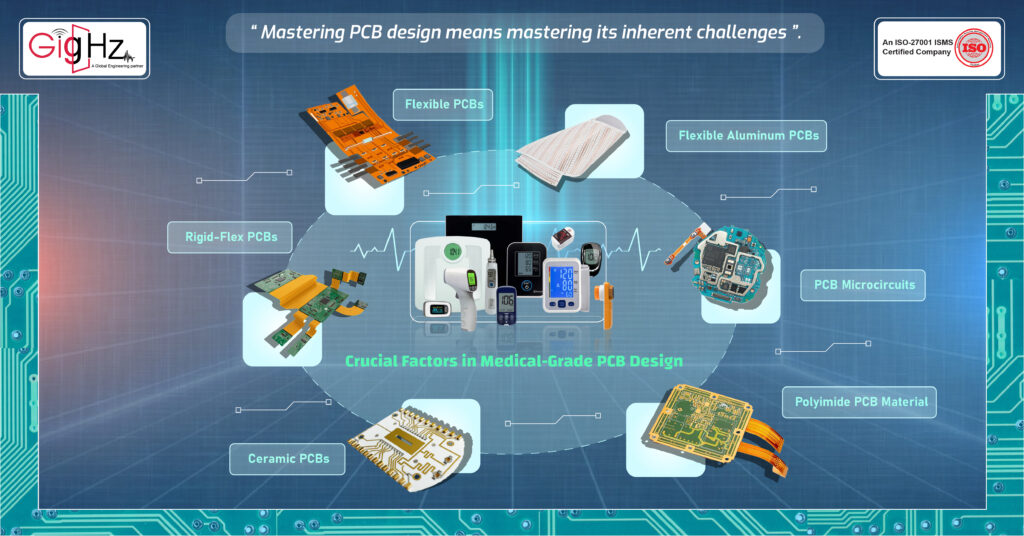

Crucial Factors in Medical-Grade PCB Design

Flexible PCBs: Flex PCBs are ideal for many medical devices due to their adaptability. Their flexible nature makes them suitable for devices that need to bend or wrap around different shapes. Choose flex PCBs when designing medical devices that require flexibility.

Flexible Aluminum PCBs: For high-power medical devices, flexible aluminum PCBs are an excellent choice. They offer superior heat dissipation, making them suitable for demanding applications such as scanning equipment and surgical lighting.

PCB Microcircuits: If you need compact yet high-performance PCBs, consider using flexible PCB microcircuits. These miniaturized boards offer flexibility and are often used in small medical devices, including industrial sensors, wearables, and hearing aids.

Polyimide PCB Material: Polyimide is a robust choice for PCB base materials. Known for its excellent tensile strength, flexibility, and durability, polyimide is thermally stable and chemically resistant, making it suitable for applications like prosthetics and implants.

Ceramic PCBs: Ceramic PCBs are ideal for devices requiring low thermal expansion and high thermal conductivity. They can withstand extreme temperatures, provide exceptional high-frequency performance, and offer high-density tracing and chemical resistance.

Rigid-Flex PCBs: Rigid-flex PCBs combine the flexibility of flex circuits with the durability of rigid PCBs. These boards use flexible materials between rigid layers to provide enhanced durability while maintaining a compact size. They are widely used in consumer electronics, lighting, instrumentation, and other applications requiring a balance of flexibility and rigidity.

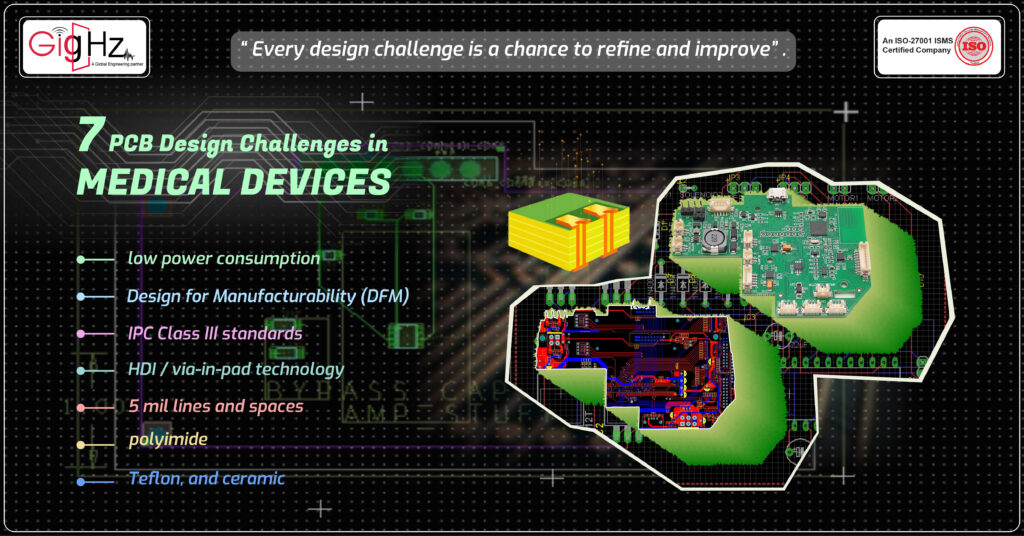

Inside the Circuit: 7 PCB Design Challenges in medical devices

When designing medical PCBs, optimizing low power consumption is crucial. Medical devices often operate on limited battery power, so it’s essential to focus on power management to extend battery life and enhance efficiency. This involves designing circuits that minimize energy use while maintaining performance.

Next, integrating Design for Manufacturability (DFM) considerations early in the design phase is vital. Addressing manufacturability from the outset simplifies the production process, reduces defects, and lowers costs. Ensuring that the design is easy to manufacture contributes to the reliability of the medical device, which is critical for patient safety.

Compliance with IPC Class III standards is another key factor. This involves adhering to strict requirements such as avoiding annular ring breakouts, maintaining a minimum of 1 mil of plating in through-holes, and adhering to tight tolerances for conductor spacing and widths. These standards ensure that the PCB meets the high reliability needed for medical applications.

Incorporating HDI / via-in-pad technology can significantly reduce the PCB footprint. By integrating vias directly into the pads, this technology allows for more compact and efficient designs, which is essential for modern medical devices that require miniaturization.

Designs with 5 mil lines and spaces require advanced fabrication techniques. PCB fabricators must use precise equipment, such as laser direct imaging, to maintain accurate line widths and spacing. This precision is necessary to meet IPC Class III standards and ensure high production yields.

Medical PCBs often need to be made from a variety of laminates. While FR-4 is common, many medical devices require expertise in materials like polyimide, Teflon, and ceramic. Each material offers unique properties that can be crucial for specific applications, such as enhanced durability or thermal stability.

Finally, utilizing free PCB DFM services before prototyping can be a game-changer. Early detection of design issues can prevent costly revisions and ensure that the design is manufacturable and reliable. This proactive approach helps avoid production delays and ensures that the final product meets high-quality standards.

By addressing these technical challenges, designers can create medical PCBs that not only meet the rigorous demands of the industry but also contribute to the overall effectiveness and reliability of medical devices.

Final Thoughts

Medical PCBs are essential components in the manufacturing of medical devices and equipment.

Choosing the right PCB manufacturer is crucial for ensuring the reliability and performance of medical electronic products. With advancements in pcb technologies, the medical industry demands the highest quality medical grade pcbs for their medical device industry.

Various types of PCBs for medical devices are used in medical instrumentation and medical pcb assembly processes. The development of medical pcb applications has led to the creation of specialized PCB assembly services tailored for medical equipment.

PCBs for the medical industry must meet stringent standards to ensure the safety and efficacy of medical devices like medical device pcbs. PCB fabrication processes for medical devices involve thorough testing and certification to comply with medical device industry regulations.

Extensive research and innovation are dedicated to improving the applications in the medical field through medical electronics and medical pcb assembly techniques.

To know more about our services, follow our founder through LinkedIn https://www.linkedin.com/in/chandra-thimma/recent-activity/all/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.