Are power integrity analysis effective for flexible PCB: Let’s Find Out!

- Posted On:

- July 11, 2024

- Category:

- Analysis & Simulation

Power Integrity Analysis

A flexible printed circuit, commonly referred to as a flex circuit, comprises a layer of metallic traces, typically copper, that is adhered to a dielectric layer, often polyimide.

The thickness of the metallic layer can range from very thin (<0.0001″) to very thick (>0.010″), while the dielectric layer thickness can vary between 0.0005″ and 0.010″.

Traditionally, the metal is bonded to the dielectric using adhesive;

however, there is a growing preference for “adhesiveless” laminates due to their superior performance and thermal benefits.

Alternative bonding methods such as vapor deposition can also be employed to affix the metal to the dielectric.

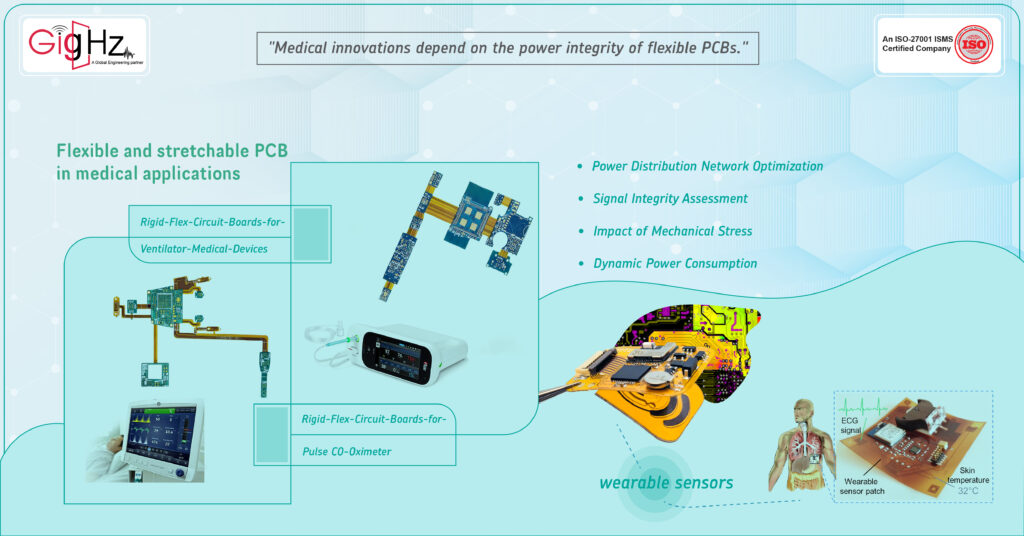

Nowadays, Flexible PCB have revolutionized the design of medical devices by offering adaptability and conformability to the human body, enabling the seamless integration of electronics into wearable sensors, smart textiles, and implantable devices.

These bendable circuit boards cater to the demand for comfortable, unobtrusive, and reliable electronic solutions in healthcare settings, empowering continuous patient monitoring and personalized healthcare delivery.

“Who is the one that stabilizes the medical devices?”

Its, Power Integrity.

Power integrity analysis plays a pivotal role in ensuring the stability, efficiency, and performance of electronic systems integrated into flexible PCB for medical applications.

By examining the power distribution network, analyzing signal integrity, and optimizing power management strategies, engineers can mitigate power-related issues, signal distortions, and dynamic power fluctuations in deformable electronic platforms, safeguarding the accuracy and reliability of patient monitoring devices.

Let’s delve in!

The basics of power integrity, Getting the Power to the Components

Power integrity is crucial in electronic pcb design to ensure that power delivery to components is efficient and reliable.

The power delivery network (pdn) is responsible for getting the voltage required by the components from the source, usually a power supply, to the IC or processor.

The pcb layout plays a significant role in this process, with power and ground planes acting as the main conductors to distribute power across the pcb.

To achieve good power integrity, pcb designers must consider factors such as impedance, inductance, and capacitance in the pdn design.

By optimizing the pdn impedance within an acceptable range for the frequency range of the components, potential power integrity problems such as voltage drop and pdn noise can be minimized.

Using techniques such as controlled routing, vias, and proper stackup of pcbs, engineers can improve power integrity and reduce impedance mismatches that may appear as crosstalk.

Are power integrity analysis effective for flexible PCB: Let's Find Out!

Absolutely, power integrity analysis is a critical component in the implementation of flexible and stretchable PCB technologies in medical applications.

Here’s how power integrity analysis can be applied to flexible and stretchable PCBs in medical settings:

- Power Distribution Network Optimization: Analyzing the power distribution network on flexible PCBs helps identify potential voltage drops, impedance variations, and noise issues that may arise due to the bending or stretching of the board. By optimizing the placement of power traces, decoupling capacitors, and voltage regulators, power integrity analysis ensures consistent power delivery to electronic components, even under dynamic mechanical conditions.

- Signal Integrity Assessment: Power integrity analysis includes evaluating signal integrity aspects such as signal propagation delay, reflections, crosstalk, and electromagnetic interference (EMI) on flexible and stretchable PCBs. Ensuring proper impedance matching, controlled impedance routing, and shielding techniques is crucial for maintaining signal integrity and minimizing signal distortions in these deformable electronic systems.

Impact of Mechanical Stress: Flexible and stretchable PCBs are subjected to mechanical stress and deformation, which can affect the electrical performance and reliability of the integrated electronics. Power integrity analysis assesses the impact of mechanical strain on power distribution and signal transmission, guiding the design of robust interconnects and flexible substrates that withstand bending and stretching without compromising functionality.

Dynamic Power Consumption: In wearable sensors and implantable devices, dynamic changes in power consumption during different operational modes or activity levels can affect battery life and overall system efficiency. Power integrity analysis helps predict power fluctuations, optimize energy management strategies, and ensure consistent power supply to accommodate varying power demands in real-time monitoring devices.

By integrating power integrity analysis into the design and validation process of flexible and stretchable PCBs for medical applications, engineers can address the unique challenges associated with these deformable electronic platforms.

This proactive approach enhances the reliability, durability, and performance of electronic systems in wearable healthcare technologies, smart textiles, and implantable medical devices, ultimately advancing patient monitoring capabilities and improving healthcare delivery outcomes.

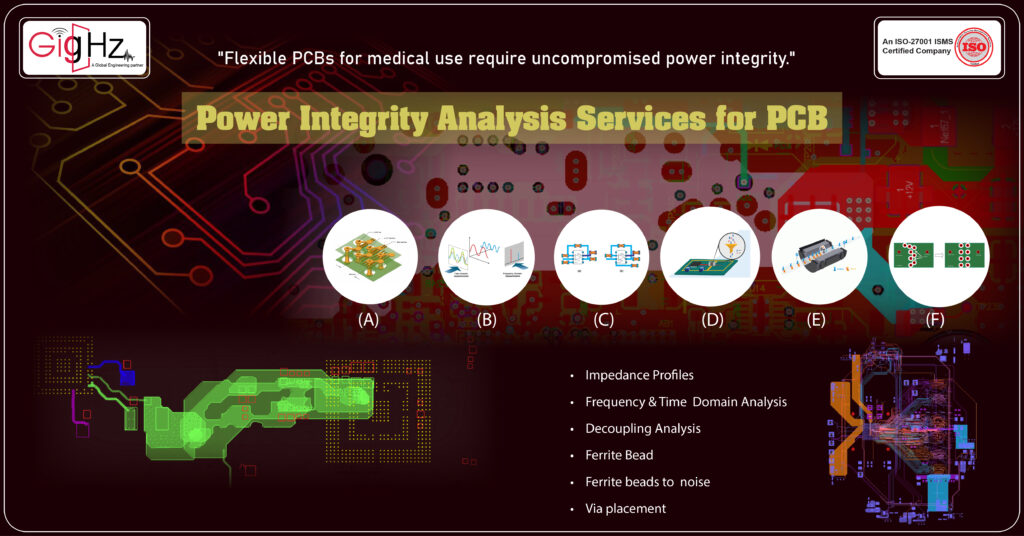

Our Power Integrity Analysis Services for PCB

At GigHz, we conduct a wide range of power integrity analyses to ensure a fully validated and optimized power delivery network (PDN). By identifying potential issues early in the design phase, we help create a robust PDN that balances cost and performance.

Impedance Profiles – We simulate PDN impedance across frequencies to detect resonance peaks and potential power distribution inefficiencies.

Frequency Domain Analysis – Evaluates noise at different frequencies to identify PDN resonant behaviors and switching noise issues.

Time Domain Analysis – Evaluates noise at different frequencies to identify PDN resonant behaviors and switching noise issues.

Isolation Studies – Ensures effective separation between power domains, such as analog and digital power planes, to minimize interference.

Decoupling Analysis – To enhance decoupling effectiveness, we analyze critical design factors, including:

- Capacitor Placement – Optimizing locations to reduce loop inductance and improve stability.

- Capacitor Selection – Evaluating different types and values to achieve the best impedance response.

- Via Placement – Strategically positioning vias to minimize current loop area and maintain signal integrity.

- Landing Pad Design – Simulating pad shapes and sizes to lower interconnect inductance.

- Ferrite Bead Use – Selecting appropriate ferrite beads to suppress high-frequency noise.

- Power Plane Splits – Implementing segmented power planes while maintaining proper isolation.

By leveraging our advanced power integrity methodology, we provide complete PDN insights, mitigating risks before manufacturing and ensuring an optimized, high-performance power distribution network.

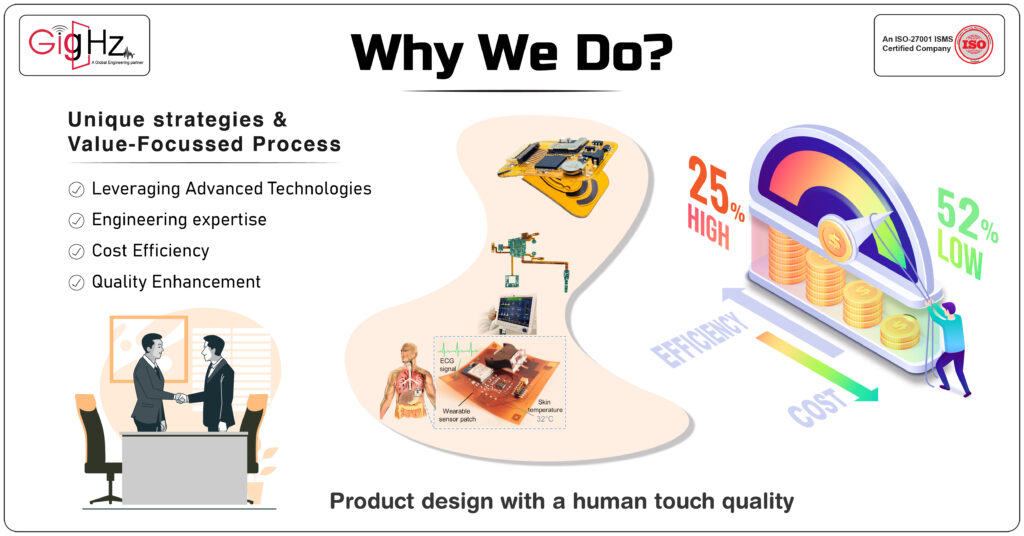

Why we Do? GigHz DNA

We push the boundaries of Analysis & Simulation with our flexible PCB engineering capabilities, embracing emerging medical technologies to optimize both time and cost. This allows us to transform product design while maintaining a human-centered approach to quality.

Despite the complexities of evolving technology, our innovative methods and value-driven processes set us apart from the competition. As a result, we have achieved a 52% cost reduction and a 25% increase in operational efficiency, delivering exceptional value to our clients.

Conclusion

Power integrity analysis is essential for the optimal performance of flexible PCBs, guaranteeing reliable power distribution and signal integrity.

Through voltage regulation, noise reduction, EMI control, and thermal management, it enhances the longevity and efficiency of components.

This analysis is crucial in ensuring stability and robustness in a variety of applications.

By addressing key challenges like voltage fluctuations and electromagnetic interference, power integrity analysis plays a pivotal role in the success of flexible PCB designs. Its impact extends to improving overall system performance and reliability, making it indispensable in modern electronics design.

Discover our Specialities. Visit our Services Page. https://gighz.net/power-integrity-analysis-services-in-pcb/

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with GigHz to bring your most innovative design concepts to life. Our engineering CAD services speed up development, letting you focus on your big vision while we handle the technical details.