7 Myths about Power Integrity Analysis in PCB design

Power Integrity Analysis

Have you ever thought about how important power, is in our lives? Not just the kind that lights up our homes, but the power that lets people do things, make decisions, and influence others. Power is like the invisible force that helps shape everything around us, from who gets to be in charge to how we work together in society.

Have you ever thought about how important power, is in our lives? Not just the kind that lights up our homes, but the power that lets people do things, make decisions, and influence others. Power is like the invisible force that helps shape everything around us, from who gets to be in charge to how we work together in society.

Category :

Published Date :

May 14, 2024

Category :

Published Date :

May 14, 2024

Category :

Published Date :

May 14, 2024

Just like how power plays a crucial role in our daily lives, it’s equally important in PCB design. Ensuring the integrity of power within these circuits is a key aspect that cannot be overlooked.

So, power integrity analysis in PCB design is all about making sure that the power flowing across the circuit board stays steady and reliable. It’s like keeping a consistent flow of electricity to prevent any hiccups that could mess with the performance of the components.

Let’s say you’re working on a high-speed digital design.

Power integrity analysis ensures that the power distribution network can handle the rapid switching of multiple components without causing voltage drops or noise that could mess up the signal quality.

It’s kind of like maintaining a smooth, uninterrupted flow of energy throughout the whole system.

In this exploration, we will delve into seven pervasive myths about power integrity analysis in PCB design, based on our findings from design analysis.

By dissecting these myths with a technical lens, we aim to illuminate the true principles of power integrity, empowering designers to navigate this complex terrain with confidence and precision.

Ready, set, go!

"7 Myths about Power Integrity Analysis in pcb design"

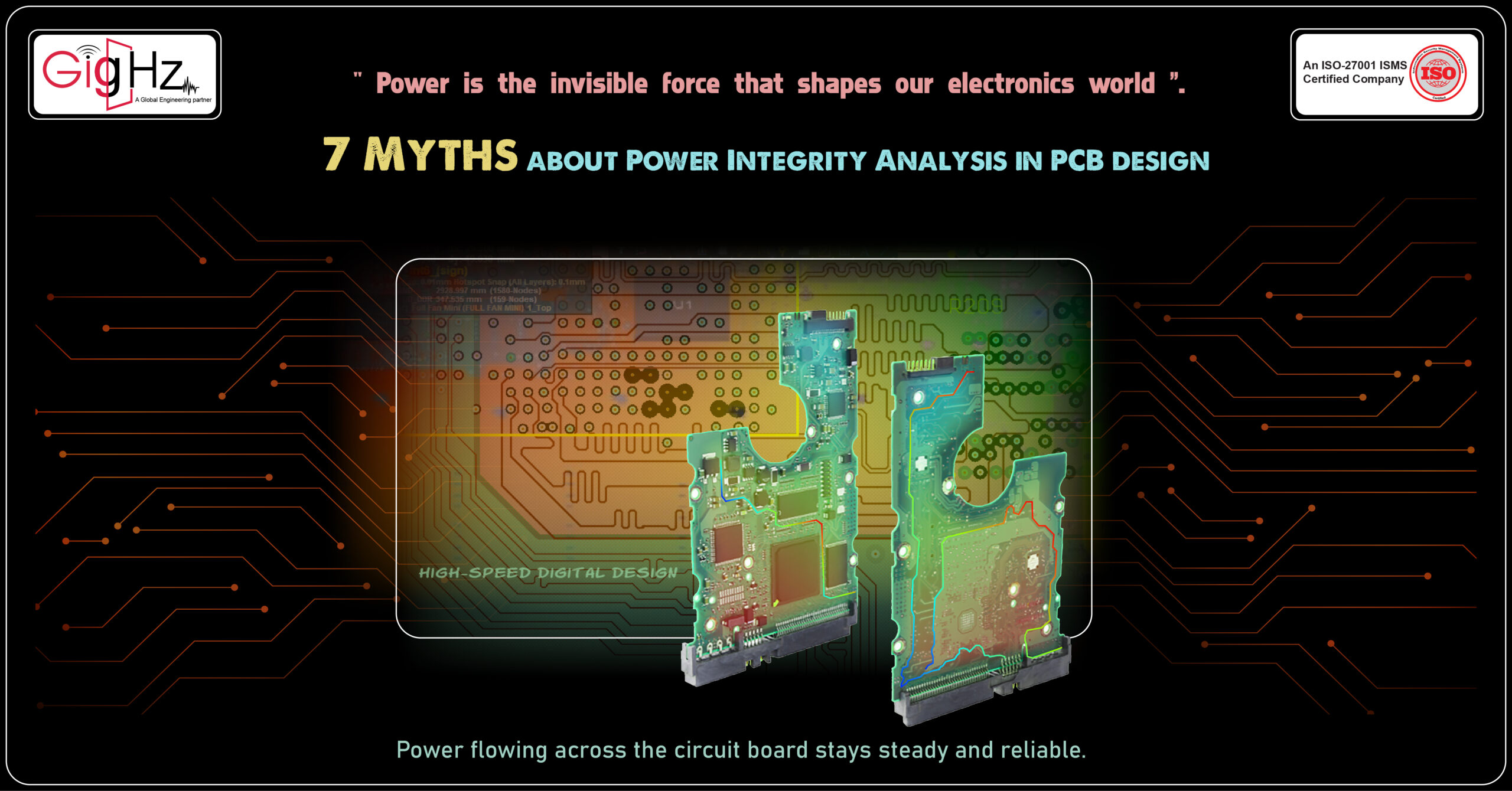

Myth 1: Power Integrity is Only About Decoupling Capacitors

You might have heard that power integrity hinges solely on decoupling capacitors.

While they are indeed crucial, the truth is, their effectiveness depends on various factors like capacitance, ESR, and ESL values.

Beyond capacitors, power integrity analysis delves into the entire Power Distribution Network (PDN), including planes, vias, and connectors, to ensure smooth operation across all frequencies.

The effectiveness of this analysis lies in its ability to maintain a stable and consistent flow of power, thereby preventing voltage fluctuations and ensuring the reliable performance of the components on the PCB.

Myth 2: Only High-Speed Designs Need Power Integrity Analysis

Some say that only high-speed designs require power integrity analysis.

But the reality is, any electronic system, regardless of speed, can be affected by power integrity issues.

Jitter, noise, IR drop, and switching noise can impact performance across the board. Ensuring low impedance paths across all frequencies is crucial for all designs.

This analysis ensures the identification and resolution of power integrity issues, leading to stable voltage references and consistent power delivery across different operational speeds of electronic systems.

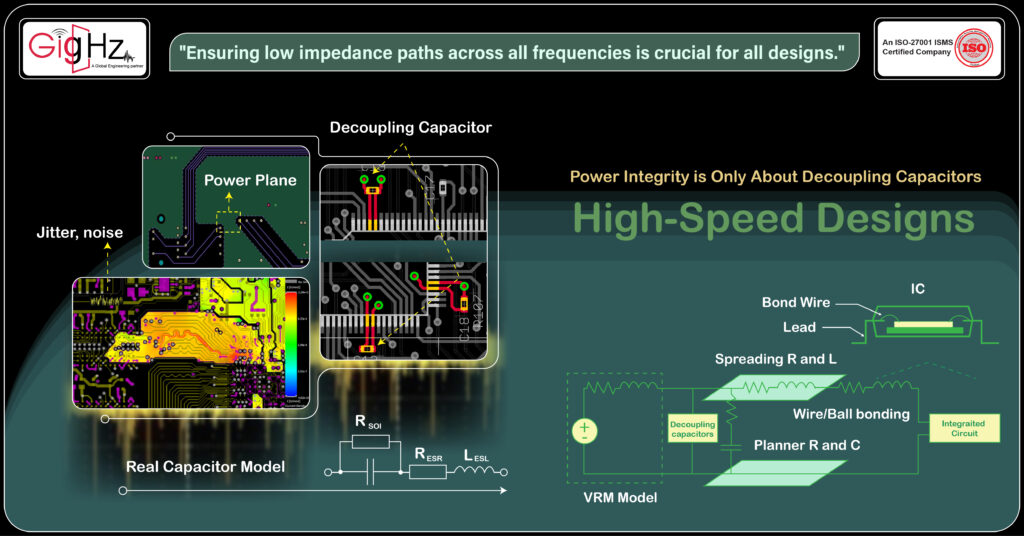

Myth 3: Power Integrity Analysis Can Always Be Done at the End

There’s a myth that power integrity analysis can always be left until the end.

However, early-stage simulations can predict potential issues within the PDN, allowing for adjustments before physical prototyping.

Incorporating power integrity considerations from schematic design through layout optimizes the entire PDN design process.

This comprehensive approach ensures that potential power integrity issues are identified and addressed proactively, minimizing the risk of costly redesigns and ensuring a more robust and reliable design overall.

Myth 4: Simpler Circuits Don’t Require Power Integrity Consideration

It’s often believed that simpler circuits don’t need power integrity consideration.

In reality, even simple circuits can suffer from phenomena like ground bounce.

Analyzing the ground network’s impedance, ensuring adequate decoupling for ICs, and thoughtful voltage regulator selection significantly impact power integrity in all designs.

Furthermore, the selection and placement of voltage regulators significantly impact the power integrity of even the simplest designs. Therefore, it’s imperative to integrate power integrity considerations into the design process regardless of the circuit’s complexity.

Myth 5: Adding More Layers Always Improves Power Integrity

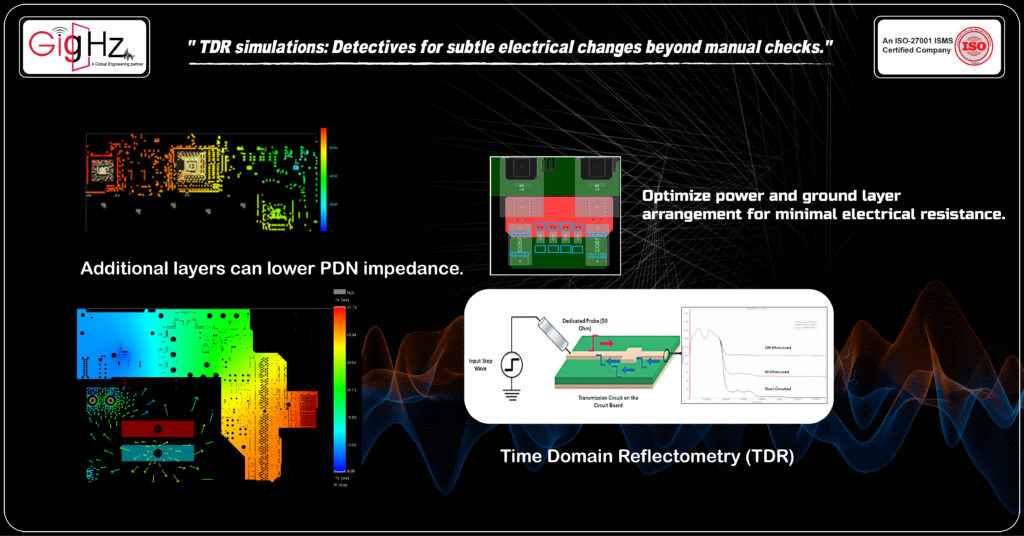

While adding layers can potentially reduce PDN impedance, it also introduces complexity in terms of via transitions and layer-to-layer connectivity.

Effective stackup design is critical, considering factors like interplane capacitance and plane coupling.

Simulation tools can help model different stackup configurations for optimal power and ground plane distribution.

By using special computer programs to simulate different layer designs, you can figure out the best way to arrange the power and ground layers to keep the electrical resistance as low as possible.

Myth 6: Manual Checks Are Sufficient for Power Integrity Analysis

Manual checks are valuable, but advanced simulation tools provide insights that manual calculations cannot.

They can identify impedance discontinuities and reveal the PDN impedance profile across a wide frequency range, offering a comprehensive view of potential resonances that could amplify noise.

For instance, there’s this cool thing called Time Domain Reflectometry (TDR) simulations. They’re like detectives that can spot sudden changes in the electrical path that might not be so obvious with manual checks.

Then there’s Frequency Domain Analysis, which takes a big-picture look at how the electrical path behaves across a wide range of frequencies, pinpointing spots where vibrations could make the noise levels increase.

Myth 7: Power Integrity is Solely the PCB Designer’s Responsibility

Thinking that power integrity is only the PCB designer’s job is not quite accurate.

The truth is, getting power to work just right involves different people and skills. Picking the right parts, like VRMs that react quickly, makes a big difference.

How things are laid out, where parts go, and how the wires connect also really matters. Even the software gets involved in managing how power is used.

Basically, getting power to work perfectly needs teamwork.

When everyone works together on parts, layout, and software, that’s when things really come together!

Our Notable Upgrade: Engineering as a Service (EaaS)

Absolutely!

The world of engineering is constantly evolving, and it’s fascinating to see how Engineering as a Service (EaaS) is keeping up with the demands of the industry.

By harnessing the power of ECAD, MCAD, and Analysis & Simulation, we’re able to provide comprehensive solutions that cover every aspect of the engineering process.

It’s really amazing how far we’ve come in terms of integrating different disciplines within engineering. With EaaS, we can seamlessly bring together electronic design, mechanical design, and analysis and simulation, all under one roof.

This not only saves time but also improves efficiency and collaboration among engineers.

Conclusion

The myths surrounding power integrity analysis have been debunked through this content.

By exploring the importance of power integrity in ensuring optimal performance of electronic systems, it is evident that it is not just a mere formality, but a critical aspect that can affect the overall functionality of a device.

Additionally, the misconceptions regarding ground bounce and its impact on signal integrity have been clarified, showing that it is a real issue that needs to be addressed in the design process.

Furthermore, the discussion on decoupling capacitors has highlighted their significance in reducing noise and improving power delivery, dispelling the notion that they are unnecessary components.

Lastly, the emphasis on simulation tools as an essential part of power integrity analysis has demonstrated the importance of leveraging technology to ensure the reliability and performance of electronic systems.

A deeper understanding of power integrity is crucial for designers to overcome these myths and create robust and efficient electronic products.

Reveal Our Passions. Journey to Our Services Page! https://gighz.net/services/