Why the Surge in Electronic Devices is Driving Automotive PCB Design Services?

- Posted On:

- September 12, 2024

- Category:

- Ecad

Automotive PCB Design Services

Imagine a world without electronic devices,

No smartphones to stay connected, no smartwatches to monitor health, and no advanced infotainment systems in cars.

Life would be significantly less connected, less convenient, and more challenging.

The surge in electronic devices is reshaping how we live and work, demanding increasingly sophisticated technology.

To meet this demand, advanced PCB designs are crucial.

These designs ensure that devices operate efficiently, handling high-speed data and maintaining signal quality.

Automotive infotainment systems are rapidly becoming a central feature in modern vehicles.

These systems seamlessly integrate navigation, multimedia playback, voice control, and smartphone connectivity into a cohesive interface, enhancing both driver and passenger experiences.

Infotainment systems are highlighted here because they represent a significant driver of demand for advanced PCB design services.

The complexity of these systems requires PCBs that can handle high-speed data transfer, maintain signal integrity, and support numerous integrated components within limited space.

As infotainment systems become more advanced, they push the boundaries of PCB design, necessitating cutting-edge solutions to meet their performance and reliability requirements.

Automotive infotainment systems are a prime example of how the increasing sophistication of electronic devices is driving the need for advanced PCB design.

Lets dig in!

Need for Advanced Automotive PCB Design Services

As the automotive industry evolves, the need for advanced automotive PCB design services becomes increasingly crucial.

Modern automobiles rely heavily on automotive electronics, which necessitate the use of printed circuit boards (PCBs) high temperatures and thermal cycling.

Automotive PCBs must adhere to strict automotive standards and automotive PCB design guidelines, ensuring effective thermal management through proper heat dissipation mechanisms, such as vias for ground and power planes and high density interconnections.

The design process for automotive PCBs involves meticulous circuit design and routing techniques, especially for HDI PCBs and rigid-flex configurations. Utilizing heavy copper PCBs enhances thermal conductivity, while multi-layer PCBs allow for complex electronic components integration.

Implementing wave soldering and ensuring manufacturability through a thorough design rule check is vital. As electric vehicles become more prevalent, the types of PCBs for automotive applications will expand, necessitating innovative PCB design tips to meet future challenges.

Why the Surge in Electronic Devices is Driving Automotive PCB Design Services?

Automotive infotainment systems are increasingly packed with features, requiring PCBs that are both compact and high-performing. The dashboard space in modern vehicles is limited, demanding PCBs that can efficiently integrate multiple components without sacrificing performance.

HDI technology enables this by allowing for a greater number of connections and higher functionality within a smaller area.

This is achieved through advanced fabrication techniques like Microvias and fine lines, which help maximize space and enhance performance.

High-Density Interconnect (HDI) Requirements

1. Compact, High-Performance PCBs:

In compact automotive infotainment systems, heat management is crucial due to the limited space and high density of components.

The use of advanced thermal management solutions, such as thermal vias (usually 0.3 mm to 0.5 mm in diameter) and heat spreaders, helps to distribute heat efficiently. For high-performance PCBs, materials with high thermal conductivity (5.0 W/m·K or more) are used to enhance heat dissipation.

Effective thermal management is essential to prevent thermal-induced failures and maintain reliable operation.

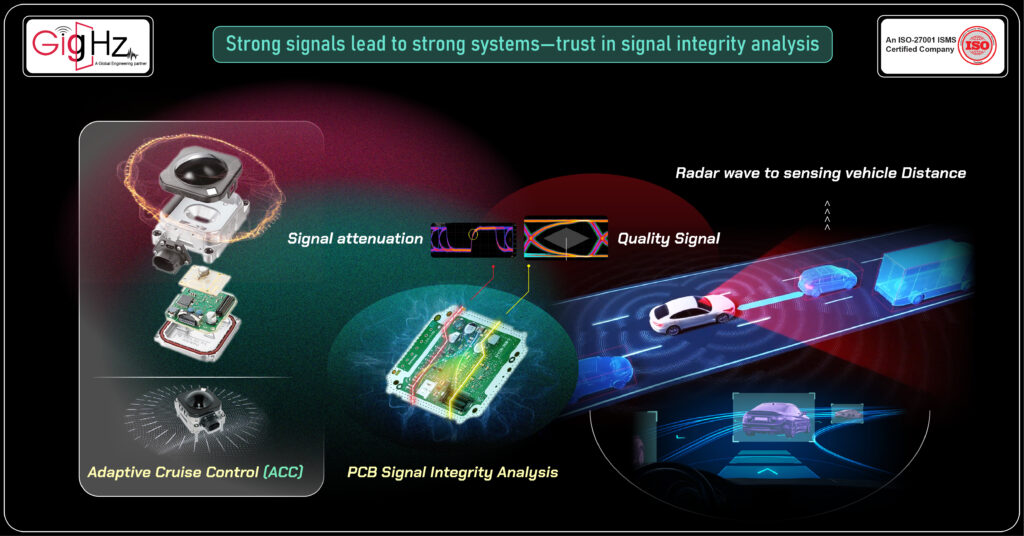

HDI PCBs must ensure signal integrity in densely packed environments.

Impedance variations must be within ±10% to prevent signal reflections and losses. For high-speed designs, microvias (typically 75 to 150 µm in diameter) are used to interconnect different layers without significant signal degradation. These microvias require precise fabrication techniques, such as laser drilling and electroplating, to achieve reliable connections within tight tolerances.

HDI PCBs often utilize fine-line traces (down to 50 µm wide) and multiple layers of interconnects. The aspect ratio of microvias (depth-to-diameter ratio) should be kept below 1:1 to ensure robust manufacturing. Advanced Lamination Techniques and electroplating processes are employed to build up layers and ensure high-density interconnects, which increases manufacturing complexity and cost.

2. High-Speed Data Transmission

High-speed data transmission requires meticulous design to maintain signal integrity.

High-speed signals, such as those at 1 GHz or higher, require controlled impedance traces, typically 50 ohms for single-ended and 100 ohms for differential pairs. Traces must be designed with consistent width and spacing to maintain impedance.

For signals operating at 1 GHz, the rise time should be less than 1 ns to prevent signal degradation and ensure accurate data transmission.

High-speed PCBs are prone to EMI, which can affect signal performance and system reliability.

Effective EMI shielding involves incorporating ground planes and copper pours to create barriers that block interference. The use of EMI filters and shielded traces can further reduce noise. EMI performance is often measured in decibels (dB), with designs aiming for a reduction of 20-30 dB in unwanted interference.

High-speed operations generate substantial heat, which must be managed to prevent overheating.

High-speed PCBs often use heat spreaders or thermal pads with thermal resistance values ranging from 1°C/W to 5°C/W. The PCB substrate material must be able to withstand temperatures up to 125°C without degradation to ensure long-term reliability.

Trace Design and Routing:

To maintain signal integrity, traces must have controlled impedance.

Design Rules:

- Impedance should be maintained within ±10% of the target value, typically 50 ohms for single-ended and 100 ohms for differential signals. This requires precise trace width and spacing calculations, often performed using electromagnetic simulation tools.

- Vias in high-speed PCBs need careful design to minimize signal loss and impedance discontinuities.

- Via Dimensions: Standard via diameters range from 0.3 mm to 0.6 mm.

- Blind and Buried Vias are used to reduce signal path lengths and minimize interference.

- Via design also involves ensuring proper via plating and via–in–pad techniques to maintain electrical performance.

Final Thoughts

The PCB design considerations ensure that these circuit boards in automotive environments can handle high currents and power dissipation, minimizing the impact of thermal shock on automotive boards.

Quality management is vital for PCB manufacturers to deliver products that meet the standards of world automotive manufacturers.

The heat resistance of automotive PCBs is essential for maintaining the integrity of electronic circuits that process sensitive signals. Utilizing metal substrate technology enhances the power distribution capabilities of these PCBs, ensuring high reliability in demanding applications.

As PCBs are used increasingly in the automotive industry, the focus on RF PCB designs that incorporate similar components will continue to grow, addressing the evolving needs of modern vehicles.

Design Beyond Boundaries—Get in Touch for Top-Tier PCB Solutions! https://calendly.com/gighz/30min

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.