PCB Design Trends

According to our Market Insights,

In 2021, the worldwide PCB market exceeded $78 billion, a figure projected to surge to $128 billion by 2030.

This expansion is driven by the prevalence of printed circuit boards (PCBs) in contemporary electronic devices, enabling size reduction and cost efficiency.

The dynamic growth of this sector has spurred various 2023 PCB trends, such as:

- Rising Adoption of Flexible PCBs

- Emphasis on Enhanced Customer Support

- Fusion of IoT and AI Innovations

- Utilization of 3D Printing for PCB Fabrication

Printed circuit boards (PCBs) are really important in most electronic devices. They help these devices work by connecting everything together.

As more advanced and smaller PCBs are needed, it’s crucial to store and protect them well to make sure they last a long time.

Taking care of PCBs also makes electronic devices more reliable and last longer.

If you want to know more about the PCB Design Trends, as well as ways to make them work better, this post talks about different ways to keep PCBs safe and in good condition.

Stay tuned for more helpful information.

What are the new technologies driving the PCB world today?

PCB technology is constantly evolving, driven by the need for smaller, faster, and more reliable electronics. The PCB industry is adopting new technologies such as 5G, IoT devices, artificial intelligence, and wearable technology to meet the demands of today’s connected world.

This has led to advancements in pcb design and manufacturing, with a focus on high-speed, high-power, and thermal management. PCB designers are now using algorithms and machine learning to optimize pcb layout for signal integrity and heat dissipation.

Additionally, manufacturers are exploring new substrates and materials to create flex pcbs and HDI pcbs that can withstand high-density and high-reliability applications in automotive, aerospace, medical devices, electric vehicles, and more.

PCB manufacturers must also consider global pcb market trends such as wireless connectivity and industrial automation when selecting a pcb for a specific application.

With the rise of IoT devices and wearable technology, pcbs are becoming more complex, requiring multiple layers and flexible printed circuits to meet industry standards. The pcb design process must now take into account the data that needs to be shared with other devices, all without compromising reliability or lead times.

The latest pcb solutions focus on thermal management, automation, and reducing harmful environmental impact, ensuring that pcbs remain at the forefront of connectivity and sensors in the foreseeable future.

PCB Design Trends: Changing the World of PCBs

From miniaturization breakthroughs to sustainability initiatives, we delve into the key developments shaping the future of PCB technology.

Miniaturisation Mastery

In 2024, PCB designs are getting better with High-Density Interconnect (HDI) technology, allowing more parts to fit in smaller spaces on PCBs.

Microvias, tiny holes in PCBs, help with routing signals efficiently. Signal quality has improved for faster data transfer, even in small devices.

HDI technology is now used in industries like automotive and medical fields. Via-in-Pad techniques and advanced Surface Mount Technology (SMT) help with fitting more components into less space and keeping devices reliable.

Flexible PCBs with many layers are great for complex designs, especially in wearable tech and IoT gadgets. Making devices smaller and lighter not only improves user experience but also saves energy.

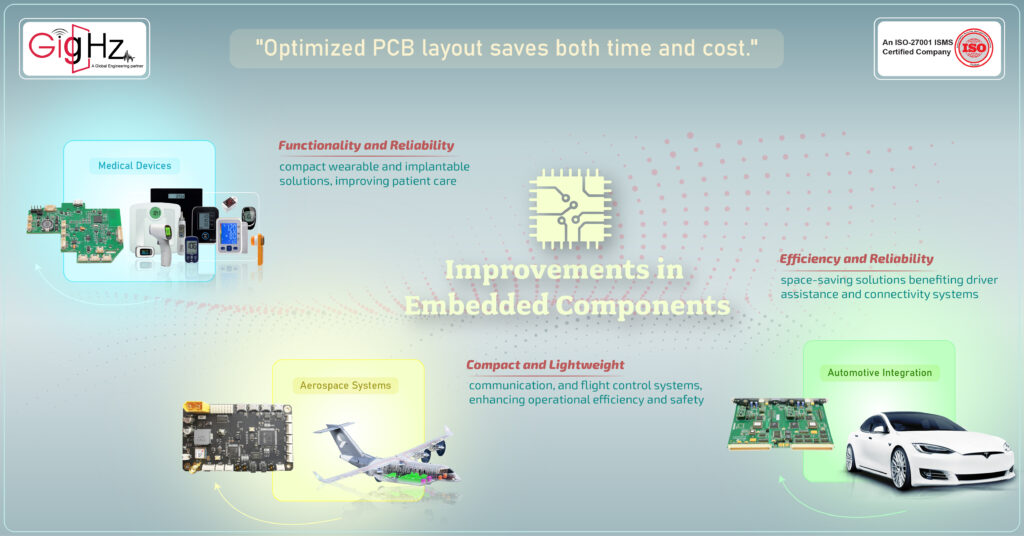

2024 PCB Design Trends: Improvements in Embedded

Components

Medical Devices: Embedded components enhance medical device functionality and reliability by shrinking size and boosting performance. This enables compact wearable and implantable solutions, improving patient care.

Aerospace Systems: Embedded components are crucial for compact, lightweight aerospace designs that meet performance and safety standards. They advance avionics, communication, and flight control systems, enhancing operational efficiency and safety.

Automotive Integration: Embedded components optimize vehicle efficiency and reliability while supporting advanced automotive features. They enable space-saving solutions without compromising performance, benefiting driver assistance and connectivity systems.

Streamlined Integration: Standardized embedded component modules simplify procurement, reducing lead times and expediting product development.

Design Compatibility: Adherence to compatibility standards ensures seamless integration of embedded components into diverse PCB designs, minimizing compatibility issues with industry-standard interfaces.

Reliability Assurance: Rigorous testing protocols verify the performance and durability of embedded components for critical applications, maintaining the highest reliability standards.

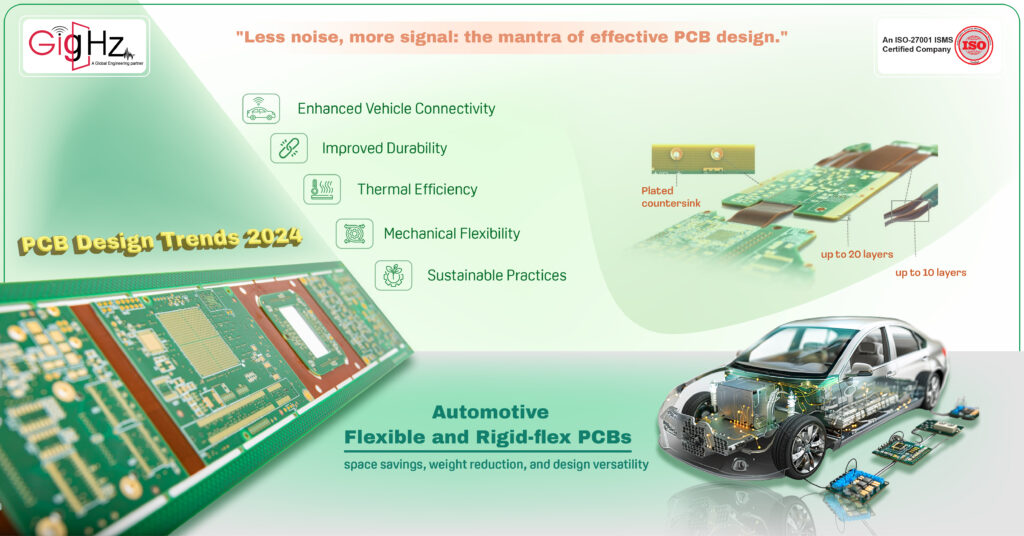

Flexibility Reigns in PCB Design Trends 2024

Automotive Advancements: Flexible PCBs in Automotive Innovation Flexible and rigid-flex PCBs revolutionize automotive electronics, offering space savings, weight reduction, and design versatility. They mold to intricate shapes, seamlessly integrating into sensors, lighting, and control modules for compact, reliable systems.

Enhanced Vehicle Connectivity: Flexible PCBs streamline wiring in modern vehicles, supporting EVs and autonomous driving. They optimize signal routing, enhancing EV drivetrains, battery systems, and autonomous sensors, boosting vehicle connectivity, efficiency, and safety.

Improved Durability: Advanced PCB substrates resist harsh automotive conditions with composite materials that enhance strength, thermal stability, and resistance to environmental stressors. By using these materials, manufacturers ensure durable electronic systems in challenging environments, enhancing vehicle longevity and performance.

Thermal Efficiency: In 2024, flexible materials improve heat dissipation, crucial for compact electronics and high-power applications. Enhanced thermal conductivity efficiently manages heat, preventing overheating and ensuring device reliability in demanding scenarios.

Mechanical Flexibility: Flexible substrates withstand bending and flexing, ideal for durable electronic devices like wearables and foldable electronics. These materials maintain integrity under stress, perfect for applications requiring flexibility and reliability.

Sustainable Practices: Eco-friendly materials reduce the environmental impact of PCB manufacturing, sourced responsibly and manufactured with minimal energy consumption and waste generation. By embracing these materials, manufacturers align with sustainability goals while delivering high-performance products for environmentally conscious consumers.

Final Thoughts

We are witnessing a transformative era in PCB design trends that are reshaping the landscape of electronic engineering.

From the integration of flexible PCBs in automotive innovation to the emphasis on durability and sustainability, these trends signify a shift towards more efficient, reliable, and environmentally conscious electronic systems.

To know more details, follow us through LinkedIn https://www.linkedin.com/in/chandra-thimma/recent-activity/all/

As we embrace thermal efficiency, mechanical flexibility, and sustainable practices, we pave the way for cutting-edge advancements that are revolutionizing the world of PCBs and driving progress in technology and innovation.

Discover our Specialities. Visit our Services Page. https://gighz.net/pcb-designing-services/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.