Plastic Vs Metal Enclosures Finding the Ideal Fit for Your Project

- Posted On:

- June 12, 2024

- Category:

- Mcad

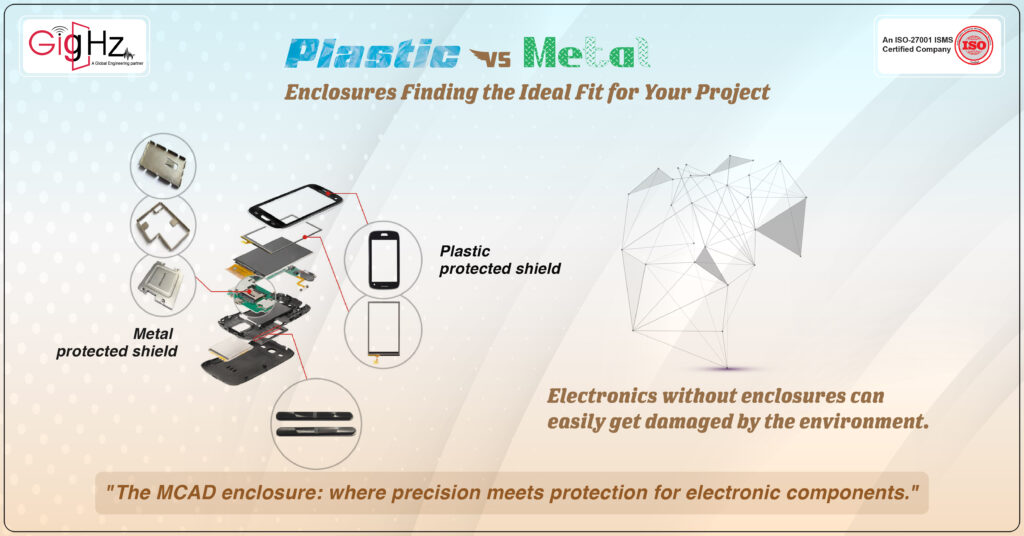

Plastic Vs Metal Enclosures

You know how important mobile phones are in our lives today, right?

From kids to grown-ups, we all rely so much on them.

But have you ever thought about the unsung hero that keeps our phones safe inside?

That hero is the mechanical enclosure.

It’s like a silent protector that shields the delicate insides of our phones from everyday bumps, spills, and other risks.

Without this invisible shield, our phones wouldn’t last long or work as well as they do.

So, next time you use your phone, remember the little enclosure that’s silently working hard to keep it running smoothly for you!

Enclosures shield gadgets from harm, making them last longer.

They help keep electronics neat and make repairs easier. Enclosures prevent accidents like shocks or short circuits, keeping users safe.

Electronics without enclosures can easily get damaged by the environment.

Devices can break easily without protection from things like water or heat.

Unprotected components can be dangerous, causing shocks or fires that harm people and property.

Here, we should consider which type of enclosure is best suited.

When designing the enclosure, let’s compare plastic enclosure versus a metal enclosure.

Plastic Enclosure

To understand the significance of plastic enclosures, it’s essential to delve into their applications and benefits,

Let’s dive into how plastic enclosures are making a big splash in the automotive world, especially when it comes to electric vehicles (EVs). Think of EV battery packs as the powerhouse of electric cars.

They’re like the heart, pumping energy to make the car zoom around.

But just like any heart, it needs protection and care, which is where plastic enclosures come into play.

Why Plastic Enclosures Are a Big Deal for EV Battery Packs?

Imagine driving your EV on a rainy day or on a dusty road.

You’d want your EV’s heart, the battery pack, to be safe from water, dust, or any bumps along the way, right? That’s exactly what plastic enclosures do. They wrap around the battery cells like a protective shield, keeping them safe from environment.

Batteries can get pretty hot, especially when you’re charging them up or pushing your car to its limits. If they get too hot, it’s not good news. Plastic enclosures can be designed to work with cooling systems, making sure the battery stays at a happy temperature. It’s like having a personal cooling fan, ensuring things don’t overheat.

In the world of EVs, every pound matters. Lighter cars can travel further on a single charge, making weight a big deal. Plastics are much lighter than metals, which means using plastic enclosures can help shave off some weight. This leads to a more efficient ride without skimping on safety or durability.

One of the coolest things about plastic is how versatile it is. You can mold it into almost any shape, which is perfect for customizing battery pack enclosures to fit snugly into any car design. This means more room for other important stuff or even bigger battery packs for a longer ride.

As we all aim for a greener planet, using recyclable and biodegradable plastics for these enclosures aligns perfectly with the eco-friendly essence of electric vehicles. It’s about moving forward not just in technology but in sustainability too.

Pros of Plastic Enclosure

Cost

One of the primary benefits of opting for plastic over metal is the cost aspect. Materials and production processes for plastic tend to be less expensive, leading to a reduction in the overall cost of the finished product.

Weight

Plastic also has the upper hand when it comes to weight. It’s generally lighter than metal, which can be particularly advantageous in sectors such as transportation, where reducing component weight is crucial for enhancing fuel efficiency.

Insulating Properties

Another advantage of choosing plastic is its insulating properties. Unlike metal, plastic does not conduct heat or electricity well, making it a safer option for applications that may come into contact with heat sources or human touch, thereby minimizing the risk of burns or electrical shocks.

Versatility

Lastly, the versatility of plastic in terms of design is unparalleled. With the right mold, plastic can be shaped into virtually any form imaginable, offering immense flexibility in product design and customization.

Cons of Plastic Enclosure

When comparing plastic to metal components, a few notable disadvantages of plastics include their strength limitations, higher minimum order quantity (MOQ) for mold setup cost justification, and the necessity of molds for production.

Physical Stress

While plastics can be engineered to possess impressive strength characteristics, they generally fall short in withstanding physical stresses to the same extent as metals within a similar cost range.

Minimum Order Quantity (MOQ)

Moreover, the MOQ required to offset the initial investment for mold setup in plastic manufacturing is typically higher, often around 250 units, compared to some metal processes that can accommodate small quantities of one or two parts.

It’s fascinating to see how something as seemingly simple as a plastic enclosure can play such a vital role in the future of automotive design and innovation.

Metal Enclosure

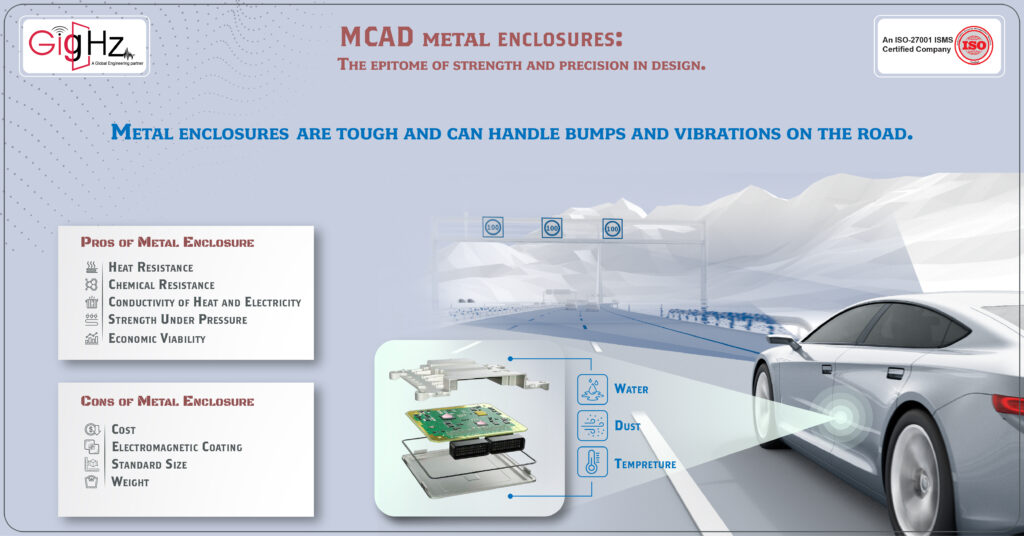

Let’s talk about how metal enclosures play a crucial role in the automotive world, especially when it comes to protecting sensitive electronic components inside vehicles like control units and sensors.

Why Metal Enclosures Matter in Cars

Metal Enclosure act like shields, protecting electronic parts from things like water, dust, and temperature changes. This helps keep the important car systems safe and working well.

They help make sure the car’s electronics work without any problems by reducing disruptive signals. This is really important to avoid any glitches or communication issues.

Metal enclosures are tough and can handle bumps and vibrations on the road. They keep everything inside safe and secure, no matter how rough the ride gets.

When things get hot, metal enclosures help take away extra heat from electronic devices. By managing temperatures, they prevent things from getting too hot and help electronics last longer.

Metal Enclosures not only protect electronics but also make sure that all the data stays safe and the car remains secure. They’re like the silent protectors of the car’s important systems.

Pros of Metal Enclosure

When comparing metal to plastic, the proper selection of metal brings about several key advantages:

Heat Resistance:

Certain metals exhibit exceptional heat resistance, capable of enduring temperatures as high as 1000°F without compromising their structural integrity.

Chemical Resistance:

With careful selection, metals can boast impressive resistance to various chemicals, surpassing the capabilities of plastics in withstanding corrosive substances over extended periods.

Conductivity of Heat and Electricity:

One of the standout features of metals is their innate ability to efficiently conduct both heat and electricity. For components requiring effective heat or electricity transfer, metal emerges as the superior choice due to its natural conductivity properties.

Strength Under Pressure:

Metals excel in handling immense pressure and force, making them ideal for applications like piping, valves, building structures, and machinery where durability and resilience are paramount.

Economic Viability:

Metal fabrication processes offer cost-effective solutions even for small-scale production runs, ranging from just one or two units to quantities between 100 and 500, often without significant non-recurring engineering (NRE) costs. This economic advantage further solidifies the case for selecting metal over plastic in certain scenarios.

Cons of Metal Enclosure

When it comes to electrical enclosures, there are certain cons to choosing a metal enclosure over a plastic one.

Cost

One of the main disadvantages of using a metal box is that it is often more expensive than a plastic one.

Electromagnetic Coating

Additionally, metal enclosures may not always provide the necessary electromagnetic coating to protect sensitive pcb and other electronic devices from emc interference.

Standard Size

Another drawback is that metal enclosures often require custom enclosure manufacturers to create them, whereas plastic cases are more readily available in standard sizes. Overall, finding the right metal electrical enclosure for your needs can be a more complex process than simply selecting a plastic box.

Weight

Moreover, another issue with metal enclosures is that they are typically heavier and bulkier than plastic enclosures.

This can be a problem if small metal enclosures are needed for a development board or other machine that requires a more compact design.

In some cases, the weight of an aluminum enclosure may also pose a challenge when mounting it on a cable or other structure. In contrast, plastic enclosures are generally lighter and easier to work with in these situations.

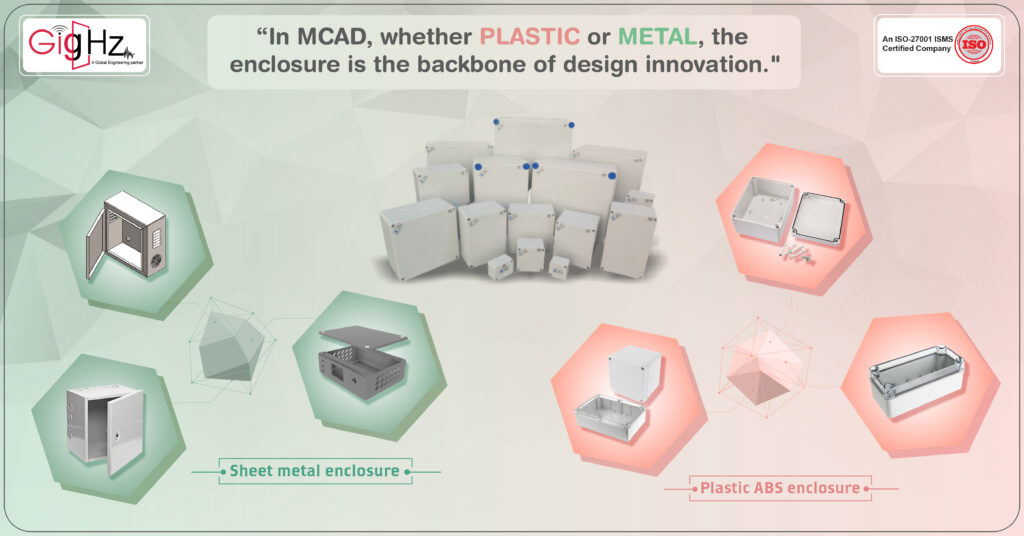

Plastic vs Metal enclosures finding the ideal fit for your project

Which is the best one for your Project Plastic or Metal Enclosure?

Choosing the right enclosure needs careful consideration of various factors to ensure the optimal protection for your project.

When it comes to enclosure materials, the two main options are metal and plastic. Metal enclosures such as sheet metal or die-cast are known for their durability and resistance to impact, making them ideal for outdoor enclosures or electrical boxes that require electrically conductive properties.

On the other hand, plastic enclosures like abs enclosures or polycarbonate are typically low-cost and offer ingress protection against dust and water.

When selecting the right material for your project, consider factors such as high temperatures, off-the-shelf options, and enclosure design to determine whether metal or plastic is the right enclosure for your enclosure’s needs.

Conclusion

Deciding between plastic and metal enclosures for your project boils down to understanding your specific needs.

If you’re looking for something lightweight, cost-effective, and resistant to corrosion, plastic is your go-to. It’s great for projects that require easy customization but don’t face extreme conditions.

However, if your project demands durability, heat resistance, and protection against electromagnetic interference, metal enclosures are the better choice, especially in harsh environments.

Ultimately, the best fit depends on balancing factors like strength, cost, environmental resistance, and production volume.

Choose plastic for flexibility and cost savings or metal for strength and protection, ensuring the material aligns with your project’s requirements for the most efficient outcome.

To know more Information, Discover our Specialities. Visit our Services Page. https://gighz.net/services/