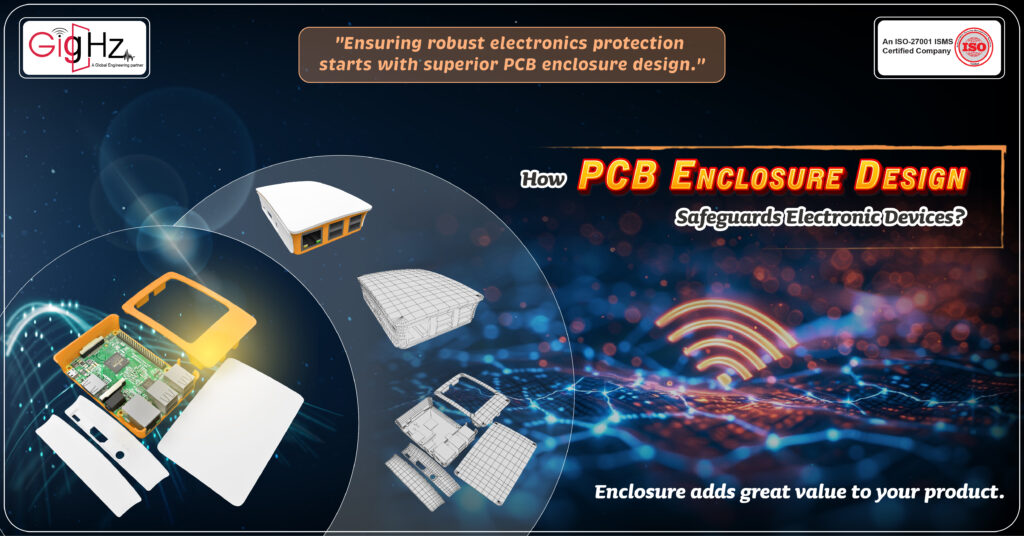

PCB Enclosure Design

mechanical enclosure adds significant value to a PCB or electronic board by protecting it and enhancing its functionality. When a PCB is housed within a metal or plastic enclosure, it transforms into a finished product that is ready for the market.

The primary application of a PCB enclosure is to safeguard the PCB from external environmental factors, ensuring it meets the required IP rating (Ingress Protection) standards. This protection is crucial for ensuring longevity and reliability, particularly in harsh environments.

In addition to its protective role, the enclosure also adds aesthetic value to the product, providing a more polished and professional appearance. For any PCB to be sold as a standalone product, enclosing it in a durable plastic or sheet metal casing is essential, not only for protection but also to enhance its market appeal and perceived quality.

So, what the pcb enclosure design intent entails?

It reflects your company brand, product, and design intent.

Let’s consider, designing the enclosure for Raspberry Pi 4 Model B with 1GB RAM, for Automotive Infotainment system, for your good understanding about enclosure design.

Do you think what will be the design considerations,

Here is the list of points you should consider during the electronics enclosure design techno-commercial decision-making process,

- Products Aesthetics

- Production volumes or market sizes

- Product Application

- Project Budget

- Cost Constraints

Let’s dig in!

How PCB Enclosure Design Safeguards Electronic Devices?

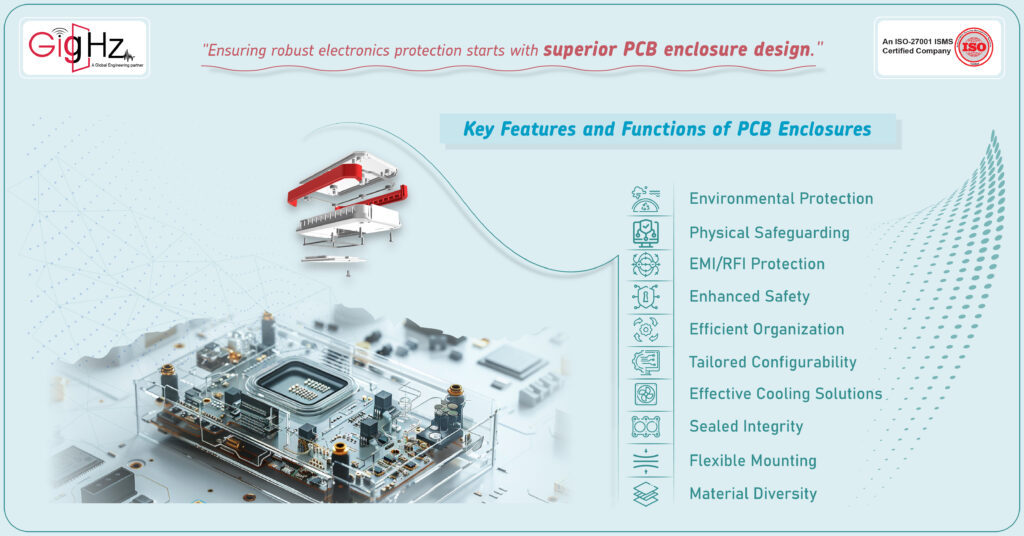

- Environmental Protection: These enclosures shield internal electronic components, like the PCB, from environmental threats like dust, moisture, chemicals, and temperature variations. This defense is crucial in preventing electronics from damage caused by harsh conditions.

- Physical Safeguarding: Enclosures provide a barrier against physical harm, impacts, and vibrations that could harm delicate PCBs and electronic parts, particularly in industrial and outdoor settings.

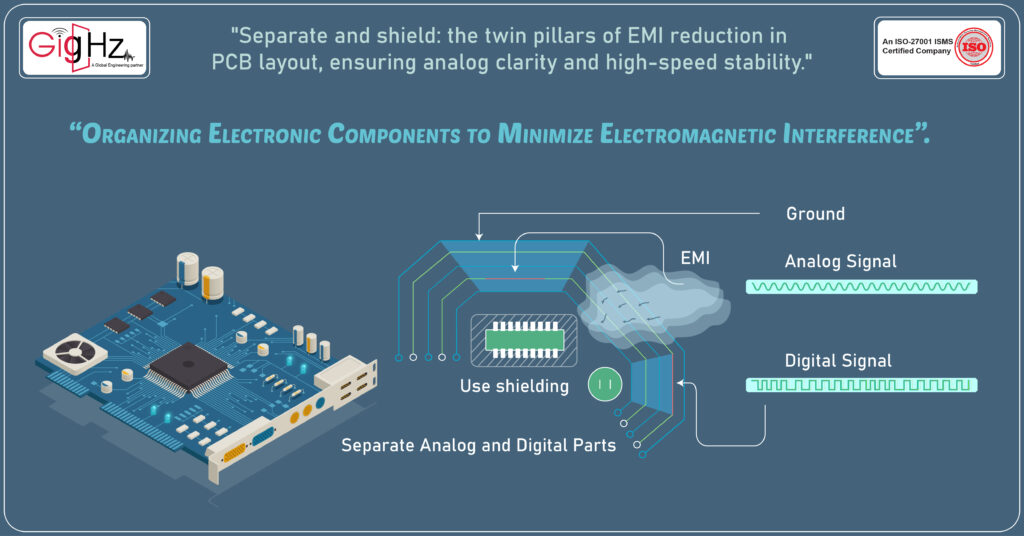

- EMI/RFI Protection: Many PCB enclosures feature shielding materials to safeguard sensitive electronics from electromagnetic interference (EMI) or radio frequency interference (RFI), ensuring signal integrity and blocking external electromagnetic disturbances.

- Enhanced Safety: By preventing accidental contact with electrical components, enclosures boost user and maintenance staff safety, mitigating risks of electric shock or fire incidents.

- Efficient Organization: Incorporating mounting rails, brackets, and cable management options, PCB enclosures streamline the arrangement and security of electronic components, maximizing space utilization and simplifying maintenance tasks.

- Tailored Configurability: Modular or customizable PCB enclosures can adapt to diverse PCB sizes, form factors, and additional elements like connectors, switches, displays, and cooling setups.

- Effective Cooling Solutions: Through ventilation slots, fans, or heat sinks, enclosures dissipate heat generated by electronics, ensuring optimal operating temperatures and averting overheating issues.

- Sealed Integrity: For applications demanding environmental sealing, PCB enclosures can integrate gaskets, O-rings, or other seals to uphold airtight or watertight properties, vital for outdoor or marine environments.

- Flexible Mounting: PCB enclosures can cater to various mounting preferences, ranging from wall, rack, to DIN rail mounting options, tailored to specific application requirements.

- Material Diversity: Enclosure materials like plastic, metal (such as aluminum or steel), and fiberglass offer distinct benefits in terms of durability, weight, and resistance to corrosion, providing choices for varied operational needs.

Our journey of designing the enclosure

Automotive Infotainment System integrating the Raspberry Pi 4 Model B (1GB RAM)

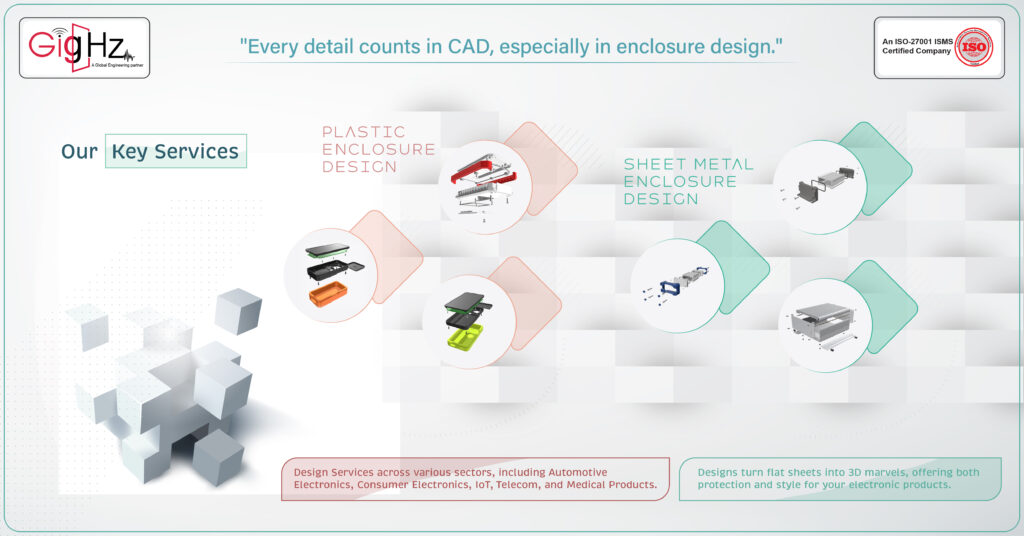

When approaching the design of a PCB enclosure for an Automotive Infotainment System integrating the Raspberry Pi 4 Model B (1GB RAM), we employ a meticulous technical strategy tailored to meet the stringent requirements of the automotive industry. Here’s how we navigate the technical intricacies for this specialized application:Comprehensive Project Requirements Analysis:We conduct a detailed assessment of the Automotive Infotainment System specifications, focusing on temperature tolerances, vibration resistance, EMI shielding, and compliance with automotive safety standards to ensure optimal performance.Careful Selection of Enclosure Materials:We opt for automotive-grade ABS plastic or similar materials renowned for their impact resistance, durability, and chemical compatibility, guaranteeing longevity and robust protection in challenging automotive environments.Precision in Dimensional Accuracy and Form Factor:We meticulously design the enclosure to precisely accommodate the Raspberry Pi 4 Model B board and associated peripherals, considering space constraints within the vehicle and ensuring seamless integration with standard mounting systems.Implementation of Advanced Environmental Sealing:We incorporate sophisticated sealing techniques such as gaskets, O-rings, and IP-rated protection to safeguard the internal electronics from moisture, dust, and other external contaminants prevalent in automotive scenarios.Efficient Thermal Management Solutions:We incorporate advanced thermal management solutions, such as heat sinks, thermal pads, and active cooling systems, to effectively dissipate the heat generated by the Raspberry Pi 4 components. This ensures the board maintains optimal operating temperatures, preventing overheating and ensuring sustained performance during extended use. By implementing these solutions, we help enhance the longevity and reliability of your Raspberry Pi 4-based projects.Optimization of Component Layout:We strategically arrange the Raspberry Pi 4 board, connectors, and peripheral interfaces within the enclosure to maximize space utilization, simplify maintenance procedures, and streamline cable routing for enhanced connectivity efficiency.Robust Cable Management Techniques:We implement advanced cable management practices, including cable routing channels, strain relief features, and cable tie mounts, to organize wiring harnesses systematically, minimize signal interference, and ensure secure connections across the system.Adherence to Safety Compliance Standards:We ensure strict compliance with automotive safety regulations such as ISO 26262 for functional safety and EMC directives for electromagnetic compatibility, ensuring the reliability and regulatory alignment of the infotainment system in automotive environments.Selection of Durable Materials for Longevity:We carefully choose high-quality enclosure materials such as ABS plastic known for its exceptional mechanical strength, chemical resistance, and UV stability, guaranteeing the enclosure’s durability and resilience to environmental challenges in automotive applications.By applying these technical principles within our PCB enclosure design process for the Automotive Infotainment System featuring the Raspberry Pi 4 Model B (1GB RAM), we create a reliable and optimized solution that safeguards the critical electronics and enhances the overall user experience within automotive setting.Our Key Services

- Molding feasibility considerations: We evaluate the design for manufacturability during the design stage.

- Customized modifications: Tailoring the enclosure to meet customer-specific requirements.

- Balancing mass and rigidity: Ensuring the enclosure is both strong and lightweight for optimal performance.

Our offerings include.Our Services Include:

- Support for fabricators and manufacturers: Helping guide the design process for seamless production.

- Efficient cooling design: Enhancing the performance of your electronic components by improving heat dissipation.

- EMI shielding: Custom-designed to meet component tolerances, protecting the circuit from interference.

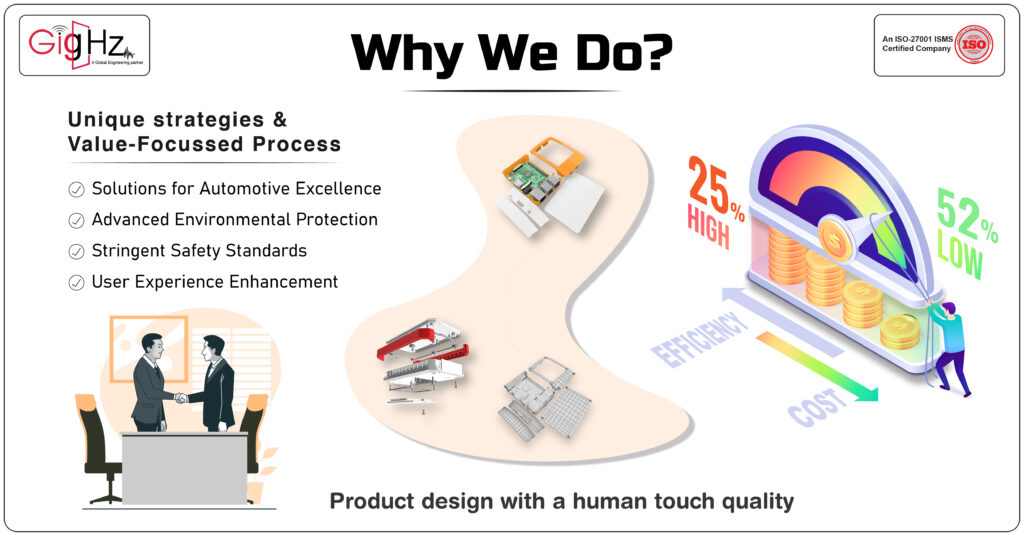

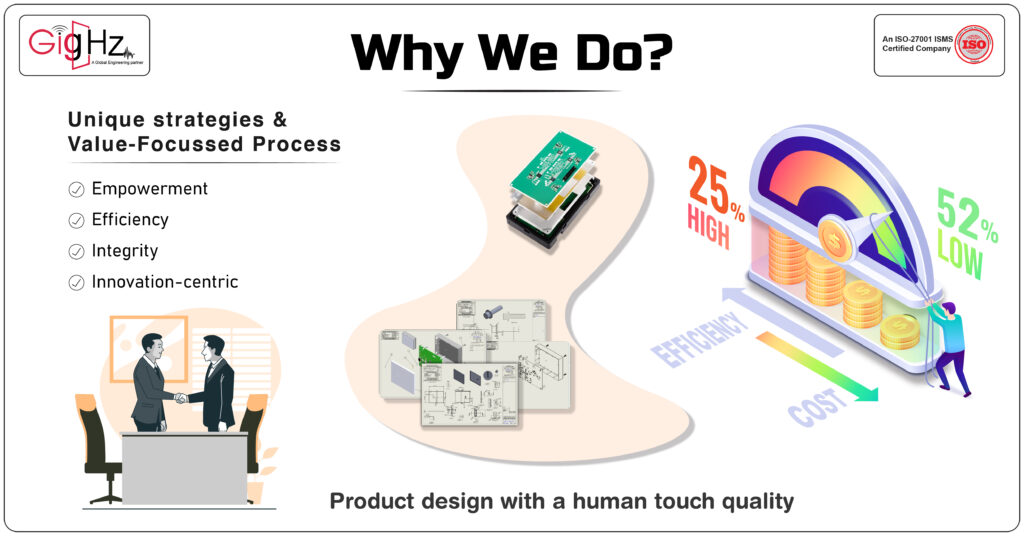

Why we Do?

At GigHz, we push the boundaries of our MCAD Engineering capabilities by integrating emerging automotive technologies, ensuring that we keep both time and costs under control while transforming product design with a human-centered quality focus.

Despite the complexities of evolving technologies, we stand out in the market due to our innovative methods and value-driven processes. This approach has allowed us to achieve impressive results, including a 52% reduction in costs and a 25% increase in operational efficiency—delivering both high performance and significant savings for our clients.

Final Thoughts

PCB enclosure design plays a critical role in safeguarding electronic devices by providing protection against environmental factors, mechanical stresses, electromagnetic interference, and ensuring overall safety.

By incorporating advanced design considerations such as IP ratings, mechanical defense mechanisms, EMI/RFI shielding, and safety measures, we enable electronic devices to operate reliably and efficiently in diverse conditions.

The customization, adaptability, and attention to sealing for protection further enhance the longevity and performance of electronic systems.

Overall, a well-thought-out PCB enclosure design is essential for ensuring the functionality, reliability, and longevity of electronic devices across various industries.

Discover Our Specialities. Visit Our Services Page. https://gighz.net/enclosure-design-services/

How PCB Enclosure Design Safeguards Electronic Devices?

Our Notable Upgrade: Engineering as a Service(EaaS)

Book a Free Consultation Call

Partner with GigHz and turn your most innovative design concepts into reality. Our engineering CAD services are designed to accelerate development, so you can focus on your larger vision while we take care of the technical details, ensuring your ideas come to life with precision and efficiency.

As we conclude our discussion on PCB power integrity, it’s important to grasp the fundamentals of power integrity and how to effectively conduct analysis during your board design.

A key element of ensuring stable power delivery and avoiding signal integrity issues is addressing the power and ground planes. Proper design of these planes ensures smooth and efficient power flow across the board, preventing noise and voltage drops that could affect system performance.

By using advanced design tools and simulations, you can identify potential power integrity problems early in the design phase. This proactive approach helps in resolving issues before they escalate, leading to a more robust and efficient design.

Incorporating techniques such as analyzing power and ground pins, power rail probes, and the Power Delivery Network (PDN) in a PCB is crucial for maintaining power integrity throughout the system. This ensures that your system operates reliably, with consistent voltage and minimized noise, laying a solid foundation for your next PCB design.

Discover our Specialities. Visit our Services Page. https://gighz.net/services/