Component Engineering Solutions

By the year 2035, self-driving technology has the potential to generate between $300 billion and $400 billion in revenue.

New research reveals what’s needed to win in the fast-changing passenger car market.

So, what’s the Autonomous Vehicles(AVs) or Self Driving Cars means for?

Self-driving cars see what’s going on around them using three main electronic “eyes”—radar, cameras and laser-based LiDar, which stands for light detection and ranging.

All three feed data into on-board processors, using sophisticated software, algorithms and machine learning to send signals to the vehicle’s actuators to trigger appropriate actions such as braking, steering and acceleration.

The array of sensors can detect a wide variety of road features and obstacles such as lane markings, curbs, pedestrians, cyclists or other vehicles.

This is done either visually, through cameras, or by bouncing light impulses or radar signals off of surrounding objects.

While self-driving automation technologies help improve safety, they are not 100% infallible, and their effectiveness can be diminished, when sensors or lane markings are covered by snow or other heavy precipitation.

So,

Imagine this one hero taking the spotlight, playing a crucial role in driving forward the advancements we’re seeing – that hero is none other than Component Engineering.

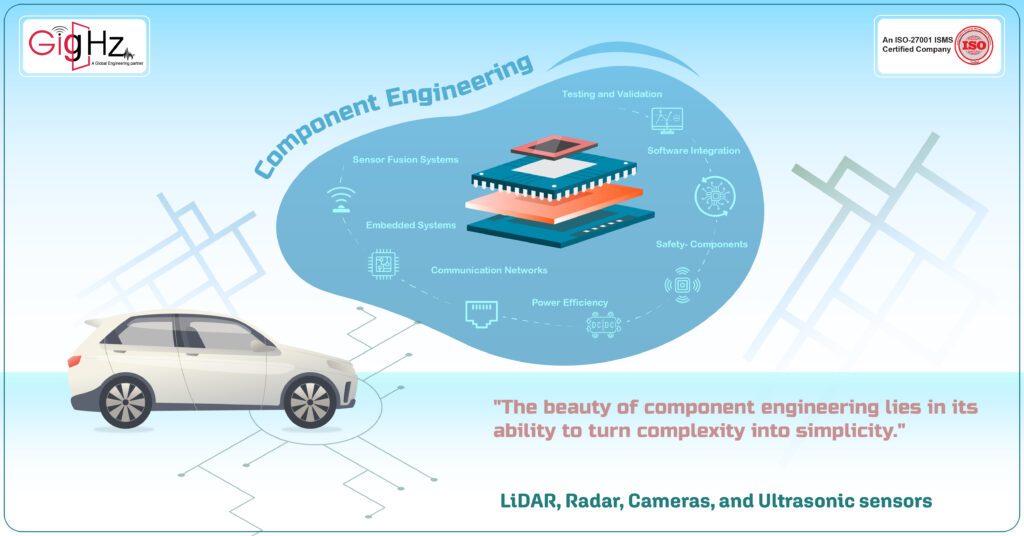

In the context of component engineering, let’s explore how the design and selection of electronic components play a crucial role in the development of autonomous vehicles.

Autonomous vehicles, or self-driving cars, rely on a sophisticated network of sensors, processors, actuators, and communication systems to navigate roads, interpret surroundings, and make real-time decisions.

Component Engineering and Product Lifecycle Management for Av's

Component engineering plays a vital role in the production and manufacturing of autonomous vehicles (AVs).

It involves the selection of the right parts from various component manufacturers and distributors to ensure the quality, reliability, and compliance of the final product.

A company offering component engineering solutions will work across different industries, including telecom and medical hi-tech electronics, to create efficient and reliable devices. Component engineering services also include testing, analysis, and support to optimize the supply chain and reduce costs. The goal is to lead product development companies in a way that offers value to the user and supports sustainability.

One important aspect of component engineering is the ability to provide component data that is relevant and reliable.

This is crucial in the manufacturing process to ensure that all parts meet the necessary regulations and standards. With the support of an expert in component engineering, companies can effectively reduce production costs and optimize their supply chain.

By practicing effective engineering processes and testing, companies can ensure that their AVs are well-equipped to meet the demands of the industry and the consumer.

The hero Shaping AVs: Component Engineering Solutions

Here’s how component engineering contributes to the innovation and advancement of autonomous vehicle technology:

- Sensor Fusion Systems: Component engineers are tasked with integrating various sensors, such as LiDAR, radar, cameras, and ultrasonic sensors, into a cohesive sensor fusion system. By selecting high-quality sensors with precise specifications and compatibility, they enable accurate perception of the vehicle’s environment for safe navigation.

- Embedded Systems and Processors: Autonomous vehicles require powerful embedded systems and processors to process vast amounts of data in real time. Component engineers select advanced microcontrollers, GPUs, and AI chips that can handle complex algorithms for object detection, path planning, and decision-making while ensuring reliability and energy efficiency.

- Communication Networks: Component engineering involves designing robust communication networks within the vehicle and with external infrastructure. Engineers choose reliable networking components, such as Ethernet switches, CAN bus controllers, and wireless modules, to facilitate seamless data exchange between onboard systems and external servers for updates and connectivity.

- Power Management and Energy Efficiency: Autonomous vehicles demand efficient power management solutions to support continuous operation and minimize energy consumption. Component engineers select power management ICs, DC-DC converters, and battery management systems that optimize power distribution, charging, and thermal performance to enhance the vehicle’s autonomy and reliability.

- Safety-Critical Components: Ensuring the safety and reliability of autonomous vehicles is paramount. Component engineers focus on selecting safety-critical components, such as redundant sensors, fail-safe actuators, automotive-grade ICs, and functional safety mechanisms, to meet stringent safety standards and mitigate risks associated with autonomous driving.

- Software Integration and Updates: Component engineering extends to software integration and over-the-air updates for autonomous vehicle systems. Engineers select components compatible with over-the-air update capabilities, secure boot protocols, and software-defined architectures to enable remote diagnostics, feature enhancements, and cybersecurity measures for continuous improvement and adaptability.

- Testing and Validation Equipment: Component engineers utilize specialized testing equipment, such as hardware-in-the-loop (HIL) simulators, environmental chambers, and reliability testing tools, to validate component performance under various conditions. Rigorous testing ensures component durability, functionality, and compliance with automotive industry standards for safe autonomous operation.

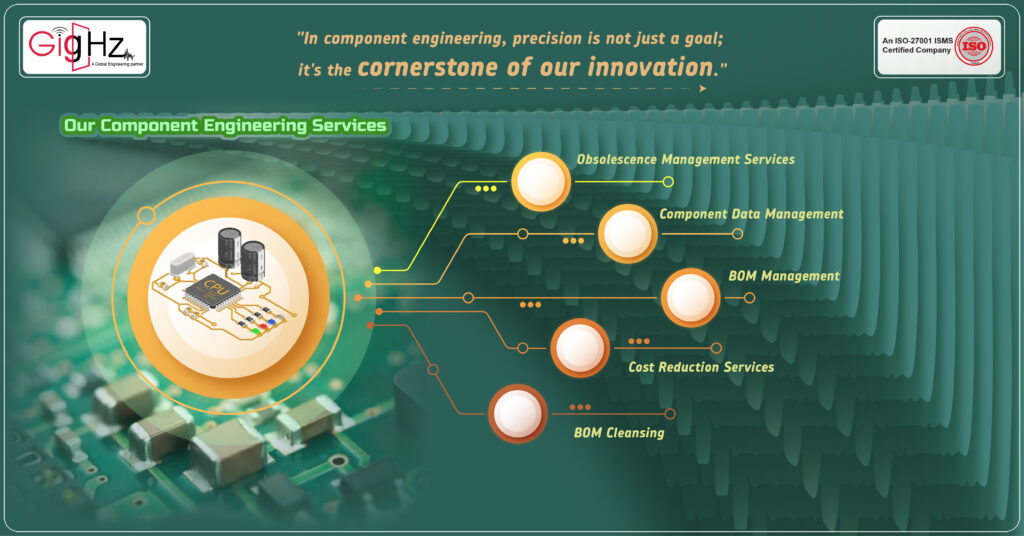

Our Component Engineering Services

GigHz provides comprehensive component engineering services designed to optimize product development from selection to modeling and integration. By evaluating parts from various suppliers based on electrical, thermal, and mechanical parameters, we offer unbiased recommendations that enhance your product’s performance.

Obsolescence Management Services

We proactively monitor component life cycles, mitigating obsolescence risks through alternative recommendations, custom orders, and redesign support to ensure long-term reliability.

Component Data Management

We offer full traceability and accessibility of component data via centralized systems that integrate seamlessly across your supply chain.

BOM Management

We optimize Bill of Materials (BOMs) to ensure cost efficiency, continuity of supply, and engineering compliance through standardized processes.

Cost Reduction Services

Our experts identify opportunities for more cost-effective components, aligning with your engineering priorities and market conditions to reduce costs without compromising quality.

BOM Cleansing

We help clean and consolidate as-built BOMs, removing redundancies and improving alignment with engineering BOMs to boost efficiency.

Partner with GigHz to accelerate your product’s path to market with a commitment to engineering excellence and seamless integration.

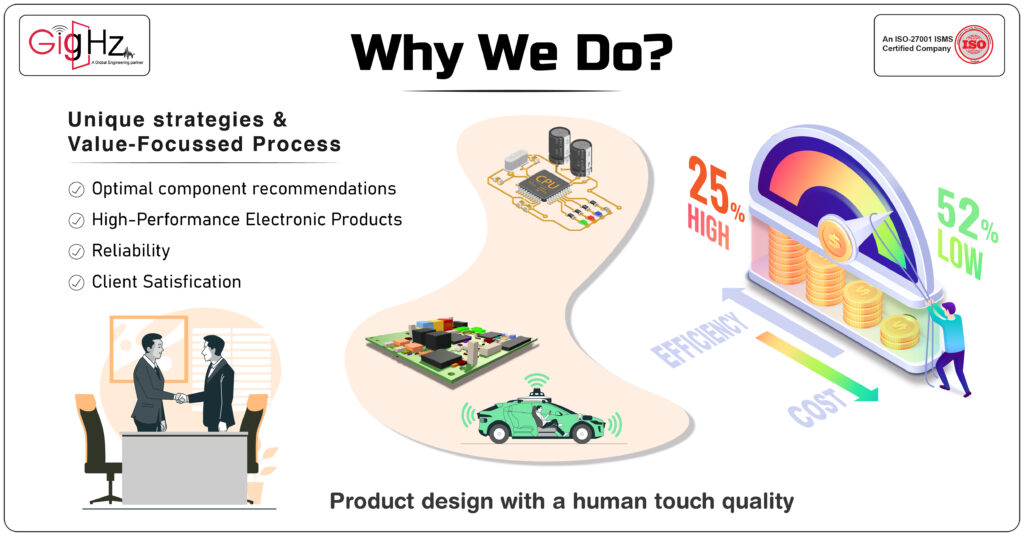

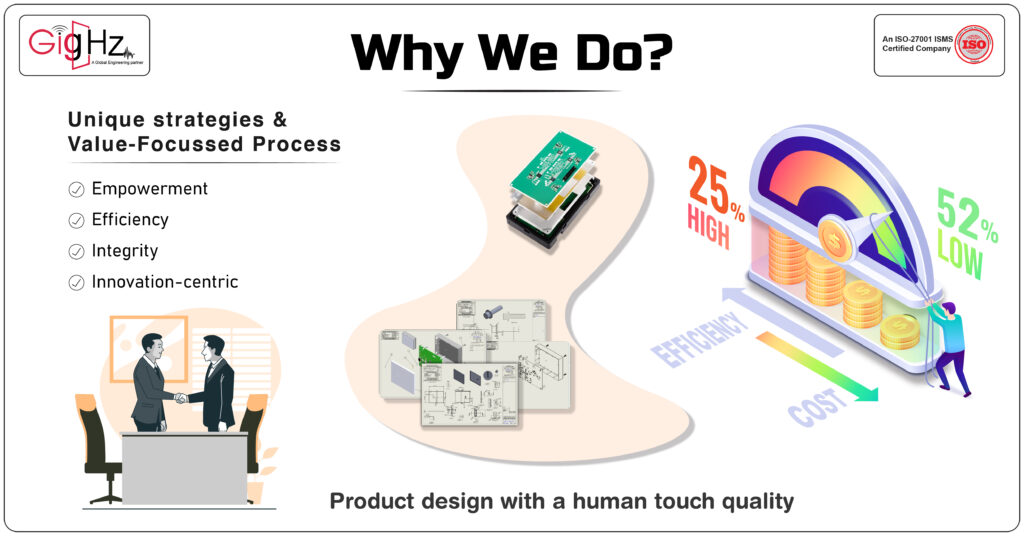

Why we Do? GigHz DNA

GigHz challenges the boundaries of component engineering by integrating emerging technologies like Autonomous Vehicles. We focus on maintaining control over time and costs, while also transforming product design with a human-centered approach that prioritizes quality.

Despite the complexity of these technologies, we stand apart from the competition thanks to our innovative methods and value-driven process. This approach has delivered impressive results, achieving a 52% reduction in costs while simultaneously boosting operational efficiency by 25%.

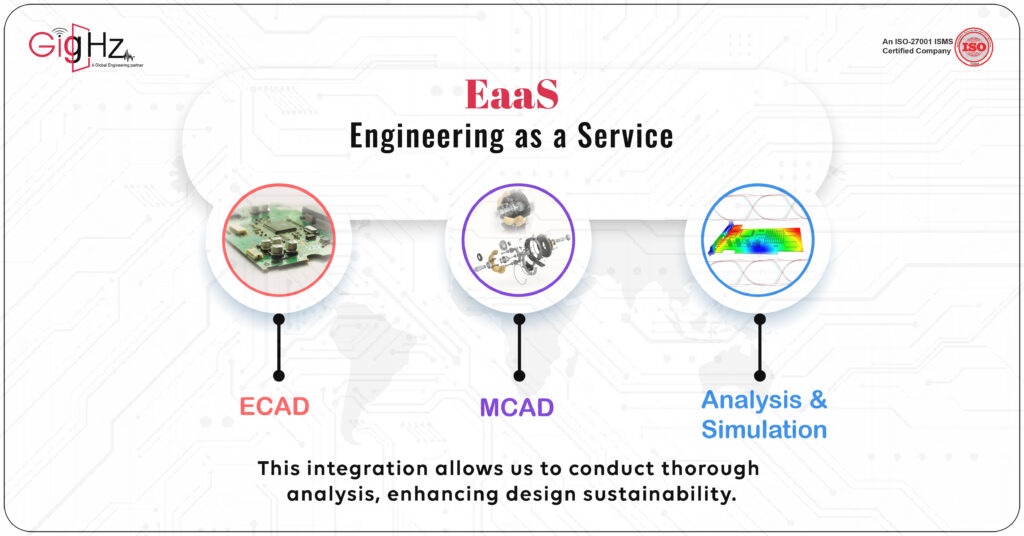

Our Notable Upgrade : Engineering as a Service(EaaS)

GigHz provides tailored component engineering services that offer significant benefits to both startups and enterprises. Our expertise includes:

Component selection – We recommend the most suitable components by carefully evaluating technical specifications, reliability, cost, availability, and other key factors to ensure the best fit for your needs.

Supplier management – We manage relationships with component suppliers, overseeing processes such as qualification, sampling, testing, and ongoing production to ensure seamless operations and consistent quality.

By providing specialized component engineering knowledge and resources, GigHz accelerates product development, helping both startups and large enterprises bring their innovations to market faster and more efficiently.

Conclusion

After considering the key points discussed in the content, it is evident that PLM plays a crucial role in the success of GigHz for industrial automation services across different products.

Utilizing component distributors and LinkedIn for networking and information sharing is essential for us, OEMs and contract manufacturers to stay ahead in the market.

The internal PLM system is a valuable component in managing client information and providing a competitive proposition.

Companies must take into consideration the various tools and platforms available to streamline their processes and improve efficiency. Overall, a well-executed PLM strategy can optimize operations and drive growth in the industrial automation sector.

Schedule a Call. Book a Free Consultation Now. https://calendly.com/gighz/30min

The hero Shaping AVs: Component Engineering Solutions

Our Notable Upgrade: Engineering as a Service(EaaS)

Book a Free Consultation Call

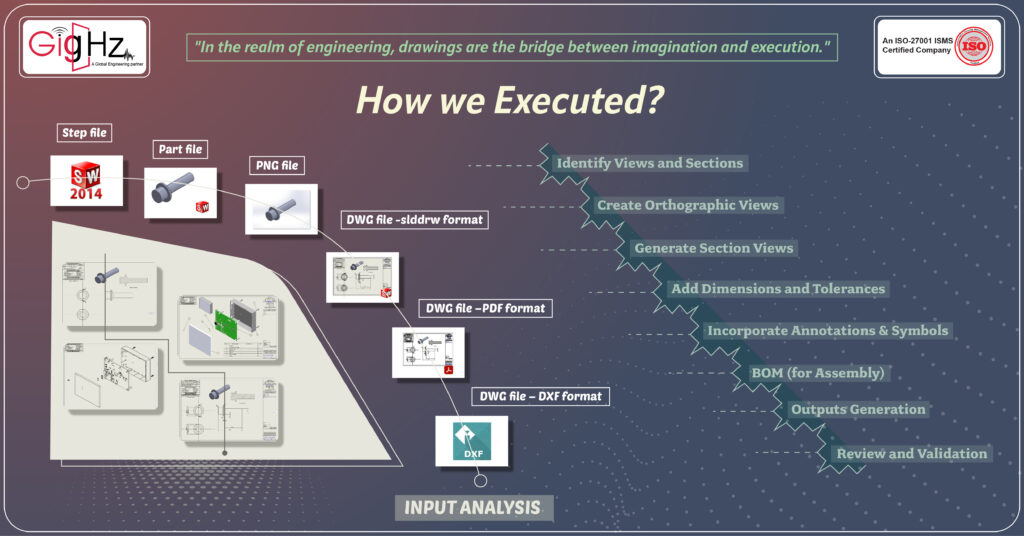

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.

As we wrap up our discussion on PCB power integrity, it’s important to understand the fundamentals of power integrity and how to effectively perform power integrity analysis during the board design process.

Ensuring stable power delivery and preventing signal integrity issues starts with addressing power and ground planes properly. These are critical to maintaining smooth power flow and avoiding disruptions in signal performance.

By using advanced design tools and simulations, you can identify potential power integrity problems early in the design phase, allowing you to resolve them before they become major issues. This proactive approach provides a strong foundation for building reliable and efficient PCB designs.

Additionally, analyzing power and ground pins, power rail probes, and the Power Delivery Network (PDN) in a PCB is essential for maintaining consistent power integrity across the system, ensuring reliable operation of the entire power system.

Discover our Specialities. Visit our Services Page. https://gighz.net/services/