So, it goes that every engineer knows the importance of schematic accuracy and layout precision, but too many projects still fail due to a weak BOM check in PCB design.

Plus, it doesn’t matter how flawless your routing looks — if your Bill of Materials is incomplete or inaccurate, production halts, costs spike, and schedules slip.

Also, skipping this step is one of the most expensive oversights in modern electronics.

What’s more, teams often catch these issues only when it’s too late!

Especially during procurement or pre-production runs—when fixes are costlier and riskier.

Accordingly, engineering effort is wasted not because the design is flawed, but because the support systems around it weren’t equally robust.

Plus, strong BOM practices are what turn a great design into a manufacturer product.

Now, that’s why addressing common BOM errors in PCB design and embedding a clear BOM validation process is not optional.

From missing components in BOM to unexpected design-to-manufacturing BOM issues, a lack of rigor can lead to delays, respins, and even customer dissatisfaction.

Likewise, the solution lies in building and following strong BOM management best practices.

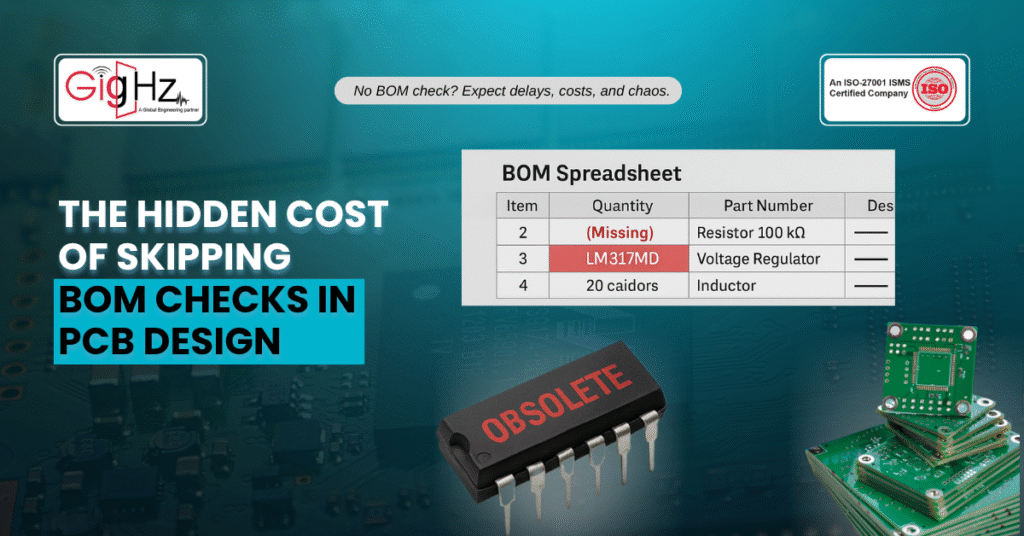

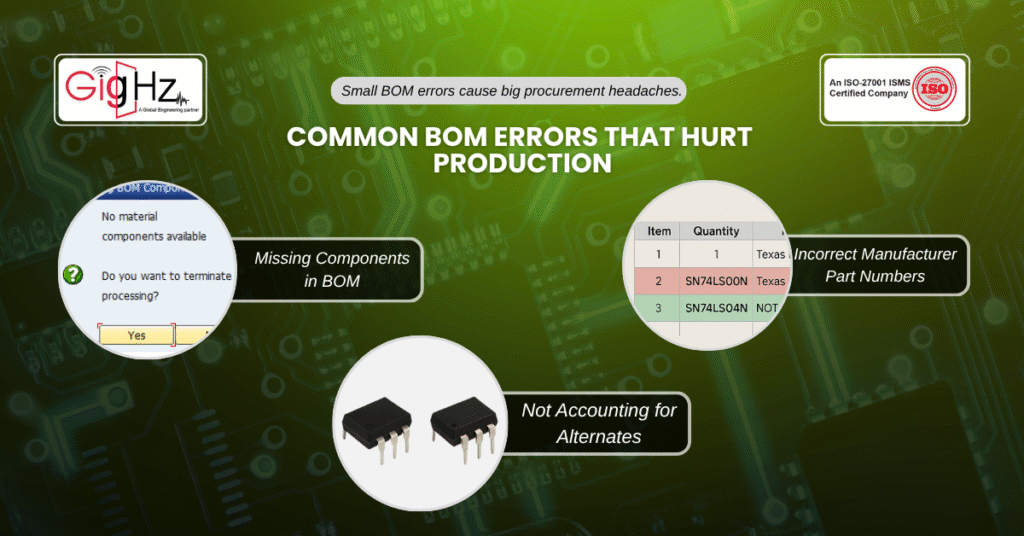

1. Common BOM Errors That Hurt Production

Now, the most frequent common BOM errors in PCB design include wrong part numbers, obsolete components, and mismatched package types. Plus, these may look minor on paper but cause massive delays during procurement.

So, key pitfalls to watch for:

- Missing components in BOM due to overlooked passives or connectors.

- Incorrect manufacturer part numbers that derail sourcing.

- Not accounting for alternates, leading to last-minute shortages.

Quick-Check Mini Checklist for BOM Validation

- Verify that component footprints match the PCB pads.

- Confirm polarity for capacitors, diodes, and ICs.

- Check supplier lead times and component availability.

- Ensure alternates are clearly defined for all critical components.

Therefore, catching these through a structured BOM validation process saves both time and money. Accordingly, an accurate BOM is more than just paperwork — Instead, it’s a critical bridge between design intent and manufacturable reality.

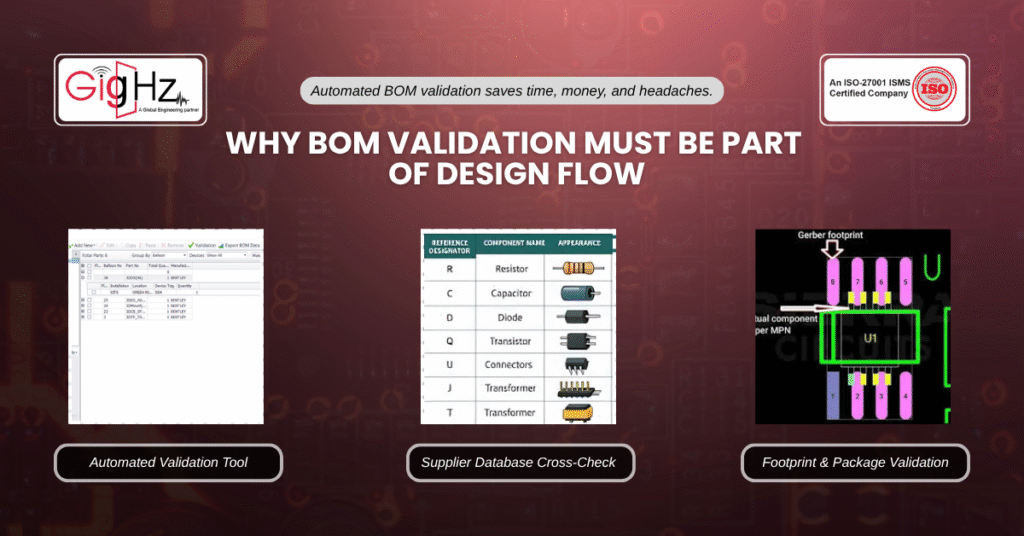

2. Why BOM Validation Must Be Part of Design Flow

Too often, BOM review happens only after the design is “finished.” By then, procurement and assembly issues surface too late. Plus, embedding a BOM validation process directly into design reviews is the smarter approach.

Best practices include:

- Running automated validation tools to flag missing components in BOM.

- Cross-checking against supplier databases to avoid obsolete parts.

- Validating footprints and packages alongside part numbers.

Consequently, this prevents the ripple effect of design-to-manufacturing BOM issues, which often cost more than the original design cycle itself. Additionally, BOM validation also strengthens collaboration between design, sourcing, and manufacturing teams—reducing delays, improving supply chain resilience, and ensuring the final product reaches the market faster and with fewer surprises.

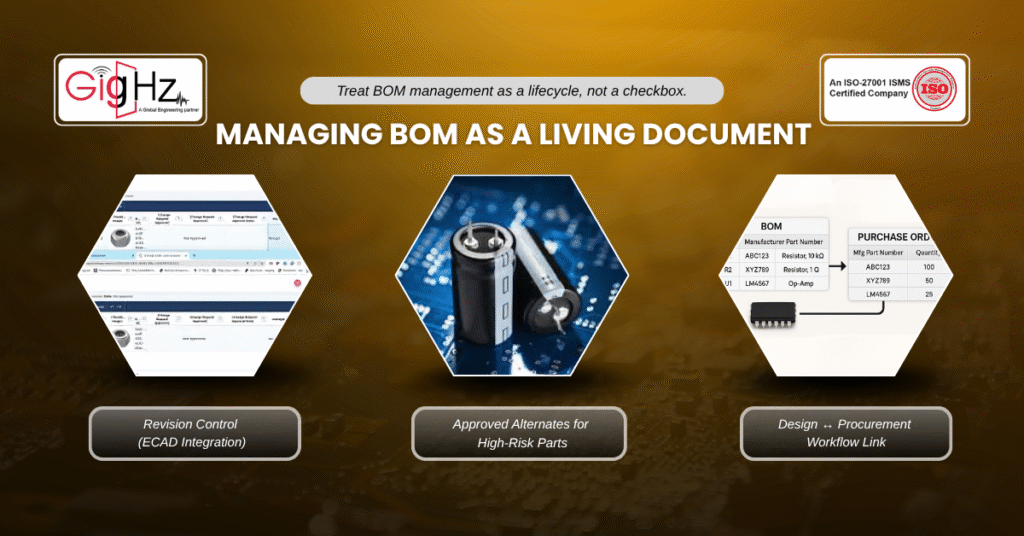

3. Managing BOM as a Living Document

Now, a bill of materials is not static—it evolves throughout the product life-cycle.

Also, treating it as a “done once” task is one of the biggest common BOM errors in PCB design.

Also, adopt BOM management best practices by:

- Keeping revision control tied to your ECAD system.

- Documenting approved alternates for high-risk parts.

- Linking BOM data to both design and procurement workflows.

Also, this ensures the BOM validation process is continuous and not just some final checkbox. A well-managed BOM improves traceability, minimizes risk during redesigns or supply chain disruptions, and keeps engineering, and manufacturing teams strongly aligned.

Real-World Example

So, one client shipped their files without a thorough BOM check in PCB design.

During procurement, they discovered over 20 missing components in BOM, and half of the specified ICs were already obsolete.

Now, the result?

A 12-week delay, expedited shipping costs, and an emergency redesign.

Consequently, this case shows how ignoring design-to-manufacturing BOM issues undermines even the most technically sound layouts.

Now, all of this could’ve been avoided with a structured BOM validation process integrated earlier in the design cycle.

Building Reliability Into Your Design Cycle

Now, a strong BOM validation process is not about slowing down engineers — So, it’s about accelerating manufacturing. Now, the difference between failure and on-time delivery often comes down to disciplined BOM management best practices.

Likewise, by avoiding common BOM errors in PCB design and systematically checking for missing components in BOM. Consequently, this proactive approach streamlines sourcing, ensures build readiness, and minimizes costly production delays. Ultimately, effective BOM validation isn’t just good housekeeping — it’s a competitive advantage that helps get quality products to market faster and more reliably.

Bottom Line

Summing up, skipping BOM validation is like skipping ERC or DRC—you may get lucky once, but eventually the cost catches up. Also, embedding BOM checks in PCB design and enforcing BOM management best practices gives you smoother handoffs, fewer respins, and lower risk of production delays.

Undoubtedly, as products grow more complex and timelines shrink, proactive BOM validation becomes essential to delivering quality hardware, on time, every time.

At Gighz, we help teams refine their BOM validation process to eliminate design-to-manufacturing BOM issues before they reach suppliers

Want to safeguard your next build?

Reach out at info@gighz.net to make sure your BOM is as robust as your design.

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.