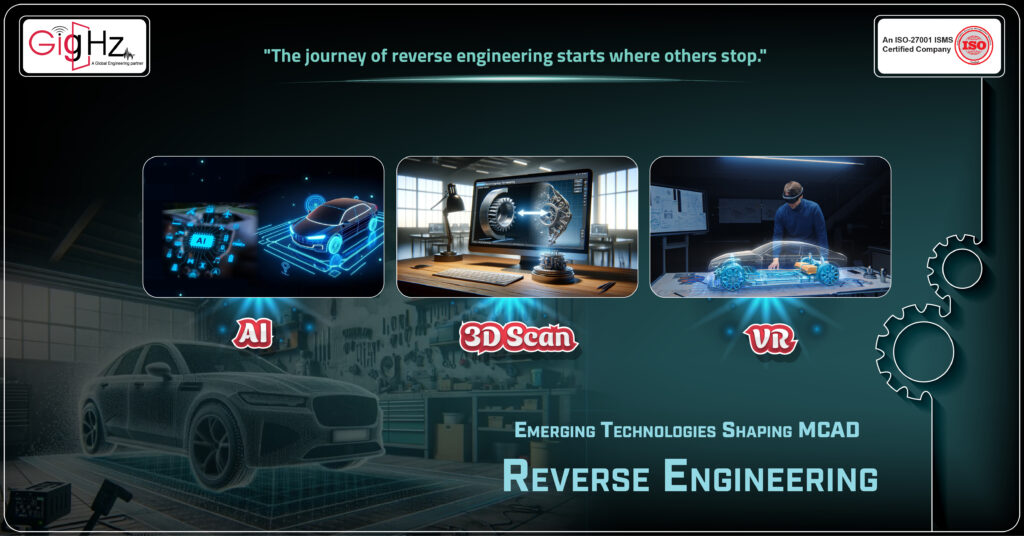

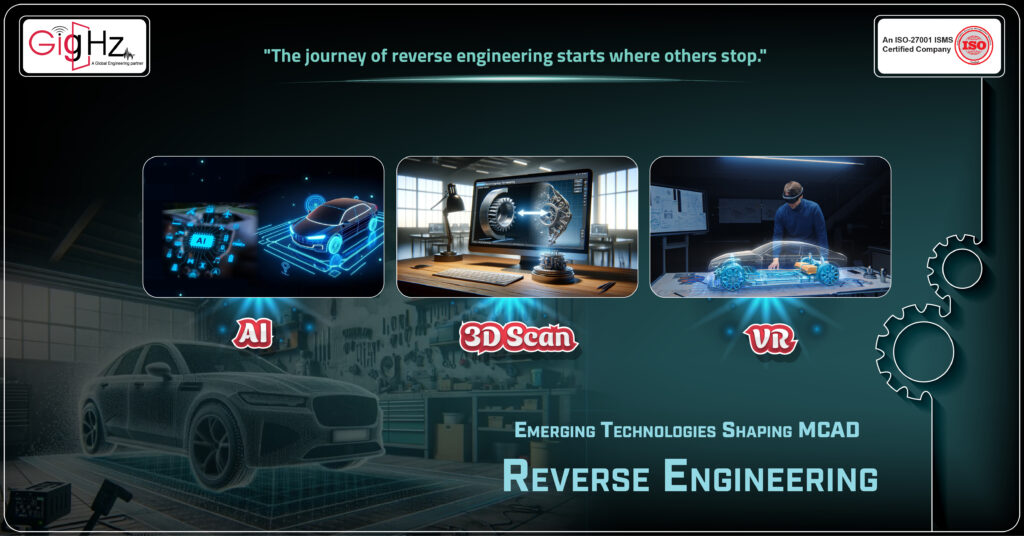

Emerging Technologies Shaping MCAD Reverse Engineering

- Posted On:

- July 23, 2024

- Category:

- Analysis & Simulation

MCAD Reverse Engineering

In the world of figuring out how things are made on computers (MCAD reverse engineering), awesome new technologies are changing the game.

From smart computer help (AI) to super-accurate picture taking (3D scanning) and even feeling like you’re inside your designs (VR), these tools are making design more efficient.

Reverse engineering is all about taking stuff apart to see how it works, then using that knowledge to create something better.

By using new technologies like AI, 3D scanning, and VR in reverse engineering, designers can better understand products, make improvements, and build new things with super accuracy and speed.

Join us on a journey through how these amazing technologies are transforming the world of MCAD reverse engineering.

Together, we’ll see how these tools are not only helping designers visualize and improve their creations but also changing how we look at reverse engineering itself.

Let’s embrace the future of design, where innovation, technology, and reverse engineering come together to unlock endless possibilities for creativity and discovery.

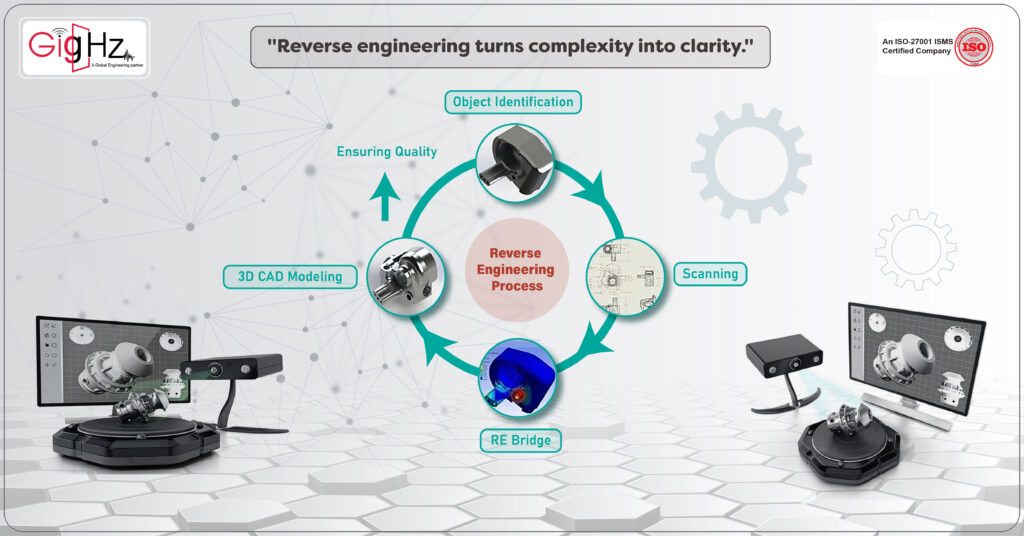

How the Reverse Engineering works?

Reverse engineering is a process that involves analyzing an existing product to gain insight into how it was designed and manufactured.

This process is invaluable in industries such as mechanical and electronics where product design is crucial. By using a combination of computer-aided design (CAD) tools, reverse engineering allows engineers to recreate a precise 3D model or 2D drawing of a component.

The reverse engineering process involves taking measurements of the original part to establish its dimensions and then using that data to reconstruct the part in a CAD model. This CAD model can then be used to optimize the design process and enhance the manufacturing of the part.

Through reverse engineering, engineers can also analyze the schematic and printed circuit board (PCB) design of an electrical circuit to understand its functionality.

By using ECAD tools, they can convert the layout of the PCB into a CAD model and simulate its performance. This allows for the refinement of the design and the optimization of the manufacturing process.

The time and effort put into reverse engineering is justifiable as it can greatly enhance the value of existing products and improve the supply chain of a company.

Emerging Technologies Shaping MCAD Reverse Engineering

Artificial Intelligence (AI) in Automotive Design

In the automotive sector, a practical real-time application of AI algorithms is in autonomous vehicle design. AI systems can continuously analyze real-time vehicle performance data gathered from sensors and cameras to make split-second decisions while driving.

By predicting possible design flaws in the autonomous driving system through AI algorithms, engineers can quickly adjust the software parameters to enhance safety and efficiency on the road.

Additionally, AI can optimize aerodynamics in real time by adjusting vehicle components like spoilers or flaps based on immediate environmental conditions, leading to improved fuel efficiency and performance of autonomous vehicles.

This real-time AI assistance in autonomous vehicle design not only enhances decision-making processes but also contributes to the creation of innovative and reliable autonomous driving solutions in the automotive industry.

3D Scanning for Automotive Prototyping

3D scanning technology in automotive prototyping is in custom part manufacturing for vehicle customization. Automotive engineers can use advanced 3D scanners in real time to capture precise details of existing vehicle components for bespoke modifications.

By digitizing these parts instantly, designers can ensure accurate replication of dimensions and contours in digital form, facilitating the rapid creation of customized prototypes. This immediate replication through real-time 3D scanning allows for on-the-spot adjustments to tailor components to specific customer preferences, expediting the production process for personalized vehicle models.

The enhanced accuracy and speed enabled by real-time 3D scanning in custom part manufacturing contribute to faster time-to-market for unique and tailored automotive designs, meeting the growing demand for customized vehicles in the automotive industry.

Virtual Reality (VR) in Automotive Design Visualization

Virtual Reality (VR) technology in automotive design is in interior cabin design evaluation. Designers can utilize VR to immerse themselves in a virtual environment that replicates the interior of a vehicle. In real time, designers can interact with the virtual cabin, assessing factors such as ergonomics, aesthetics, and overall design coherence by experiencing the space from a user’s perspective.

During real-time VR simulations, design teams can collaborate effectively, exploring different design options, visualizing concept interiors in detail, and making immediate modifications based on instant feedback.

This real-time immersive approach to interior cabin design evaluation enhances communication among team members, stimulates creativity in design solutions, and accelerates decision-making processes, leading to the development of advanced and user-centric vehicle interiors in the automotive sector.

Our Reverse Engineering Services

Project Initiation / Object Identification

The GigHz reverse engineering process begins by identifying the object of interest for analysis. We first understand your specific requirements, including the purpose, timelines, and constraints. Whether the goal is to replicate, enhance, or optimize the object, we tailor our approach to meet your objectives.

Scanning

In this phase, we apply Design for Manufacturability (DFM) to determine the appropriate sheet metal dimensions, ensuring the final product is of the highest quality. We also perform an analysis to optimize the design. If additional collaboration is required, we issue RFIs (Requests for Information) promptly. Advanced scanning techniques, such as laser scanning or structured light scanning, are employed to capture the physical geometry of the object, generating a precise digital representation.

RE Bridge

The Reverse Engineering (RE) Bridge connects the physical object with its digital representation. This step involves converting the scanned data into a format compatible with CAD software, enabling further analysis, refinement, and manipulation of the digital model.

3D CAD Modeling

We then transform the collected data into actionable insights by creating 3D CAD models. Along with the model, we generate a Bill of Materials (BOM). The 3D model undergoes rigorous tolerance analysis using tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to assess its stability. After finalizing the model and ensuring its quality, we integrate detailed component and assembly drawings into the 2D CAD schematic package.

Ensuring Quality and Swift Dispatch

Once we integrate your feedback, the deliverables — including models and drawings — undergo a detailed quality check to ensure they meet your specifications. The finalized files, including a fully functional 3D model (in native and .STP formats) and 2D drawings in PDF format, are delivered promptly. These drawings include GD&T annotations, component details, and custom notes tailored to your project requirements.

This comprehensive process ensures precision, quality, and timely delivery for all reverse engineering projects.

Conclusion

At lastly, the evolution of emerging technologies is significantly shaping the landscape of Mechanical Computer-Aided Design (MCAD) reverse engineering.

By leveraging cutting-edge tools like 3D scanning, AI algorithms, and virtual reality simulations, designers and engineers can now streamline the reverse engineering process, improve accuracy, and accelerate innovation in product development. These technologies enable faster data capture, precise modeling, and enhanced visualization, leading to more efficient workflows and enhanced design outcomes.

As MCAD continues to embrace these emerging technologies, the future holds exciting possibilities for revolutionizing reverse engineering practices and driving forward the boundaries of design excellence in the mechanical engineering domain.

Discover our Services. Start your journey now! https://gighz.net/services/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.