Avoid These 5 Common Mistakes When Outsourcing your PCB Design

- Posted On:

- November 19, 2024

- Category:

- Ecad

PCB Design Outsourcing

When people discuss outsourcing in business, they often think of negative aspects like losing control, job cuts, and lower quality.

However, the advantages of outsourcing PCB design are frequently overlooked.

Outsourcing your PCB design can help you save time and money to grow your business.

Instead of hiring or training someone for PCB design,

You can use those resources for other important parts of your company.

Plus, it can be tough to find an experienced PCB designer who doesn’t need extra training. While you may have some experience in creating PCBs, outsourcing your design ensures that you receive professional services from someone who specializes in PCB design.

This expertise makes them more efficient and effective in their work.

Professional designers are typically highly skilled, experienced, and hold the necessary certifications, such as IPC Certified Interconnect Designer, to get the job done right.

Additionally, you won’t need to worry about buying the right software for PCB design or needing advanced artistic skills.

Managing a project and sticking to a timeline can consume your entire day.

PCB design is just one small part of the overall project you’re currently working on.

While it’s a crucial element in developing your product, any delays in completing the PCB design can impact other areas of the project.

Let’s dig in for more details!

Why choose PCB design outsourcing?

Many companies have design teams but only seek outside help when their staff can’t meet deadlines or quality standards. This leads to struggles to meet deadlines, as hardware engineers, who are often responsible for PCB design, must also handle planning, chip selection, and debugging, delaying product launches.

The need for faster development increases the growing demand for high-speed PCB design. With the rise of 5G technology, tasks like checking signal integrity and managing crosstalk are essential. However, relying solely on hardware engineers for complex boards can further slow down development.

Compounding this issue is the difficulty in finding experienced PCB designers. Skilled engineers are hard to come by, and it often takes 2-3 years to train juniors, with retention being a challenge during this period.

Additionally, small and medium-sized businesses often lack dedicated PCB design engineers. Hiring full-time engineers for limited projects can waste resources, making outsourcing PCB design services a more cost-effective and efficient option.

Avoid These 5 Common Mistakes When Outsourcing your PCB Design

Let’s refine the list to include more aspects related to outsourcing PCB design,

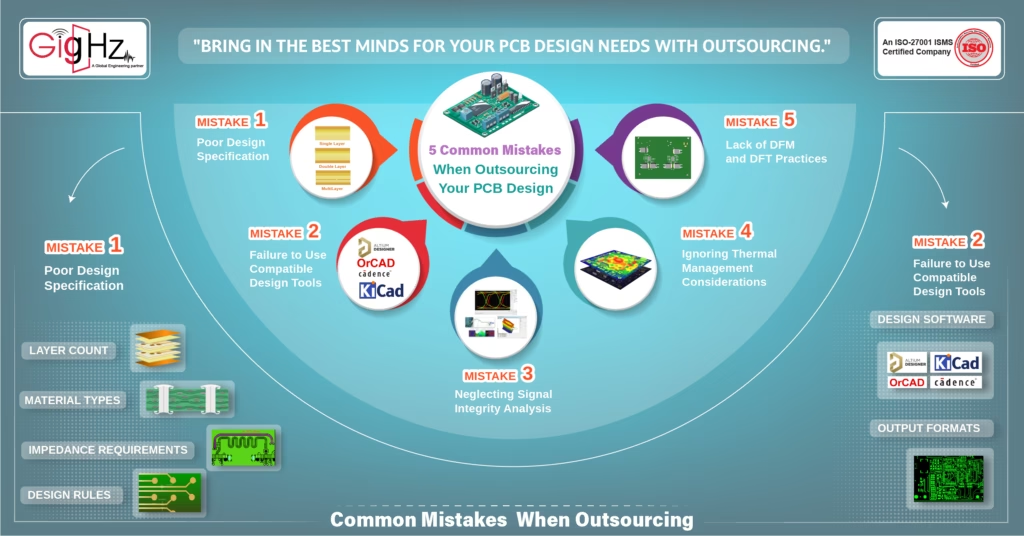

Mistake 1: Poor Design Specification

Not providing detailed and precise design specifications can lead to misinterpretations. Clearly define requirements such as layer count, materials (FR-4, Rogers, etc.), impedance control, and specific design rules (trace width, spacing) to ensure the outsourced team fully understands your needs.

- Layer Count: Clearly define whether the design is single-layer, double-layer, or multi-layer (e.g., 4-layer or 6-layer).

- Material Types: Specify the preferred materials, such as FR-4, Rogers (e.g., Rogers 4350 for RF applications), or other high-frequency materials.

- Impedance Requirements: Provide target impedance values (e.g., 50Ω for RF signals) and specify if differential pairs are required.

- Design Rules: Include trace widths, spacing, pad sizes, and via types (through-hole vs. blind/buried vias).

Mistake 2: Failure to Use Compatible Design Tools

Not aligning on the design software or tools can result in compatibility issues. Ensure that the outsourcing partner uses the same tools (e.g., Altium, Cadence, Eagle) or that the output files are compatible with your system to facilitate seamless integration and modifications.

- Design Software: Specify the required software (e.g., Altium Designer, Cadence OrCAD, Eagle, KiCAD) and any necessary version details.

- Output Formats: Clearly state the required output file formats (e.g., Gerber files, IPC-2581, ODB++), ensuring compatibility with your manufacturing processes

Mistake 3: Neglecting Signal Integrity Analysis

Overlooking the need for signal integrity (SI) analysis during the design phase can lead to performance issues, especially in high-speed applications. Specify requirements for SI simulations, including crosstalk, impedance matching, and return path considerations, to ensure optimal performance.

- Simulation Tools: Specify the use of tools like HyperLynx, SIwave, or ADS for signal integrity analysis.

- Parameters to Analyze: Include requirements for analyzing crosstalk, return paths, transmission line effects, and impedance matching for high-speed signal traces (e.g., 1 Gbps or faster).

Mistake 4: Ignoring Thermal Management Considerations

Not addressing thermal management in the design can lead to overheating issues. Ensure that the outsourced team understands your thermal requirements, including the use of heat sinks, thermal vias, and proper component placement to dissipate heat effectively.

- Maximum Operating Temperature: Specify the maximum operating temperature for components.

- Heat Dissipation Strategies: Define the need for thermal vias, heat sinks, or copper pours to dissipate heat from high-power components (e.g., FETs, voltage regulators).

- Thermal Simulation Requirements: Specify any thermal simulation tools (e.g., ANSYS, SolidWorks Flow Simulation) to be used for thermal management analysis.

Mistake 5: Lack of DFM and DFT Practices

Failing to incorporate Design for Manufacturing (DFM) and Design for Testability (DFT) principles can result in production challenges and difficulty in testing the final product. Specify requirements for component accessibility, test points, and fabrication constraints to enhance manufacturability and testability.

- Component Placement Guidelines: Specify guidelines for component placement (e.g., keep sensitive components away from noisy components).

- Test Points and Accessibility: Define the number of test points required and ensure they are easily accessible for testing (e.g., boundary scan points for JTAG testing).

- Fabrication Constraints: Include specifications for minimum hole sizes, maximum aspect ratios, and surface finish requirements (e.g., ENIG, HASL).

Conclusion

Design work is a crucial aspect of any pcb design project, and companies often find themselves considering outsourcing their pcb design needs to streamline the design process.

Design bureaus can provide the expertise required for a successful initial design, helping to navigate the five stages of design.

However, before you outsource your pcb design work, it’s essential to assess the work required before outsourcing and ensure that you have a clear design flow in mind.

“Your Needs, Our Solutions – Visit Our Services Page Today!” https://gighz.net/services/

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.