7 Step by Step Guide to select right components for MCAD Enclosure Design

- Posted On:

- August 14, 2024

- Category:

- Mcad

MCAD Enclosure Design

Hey there!

Smileful day to all!

Being aware of new innovations is highly beneficial for enhancing our experience and expanding our knowledge, don’t you think?

During a web search in the medical industry, a report on eyesight, highlighted challenges faced by the medical field, in designing MCAD enclosures.

The report posed a question:

“What is the process for choosing the correct components for MCAD Enclosure Design?” as a solution to these challenges.

When you are designing a custom enclosure for your specific project or prototype, it’s important to start on the right foot by choosing the component that will best suit your needs.

To recap, there a few good questions to guide you in your choice:

- Where will my enclosure be stored?

- Will my case need to withstand harsh environmental elements?

- How much is weight an issue for my enclosure?

- How budget-conscious do I need to be?

Once you have answered these questions and considered your needs thoroughly, you will have some guidance on selecting the right metal for your custom enclosure or part.

Let we dive deeper for more!

Step by Step Guide to select right components for mcad Enclosure Design

In the medical field, MCAD enclosure designers are encountering challenges related to the development of enclosures for cutting-edge medical devices and equipment.

With the rapid advancements in healthcare technology, there is a growing need for enclosures that can house intricate electronic components while meeting stringent regulatory requirements and ensuring patient safety.

Designing enclosures for Patient Monitors in the medical field presents unique challenges due to the stringent requirements for electromagnetic compatibility, safety, and patient comfort.

Selecting the right components for Patient Monitors enclosures demands careful consideration of specialized materials, shielding solutions, and regulatory compliance.

Here’s how you can navigate the complexities of component selection for Patient Monitors enclosures:

1. Material Selection:

Non-Magnetic Materials: Choose non-magnetic materials such as aluminum, titanium, or specific grades of stainless steel to prevent interference with the Patient Monitors.

Radiofrequency (RF) Transparency: Opt for materials that are RF-transparent to ensure minimal signal attenuation during imaging procedures.

2. Shielding Solutions:

RF Shielding: Implement high-performance RF shielding materials like copper to contain electromagnetic emissions and prevent external interference.

Gradient Shielding: Incorporate gradient shielding components to reduce eddy currents and distortions in the magnetic field within the enclosure.

3. Safety Compliance:

Biocompatible Materials: Use biocompatible materials for components that come into contact with patients to ensure safety and minimize allergic reactions.

4. Cooling and Ventilation:

Heat Dissipation: Integrate efficient cooling systems, such as liquid cooling solutions or specialized fans, to manage heat generated by the Patient Monitors components.

Airflow Management: Design ventilation systems that maintain positive pressure inside the enclosure to prevent the entry of external contaminants while ensuring proper airflow for cooling.

5. Electrical Component Integration:

EMI Filtering: Include electromagnetic interference (EMI) filters for sensitive electronic components to prevent disruptions from the Patient Monitors’s strong magnetic fields.

Isolation Barriers: Implement isolation barriers for electrical connections to mitigate potential electromagnetic interference and ensure signal integrity.

6. Regulatory Considerations:

FDA Compliance: Ensure that all enclosure components meet the regulatory requirements set forth by the Food and Drug Administration (FDA) for medical device safety and performance.

CE Marking: Comply with CE marking standards for electromagnetic compatibility (EMC) to guarantee that the enclosure components do not interfere with the Patient Monitors functionality or accuracy.

7.Customization and Testing:

Custom Enclosure Design: Work closely with specialized enclosure manufacturers to develop custom solutions tailored to the specific requirements of the Patient Monitors and its operational environment.

Thorough Testing: Conduct rigorous testing of the selected components and the assembled enclosure to validate performance, safety, and compliance with industry standards before deployment.

By extrapolating and adapting the technical considerations for Patient Monitors enclosures to other MCAD enclosure designs in the medical field, designers can enhance the functionality, safety, and regulatory compliance of a broad range of medical devices.

Customization based on the specific needs of each application is key to ensuring the success of MCAD enclosure designs across different medical specialties.

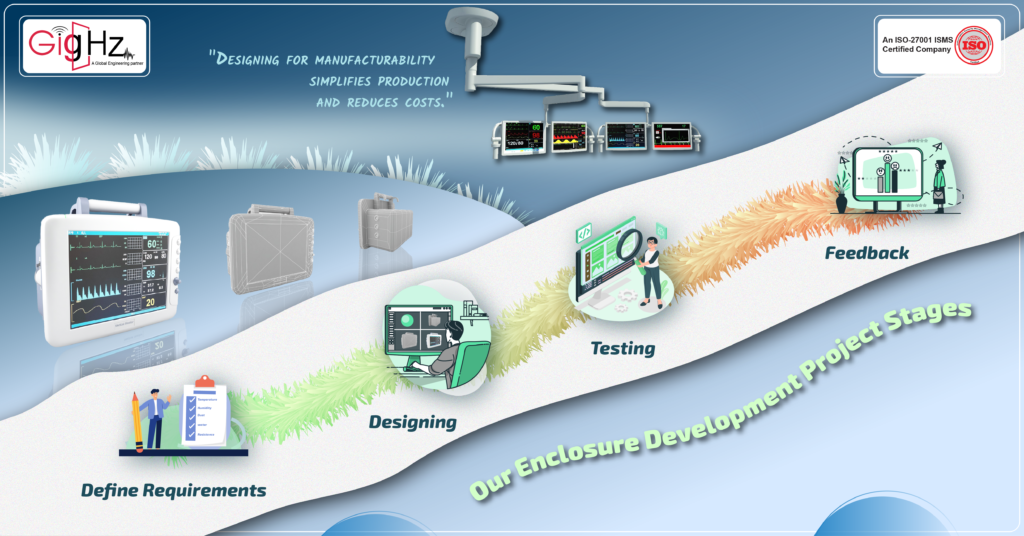

Our Enclosure Development Project Stages

At our company, we help shape the next generation of devices by providing end-to-end support in design and development. From concept to realization, we ensure a seamless and comprehensive journey tailored to your needs.

Define Requirements

Our process begins with clearly defining the enclosure’s purpose and assessing key environmental factors such as temperature, humidity, dust, and water resistance.

- We determine the optimal size and shape based on component requirements.

- Technical specifications for all components are gathered and integrated into the design.

- Compliance with legal and industry standards is prioritized to ensure regulatory adherence.

Designing

With the foundational requirements in place, we move to the design phase, carefully considering manufacturability, aesthetics, and ease of assembly.

- A detailed analysis of material options is conducted to evaluate pros and cons.

- Using advanced CAD tools, we create precise 3D models, ensuring accurate dimensions and tolerances.

Testing

Once the design is complete, our in-house engineers perform rigorous testing to validate its performance under real-world conditions.

- Software tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are used for in-depth evaluation.

- If any issues arise, corrective measures are taken to refine and optimize the design.

Potential Feedback and Improvements

After successful testing, we incorporate valuable feedback to further enhance the design.

- Our experts analyze and implement iterative improvements to exceed expectations.

- The final optimized design is delivered in your preferred file format for seamless integration.

By combining innovation with precision, we ensure that your product is not only functional but also future-ready.

Final Thoughts

Selecting the right components for MCAD enclosure design is a crucial process that involves thorough research, consideration of technical specifications, compatibility, durability, and functionality.

By following a step-by-step guide, you can ensure the successful creation of an effective and reliable enclosure that meets the requirements of the electronic device while addressing any challenges that may arise during the design process.

Stay updated on our services—connect with our founder on LinkedIn: https://www.linkedin.com/in/chandra-thimma/recent-activity/all/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with GigHz to bring your most innovative design concepts to life. Our engineering CAD services streamline development, allowing you to focus on your big vision while we handle the technical precision.