How to Upgrade ECU Enclosure IP Rating Without Re-Molding

- Posted On:

- September 17, 2025

- Category:

- Mcad

There was this time when one of our client’s engineering team called us in a completely panic-stricken situation .

Apparently, their prototype ECU had just passed thermal and vibration tests but tragically failed during ingress protection. Now, the IP54-rated enclosure wasn’t cutting it anymore. Plus, their Tier 1 customer demanded complete IP67 compliance.

So, coming to their first question?

“Do we have to redesign and re-mold the entire housing?”

Well, nope! Not at all. Moreover, with the right tweaks and zero tool changes we were able to demonstrate how to upgrade ECU enclosure IP rating efficiently.

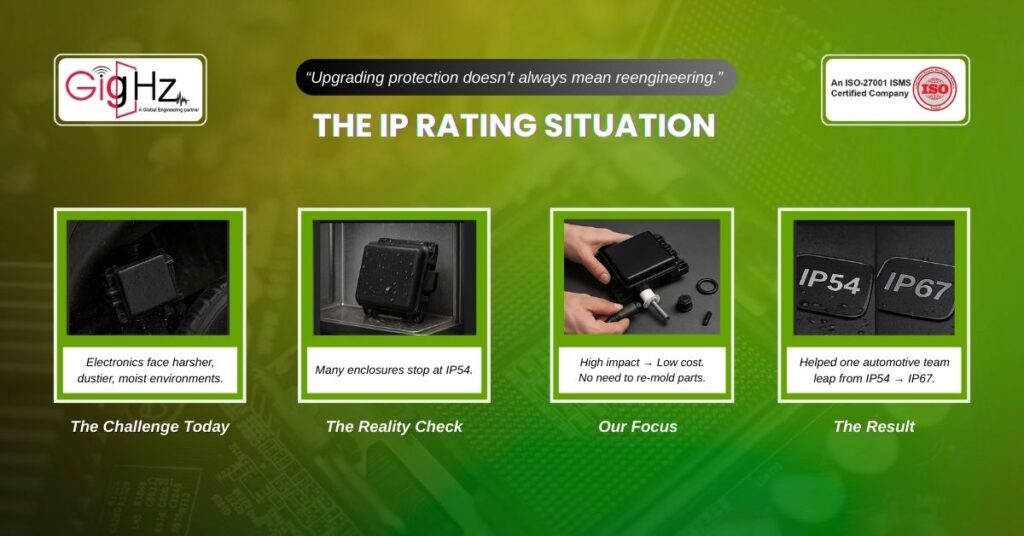

The IP Rating Situation

Now, this challenge isn’t rare these days.

As we all know that electronics today are pushed into quite harsher, dustier, moist- environments. However, the pressure to improve these protective measures collides with budget, tooling, and time constraints.

Also, going for a full reengineering of a part just to meet IP67 isn’t always a feasible option.

Now, that’s why we primarily focus on ECU enclosure waterproofing tips that offer high impact with low costing.

here’s how we helped one automotive team go from IP54 to IP67 and that too without re-molding a single part.

Case Study: The Fix That Saved $120K

- The Problem:

So, the client’s ECU was fixed near the underbody, exposed to immense water splashes and road debris. Evidently, its plastic housing was well-vented but very much vulnerable. Consequently, gaps near the gasket and cable entry points led to water ingress in pressurised wash tests.

- The Constraint:

Now, the injection mold tools were already built-in. Also, changing them meant weeks of delay and over $120K in new complete tooling.

- The Goal:

Fully, improve enclosure IP rating cost-effectively and seamlessly.

- Our Strategy:

Likewise, we decided for a complete step-by-step retrofit using proven ECU enclosure waterproofing tips backed by lab tests and real-time field use.

5 Changes That Delivered an IP67 Upgrade Without Re-Molding

1. Upgrade the Gasket Material

Clearly, the original enclosure used a very generic EPDM seal. So, we swapped it for a closed-cell silicone foam with better compression. Plus, we implemented and sealed it under a variable torque.

As a Result? There was Zero leakage even under simulated splash and submersion cycles.

2. Use a Compression Limiter

Now, the torque variation was very much distorting the entire gasket chamber . So, by adding stainless compression limiters in the screw bosses, we ensured consistent seal force which is very much critical for IP67 upgrade for electronic enclosures.

3. Add a Waterproof Vent

Then, the enclosure needed to breathe but shouldn’ t allow any water flow inside.

Plus, we added a waterproof ePTFE membrane vent which allows pressure equalization without compromising ingress protection.

Also, this is one of our top ECU enclosure waterproofing tips which is cheap, effective, and retrofittable.

4. Seal Cable Entry with Gel Grommets

On the other hand, the cables were routed through a press-fit rubber grommet, which failed under immense wash pressure. So, we switched it to a split gel grommet while making sure that it has an IP68 rating.

Bonus: it needed no housing modification or any modification.

5. Apply Surface Coatings

Besides, the mating flange had micro-imperfections causing severe leaks. Accordingly, a conformal silicone coating on the flange surface improved the micro-sealing performance without tool changes at all.

Consequently, all in one five of these steps helped us increase IP rating without re-molding keeping the original design intact.

6. Validate Materials & Components Early

Always validate gasket material, vent membranes, and coatings early in the design process. Early validation prevents last-minute surprises and reduces redesign costs.

7. Prioritize Integration & Consistency

Compression limiters, vents, grommets, and coatings must work together as a system. A uniform sealing and EMI-safe strategy ensures long-term durability and reliable compliance.

Bottom Line

So, summing up that after retrofitting just 20 pilot units with these changes, we ran them through standardized IEC 60529 IP67 testing. Evidently, everything got a clear perfect passing score to seal our QC mark.

On the other hand, the team avoided any serious mold changes. Most importantly, they met their customer’s compliance needs and protected their revenue stream.

As a consequence, this is the real-world power of smart design upgrades – proving that you can improve enclosure IP rating cost-effectively without a total redesign.

Likewise, we help engineers in improving enclosure IP rating cost-effectively without triggering expensive re-molding or redesign. Plus, we improve existing processes without triggering expensive re-molding or redesign.

Because IP compliance shouldn’t mean starting over! Sometimes, it just means starting smarter.

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.