How 3D Modeling Enhances Your PCB Layout and Prevents Design Errors

- Posted On:

- June 20, 2025

- Category:

- Mcad

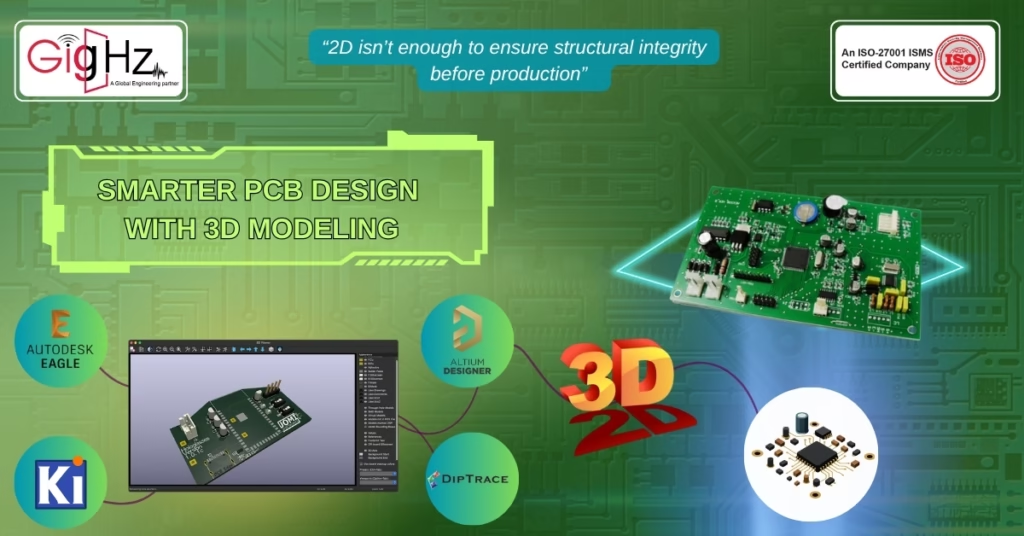

Nowadays, most engineers think their designs are complete once the layout’s done.

But the truth is that without utilizing any 3D modeling services, you cannot call your PCB to be read. Yes, It may look polished in 2D, but the moment it hits production or worse, in the mechanical integration. Eventually, structural integrity may degrade, leading to component failure.

And, that’s when the true costs start to emerge.

The Ultimatum: Why You Need More Than Just a Layout

In the contemporary market, product development cycles, mechanical and electrical teams can no longer work in isolation. Obviously, you can’t just afford to wait until the final assembly realizes that your heat sink clashes with a capacitor – Or worse that your connector is completely misaligned by not just 1mm but by 5 or more.

Now, that’s why 3D CAD modeling services are becoming highly mission-critical for companies across industries.

Likewise, with proper 3D modeling software, you can completely visualize your entire board within its enclosure. In addition, you will be able to proactively catch any significant issues like:

- Misplaced mounting holes

- Incorrect component heights

- Port alignment problems

- Cooling path conflicts

And the best part? You don’t have to wait at all until the prototype stage in order to fix these.

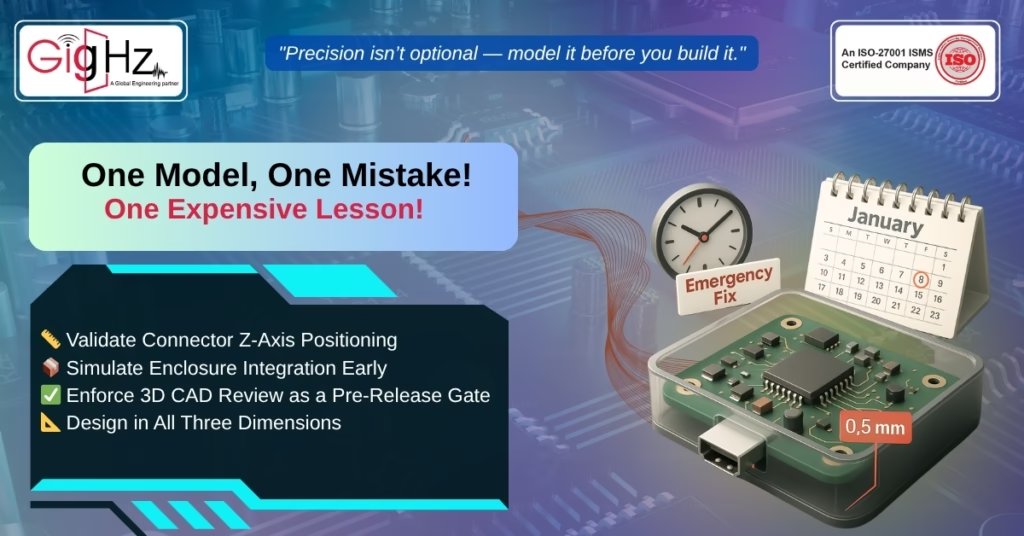

One Missed Model Nearly Cost Us a Product Launch

Now, allow me to tell you an interesting takeout from our experience.

Once, we had a client preparing for CES (Consumer Electronics Show, a major annual trade show organized by the Consumer Technology Association) finalizing their new IoT device. Everything looked perfect in the layout in the first place. Also, they skipped the 3D model to save time until the enclosure manufacturer called them to say:

“Your USB port sits 0.5mm too low to align with the case.”

Can you just imagine? With only just two weeks to go, the fix required an emergency board spin, fast-tracked shipping, and overnight assembly.

All because they didn’t bother to review it in a 3D modeling software before pushing it to production.

That’s why each and every project of ours undergoes full 3D CAD modeling before approval.

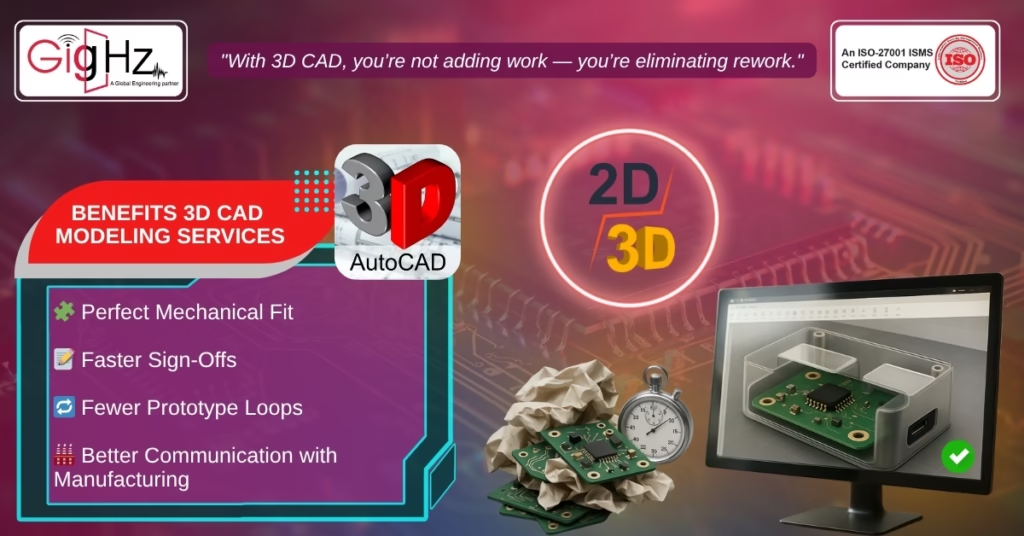

What Will You Gain from 3D CAD Modeling Services

So, without beating around here’s what utilizing 3D modeling to your workflow actually delivers:

- Perfect Mechanical Fit: Visualise how your board lives inside the product. So, no more room for any guessing.

- Faster Sign-Offs: Besides, when ECAD and MCAD teams speak the same visual language, the approvals get much swifter and seamless.

- Fewer Prototype Loops: Most importantly, you can pinpoint almost 95% physical design issues beforehand.

- Better Communication with Manufacturing: Also, a clear 3D model removes ambiguity, reducing back-and-forth during fabrication or assembly.

Meanwhile, with the current 3D modeling softwares, especially those that support ECAD–MCAD collaboration you’re not just adding steps — Rather, you’re just saving them.

Bottom Line

Summing up, if your team isn’t using any 3D CAD modeling services yet, then now is the time.

Yes, whether you’re working on a compact wearable or a full-scale industrial controller – 3D models are the missing link between design and reality.

Also, it’s never been easier to implement with modern tools and experienced providers.

Remember, your PCB layout might be done but it’s not fully complete until it works in the real world. Hence, utilizing any 3D modeling services for your designs will make sure it does.

To know more, contact us at info@gighz.net for a free consultation.

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.