How is a PCB Enclosure made to be rugged?

Hello there, tech-curious friends!

Have you ever held a device in your hand and wondered about the sturdy shell that protects its electronic brain? That’s what we call a PCB (Printed Circuit Board) enclosure, and when it’s particularly tough, we call it rugged.

Hello there, tech-curious friends!

Have you ever held a device in your hand and wondered about the sturdy shell that protects its electronic brain?

That’s what we call a PCB (Printed Circuit Board) enclosure, and when it’s particularly tough, we call it rugged.

Category :

Published Date :

January 18, 2024

Category :

Published Date :

January 18, 2024

Category :

Published Date :

January 18, 2024

So, what’s this ‘rugged’ all about?

Imagine this – a piece of technology is exposed to harsh conditions.

It could be extreme heat in a factory, corrosive liquids in a chemical plant, or heavy vibrations in a vehicle.

That’s when a rugged PCB enclosure steps in, acting like a superhero shield, keeping the delicate electronics safe and functional.

But the question is – what makes a PCB enclosure so rugged? What’s its secret sauce?

Firstly, it all comes down to resilience.

A rugged PCB enclosure is built to withstand a variety of harsh conditions, including extreme heat, corrosive liquids, intense vibration, and shock.

These enclosures are quite literally designed to weather storms, both metaphorical and literal!

Well, it’s a fascinating blend of science and engineering, and today, we’re going to uncover just that.

So, let’s dive into the world of rugged PCB enclosures and explore how they stand tall against all odds.

Ready? Let’s get started!

When it comes to creating printed circuit board (PCB) enclosures, there are a lot of factors to consider in order to make them as rugged as possible, especially if they will be used in harsh environments.

Whether you are looking for an enclosure for industrial, military, or aerospace applications, ruggedness is a key requirement.

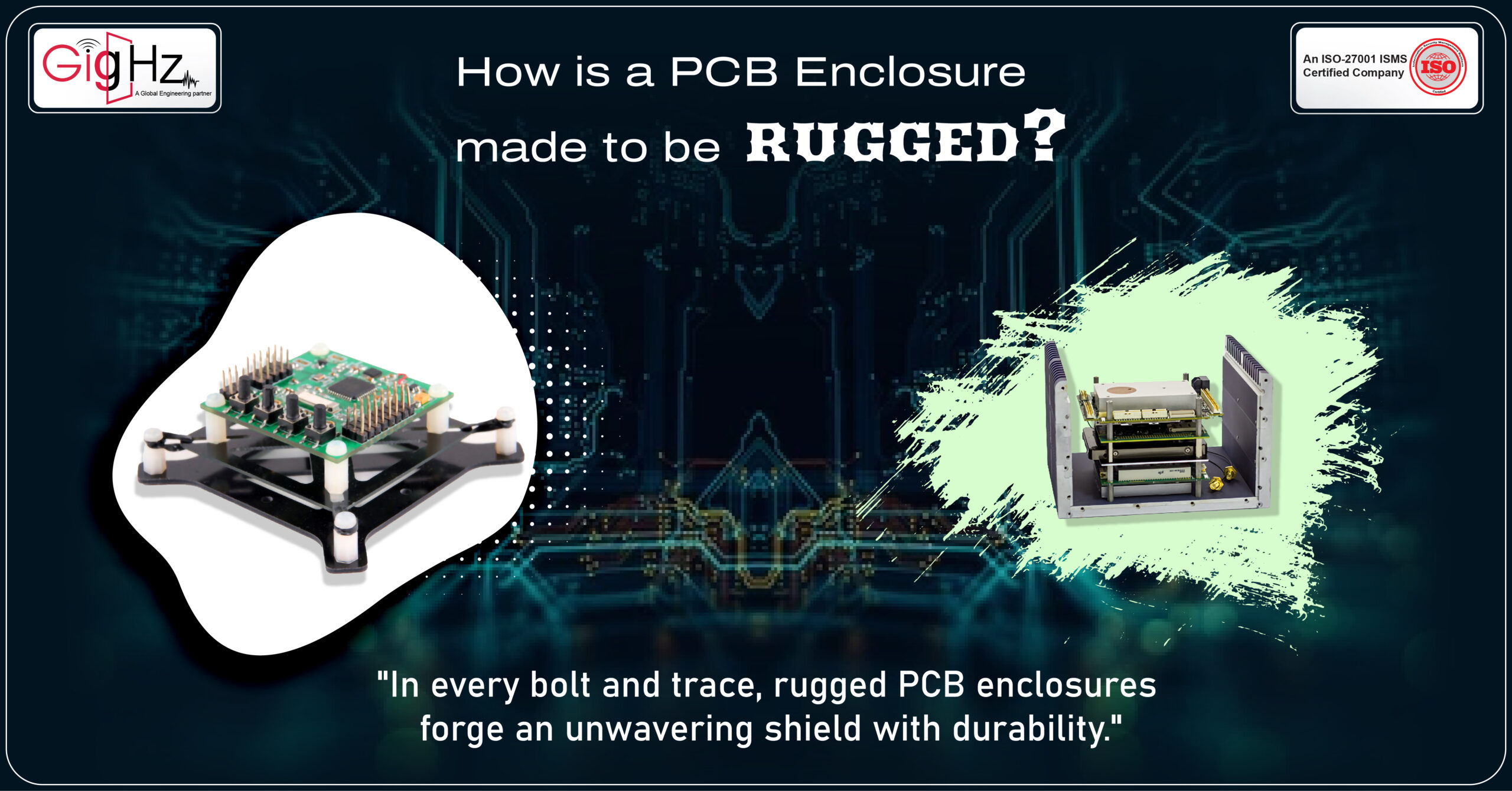

Choosing the Perfect Material for Durability and Performance

So, you’re on a mission to create a tough-as-nails PCB enclosure, huh?

Well, step one is to get your hands on the right materials.

This isn’t just any material; it needs to endure extreme temperatures, resist destructive chemicals, absorb relentless vibrations, and still remain lightweight and user-friendly.

Aluminum often emerges as the star player in this field. It’s renowned for its superior heat dissipation properties and remarkable resistance to corrosion. But don’t be disheartened if aluminum doesn’t meet your specific requirements, plenty of other materials are waiting in the wings. Stainless steel and carbon fiber are excellent alternatives, noted for their strength and durability.

Additionally, various plastic types like polycarbonate, ABS, and PVC offer a balance between toughness and flexibility.

But here’s the catch, each material has its unique set of advantages and limitations. For instance, while aluminum is excellent for heat dissipation, it may not be the best choice for radio frequency (RF) sensitive applications due to its electrical conductivity. Similarly, although plastics like ABS and PVC offer great versatility, they might lack the mechanical strength required in high-stress environments.

Therefore, understanding the specific needs of your application is crucial. You need to consider factors like the operating environment, the level of protection needed, and the physical and electrical requirements of the enclosure. Only then can you zero in on the perfect material for your rugged PCB enclosure.

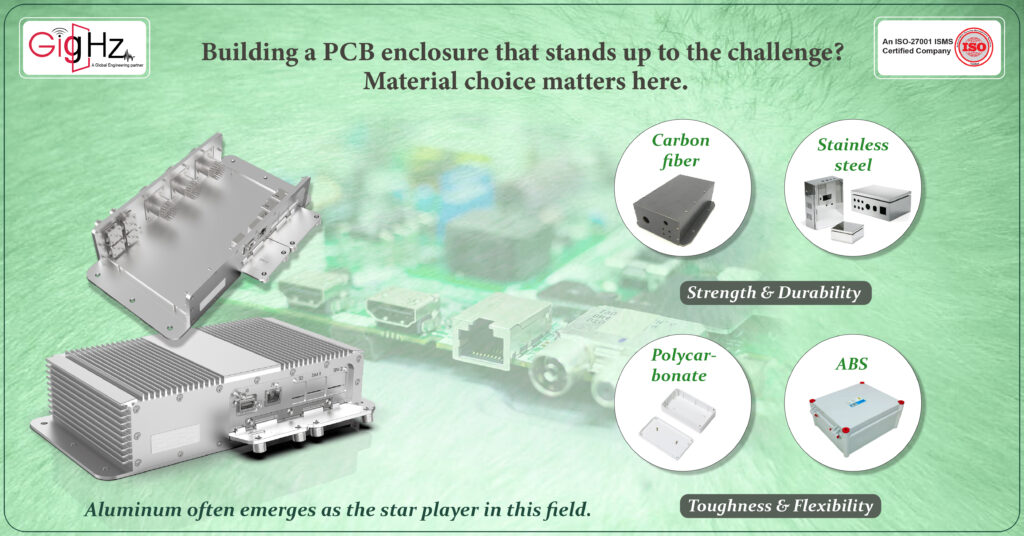

Innovative Design Approaches for Unstoppable Enclosures

Another key factor that goes into creating a rugged PCB enclosure is, design.

When designing the enclosure, you need to think about how and where it will be used.

The design needs to be adapted to the specific use-case and environment of the enclosure.

Firstly, consider the environmental conditions the enclosure will encounter. If it’s likely to face dust, moisture, or debris, incorporating protective features such as gaskets, seals, and fasteners is paramount. These features help in maintaining the integrity of the enclosure by preventing the ingress of harmful elements.

High-temperature environments pose another challenge. In such cases, the design should facilitate effective heat dissipation. This can be achieved by implementing heat sinks, ventilation slots, or even fans in the design. This ensures that the electronics within the enclosure remain cool and function optimally.

Shock and vibration are other factors that need to be accounted for, especially in industrial or automotive applications. Here, special mounting techniques or reinforcement strategies might be necessary. For instance, rubber shock mounts or vibration dampers can be used to absorb the energy from shocks and vibrations, thereby protecting the PCB within.

Remember, the design of your PCB enclosure plays a pivotal role in its ruggedness. By considering the specific demands of your application and incorporating suitable design features, you can create a truly unstoppable PCB enclosure.

Sealing the Deal: Coatings and Finishes that Make All the Difference

To truly fortify your PCB enclosure, coatings and finishes can serve as the final line of defense. These protective layers shield your enclosure against corrosion, physical abrasion, and various forms of damage, ultimately enhancing its durability.

One of the leading contenders in this domain is epoxy. Known for its superior toughness, epoxy coating forms a hard, protective layer that excels in chemical resistance. This makes it an ideal choice for enclosures that will be exposed to harsh chemical environments.

Another outstanding option is powder coating. Not only does it provide a durable finish that resists scratching, chipping, and fading, but it also offers an aesthetically pleasing look. Powder coatings are also environmentally friendly as they contain no solvents and emit negligible, if any, volatile organic compounds (VOCs).

But the list doesn’t end there. Anodizing, a process used mainly for aluminum enclosures, provides a hardened surface that’s resistant to wear and corrosion. Electroplating, on the other hand, deposits a thin layer of metal onto the enclosure, providing excellent corrosion resistance and electrical conductivity.

Lastly, painting, while often used for aesthetic purposes, can also offer protection against environmental factors like UV radiation and moisture.

The right coating or finish can significantly enhance the ruggedness of your PCB enclosure. By considering the specific challenges your enclosure will face, you can select the most suitable protective layer and truly seal the deal on its durability.

Test, Refine, Conquer: Ensuring Top-Notch Quality Control

Once a PCB enclosure has been designed and manufactured, it is important to test and inspect it thoroughly to ensure that it meets the required standards.

High-quality rugged enclosures must undergo a series of stringent tests. Shock and vibration testing, for instance, is vital especially for enclosures destined for high-movement environments like vehicles or machinery. This test simulates the physical stress the enclosure might encounter, ensuring it can maintain its integrity under such conditions.

Temperature cycling is another essential test. It subjects the enclosure to extreme temperature fluctuations to assess its thermal performance and ensure it can effectively protect the PCB from overheating or freezing.

Exposure to harsh environmental conditions, such as humidity, dust, and corrosive chemicals, is also part of the testing process. These tests help to verify the enclosure’s resistance to these elements and validate its IP (Ingress Protection) rating.

Quality control procedures are equally important. They ensure that each enclosure is manufactured consistently and adheres to the required specifications. Procedures may include visual inspections, dimensional checks, or even functionality tests.

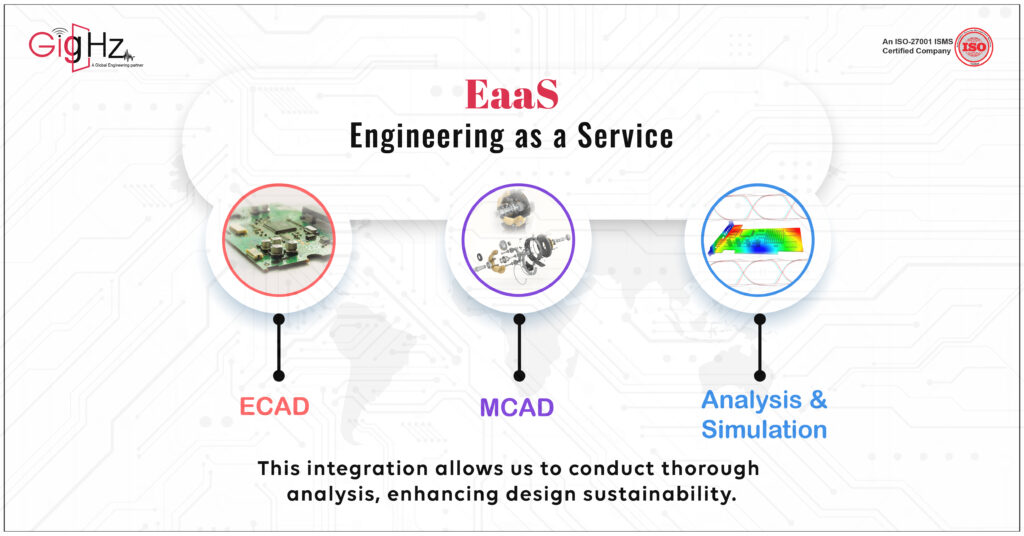

Our Notable Upgrade: Engineering as a Service (EaaS)

You know, as the need for advanced and integrated engineering solutions keeps soaring, our Engineering as a Service (EaaS) are really stepping up the game.

We’re harnessing the power of ECAD, MCAD, and Analysis & Simulation. This gives us a great position to be frontrunners in this industry.

What’s really cool is that we offer a full package, covering every single step of the engineering process.

And honestly, it’s this kind of approach that’s going to shape the future of our engineering.

It’s exciting stuff!

Why we do?

We challenge our Engineering capabilities with emerging technologies to keep your time and cost in control, thereby transforming product design with human touch quality.

Conclusion

It is clear that creating a rugged PCB enclosure requires discipline in both the design and manufacturing stages. With thoughtful attention to detail, an efficient and durable PCB enclosure is a process that is achievable for any designer. Taking into account aesthetics, waterproofing, shielding, rigidity, mounting, and durability are just some of the important considerations when designing a rigid PCB enclosure.

Additionally, choosing a reliable manufacturer with the right expertise is key in ensuring quality control from start to finish. All these elements taken together make for an ultimately successful ruggedization process.

As technology within the industry continues to evolve, it’s exciting to keep up with trends like providing more standardized electrical enclosures and using transition mount designs for increased flexibility going forward.

Now that you have learned more about how to create a robust PCB enclosure for your project — now it’s time to take action!

Research GigHz website today and find the perfect PCB enclosure that meets all of your requirements and bring your project one step closer to success www.gighz.net