The Real Reason Prototypes Fail Before Investor Demos (for University Teams)

- Posted On:

- January 8, 2026

- Category:

- Ecad

Ten minutes before your investor demo, everything stops working. Frustratingly, this happens again and again, even to the most promising university teams.

Why does it happen? Let’s decode the real reasons prototypes fail before they even get a chance to shine.

When university teams prepare for investor demos, the focus is often on showcasing the idea — the new circuit, clever design, or smart integration.

But investors care about more than just ideas; they want to see a prototype that works reliably.

A device that only functions perfectly in the lab rarely inspires confidence.

Most student prototypes fail not because the idea is weak, but because the design is not fully ready.

Electrical issues, software bugs, or poor hardware-software integration can make the system fail.

What seems like a small glitch during a demo often stems from skipped tests, missing reviews, or untested real-world conditions.

Investor demos put prototypes under real stress — repeated power cycles, real-life loads, and the need to perform consistently.

If the prototype is unstable, even the best idea can appear unready.

In this article, we’ll explore the main technical reasons prototypes fail before demos and how university teams can approach their designs with the care and rigor of professional engineering teams.

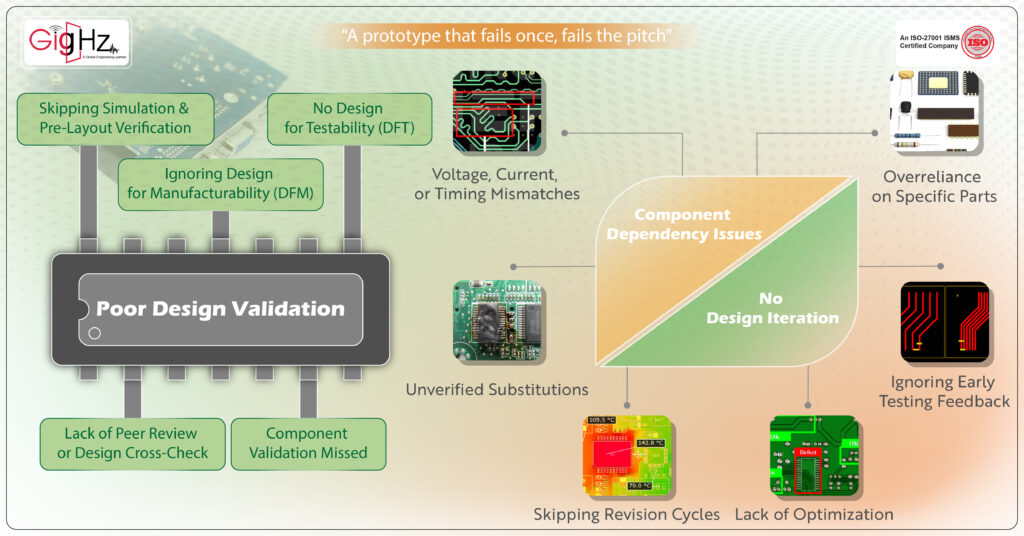

1. Poor Design Validation

a. Skipping Simulation & Pre-Layout Verification

- They directly move from schematic to PCB layout without simulating signal flow, current draw, or timing.

- Example: The microcontroller resets when the motor starts — because no power integrity or decoupling analysis was done.

b. Ignoring Design for Manufacturability (DFM)

- Track widths, spacing, hole sizes, or silkscreen overlaps don’t meet fabrication standards.

- Result: PCB vendor rejects the Gerbers or produces faulty boards.

c. No Design for Testability (DFT)

- Teams don’t include test points or debugging headers.

- During testing, if something fails, it’s hard to isolate the problem — wasting critical demo time.

d. Component Validation Missed

- Parts selected from random online sources (e.g., Arduino-level components) without checking datasheet specs, footprints, or supply voltage tolerance.

- Leads to burnt ICs, unstable circuits, or mismatched footprints during soldering.

e. Lack of Peer Review or Design Cross-Check

- One student designs the schematic and layout alone.

- No cross-check for net mismatches, floating pins, or wrong pin mapping.

- Result: Errors only discovered after the prototype arrives.

2. Component Dependency Issues

a. Overreliance on Specific Parts

- Teams often select certain components without checking for availability, lead time, or compatibility with other parts.

- Example: A specific sensor is chosen without checking suppliers. When it goes out of stock, the prototype halts.

b. Voltage, Current, or Timing Mismatches

- Components may not match each other’s electrical requirements.

- Example: Using a low-current voltage regulator with a high-power motor driver can cause voltage drops, resets, or overheating.

c. Unverified Substitutions

- Replacing components without confirming datasheets, footprints, or tolerances can lead to soldering errors or circuit malfunction.

- Outcome: Burnt ICs, damaged traces, or intermittent failures during demos.

3. No Design Iteration

a. Skipping Revision Cycles

- Teams sometimes finalize the layout after the first design without multiple iterations.

- Consequence: Signal routing, thermal distribution, and board size optimization are neglected.

b. Ignoring Early Testing Feedback

- Prototype issues that appear during initial testing are not used to improve the next revision.

- Example: Trace widths too small for required current, thermal hotspots, or noisy high-speed signals remain unresolved.

c. Lack of Optimization

- Without iterative improvements, the design remains unrefined for manufacturability, reliability, and cost.

- Impact: The first prototype often fails, wasting time and resources before demos or competitions.

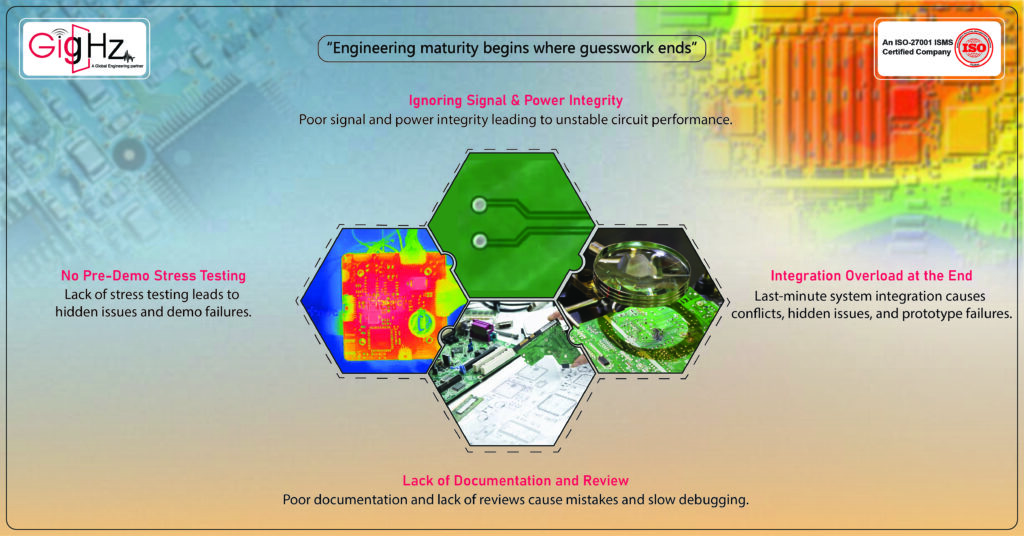

4. Ignoring Signal & Power Integrity

a. Poor High-Speed Trace Design

- Long traces without controlled impedance, sharp bends, or mismatched lengths cause reflections and timing issues.

- Example: High-speed communication lines fail intermittently or produce corrupted data.

b. Ground and Power Plane Problems

- Split or incomplete ground planes and distant decoupling capacitors create voltage ripple and unstable power delivery.

- Outcome: Microcontrollers, sensors, or drivers may reset unexpectedly under load.

c. Lack of Pre-Layout Analysis

- Teams often skip power integrity and return-path analysis before routing.

- Result: Boards appear functional in short tests but fail under real operational conditions or continuous use.

5. Integration Overload at the End

a. Last-Minute System Integration

- Teams often wait until all modules are individually built before combining them.

- Consequence: Multiple subsystems may conflict, causing unexpected failures that are hard to trace.

b. Complex Dependencies

- Hardware and firmware are integrated without verifying interfaces or timing compatibility.

- Example: A motor control module interferes with sensor readings because both draw from the same poorly decoupled power line.

c. Troubleshooting Bottlenecks

- Integrating everything at the last moment leaves little time to isolate or fix issues.

- Outcome: Prototype malfunctions appear right before demos or competitions.

6. Lack of Documentation and Review

a. Missing Design Records

- Schematics, PCB layouts, BOMs, and test procedures are often incomplete or missing.

- Consequence: Team members cannot reproduce or debug the design efficiently.

b. No Peer or Mentor Review

- Without cross-checks, mistakes such as net mismatches, wrong footprints, or signal conflicts remain unnoticed.

- Example: A sensor pin is miswired, causing erratic readings that are only discovered on the assembled board.

c. Knowledge Gaps During Handoffs

- When team members leave or new members join, undocumented design choices create confusion.

- Impact: Debugging, maintenance, or upgrades become slow and error-prone.

7. No Pre-Demo Stress Testing

a. Skipping Extended Operation Tests

- Boards are often tested only briefly in the lab, not under realistic continuous loads or environmental conditions.

- Consequence: Issues like overheating, voltage drops, or firmware crashes go unnoticed.

b. Ignoring Edge Cases

- High-speed communication, power surges, or sensor noise conditions are not tested.

- Example: The microcontroller resets when multiple sensors are active simultaneously.

c. Last-Minute Failures

- Without stress testing, problems only appear during demos or competitions.

- Outcome: Teams face embarrassing failures in front of judges or investors, despite functional lab prototypes.

Bottom Line

Prototypes fail not because students lack ability, but because they skip structured engineering steps.

True reliability comes from consistent validation, dependable components, iterative testing, signal integrity control, early integration, disciplined documentation, and real-world stress evaluation.

Investor demos test more than creativity — they test engineering maturity. A stable, repeatable prototype reflects professionalism.

When every subsystem works predictably, investors see readiness for scaling, not just experimentation.

University teams that apply these principles transform their approach from trial-based building to professional engineering.

And when that shift happens, demo day stops being a risk — it becomes proof of design strength and technical confidence.

Book a Call. Schedule a Free Consultation now https://calendly.com/gighz/30min

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.