5 Design Tips to Make Your MVP a Viable, Investor-Ready Product

- Posted On:

- December 29, 2025

- Category:

- Ecad

Every startup begins with an idea.

But turning that idea into something an investor can see, touch, and believe in — that’s the real test.

Your MVP (Minimum Viable Product) isn’t meant to be perfect.

It’s meant to validate your concept — to prove that your design works technically, that it can be built efficiently, and that it has the potential to scale commercially.

In hardware, especially in PCB-based product development, that line between a “prototype” and a “product” defines your next funding milestone.

A messy proof-of-concept might work on your lab bench, but investors are looking for something that feels real — an early version that reflects engineering discipline and manufacturing foresight.

Let’s walk through how to design an MVP that feels like a product, not a prototype

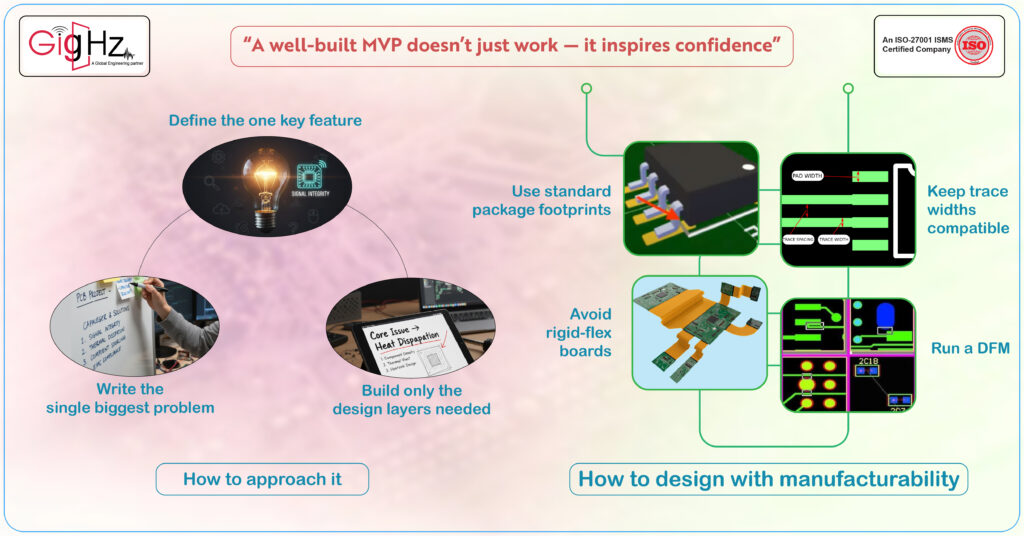

1. Start with the Core Function — Not the Full Feature List

When designing your MVP, your goal isn’t to fit everything your final product will have.

Your goal is to prove that the main function your idea promises actually works — consistently, safely, and predictably.

Here’s how to approach it:

- Write down the single biggest problem your product solves.

- Define the one key feature that directly delivers that solution.

- Build only the design layers needed to make that feature stable and testable.

For example, if your product is a smart power controller, the MVP doesn’t need a mobile app or a cloud dashboard yet.

It just needs reliable power sensing, switching, and safety logic.

Many teams waste early months chasing secondary features instead of proving the core performance.

But in PCB design, every extra circuit, interface, or sensor adds new chances for failure.

Design Insight:

Simplify your schematic to its minimum working block. Avoid stacking advanced features (Wi-Fi, BLE, sensors) until your base circuit is verified and stable. This keeps your testing clear and your prototype focused.

2. Design for Manufacturability — Even at Prototype Stage

A common mistake: treating MVPs like one-off lab experiments.

Investors, however, don’t just look for innovation — they look for repeatability and manufacturing readiness, even in the first version.

Here’s how to design with manufacturability in mind:

- Use standard package footprints and easily available components.

- Keep trace widths, clearances, and layer stack-ups compatible with low-cost PCB fabs.

- Avoid exotic parts or rigid-flex boards unless absolutely required.

- Run a DFM (Design for Manufacturability) check before ordering.

When your board can be fabricated, assembled, and tested using standard processes, you’re sending a strong message: this design can scale.

Design Insight:

Design with mass-producible habits from day one. Even if you only build five prototypes, make them like you’re building fifty.

You’ll save redesign time later and demonstrate technical foresight to investors.

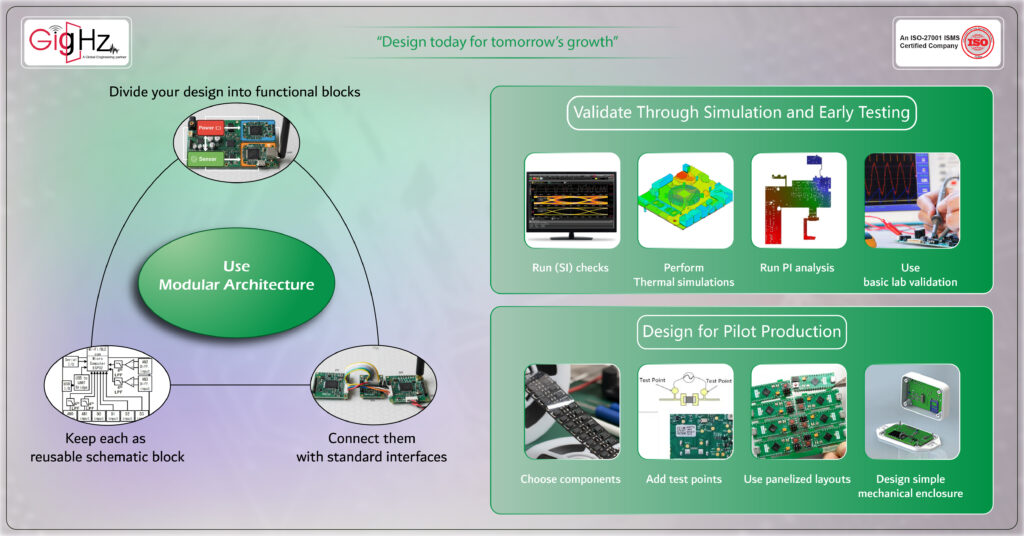

3. Use Modular Architecture — Design Like It’s Going to Grow

An MVP that scales easily is an MVP that wins investor trust.

Why? Because it shows your design isn’t just a one-shot demo — it’s a platform that can evolve into multiple products.

Here’s how to build modularly:

- Divide your design into functional blocks — Power, MCU, Communication, Sensors, etc.

- Connect them with standard interfaces (I²C, SPI, UART) instead of hardwiring everything.

- Keep each section as a reusable schematic block.

This makes it possible to:

- Swap or upgrade parts without full redesigns.

- Add new features in later versions (V2, V3, etc.) with minimal disruption.

- Debug or test individual modules faster.

Design Insight:

Think of each block as plug-and-play. A modular architecture doesn’t just help your engineers — it helps investors visualize a roadmap.

It tells them, “This product isn’t static. It’s designed to evolve.”

4. Validate Through Simulation and Early Testing

An investor-ready MVP isn’t just working — it’s verified.

Too many startups skip this step, assuming that if it powers on, it’s “good enough.”

But investors — especially in hardware — want proof that your design has technical depth and reliability.

Here’s how to validate your design early:

- Run Signal Integrity (SI) checks if you’re dealing with high-speed signals.

- Perform Thermal simulations to predict hotspots and manage component placement.

- Conduct Power Integrity analysis to ensure steady voltage across all loads.

- Use basic lab validation — oscilloscopes, thermal cameras, or even simple JTAG tests — to verify assumptions.

When you show actual simulation screenshots or testing graphs in a pitch deck, you’re not just showing results.

You’re showing that your engineering process is data-driven — that your team doesn’t rely on guesswork.

Design Insight:

Bring simulation visuals or reports to investor meetings. They communicate technical maturity better than words. They show your design choices are intentional, not accidental.

5. Design for Pilot Production — Not Just a Working Board

Your MVP’s final goal is not to sit on your lab desk — it’s to be built, tested, and shown in real conditions.

So even while designing your first working version, think about pilot production.

Here’s how:

- Choose components available in tape/reel packaging for automated assembly.

- Add test points for in-circuit and functional testing.

- Use panelized layouts so multiple boards can be fabricated in one batch.

- Design a simple mechanical enclosure or casing that presents the product professionally.

A functional PCB inside a neat enclosure changes perception instantly. Investors stop seeing a “test board” and start seeing a “ready-to-scale product.”

Design Insight:

Even a simple 3D render or enclosure prototype can shift how investors perceive your stage. It signals readiness — that you’re not just proving function, but preparing for production.

Bottom Line

An MVP (Minimum Viable Product) success isn’t about doing everything.

It’s about proving the right things — functionality, manufacturability, and scalability.

When your MVP is designed with:

- A clear core function

- Manufacturability

- Modularity

- Validation

- Pilot readiness

—you don’t just show an idea. You show a product that’s real, reliable, and ready to grow.

And that’s what turns an investor’s reaction from “Nice concept” to “Let’s invest.”

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.