How to Cut PCB Costs with BOM Optimization: Stop Overpaying for Components

- Posted On:

- June 10, 2025

- Category:

- Ecad

Clearly,

If your PCB design team or someone from procurement has not looked at your BOM (Bill of Materials) recently –

Then, you are probably bleeding unnecessary expenses and resources.

With the prices constantly shifting globally and parts rapidly going obsolete, such instances are quietly eating into your margins.

Now, this is where BOM management services come in!

Accordingly they help you in avoiding any hefty expenses and supply chain gaps to last-minute sourcing chaos.

Besides, standing in 2025 – it’s not just helpful but crucial to thrive in today’s business landscape.

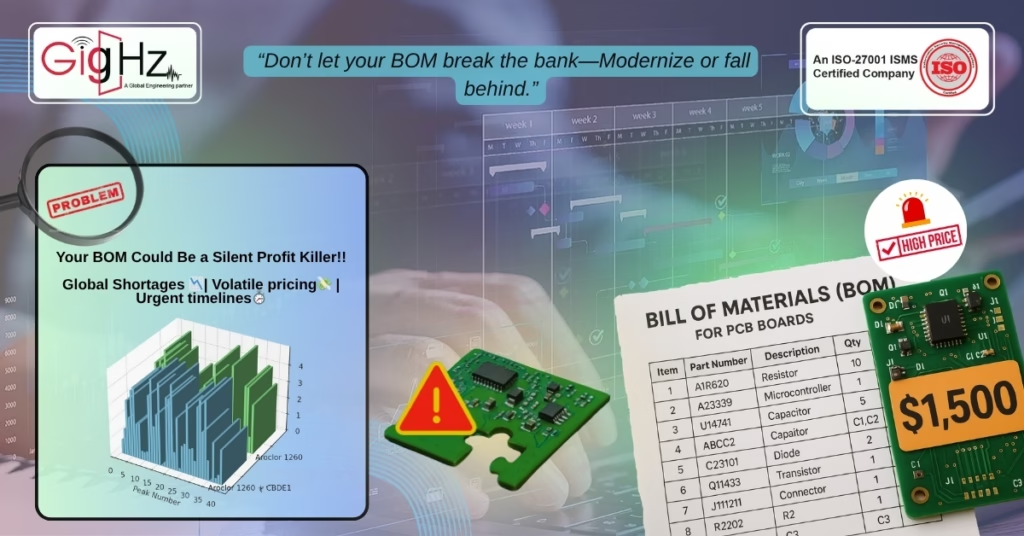

The BOM Problem No One Talks About

Over the last few years, certain transformations have changed the way engineers and sourcing teams manage their hardware parts. Between global shortages, volatile pricing, and growing pressure to ship faster – your BOM can become a silent profit killer

Now, you might think and assure yourself that your parts list is fine. But if it hasn’t been reviewed or optimized recently, chances are you’re either:

- Using outdated or overpriced parts,

- Missing cheaper, more reliable alternatives, or

- Risking production delays due to obsolete components.

Apparently, this is where electronic component lifecycle management and smart sourcing strategies make the difference. Yet, many teams are still using static spreadsheets or outdated procurement systems to track high-value components.

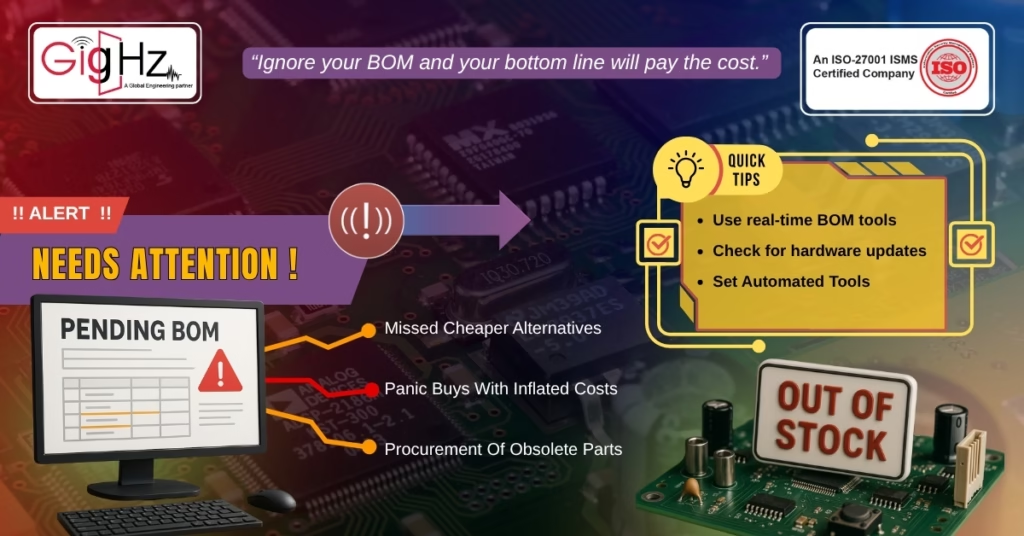

How Poor BOM Management Hurts Your Bottom Line

Now, let’s make this completely real!

Assume that your BOM has not been updated in the last 6 months. Meanwhile, five of your components have become rare to be found. Plus, your sourcing team is forced to panic-buy from secondary suppliers and that too at a premium price. Unbelievable right?

On the other hand, your design team is left with no choice other than to use overstocked parts or the ones getting discontinued.

The results? Well, you can see it for yourself:

- Missed cost-saving alternates.

- High-priced buys driven by last-minute urgency.

- Wasted time searching for parts no longer available.

Moreover, without a proper component engineering outsourcing or electronic parts procurement services, you’re not just overpaying—you’re flying blind.

Real-World Example

A startup in the IoT landscape learned this the hard way! With a tight launch deadline, they didn’t do a final BOM sweep.

Consequently, just two weeks before the assembly session, their main microcontroller went out of stock. Then, they had to scour it from various sources from three different vendors at a double price. By the time the product shipped, they already lost 18% of their profit margin — All due to a preventable sourcing issue.

Now, this is exactly where component engineering consulting could have made a difference. Likewise, the right partner would’ve flagged the risk early, recommended alternates, and preserved their margins.

BOM Optimization Strategies That Work

So, coming to the best part! You don’t need to overhaul your entire design process to save money. Instead, all you need is some smarter BOM practices in your operations.

Let’s see how to make that happen:

Use Cross-Reference Tools

Yes, automated tools can instantly suggest equivalent parts and that often at a better price or from more reliable suppliers. Likewise, this is a must-have for effective electronic component lifecycle management.

Design with Flexibility

Now, wherever it’s possible, include multiple footprints or part numbers. Consequently, this will allow your sourcing team to pivot quickly if a preferred part becomes unavailable. Also, it’s a core part of electronic component redesign services, where agility reduces long-term risk.

- Keep BOMs Live and Synced

Finally, your BOM should be a living document! Definitely not a static file. Most importantly, make sure that you sync regularly with suppliers, update lifecycle statuses, and remove obsolete parts before they cause production hiccups.

Bottom Line

Summing up, you don’t need to justify high costs or last-minute sourcing stress as “just part of the job.” process. Evidently, with smarter BOM strategies and support from reliable electronic parts procurement services – you can cut costs, reduce risk, and build more resilient products.

Therefore, it’s time to put a stop to outdated BOMs from draining your resources. Act now, before it’s too late! Reach out to us at info@gighz.net for a free consultation.

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.