4 Tips for PCB Component Obsolescence in a Shortage Market

- Posted On:

- October 9, 2024

- Category:

- Ecad

PCB Component Obsolescence

When we bought our house years ago, we loved the unique light fixtures scattered throughout.

But now, as incandescent bulbs are replaced by LEDs, finding bulbs that fit these fixtures has become a challenge.

We’re left choosing between unattractive, mismatched bulbs or stumbling around without proper lighting.

Eventually, we’ll need to replace these fixtures, but for now, we’re stuck with the options available.

Similarly, in electronics, things change over time.

Just as light bulbs are updated, the components used in circuit boards also get replaced with newer versions.

When a component you rely on is discontinued, redesigning the circuit board to fit the new part can be costly and time-consuming, especially with the required testing.

In automotive PCB design, each component plays a crucial role in ensuring that the vehicle’s electronic systems function reliably and efficiently.

The failure of a single part can lead to significant safety risks, making the sourcing of high-quality, reliable components a top priority during the PCB design process.

In the current global supply chain, the availability of specific components is a significant concern.

The global shortage of semiconductor chips, driven by factors such as increased demand for consumer electronics and supply chain disruptions, has had a profound impact on the automotive industry.

This shortage affects critical components like microcontrollers, power semiconductors, and sensors, all of which are integral to modern automotive PCB designs.

The unavailability of these parts can delay production, increase costs, and force design changes, underscoring the importance of strategic sourcing and supply chain management.

Here are some simple tips to manage component obsolescence and avoid getting stuck in a tough spot.

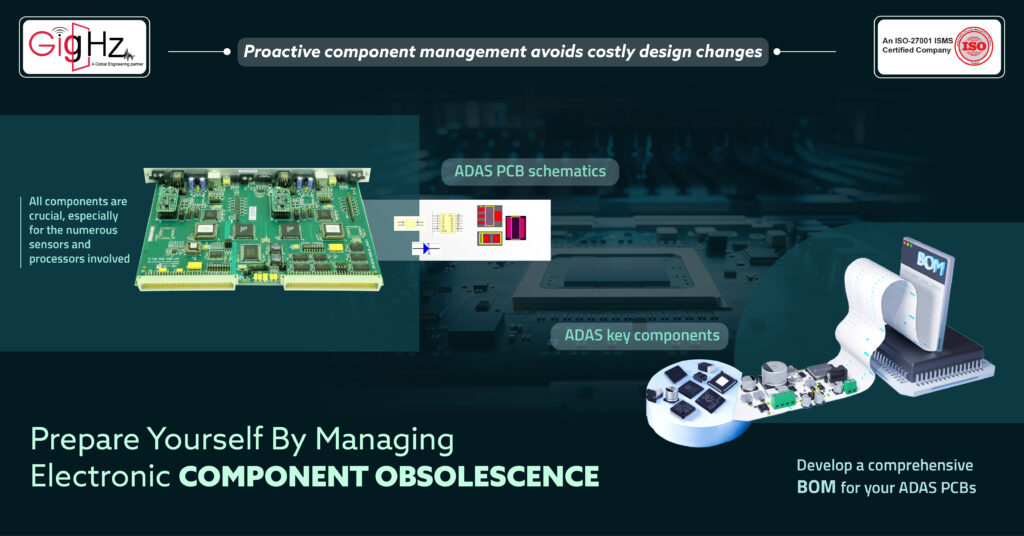

Prepare Yourself by Managing Electronic Component Obsolescence

To effectively manage component obsolescence in Advanced Driver Assistance Systems (ADAS) PCB design,

- Ensure that your ADAS PCB schematics are clear and well-organized. Accurate and readable markings and labels for all components are crucial, especially for the numerous sensors and processors involved. Update legacy designs with precise and current markings to avoid confusion and errors in new ADAS designs.

- Develop a comprehensive Bill of Materials (BOM) for your ADAS PCBs. Since ADAS components can be specialized and complex, older designs might lack essential details. Regularly review and update your BOMs to ensure they include all necessary specifications, making it easier to find and replace components as needed.

- Given the current shortages in semiconductor components, maintain close contact with your suppliers and distributors. They can provide updates on the availability of critical ADAS parts and help you plan for potential shortages. Partnering with a PCB contract manufacturer can also be advantageous, as they often have established relationships in the supply chain and can offer additional support.

- For critical ADAS designs, actively monitor the availability of key components. Leverage your network of suppliers and distributors to stay informed about potential shortages and supply issues. Collaborate with your PCB contract manufacturer’s team to track parts and address any potential problems proactively, ensuring you’re prepared for any supply disruptions.

4 Tips for PCB Component Obsolescence in a Shortage Market

1. Update Your Automotive PCB Design Libraries Regularly

The ABS control module is a vital component in modern vehicles, ensuring safety by preventing wheel lock-up during braking. Over time, certain microcontrollers and sensors used in these modules can become obsolete. For instance, an older model of an ABS control module may have used a specific pressure sensor that is now discontinued.

To address this, regularly update your PCB design libraries to reflect the latest components. Tools like Allegro Design Entry or KiCad can help you stay current with the latest parts. If the original pressure sensor is obsolete, update your library with newer sensors that meet the same specifications.

This proactive approach ensures that you can quickly find suitable replacements and integrate them into your designs without compromising the module’s functionality.

2. Carefully Review Copied Circuitry

When adapting or reusing circuitry from previous ABS control module designs, there is a risk of inheriting outdated or obsolete components. For instance, if an older ABS design was copied for a new model but included an obsolete analog-to-digital converter (ADC), this could impact the new module’s performance.

Perform a thorough review of the copied circuitry to ensure all components are up-to-date and available. Verify that the ADC or any other crucial component in the design is still in production and meets current performance standards.

Replacing obsolete parts with current equivalents ensures that the new ABS control module maintains high performance and safety standards.

3. Conduct Regular BOM Reviews

The Bill of Materials (BOM) for an ABS control module can include components that have been phased out or are no longer readily available. This can cause delays in manufacturing or issues in sourcing replacement parts.

Regularly review and update the BOM during the design and production phases. This review should identify any obsolete components and ensure that all parts listed are accurate and available. Collaborate with your PCB contract manufacturer to validate component availability and get the best prices.

If an older component like a specific MOSFET is no longer available, the BOM review will help you find a compatible replacement, ensuring a smooth production process.

4. Implement Component Lifecycle Management

The ABS control module uses various components with different lifecycles. Some parts might be nearing obsolescence, affecting the long-term viability of the module.

Use a component lifecycle management system to track the status and availability of each part. Tools like Octopart or Silicon Expert can provide insights into component lifecycle stages and help you find alternatives before components become obsolete.

For instance, if a critical component in the ABS module is about to be phased out, the lifecycle management system will alert you to start sourcing replacements, ensuring the module remains functional and compliant with safety standards.

Final Thoughts

Effective obsolescence management is crucial for navigating the complex life cycle of electronic products, particularly in the electronics industry.

As printed circuit boards (PCBs) play a pivotal role in the functionality of these products, design teams must address potential obsolescence risks during the design phase.

By leveraging management software to track parts obsolescence, manufacturers can mitigate the risk of obsolescence and ensure a smoother transition from EOL (end-of-life) notifications to new designs.

To know more insights, reach our experts,

Schedule a Call. Book a free consultation now. https://calendly.com/gighz/30min

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.