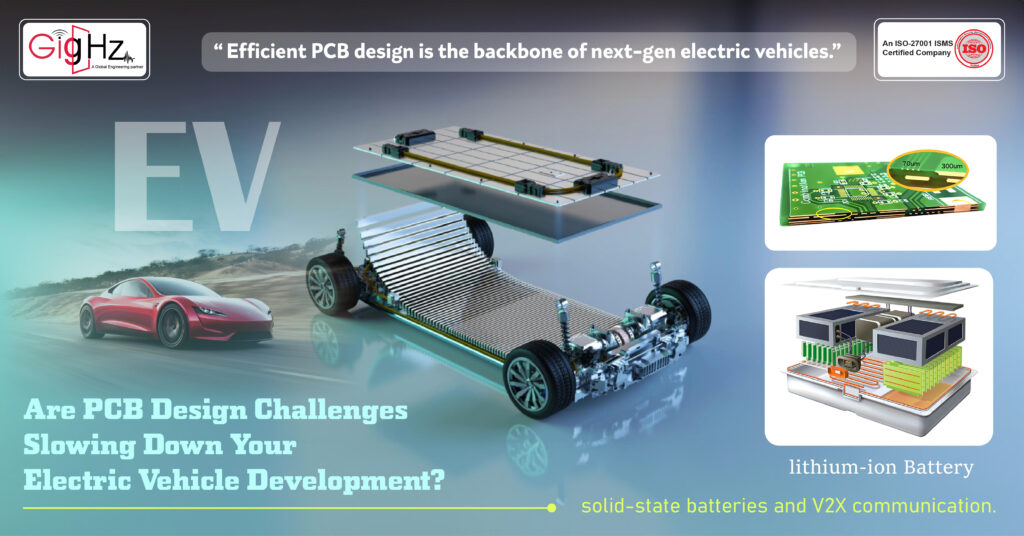

Are PCB Design Challenges Slowing Down Your Electric Vehicle Development?

- Posted On:

- October 16, 2024

- Category:

- Ecad

PCB Design Challenges

Early electric vehicles (EVs) used basic battery systems and simple wiring.

PCBs, as we know them, didn’t exist yet.

Technology was focused on basic electrical connections.

Gasoline cars became popular due to their affordability and performance.

EVs struggled with battery life and cost.

PCB design didn’t advance much during this time, keeping technology simple.

Interest in EVs revived due to oil shortages and environmental concerns.

New battery technologies, like nickel-metal hydride (NiMH) and lithium-ion, emerged.

PCBs started managing battery systems and power distribution, becoming more important as EVs grew complex.

With models like the Tesla Roadster, EVs showed improved range and performance.

PCBs adapted to manage high-power components, regulate power, and handle heat, becoming crucial for advanced electrical systems.

EVs introduced advanced features such as driver assistance and connectivity.

PCBs evolved to support high-speed data transfer, complex power systems, and thermal management, integrating sensors and communication modules.

Today’s EVs focus on sustainability and advanced technologies like solid-state batteries and V2X communication.

PCBs are designed to handle fast charging, efficient power management, and cutting-edge technology.

In smart manufacturing facilities that incorporate electric vehicles for logistics and transportation, EV charging stations require efficient power management to handle high power loads and ensure quick and safe charging.

PCBs in EV charging stations must manage high currents and voltages, regulate charging speed, and provide safety mechanisms to prevent overcharging and overheating.

They must also ensure compatibility with different EV types and charging standards.

Lets dig in!

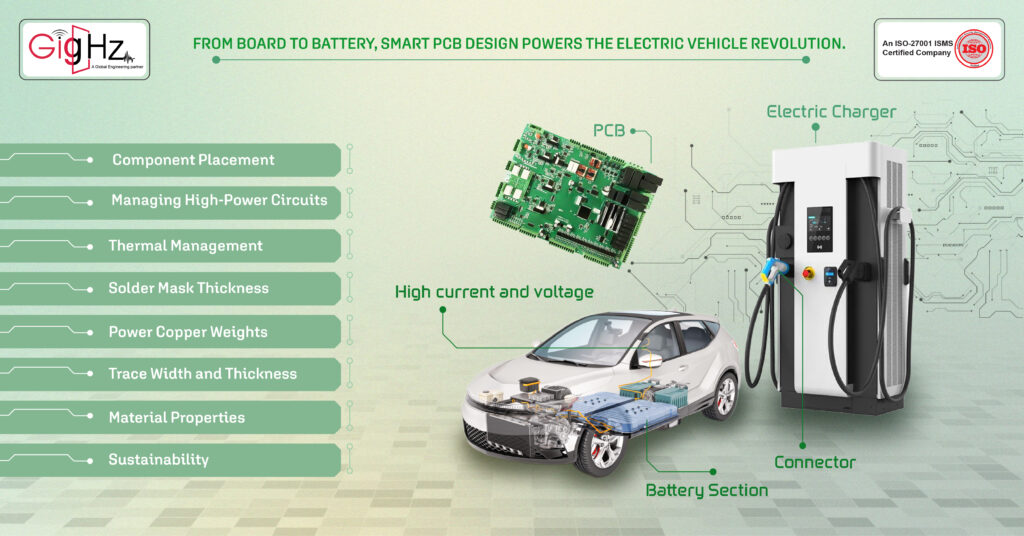

Key Factors for PCB Design in Electric Vehicle Chargers

Designing PCBs for electric vehicle (EV) chargers involves several crucial factors to ensure performance, safety, and reliability. Here’s a detailed look at the key aspects:

- Managing High-Power Circuits

EV chargers operate with high-power circuits that require careful design to handle elevated voltage and current levels. Key considerations include:

- Ensuring that the PCB can support high currents and voltages effectively.

- Implementing adequate cooling solutions to manage heat and prevent thermal stress.

- Incorporating safety features to protect against overvoltage and short circuits.

- Component Placement

Effective placement of high-power components is critical for reducing thermal resistance and ensuring reliable operation:

- Place heat-generating components away from the PCB edges to facilitate better heat dissipation.

- Distribute heat-generating components evenly to avoid creating hotspots.

- Keep sensitive components away from high-power areas to prevent damage.

- Thermal Management

Proper thermal management is essential for handling the heat generated by high-power components:

- Use heat sinks and optimize enclosure airflow to manage heat effectively.

- Design wider copper traces and use heavy copper foils on inner layers to improve heat dissipation.

- Avoid grouping high-power components together and consider thermal simulations early in the design process.

- Solder Mask Thickness

The solder mask’s thickness is important for high-power PCB designs:

- For PCBs with heavy copper, a thicker solder mask may be needed to cover the gaps between tracks.

- Adhere to IPC recommendations, using Class T for performance class 2 circuits and Class H for performance class 3 circuits.

- Consider additional conformal coatings for enhanced insulation.

- Power Copper Weights

The thickness of the copper used in power traces affects current-carrying capacity and heat dissipation:

- Heavier copper weights improve thermal management and current handling. For instance, a 3oz copper thickness requires traces wider than 350µm on external layers.

- Balance copper thickness with design requirements to avoid limitations on feature sizes.

- Trace Width and Thickness

The width and thickness of copper traces must match the power requirements:

- Thicker traces are necessary for higher power applications. For example, a 105µm copper thickness requires a minimum trace width greater than 350µm on external layers.

- Material Properties

Choosing the right materials is essential for both thermal and electrical performance:

- Use materials with high Comparative Tracking Index (CTI) for better insulation. Standard FR4 materials typically meet PLC 3 requirements, but materials with higher CTI ratings can be used for more demanding applications.

- Consider materials with high Maximum Operating Temperature (MOT) ratings for environments with high temperatures. For instance, FR4.0 and FR4.1 are approved for up to 130°C, while FR15.0 and FR15.1 can handle temperatures up to 150°C.

- Sustainability

Designing compact PCBs can reduce material use and environmental impact:

- Smaller PCBs minimize waste and resource consumption, contributing to sustainability.

By addressing these key factors, you can design effective and reliable PCBs for electric vehicle chargers, ensuring they meet the demands of high-power applications and contribute to efficient, safe, and sustainable operation.

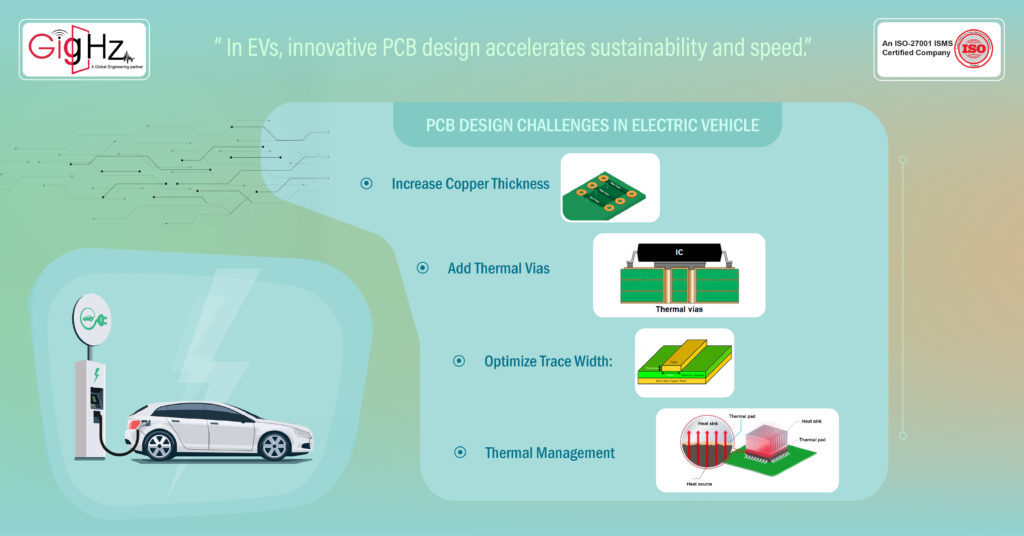

Are PCB Design Challenges Slowing Down Your Electric Vehicle Development?

EVs require PCBs to handle high currents and voltages due to their powerful systems, which can cause excessive heat and potential circuit failure if not properly managed.

- Increase Copper Thickness: Utilize thicker copper layers (e.g., 3 oz/ft²) to improve current carrying capacity and heat dissipation.

- Add Thermal Vias: Implement thermal vias to transfer heat from hot components to heat spreaders or heatsinks effectively.

- Optimize Trace Width: Design trace widths according to standards like IPC-2221 to ensure they can handle the required current without excessive heating.

Excessive heat generated by high-power components can compromise the performance and reliability of the PCB.

- Use Thermal Management Materials: Select materials with high thermal conductivity and high-Tg (glass transition temperature) materials to withstand elevated temperatures.

- Implement Heat Spreading Techniques: Use heat spreaders, thermal vias, and heatsinks to manage and dissipate heat efficiently.

- Conduct Thermal Simulations: Employ thermal simulation tools to predict and address potential overheating issues, optimizing component placement and layout.

Proper placement of high-power components is crucial to ensure efficient thermal management and minimize interference with sensitive components.

- Strategic Placement: Place high-power components away from sensitive or small components to prevent heat-related damage.

- Spread Out Heat Generators: Distribute heat-generating components evenly across the PCB to avoid localized hotspots.

- Ensure Adequate Spacing: Maintain appropriate spacing between components to facilitate effective heat dissipation and reduce electromagnetic interference (EMI).

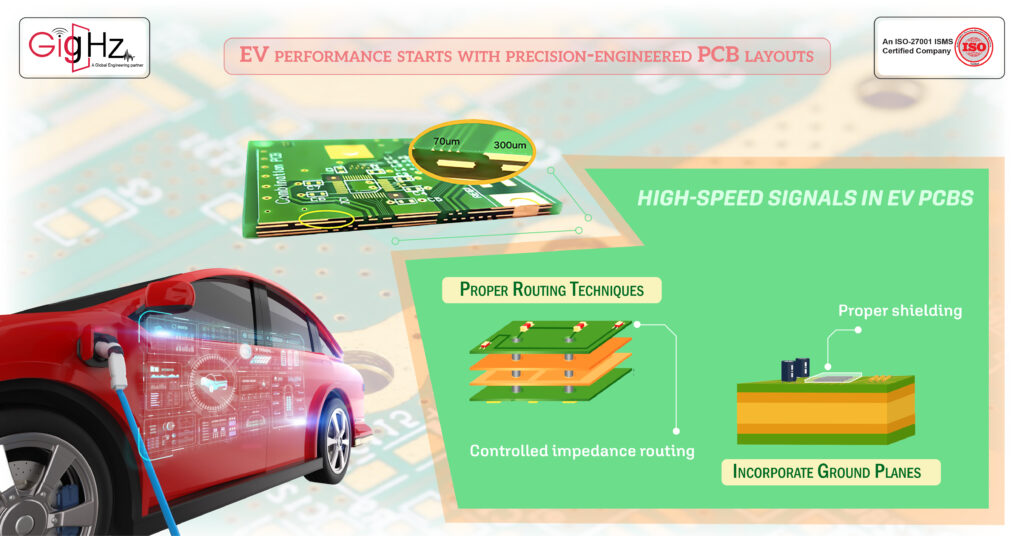

High-speed signals in EV PCBs can suffer from signal degradation, which can impact performance and reliability.

- Use Proper Routing Techniques: Implement controlled impedance routing and minimize trace lengths to preserve signal integrity.

- Incorporate Ground Planes: Use ground planes and proper shielding to reduce noise and signal interference.

- Employ Signal Integrity Analysis: Conduct signal integrity simulations to identify and mitigate potential issues before fabrication.

EV PCBs must adhere to various industry standards and regulations, including safety, electromagnetic compatibility (EMC), and environmental requirements.

- Follow Industry Standards: Design PCBs in compliance with relevant standards like IPC-2221 for design guidelines and IPC-610 for quality standards.

- Include Protection Features: Integrate features such as overvoltage protection, short-circuit protection, and thermal protection to meet safety and compliance requirements.

- Regular Testing and Certification: Ensure the PCB design undergoes rigorous testing and certification processes to verify compliance with industry standards.

Modern EVs incorporate complex systems with multiple functions, leading to intricate PCB designs that are challenging to develop and verify.

- Adopt Modular Design: Use modular design approaches to simplify complex systems and manage design complexity effectively.

- Utilize Advanced CAD Tools: Employ advanced PCB design and simulation tools to handle complex designs and verify performance before production.

- Collaborate with Experts: Work with experienced PCB designers and engineers to address intricate design challenges and ensure high-quality results.

Conclusion

The evolution of the automotive industry towards electric vehicles (EVs) has brought forth significant challenges and opportunities, particularly in the realm of printed circuit board (PCB) technology.

As automakers strive to develop safe and reliable electric cars, it is important to ensure that the PCB applications address critical aspects such as managing power, thermal management, and compliance with safety standards.

The role of PCBs in vehicle systems cannot be overstated, as they play a crucial role in the electronic systems that power these innovative designs. By leveraging innovative design techniques and utilizing advanced PCB design and analysis software, automakers can accelerate the development of electric vehicles while overcoming the inherent challenges in a limited space.

To reach the expert insights, Book a Call. Schedule a Free Consultation now. https://calendly.com/gighz/30min

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.