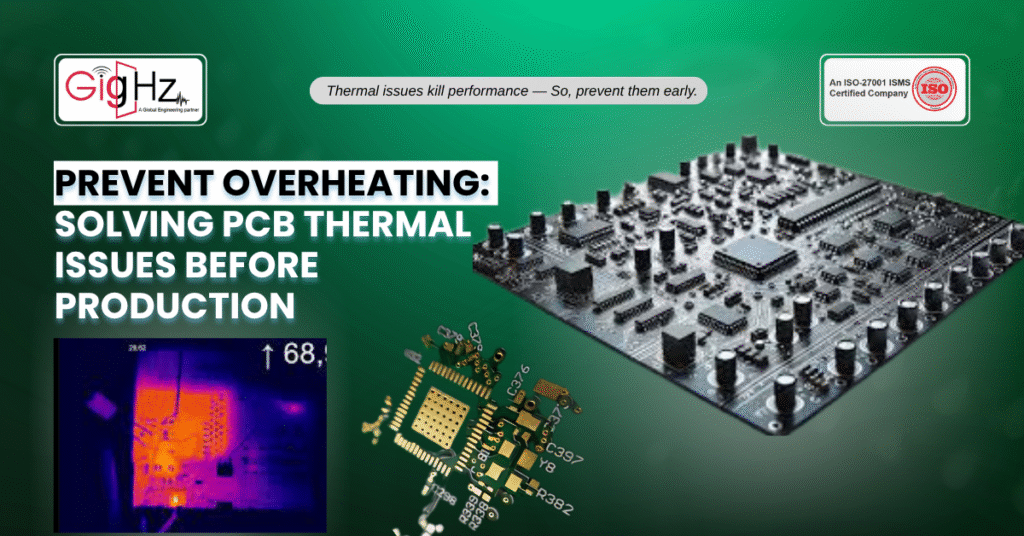

Prevent Overheating: Solving PCB Thermal Issues Before Production

- Posted On:

- November 19, 2025

- Category:

- Analysis & Simulation

So, what do you think?

One of the biggest risks in high-density electronics is?

Of course it’s gonna be ignoring PCB thermal management.

On the other hand, overheating is not just a performance issue — as it directly affects reliability, lifespan, and compliance.

Also, by carefully applying thermal vias in PCB, choosing the right PCB heat dissipation techniques, and validating with thermal simulation PCB tools, you can prevent costly failures before boards ever reach production.

Plus, modern designs demand not only functionality but also precision in designing for thermal reliability.

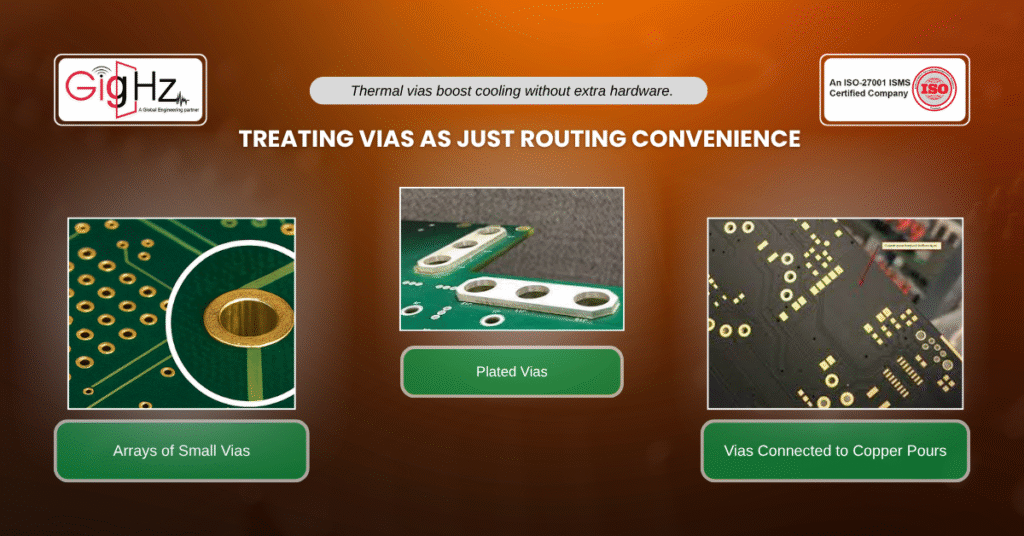

1. Using Thermal Vias in PCB Design

Now, thermal vias are one of the most effective ways to spread and conduct heat away from hotspots. But their effectiveness depends on correct planning.

Key practices:

- Use arrays of small vias instead of a few large ones to maximize surface area.

- Plate vias properly to improve thermal conductivity.

- Connect vias directly to copper pours for better heat transfer.

Also, Incorporating thermal vias in PCB at the layout stage helps build a passive and cost-effective approach to PCB overheating solutions. So, when designed thoughtfully, they not only reduce the need for bulky cooling hardware but also enhance the board’s thermal reliability, especially in compact or high-density designs where space is limited.

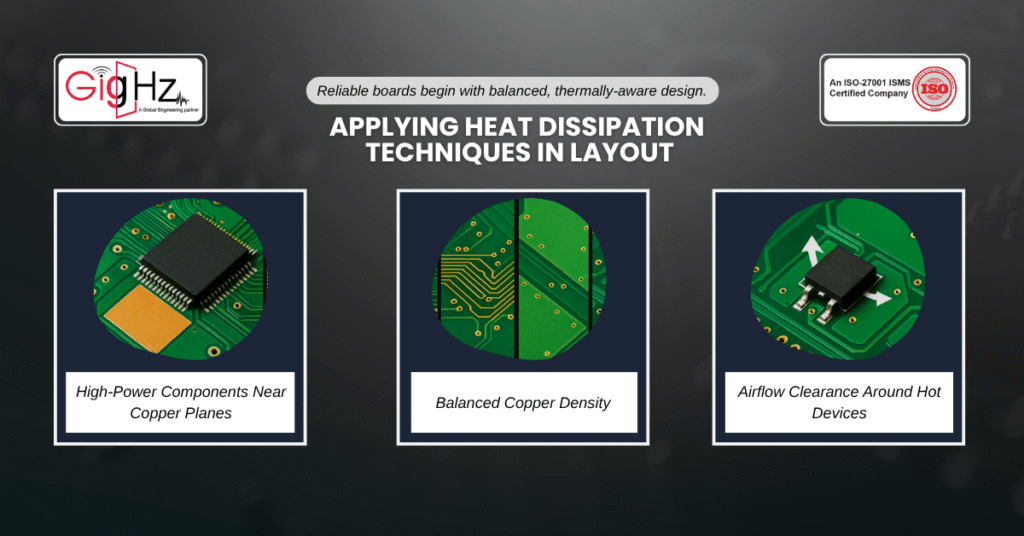

2. Applying Heat Dissipation Techniques in Layout

Good PCB heat dissipation techniques aren’t limited to adding fans or heat sinks—they begin with layout. Also, placement, copper balancing, and spacing all contribute to heat flow.

Checklist for better results:

- Keep high-power components near copper planes for heat spreading.

- Balance copper density to avoid localized hotspots.

- Leave clearance for airflow in areas with power-hungry devices.

Consequently, these measures form the foundation of designing for thermal reliability, ensuring thermal stability without relying solely on external cooling.

When implemented early, these practices reduce thermal stress, enhance long-term reliability, and make compliance with safety and performance standards easier—resulting in fewer failures and better-performing products across a wide range of applications.

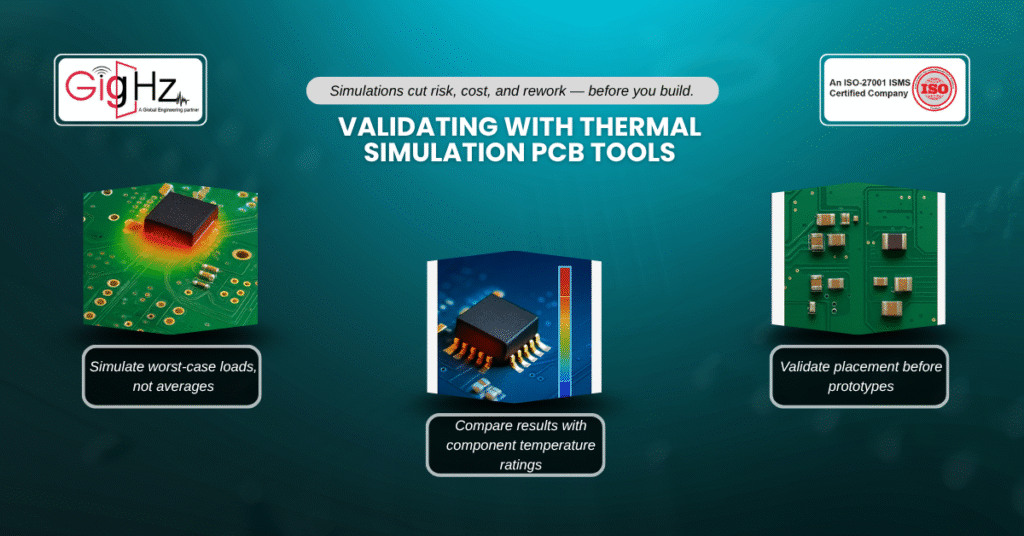

3. Validating with Thermal Simulation PCB Tools

Even with smart design choices, assumptions aren’t enough. Running thermal simulation PCB models allows you to predict where heat will accumulate and test different strategies early.

Best practices:

- Simulate worst-case loads, not just average conditions.

- Compare results against component temperature ratings.

- Use simulations to validate placement and refine PCB overheating solutions before prototypes.

Likewise, by integrating simulation into your workflow, you gain insight that’s often impossible to capture through physical testing alone. Also, it speeds up development cycles, reduces costly iterations, and gives you data-driven confidence that your design can handle real-world thermal stresses before a single board is built.

The Role of Placement Discipline

Beyond vias and simulation, component placement often decides thermal performance.

Grouping high-dissipation devices too closely accelerates heat buildup, while poor separation from sensitive analog sections can cause failures.

Also, small layout adjustments can reduce junction temperatures significantly—sometimes more effectively than adding external cooling

So, integrating simulation into the design cycle ensures you’re not just reacting to problems after production.

Building Thermal Reliability Into Every Design

Now, the most reliable designs treat PCB thermal management as part of the design DNA, not an afterthought. So, that means combining thermal vias in PCB, optimized PCB heat dissipation techniques, and accurate thermal simulation PCB models with thoughtful placement and documentation.

So, when you commit to designing for thermal reliability, you’re not just solving PCB overheating solutions! Also, you are extending product life, improving compliance, and reducing field failures.

Material Choices That Influence Thermal Paths

Apparently, even the best component placement and simulation can be undermined by poor material choices. Likewise, the thermal conductivity of the PCB substrate—like standard FR4 versus metal-core or ceramic boards—can dramatically affect how heat spreads and dissipates. Thicker copper layers, thermal interface materials (TIMs), and even board finishes all play a role. Evidently, skilled designers evaluate material stacks early in the design process, ensuring the PCB isn’t just electrically optimized but thermally efficient as well.

Design Documentation and Manufacturer Collaboration

Clearly, thorough documentation is essential to communicate thermal expectations to manufacturers. Include thermal simulation results, placement rationale, and specific instructions for thermal vias or heat sinks. Also collaborating with fabricators and assemblers ensures that your thermal design intentions are preserved through production, minimizing issues and reducing rework. As a result, it turns thermal design from a closed-loop internal process into a robust, end-to-end strategy.

Bottom Line

Summing up, thermal issues are preventable when addressed early! Likewise, by embedding PCB thermal management practices into layout and validation, engineers avoid costly surprises during testing and production.

Subsequently, at Gighz, we help teams integrate thermal simulation PCB tools, optimize thermal vias in PCB, and apply proven PCB heat dissipation techniques—all to ensure long-term reliability.

So, do you want expert support for designing for thermal reliability?

Then, contact us at info@gighz.net and let overheating problems go away for forever .

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.