Signal Integrity in Automotive PCB Design: What’s True and What’s Not?

- Posted On:

- November 20, 2024

- Category:

- Analysis & Simulation

PCB Signal Integrity

While you’re traveling in your car, you may notice how quickly it responds to what you do.

Have you ever thought about how that works?

It’s all because of signals!

It sends precise commands to various systems like the engine or transmission, Temperature readings from an engine sensor or the position of the accelerator pedal.

So, how it travels?

In adaptive lighting systems, signal integrity is crucial for making sure everything works smoothly.

These systems adjust the lights based on different conditions, like how dark it is or how fast the car is moving.

For them to work correctly, the electrical signals that control the lights need to be clear and stable.

If there’s a problem with the signal, it can cause flickering lights, slow responses, or incorrect adjustments, which can be unsafe. By keeping an eye on things like noise and interference in the signals, engineers can improve communication between the sensors, controllers, and lights.

This leads to better and more efficient lighting that reacts quickly to changes.

Let’s dig in!

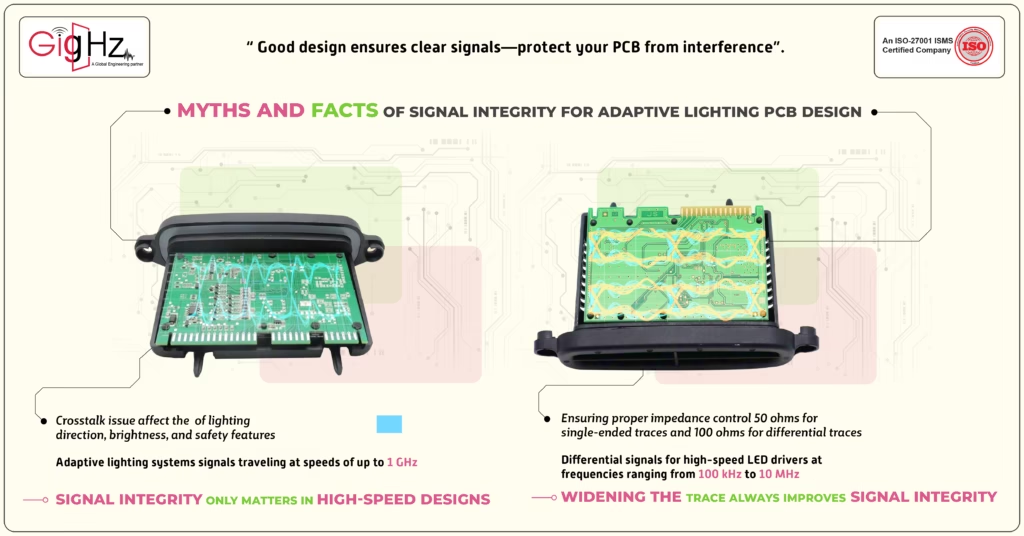

5 Myths and Facts of Signal Integrity for Adaptive Lighting PCB Design

Myth 1: Signal integrity only matters in high-speed designs

Even though the data transmission in these systems may not be as fast as in other high-speed applications, signal integrity is still crucial.

Issues like crosstalk or reflections can affect the real-time control of lighting direction, brightness, and safety features.

Adaptive lighting systems may involve control signals traveling at speeds of up to 1 GHz or higher, meaning even minor signal degradation can result in incorrect headlight alignment or failure to respond to environmental changes.

Myth 2: Widening the trace always improves signal integrity

In adaptive lighting, signal crosstalk and reflections can still occur even with wide traces, especially when high-frequency control signals are involved.

Differential signals for high-speed LED drivers or PWM (Pulse Width Modulation) signals for headlight control may operate at frequencies ranging from 100 kHz to 10 MHz or higher, where increasing trace width might not be sufficient to avoid signal degradation.

Signal integrity is about more than just trace width—it’s about ensuring proper impedance control (typically 50 ohms for single-ended traces and 100 ohms for differential traces), grounding (using solid or split ground planes depending on the design), and minimizing electromagnetic interference (EMI) through shielding and careful PCB layout.

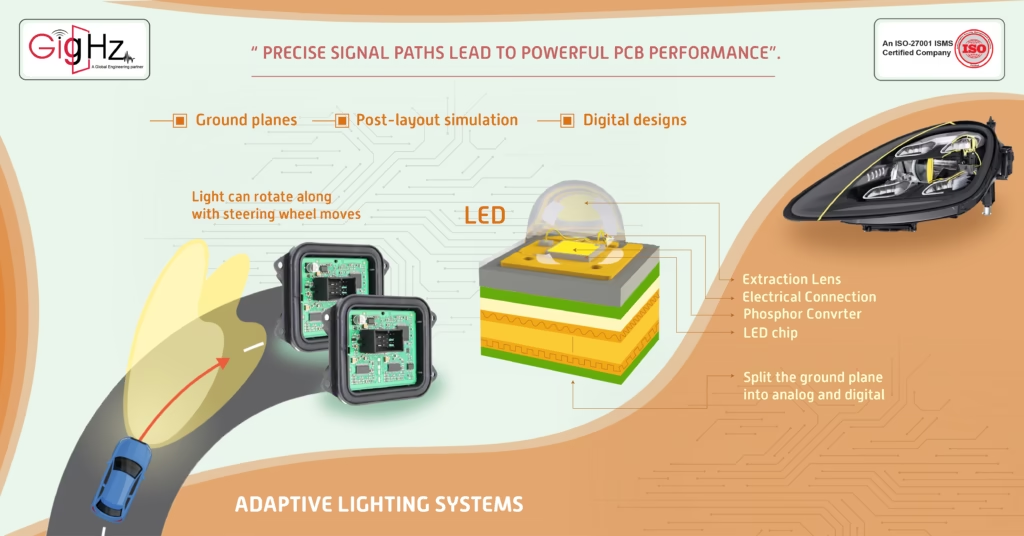

Myth 3: Ground planes must always be solid

In adaptive lighting, high-current paths (for LED drivers or motors for headlight adjustment) may cause voltage fluctuations or noise coupling if a solid ground plane is used, potentially interfering with delicate control signals.

In adaptive lighting systems, it’s often better to split the ground plane into smaller sections (e.g., analog and digital ground planes) to avoid ground loops and EMI. Proper grounding design and sectioning (keeping high-speed signals away from high-current paths) are essential for ensuring clean signal transmission and reducing electromagnetic interference (EMI).

Myth 4: You can fix signal integrity issues later using post-layout simulation

Post-layout simulation tools can help identify signal integrity issues, but they often can’t fix fundamental design problems.

In adaptive lighting systems, proactive design decisions from the start—such as proper routing of high-speed signals, shielding, and signal termination—are crucial.

Adaptive lighting systems using PWM signals for LED dimming or CAN (Controller Area Network) protocols for real-time communication must adhere to strict time delays (less than 100ns) to ensure proper synchronization between control units.

Waiting until the post-layout phase might not catch all potential issues, leading to poor lighting performance or unsafe driving conditions due to timing errors or signal distortion.

Myth 5: Signal integrity is only a concern for digital designs

Signal integrity isn’t limited to digital designs alone, especially in automotive lighting systems.

In adaptive lighting, analog control signals that adjust the headlights’ angle or brightness can also be compromised by noise or interference.

These analog signals, operating in the range of 10 Hz to 100 MHz, are critical for the precise control of headlight movement or dimming based on road conditions and other sensors.

Both digital (e.g., CAN bus communication for adaptive lighting control) and analog (e.g., PWM dimming signals) signal integrity must be addressed to ensure proper operation of sensors, actuators, and LEDs. Failing to account for both can lead to flickering lights, incorrect headlight angles, or even complete system failure, compromising both safety and vehicle performance.

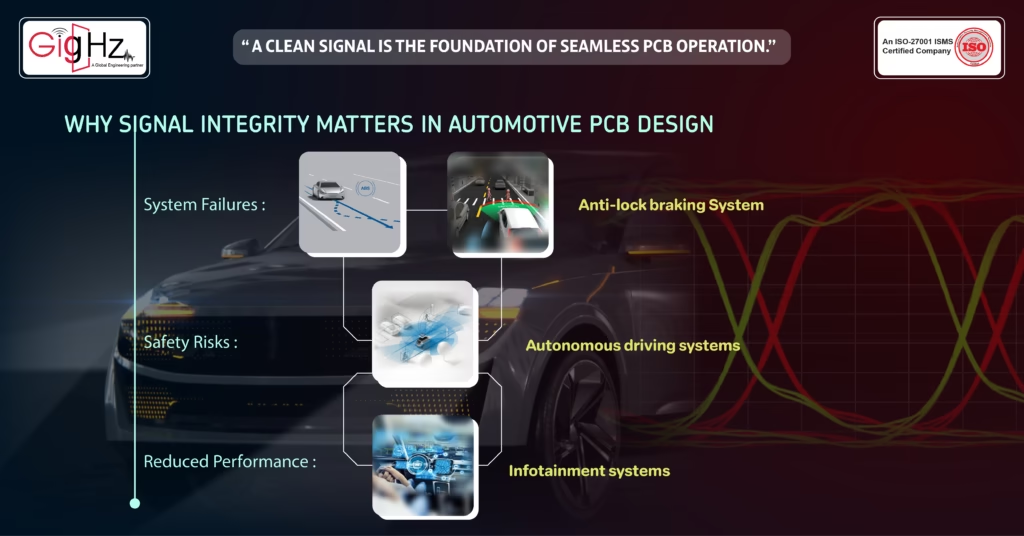

Why Signal Integrity Matters in Automotive PCB Design?

Automotive systems rely on the seamless flow of information between sensors, processors, control units, and other electronic components. Poor signal integrity can lead to issues such as:

System Failures: In critical systems like anti-lock braking, stability control, or collision detection, poor signal integrity can lead to delayed responses or failure to activate in emergency situations.

Safety Risks: In autonomous driving systems, real-time data processing is key to making quick decisions. Signal degradation can result in the vehicle failing to recognize hazards or properly navigate, leading to accidents.

Reduced Performance: Infotainment systems, navigation, and communication technologies all depend on precise signal transmission. Degradation in signal quality can lead to poor audio/video quality, dropped connections, or slow processing speeds.

Summary

Understanding signal integrity is crucial in the design process of high-speed digital circuits.

As signals travel through transmission lines on PCBs, they encounter various signal integrity problems such as ground bounce and impedance matching issues, which can lead to a signal being reflected back instead of reaching its destination. Utilizing tools like the eye diagram helps visualize signal rise and signal bandwidth, allowing engineers to identify SI issues early in the physical design.

Termination techniques and proper management of return paths are essential in minimizing cable and PCB trace capacitance and inductance, which can degrade the original signal.

Start improving signal integrity—click to get the solution! https://calendly.com/gighz/30min

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.