How to Perform a 7-Point Worst-Case Circuit Analysis

- Posted On:

- August 19, 2025

- Category:

- Analysis & Simulation

Let it be in aerospace, medical devices, auto-mobile manufacturing or any other mission-critical electronics!

System failure is completely unacceptable due to the stringent reliability and safety standards required in these industries.

And yet, most circuit designs are validated only under “typical” conditions. Now, that’s why we always perform Worst-Case Circuit Analysis (WCCA) into every high-reliability project that we touch from day one.

Because, it’s not just about passing tests!

Rather, It’s about anticipating every point of failure before your board ever hits production. Now, this post breaks down our internal 7-point checklist based on proven worst case circuit analysis application guidelines. Likewise, it is especially relevant for sensitive components like si photodiodes worst case circuit analysis in precision systems.

1. Define Operating Ranges — Not Just The Nominals

So, a lot can go wrong when you are assuming that all parameters behave optimally.

That’s why, you must always start by defining extreme upper and lower limits for temperature, voltage, and component tolerances.

As, this is a foundational part of all worst case circuit analysis application guidelines and should be tailored for your industry. Moreover, in the case of si photodiodes worst case circuit analysis, photodiode gain, dark current, and temperature drift must be validated across full environmental ranges.

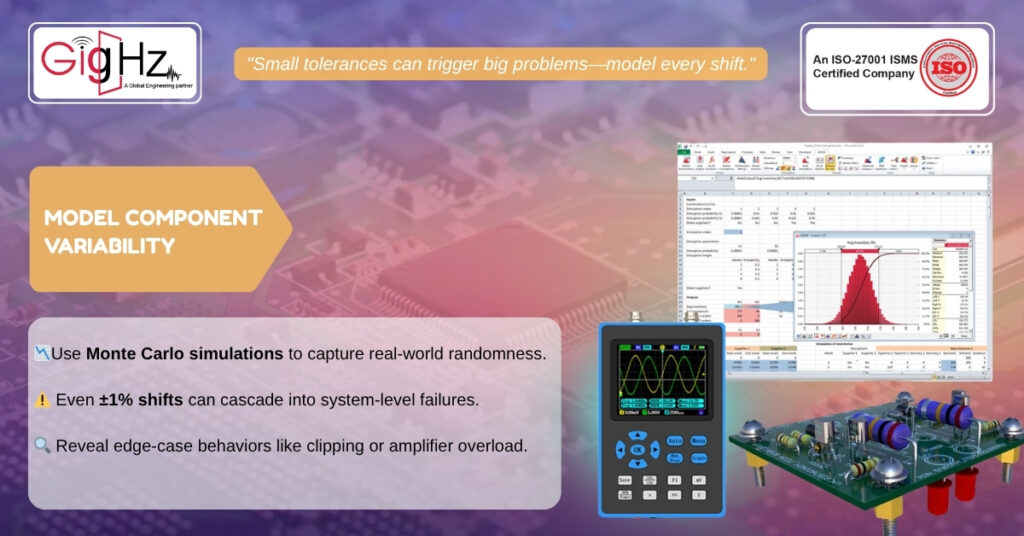

2. Model Component Variability (Statistical + Corner Cases)

As we know, every resistor, op-amp, and capacitor has variability—even if it’s just ±1%.

Likewise, use Monte Carlo simulations or worst-case corners (min-max) to capture how real-world shifts affect performance. When applying worst case circuit analysis application guidelines, this step is essential to identify unexpected cascades in behavior.

Meanwhile, in si photodiodes worst case circuit analysis, this might reveal signal clipping, amplifier overload, or current noise which might not be caught in basic testing.

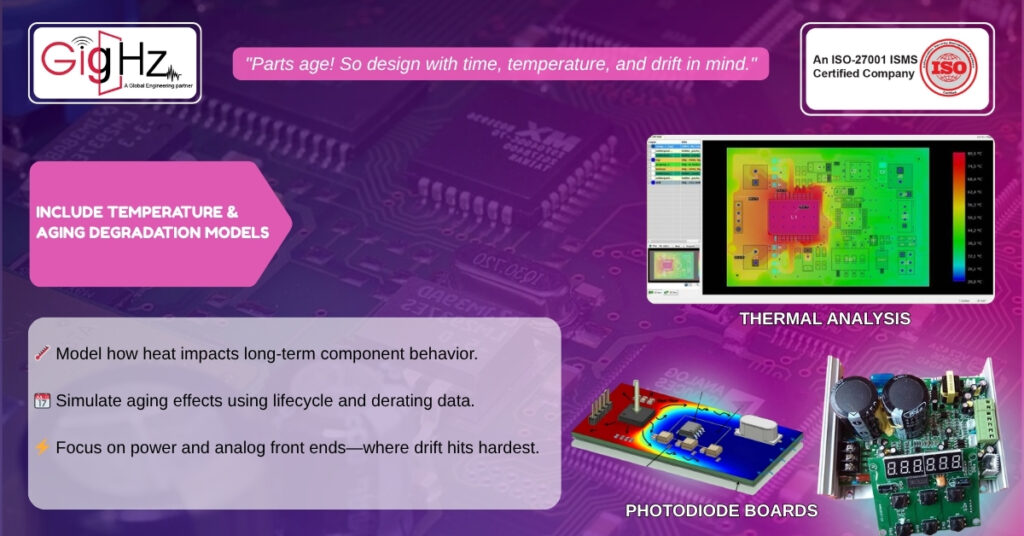

3. Include Temperature and Aging Degradation Models

Evidently, parts don’t just operate, they also age, right?

Apparently, thermal cycles, humidity, and time can degrade component parameters drastically over time. Also, using derating models and lifecycle data, especially for power components and analog front ends, it ensures reliability over the long term.

Hence, for high-reliability sensors like si photodiodes, temperature-induced leakage and responsivity drift must be considered over the product lifetime. Also, It’s a key pillar in advanced worst case circuit analysis application guidelines.

4. Simulate Failure Modes and Worst Outcomes

Most importantly, don’t just ask, “Will it work?” or Ask, “How will it fail?”

Always, run simulations for power loss, short circuits, sensor overexposure, and ESD conditions. In si photodiodes worst case circuit analysis, for instance, overstimulation from stray IR/UV can saturate amplifiers or damage ADCs.

Plus, anticipating and simulating these “stress cases” helps you design defensively! Also, consider adding clamps, filters, and safe shutdown logic before you need them.

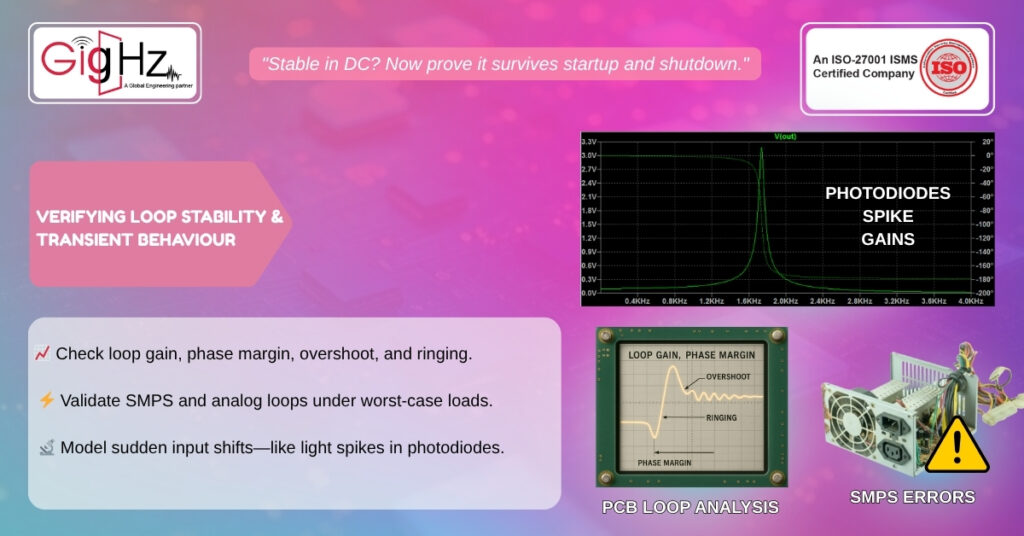

5. Verify Loop Stability and Transient Behavior

Now, DC performance is one thing. Whereas, transients are another!

Likewise, in electrical systems, it’s essential to understand the difference between DC behavior (steady-state performance) and transients (temporary changes in voltage or current). Because, both play a crucial role in system performance, but failures often occur during transient events like startup, switching, or shutting down.

Moreover, in this state, the system’s components function predictably, with minimal voltage or current changes. Consequently, this is the “normal” operating condition where failures are rare, and the system performs as expected.

Consequently, many failures emerge not in steady-state but during startup, shutdown, or switching. Therefore, simulate with worst case circuit analysis application guidelines that focus on overshoot, ringing, and loop gain margins. Especially in analog signal chains or SMPS designs.

Moreover, this is particularly critical in si photodiodes worst case circuit analysis, where sudden light changes can destabilize feedback loops.

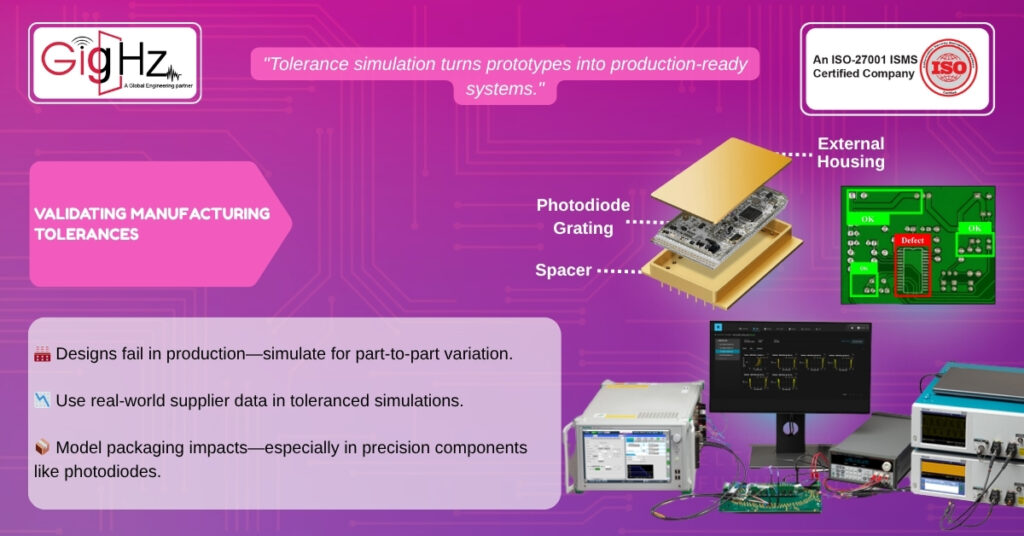

6. Validate Across Manufacturing Tolerances

Now, even perfect designs can fail if parts come from different lots, vendors, or lines at times.

That’s why you must always use toleranced simulation with real-world supplier data to assess and yield the associated risks.

As a result, it ensures that your final build won’t only pass the lab tests but also pass in the factory, too.

Therefore, applying this step in worst case circuit analysis application guidelines gives you the leverage in repeatability.

On the other hand, with si photodiodes, small packaging differences can affect alignment and response times, so don’t ignore them.

7. Document, Review, and Repeat

Finally, make WCCA a documented, reviewable process and not a one time process.

Likewise, use structured forms, summary tables, and risk classifications precisely and extensively. Also, tie the checklist to validation protocols and build it into your design release process. For regulated industries, following formal worst case circuit analysis application guidelines not only reduces risks! But also to protect your products from compliance issues later.

Bottom Line

Summing up, our team always prioritizes this 7-point worst case circuit analysis checklist for every project involving high-reliability systems. From medical imaging to aerospace signal chains – We have saved clients months in late-stage debugging.

Notably, we prevented a potential field failure in an automotive sensor array that could have led to costly recalls and safety risks.

So, looking for a checklist in a downloadable, editable format to train your team or include in your own process?

Most PCB designs fail not because of bad ideas, but because of missed checks.

That’s why we’re offering a free early-stage design review — so you can catch the hidden risks before testing.

Get Your Review Today

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.