6 Practical Tips for Managing White-Label PCB Design Projects

- Posted On:

- January 14, 2026

- Category:

- Ecad

When you Managing multiple PCB design Projects clients under a white-label model means you’re responsible for both the experience and the final quality.

Even when the engineering work is done behind the scenes.

Your clients see everything under your brand, so smooth coordination, clarity, and consistent delivery become critical.

But working with an external engineering partner also brings its own challenges.

You need to maintain version control across many projects, keep design reviews structured, ensure every layout follows strong DFM rules, and meet client deadlines without unexpected delays.

A small communication gap can turn into rework, missed milestones, or confusion in front of your clients.

Based on our experience supporting several white-label service providers, here are six practical ways to manage your PCB design projects more effectively and confidently — with clear handovers, predictable timelines, and stronger output quality.

1. Standardize Design Inputs and Checklists

One of the most common reasons for rework in white-label PCB projects is unclear or incomplete design inputs.

When requirements are scattered or inconsistent, the layout team has to make assumptions — and those assumptions often lead to revisions later.

Before starting any new project, build a standardized input checklist that covers all essential items, including:

- Schematic files, BOM, and clear design-intent notes

- Electrical constraints, placement rules, and mechanical boundaries

- Preferred stack-up, trace widths, impedance targets, and DFM limits

- Naming conventions, file structure, and version control format

Pro Tip: Ask your engineering partner to conduct a Design Review for every project.

This ensures all inputs are validated, clarified, and documented before layout begins — reducing back-and-forth and preventing avoidable mistakes.

2. Maintain Version Control Across Both Teams

With multiple projects running at the same time, managing design revisions and tracking change requests can easily become messy.

Files move around, updates get missed, and two designers may unknowingly edit the same schematic or layout.

Using a structured version control system — such as Altium 365, Concord Pro, or a Git-based PLM setup — helps you keep everything organized and traceable.

It ensures that:

- All design files stay synchronized across teams

- Every change is logged with the person, time, and reason

- Overlapping edits or outdated file versions are avoided

Pro Tip: If your engineering partner uses their own version control system, decide on a fixed sync routine (daily or weekly).

This keeps both sides aligned and prevents mismatched datasets when you present updates to your clients.

3. Define Your Review and Sign-Off Milestones

Instead of waiting until the final Gerber delivery, establish three defined review points:

- Pre-layout sign-off (schematic + stack-up validation)

- Mid-layout review (critical nets, routing strategy, placement validation)

- Final DFM review (before Gerber release)

This milestone-based system gives your in-house team visibility and control at every step—without micromanaging your partner.

Pro Tip: Request a shared progress tracker that visually shows design stages and pending reviews.

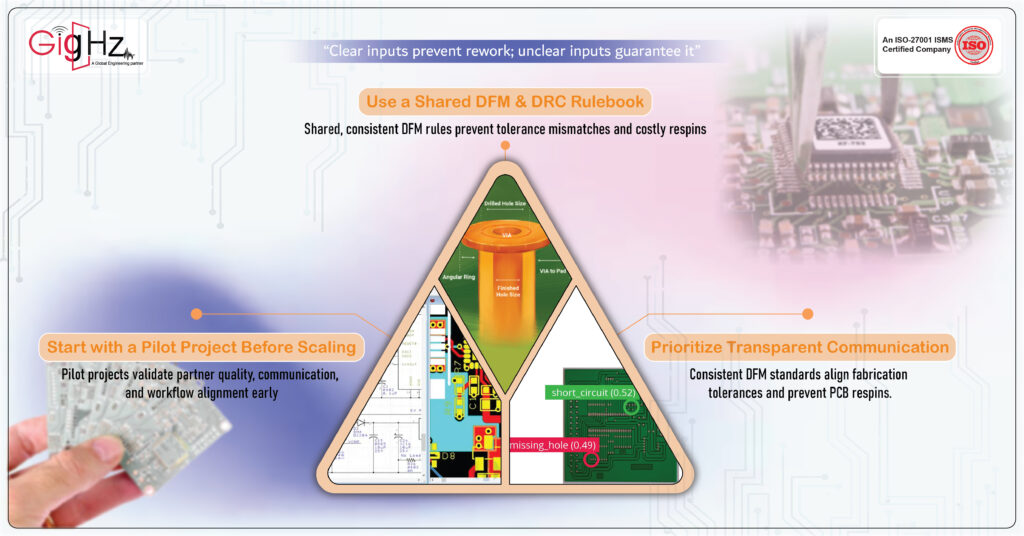

4. Use a Shared DFM & DRC Rulebook

Every fabrication vendor has slightly different tolerances. A mismatch between your client’s DFM rules and your partner’s layout settings can cause costly board respins.

Create a shared rulebook that defines:

- Via and trace limits

- Differential pair constraints

- Component spacing and keep-out rules

- Board outline and 3D interference zones

Pro Tip: Ask your engineering partner to integrate your DFM constraints directly into their EDA environment—this ensures every board is compliant by design.

5. Prioritize Transparent Communication

In a white-label project, your engineering partner is an extension of your brand.

Any delay, unclear update, or missing detail reflects directly on you.

That’s why consistent, structured communication is one of the strongest ways to protect your reputation and keep clients confident.

Set up a clear communication workflow with your partner, including:

- Weekly sync calls to review design status, risks, and open issues

- A shared issue log with ownership, timestamps, and expected resolution dates

- Standardized report templates that you can forward to clients without spending time reformatting

Pro Tip: Define a simple response SLA — for example, “all design queries responded to within 24 hours.”

This helps maintain momentum, reduces bottlenecks, and keeps trust high on both sides.

6. Start with a Pilot Project Before Scaling

Before committing to a large batch of designs, start with a small pilot project of around 5–10 boards.

This controlled phase helps you understand how your engineering partner actually works in real conditions, without risking major delays or rework later.

A pilot allows you to validate:

- The quality of PCB design, documentation, and reviews

- The communication rhythm, clarity, and response time

- Compatibility of all deliverables — schematics, footprints, Gerbers, stack-up notes, and 3D models

Pro Tip: Use the pilot stage to refine workflows, naming conventions, and templates together.

A few hours of alignment here can save weeks of confusion once you scale up and multiple projects start running in parallel.

Bottom Line

A strong white-label partnership thrives on structure, transparency, and repeatability.

When you collaborate with a partner who not only executes designs but also helps you systemize delivery, you gain speed, consistency, and client confidence.

Our engineering team has worked with several white-label providers worldwide—supporting their internal brand delivery with:

- End-to-end PCB design & DFM reviews

- Library standardization and ECAD–MCAD alignment

- Multi-EDA platform expertise (OrCAD, Altium, PADS, Allegro)

If you’re looking to streamline your next white-label PCB design project or want a structured pilot plan, we’d be happy to share a ready-to-use project management template to start with.

Book a Call. Schedule a Free Consultation now https://calendly.com/gighz/30min

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.