As we all know that PCB design has always been about very severe precision, iteration, and speed.

Yet, engineers know how long routing, verification, and debugging cycles can drag out development timelines.

Now, that’s where AI in PCB design is beginning to change the game.

So, instead of waiting days or weeks for layouts and reviews, engineers can now use AI-powered PCB design software to accelerate tasks that once consumed the majority of project schedules.

Also, this shift is not about replacing engineering judgment — it’s about using AI for PCB layout optimization to handle repetitive, time-intensive work while freeing designers to focus on critical architecture and system-level tradeoffs.

As the future of PCB design with AI becomes clearer, we are seeing not just incremental improvements but a fundamental change in how boards are created, tested, and brought to market.

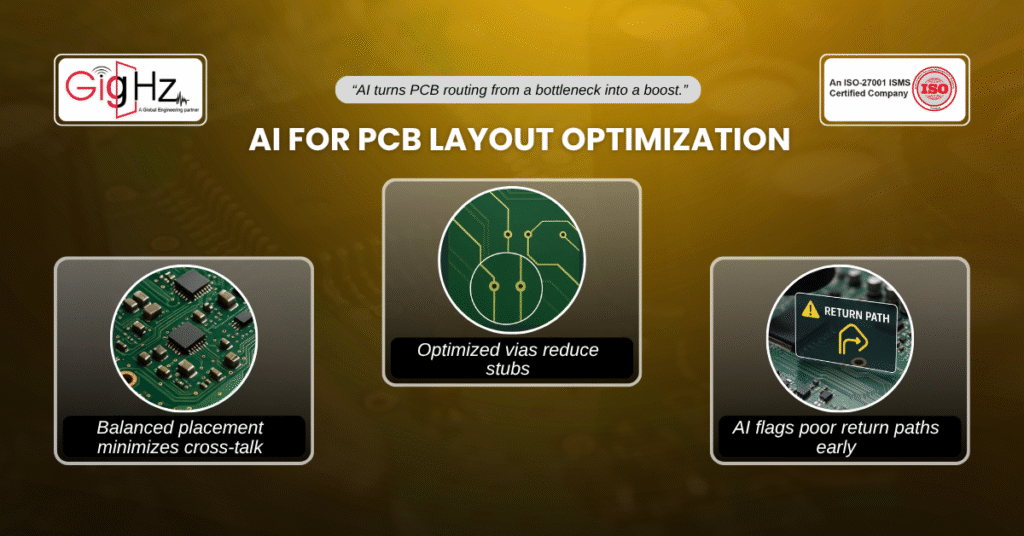

1. AI for PCB Layout Optimisation

Now, one of the most time-consuming parts of PCB work is routing.

Earlier, engineers balance trace lengths, differential pair constraints, impedance control, and return paths through hours of manual effort.

Even with automated routing tools, the results often need heavy rework to meet high-speed requirements.

With AI for PCB layout optimization, the process looks different.

Machine learning algorithms learn from past designs, recognize recurring constraints, and propose routing solutions that already align with high-speed performance and EMC requirements.

Instead of “autoroute and fix,” the workflow becomes “AI route and refine.”

Now, Examples include:

- Optimizing placement for thermal balance while minimizing cross-talk.

- Suggesting via configurations that reduce stubs in high-speed paths.

- Automatically flagging problematic return paths before layout lock-in.

As a result, the results were shorter design cycles and fewer late-stage revisions.

By speeding up PCB development with AI, teams spend less time correcting layouts and more time validating end performance.

2. Faster Verification and Sign-off

Even after layout is complete, verification can feel like a bottleneck.

Signal integrity, power integrity, and EMI simulations all require setup, model integration, and repeated adjustments.

Here’s where AI-powered PCB design software is proving valuable. Instead of running thousands of brute-force simulations, AI engines predict which nets are most at risk of violations based on past project data.

This reduces the number of simulations needed while still ensuring accuracy.

In practical terms, engineers gain:

- Automated detection of DDR/PCIe timing risks before signoff.

- Smarter power delivery checks that highlight likely resonances or parasitic issues.

- Targeted electromagnetic interference analysis without running unnecessary cases.

Also, by applying AI in electronics design, validation becomes faster and less resource-heavy.

Plus, teams move from long simulation cycles to real-time feedback that helps prevent late surprises.

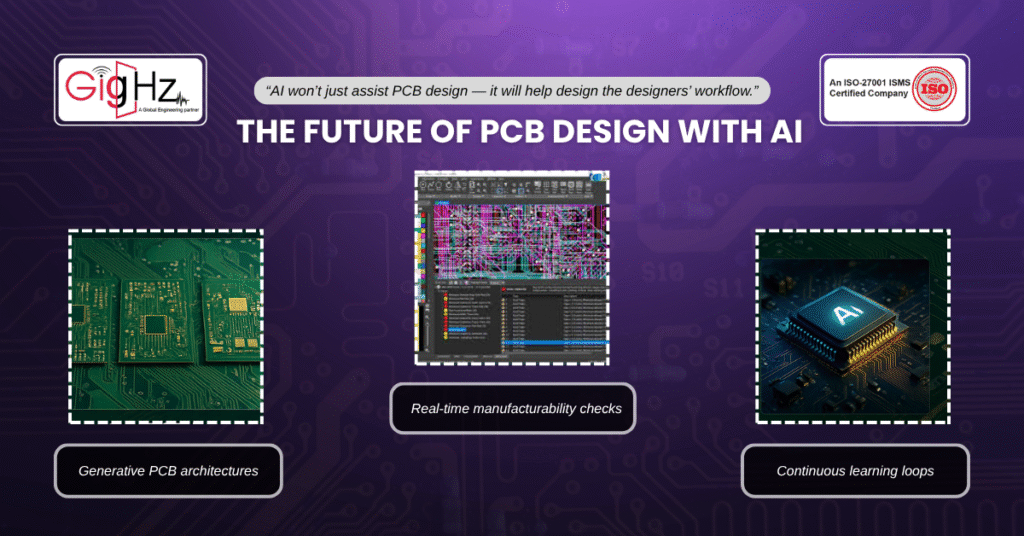

3. The Future of PCB Design with AI

Now, perhaps the most exciting shift is how AI will reshape workflows over the next decade.

The future of PCB design with AI won’t be limited to layout optimization or simulation shortcuts.

Instead, we’ll see AI embedded across the lifecycle — from schematic capture to manufacturing feedback.

Some emerging directions include:

- Generative PCB architectures: AI that proposes multiple board configurations optimized for size, cost, and thermal performance.

- Real-time manufacturability checks: Early feedback on whether a design violates DFM rules, cutting delays at the fabrication stage.

- Continuous learning loops: Every board produced feeds new data back into the AI, improving predictions for future designs.

Consequently, this means that AI in electronics design will evolve from being a tool to being a collaborative partner — one that speeds up not only design but also testing and production.

The long-standing delays of manual routing, exhaustive verification, and error-prone reviews may soon be reduced to a fraction of current times.

Bridging Design and Manufacturing with AI

Most importantly, a critical but often disconnected phase in PCB development is the transition from design to manufacturing.

Misalignments here can lead to delays, costly respins, or yield issues.

AI is now stepping in to bridge this gap by translating design intent into manufacturing-ready outputs more intelligently.

Advanced AI systems can analyze fabrication and assembly constraints in real-time and suggest adjustments during design — like repositioning components to improve solderability or adjusting pad geometries for better yield.

Bottom Line

Summing up, AI won’t eliminate the need for human expertise in PCB engineering. Instead, it offers a way to move past repetitive bottlenecks and focus on innovation. By using AI for PCB layout optimization, validating designs faster, and preparing for the future of PCB design with AI, teams can shorten development cycles without compromising reliability.

The promise of AI-powered PCB design software isn’t just efficiency — it’s accuracy, consistency, and the ability to learn from every design iteration. For companies under pressure to deliver hardware at startup speed, speeding up PCB development with AI is no longer a distant vision. It’s already becoming a practical advantage.

At Gighz, we’re tracking these advances closely and helping clients integrate them into workflows.

If you’d like to explore where AI in electronics design can deliver the most value for your team, reach out at info@gighz.net — the future is already here, and it’s designing boards faster than ever before.

To know more our trending activities, follow us on LinkedIn https://www.linkedin.com/company/3483128/admin/dashboard/

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.