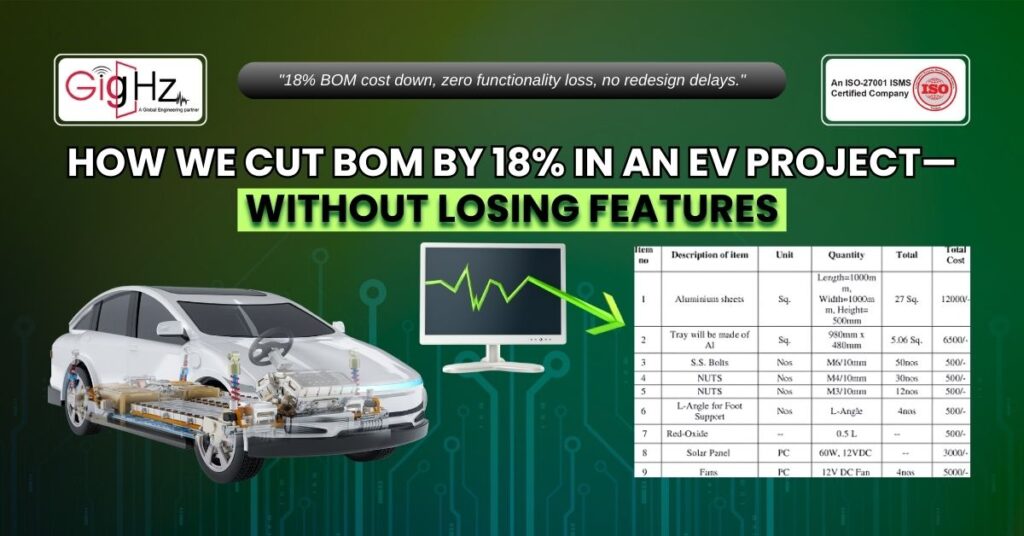

How We Cut BOM by 18% in an EV Project—Without Losing Features

- Posted On:

- September 19, 2025

- Category:

- Ecad

“18% BOM cost down, zero functionality loss, no redesign delays.”

When we first got the call, the client was already behind the schedule!

Yes, it truly happened.

Evidently, their entire EV platform was entering design validation, and the bill of materials was becoming gigantic day-by-day which was beyond the original cost targets.

So, they asked us –

Can you help us reduce BOM cost in EV projects without losing any of the core functionality?

And, that’s then we jumped into helping them cut BOM by 18%, preserve every key feature, and also avoid a daunting redesign cycle.

In addition, it’s completely replicable with the right method.

The Real BOM Problem

Nowadays, most engineers see the BOM as a fixed consequence of design process decisions.

But in our experience, it’s often just a snapshot of untapped opportunities.

Because in fast EV programs, teams over-spec for safety margins, reuse old designs blindly, and default to vendor recommendations — all of which quietly inflate costs.

And the good news is: you don’t need to rip out critical features to reduce EV manufacturing expenses.

What you really need is to approach the design differently, from a value-proof perspective.

Now, that’s where value engineering for electric vehicles steps in.

Take this client, for instance. They had a verified, efficient engineering team.

But the subsystems were overdesigned, connectors were over-specified, and housing features were duplicated.

On top of that, additional costs had crept in quietly — just as they do in every EV project under pressure.

Old vs New: What Changed in Our Approach

Before:

- Designed for max performance and not optimized for value proposition

- Used vendor-suggested parts without any cost tier review

- No end-to-end analysis of sub-assembly redundancy

After applying value engineering for electric vehicles:

“From subsystem mapping to OEM-ready savings.”

- The, we ran a functional vs cost mapping for each subsystem

- Plus, we reviewed alternate qualified components with lower cost tiers

- In addition, we consolidated the mechanical parts across every enclosures

Consequently, all the results weren’t just theoretical!

Apparently, they were visible in the BOM optimization checklist for EVs which we built specifically for them and use across multiple OEM projects.

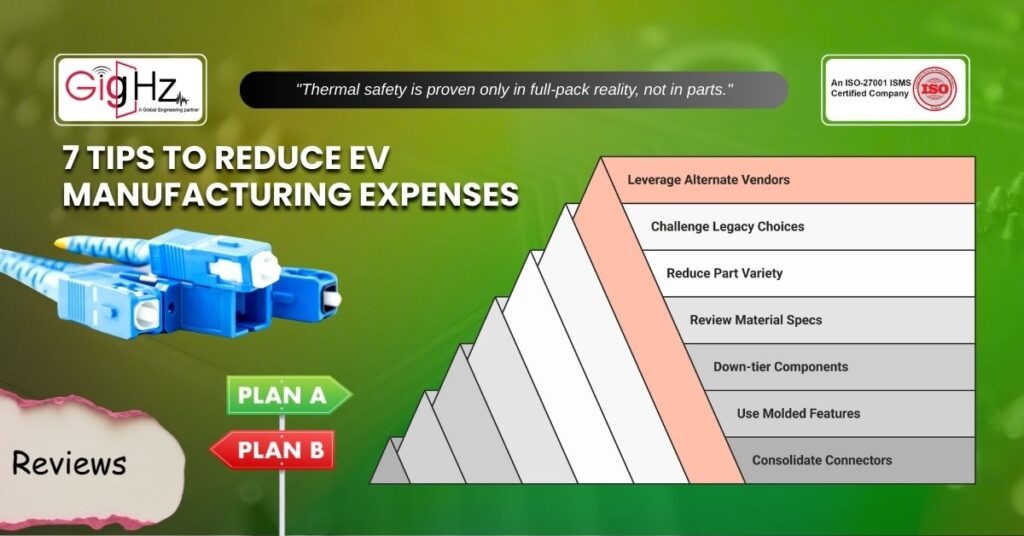

7 Pro Tips From Our BOM Optimisation Checklist for EVs

Now, these are some of the levers which we pulled to reduce EV manufacturing expenses fast and that too without affecting any of the reliability and safety measures.

1. Consolidate Connectors

They had some redundant signals and power lines had led to separate connectors across modules. So, we merged interfaces where current and EMI allowed it to drop part count and harness cost by 9%.

2. Use Molded-In Features for Mounting

On the other hand, two mechanical brackets were eliminated by adding molded bosses to an existing enclosure. Consequently, this avoided secondary hardware and cutting BOM in electric vehicle design without function loss.

3. Down-tier Passive Components

Additionally, we found high-voltage resistors rated at 250V being used for 60V circuits. Plus, switching to appropriate voltage-rated passives brought a 22% reduction in component cost within that board.

4. Review Material Specs Across Enclosures

Moreover, the team had spec’d aluminum where high-temp nylon would suffice. Now, that swapped alone cut down $4.5/unit and simplified vendor sourcing.

5. Reduce Part Variety

Also, by standardizing to two cross-functional SKUs, we simplified inventory and dropped unit cost due to volume consolidation.

6. Challenge “Legacy” Choices

Furthermore, several parts were carried over from previous EV platforms. Now, once re-evaluated for current load, thermal profile, and function, they were swapped with more cost-effective and readily available options.

7. Leverage Alternate Approved Vendors

Lastly, a second source isn’t just good for risk mitigation — So, it’s better for cost efficiency too. Also, we reviewed 17 parts across the BOM and found alternate suppliers with equal specs and 12–30% lower pricing.

Besides, all of these moves came from one idea: smart value engineering for electric vehicles is proactive, not reactive.

The Result

“18% BOM cut. Zero loss. No delays—while others stalled.”

Now, let’s say rephrase it again, so make sure of :

- 18% BOM cost reduction

- Zero functionality loss

- No retooling delays

Now, that’s what’s possible when the BOM optimisation checklist for EVs meets cross-domain engineering rigour.

Also, the team moved forward with full confidence while their competitors were still in design review.

Bottom Line

Summing up, Designers who embed value engineering for electric vehicles into their process can innovate and hit a budget.

In addition, those who wait for finance to raise red flags? They’re often too late.

Likewise, we help EV teams reduce EV manufacturing expenses through hands-on BOM reviews, smart part substitutions, and proven cost-optimization tactics.

So, whether you’re pre-DV or already in progress, we help you to cut BOM in electric vehicle design the right way.

Contact us today! For a free consultation at https://gighz.net/contact-us/

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.