20+ YEARS of Design Excellence

100+ CAD Designs Completed

50+ PCB Design Engineers

99% Customer Retention Rate

24 x 6 Support Available

Get Professional CAD Engineering Services with Decades of Experience!

We Engineer and Design the Future

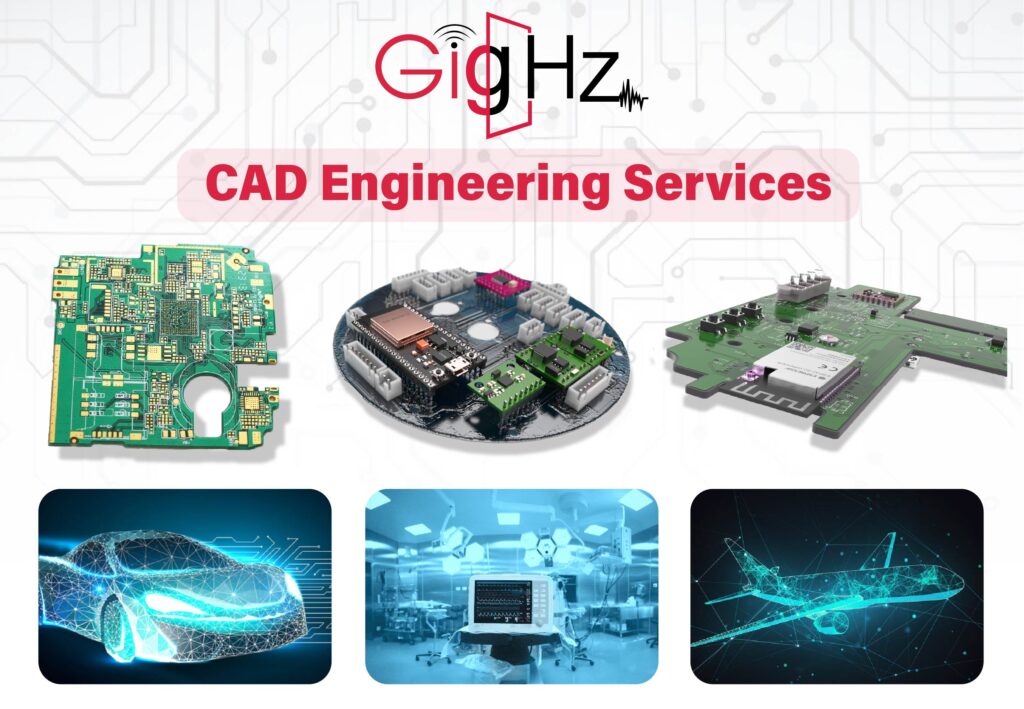

GigHz leverages decades of engineering expertise to optimize every stage of embedded product development. Our proficient teams deliver CAD engineering services, including 3D CAD design services and 3D CAD solutions, tailored for the unique demands of the automotive, medical, aerospace, and telecom industries. Through integrated ECAD, MCAD, and simulation-driven design, we bring precision and innovation to every project.

By customizing each design through innovation, we aim to reduce costs by over 52% while accelerating time-to-market by 25%. With a focus on quality, on-time delivery, and customer-centric solutions, we help clients bring ideas to life. As a trusted partner, GigHz fosters collaboration with startups and enterprises to turn complex projects into seamless realities that exceed expectations.

Why Choose Us?

- Expertise with leading EDA platforms and industrial standards for quality results

- Structured, and optimized design processes for efficiency and data integrity

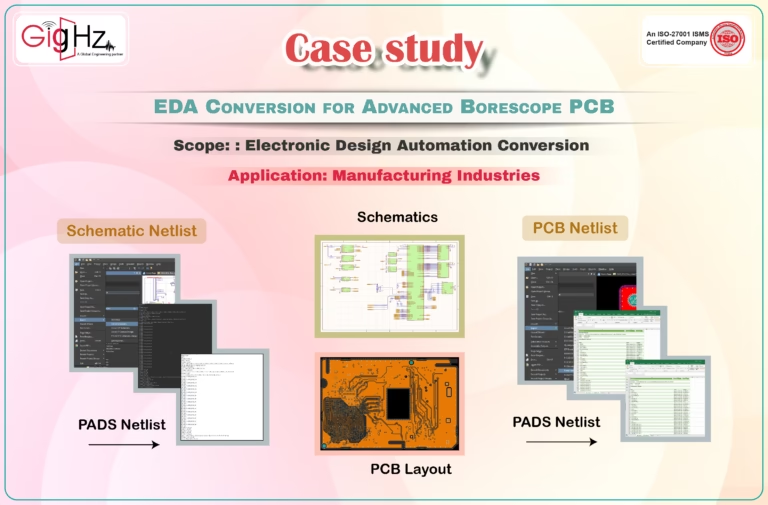

- Seamless EDA conversions while preserving original design data

- Integrating MCAD tools into product lifecycle management

- Leveraging advanced CAD tools and simulation for modular designs

- Proficiency with SolidWorks, CATIA, Siemens NX, Creo, and more

- Transform hand-drawn schematics into meticulously organized multilevel hierarchies for flawless diagrams, showcasing unparalleled expertise.

- Specialized in multi-layer designs, component placement, routing techniques, and ground plane design.

Industries We Serve

Automobile Industry

We accelerate automotive innovation and cut development timelines through deep CAD expertise across electrical and mechanical systems.

Medical

Our specialized CAD services empower rapid design and compliance for medical device makers seeking to enhance high speed design outcomes.

Aerospace

We reduce aerospace development timelines through collaborative CAD support across complex spacecraft and defense programs.

Telecom

Our CAD skills help telecom equipment makers design high-density electronics, optimise thermal properties, and validate signal integrity through simulation.

Comprehensive CAD Engineering Services

Elevating Your Business With Our End-to-End Engineering Services

Seamless Automation For Electronic Design (ECAD)

Our end-to-end Electronic CAD design services boost your productivity and accelerate time-to-market. We create custom component libraries optimized for your workflows to boost efficiency. Our experts deliver ready-to-manufacture schematics tailored to your design needs. We transform schematics into physical PCBs optimized for manufacturability, performance, and cost.

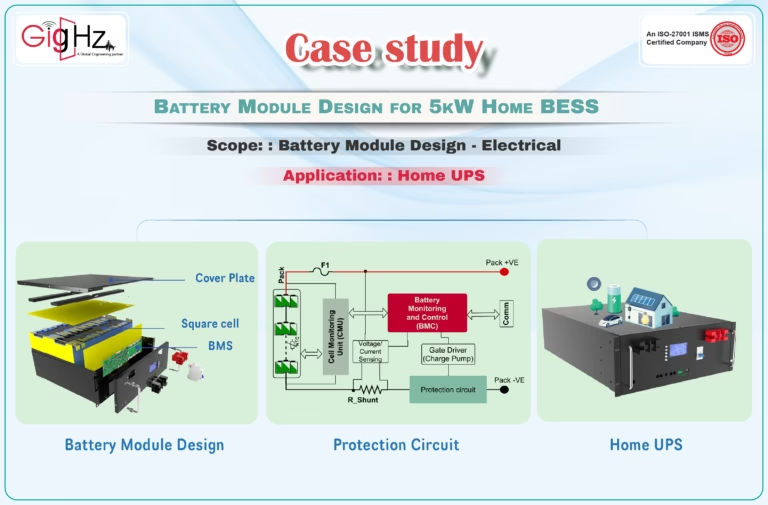

Simulating the Future with MCAD Solutions

Our MCAD solutions enable digital prototyping to simulate products before manufacturing. We build robust 2D engineering drawings optimised for simulation, visualisation, documentation, and manufacturing. Our expertise spans 3D modelling from concept to completion, enclosure design, reverse engineering of physical parts, engineering drawings for manufacturing, and value engineering to cut costs.

By leveraging our full range of MCAD services you can bring innovative products to market faster and more cost-effectively. We become your virtual product development team to simulate before you fabricate.

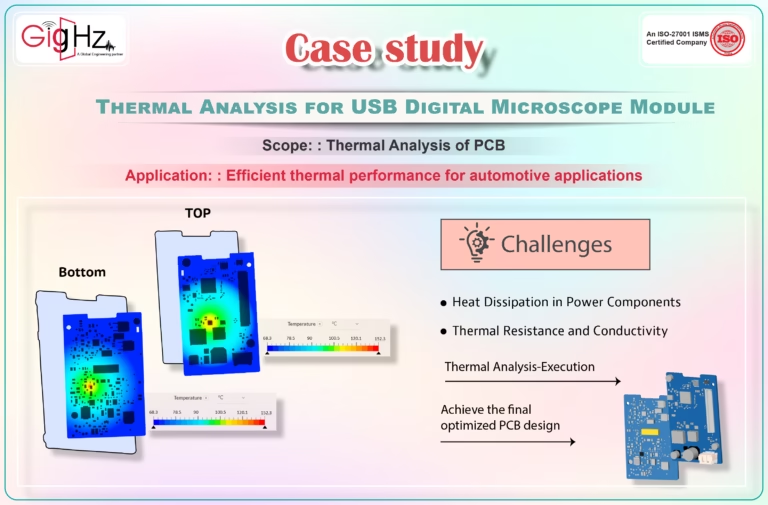

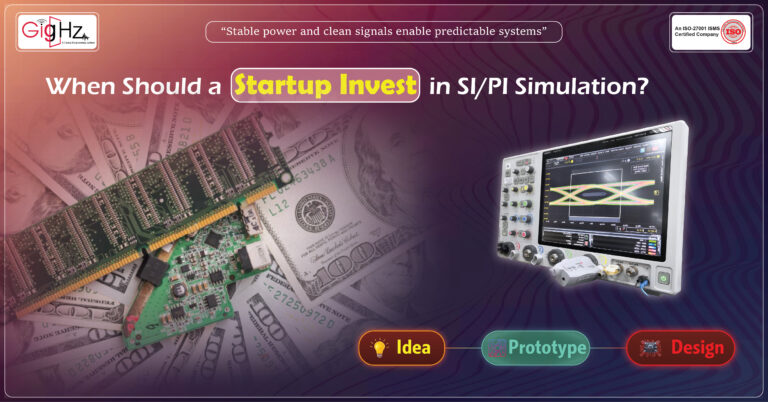

Analysis & Simulation Services Before Manufacturing

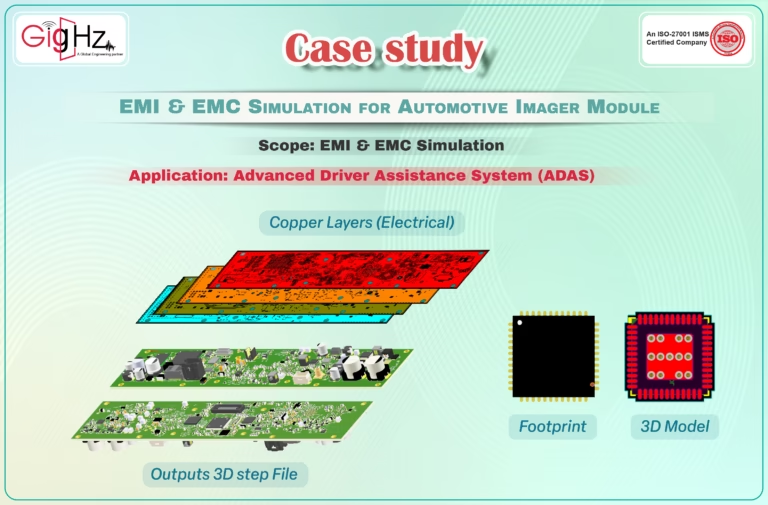

Our expert analysis and simulation services provide critical insights before manufacturing. Thermal analysis identifies issues and solutions to maintain safe operating temperatures. Signal and power integrity analysis ensures error-free signal transmission and clean power delivery.

Worst-case circuit analysis predicts reliability under extreme conditions. EMI/EMC analysis verifies your design meets regulatory standards. Identifying issues early optimises designs for reliability, safety, and compliance. Our virtual testing gives actionable feedback when changes are most cost-effective.

Leverage our simulation services to validate your product meets specifications the first time. We help you get it right before manufacturing.

Customer Recommendations & Testimonials See for yourself what our customers are saying!

“GigHz Technologies has been an invaluable partner for our company. Their expertise in Electronic PCB design and Analysis is unparalleled. They took our complex project and turned it into a seamless reality, all while keeping costs in check.”

North American – Tier I Automotive Supplier

Still continuing – 3rd year

“As a startup, finding a reliable partner for our Electronic and Mechanical design needs was crucial. GigHz Technologies exceeded our expectations with their attention to detail and personalized approach.”

Research Engineer

Haystack Research Observatory, MIT, USA

“Collaborating with GigHz Technologies was a game-changer. Their ECAD–EMI/EMC capabilities saved us time and resources with innovative solutions and strong global partnerships.”

Engineering Director

Aerospace Company, USA

Why Choose Gighz

The engineering team at GigHz stays ahead of the curve by actively adopting new technologies to expand expertise and master emerging tools. Our commitment to innovation is matched by our hands-on approach, where 3D CAD design services and simulation-led workflows are enhanced by human insight. We believe quality results come from oversight, not automation alone—our experts supercharge every stage, from early concepts to ready-to-manufacture designs.

We constantly challenge our engineering capabilities through advanced tools and 3D CAD solutions, keeping your time and cost in check. By integrating 3D CAD design services with domain expertise, we transform embedded product design—delivering precision with a human touch.