10 Ways Worst Case Circuit Analysis(wcca) Enhances Safety in EV Battery Systems

- Posted On:

- August 27, 2024

- Category:

- Analysis & Simulation

Worst Case Circuit Analysis

In the rush of getting to the office,

Have you ever been stuck in traffic and noticed how the pollution from cars can be irritating and disruptive?

The smog, noise, and exhaust fumes can really affect our daily lives.

This is where electric vehicles (EVs) come in, offering a breath of fresh air.

Research shows that as more consumers prioritize environmental sustainability and energy efficiency, the adoption of EVs is accelerating.

People are welcoming this shift because EVs promise cleaner air, reduced carbon footprints, and lower fuel costs.

With more EVs on the road, our cities will be quieter and the air will be cleaner.

This shift is an important part of fighting climate change and creating a better future for everyone.

At the core of these innovative vehicles are advanced battery systems that power their performance.

To ensure these batteries are both safe and reliable, engineers use a technique known as Worst Case Circuit Analysis (WCCA).

Here’s how WCCA works.

Worst-Case Circuit Analysis puts battery systems through tough tests to see how they handle extreme conditions.

Engineers simulate scenarios like very high temperatures or heavy loads to find and fix any potential problems before they become real issues.

Why does this matter?

By spotting and addressing these problems early, WCCA helps make sure EVs are safe and reliable.

It’s like having a tool to predict how the battery will perform under stress, ensuring it’s ready for anything.

In this blog, we’ll explore ten ways WCCA improves the safety and reliability of EV battery systems.

Whether you’re an EV enthusiast or just curious about the technology, you’ll learn how this vital analysis is shaping the future of transportation.

Let’s dive in and see how WCCA is making EVs safer and more effective.

Upcoming to the worst-case circuit analysis, what it is?

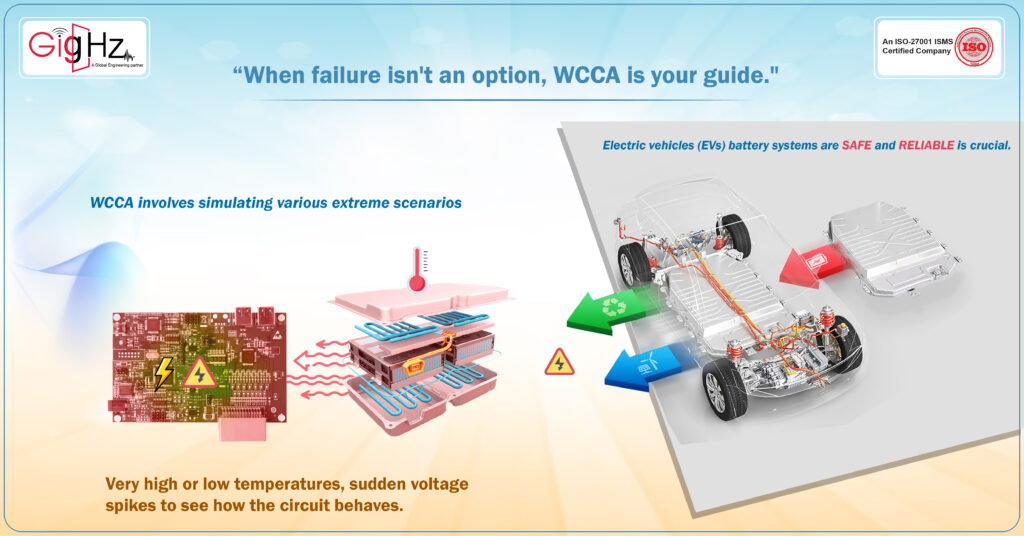

As electric vehicles (EVs) become more popular, ensuring their battery systems are safe and reliable is crucial. This is where Worst-Case Circuit Analysis (WCCA) comes into play.

But what exactly is WCCA?

WCCA is a technique used to test and verify how a circuit will perform under the most extreme conditions it might encounter. It’s like stress-testing a system to its limits to make sure it can handle anything unexpected.

In essence, WCCA involves simulating various extreme scenarios—such as very high or low temperatures, sudden voltage spikes, or heavy loads—to see how the circuit behaves. Engineers use these simulations to identify potential issues that might not be evident under normal operating conditions.

For EV batteries, this analysis is especially important. The battery systems in EVs must operate reliably under a range of conditions and stresses. WCCA helps ensure that all components, from voltage regulators to thermal management systems, function correctly even when pushed to their limits.

By anticipating and addressing potential problems before they occur, WCCA helps in designing safer and more reliable EV battery systems. It’s a vital step in making sure that these advanced vehicles can perform well and stay safe, no matter what challenges they face.

10 Ways Worst Case Circuit Analysis(wcca) Enhances Safety and Reliability in EV Battery Systems

Here’s how WCCA plays a critical role in enhancing the performance of EV battery system PCBs:

1. Identifies Potential Overvoltage Conditions

The BMS PCB monitors the battery’s voltage levels, while the Charging PCB manages how power is delivered during charging. Overvoltage conditions can occur during rapid charging or sudden load changes. WCCA helps by simulating extreme voltage scenarios to ensure that the voltage regulators and protection circuits on these PCBs can handle such conditions. This helps prevent potential damage and ensures that the battery parameter functions safely even under stressful conditions.

It is also better to perform sensitivity analysis, sensitivity of these components to changes in operating conditions, engineers can design more robust voltage protection mechanisms.

2. Assesses Thermal Stress and Heat Dissipation

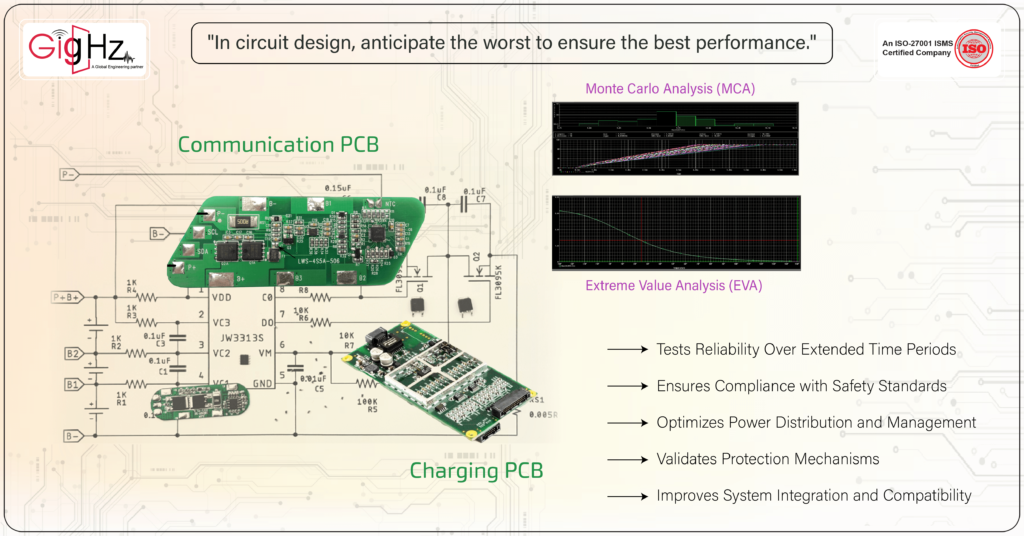

The Thermal Management PCB controls the temperature of the battery, while the Power Distribution PCB handles the power flow, which generates heat. WCCA uses Extreme Value Analysis (EVA)simulation is to evaluate how heat is generated and dissipated under extreme conditions and worst-case scenario. This analysis ensures that heat sinks, thermal vias, and component placements effectively manage heat, preventing overheating and ensuring the PCB remains within safe temperature limits.

3. Evaluates Performance Under Maximum Load

The Power Distribution PCB and Charging PCB must handle high currents during peak loads or charging.

Monte Carlo Analysis (MCA) is used to test how these PCBs circuit design perform under maximum load conditions. This analysis ensures that power traces, connectors, and components can reliably manage peak currents without failure, enhancing the overall reliability of the battery system.

4. Simulates Component Tolerances and Variations

The BMS PCB maintains cell balance and monitors battery health, while the Safety and Protection PCB guards against faults. Component tolerances and variations can impact performance. Monte Carlo Analysis (MCA) models these variations and assesses their effects on PCB performance. This ensures that even when components deviate from their nominal values, the PCB continues to function correctly and reliably.

5. Predicts Failure Modes and Mechanisms

The Safety and Protection PCB detects faults, and the BMS PCB prevents battery damage. WCCA uses Extreme Value Analysis (EVA) to predict how the PCB might behave under conditions that could lead to failure. This helps identify potential weaknesses and guides the design improvements needed to enhance reliability and prevent failures.

Tests Reliability Over Extended Time Periods

The BMS PCB ensures long-term battery health, while the Monitoring and Diagnostics PCB provides ongoing diagnostics. Root Sum Square (RSS) Analysis evaluates how the PCB performs over long periods of usage. This helps ensure that the PCB remains reliable and durable throughout the battery’s lifecycle.

Ensures Compliance with Safety Standards

The Safety and Protection PCB and Charging PCB must comply with safety standards to ensure safe operation. Extreme Value Analysis (EVA) verifies that these PCBs meet safety regulations under extreme conditions, testing for overcurrent, overvoltage, and thermal limits to ensure they adhere to required safety standards.

Optimizes Power Distribution and Management

The Power Distribution PCB and BMS PCB are responsible for efficient power routing and management. Extreme Value Analysis (EVA) is used to optimize how power is managed and distributed. This ensures that the PCB handles extreme power conditions effectively, leading to better power delivery and overall system efficiency.

Validates Protection Mechanisms

Protection mechanisms on these PCBs safeguard against electrical faults and damage. Root Sum Square (RSS) Analysis validates these mechanisms by simulating combined stress scenarios. This ensures that protection devices like fuses and circuit breakers operate correctly and prevent potential damage.

Improves System Integration and Compatibility

The Communication PCB facilitates data exchange between the battery system and other vehicle components, while the BMS PCB integrates with various systems for comprehensive battery management. Monte Carlo Analysis (MCA) evaluates how system integration affects PCB performance, ensuring seamless operation and compatibility with other components.

Conclusion

In conclusion, successfully navigating the complexities of automotive electronic systems requires a robust understanding of various engineering methodologies.

The design process must prioritize signal integrity and circuit performance to ensure that the circuit’s functionality meets stringent industry standards.

Implementing worst-case analysis (WCCA) is essential; as WCCA is no joke, it helps in identifying potential failures that could arise during operation.

Discover our Specialities. Visit our Services Page. https://gighz.net/worst-case-circuit-analysis-in-embedded-systems/

Table of Contents

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.