So, let me tell you a story that still stings today. We were working hard to meet a tight deadline for a client and making haste in delivery. But a tiny blunder in our PCB design cost us over $10,000 to redesign it and led to further delays. Ofocurse, a harsh punishment, wouldn’t you say? Well, it was!

Now, it goes without saying that using PCB layout and design services for reliable electronics is highly essential. However, even a small error can blow the entire budget. Meanwhile, whether you’re a big startup or just a citizen engineer, you’ll find such common errors jumping in way more than you’d think! And not to forget that they are very expensive to patch later.

Therefore, here is what you should watch out for in PCB designing and services.

Why One Mistake Can Break Your Budget

Now in more recent times, hardware development has become quite agile! Because everything is happening fast: From deadlines, prototypes to mass production.

Afterall, the faster you go, the more risk you take.

Likewise, complex PCB boards are highly demanded by modern electronics. And when teams cut corners to move faster, inspection becomes hurried. Hence, PCB design and layout services must therefore be concerned with quality and foresight alongside speed.

Moreover, a study by IPC states that design-related errors contribute over 65% of the delays in PCB manufacturing.

That’s why, there’s no room for rework in tight budgets! So, now let’s have a look at the top 3 mistakes when it comes to.

Mistake #1: Ignoring Design Rule Checks (DRC)

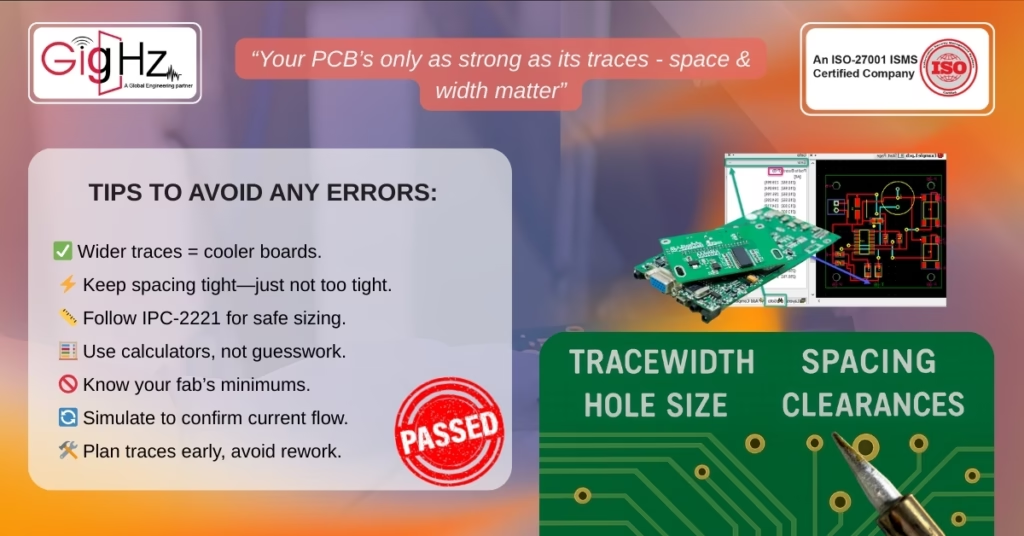

Design Rule Checks (DRC) are automatic checks that ensure your PCB layout is conforming to the manufacturer’s constraints, like:

- Trace width

- Spacing

- Holes sizes

- Clearances

Now, in consideration of the tight schedule, most teams skip or rush through DRCs. Consequently, the boards failing in DRCs will be rejected at the manufacturer or fail during testing. On the other side, it will result in the prototypes getting wasted, schedules are stretched out, and costs increasing.

So, coming to the fix! Always use a qualitative IDRC tool in your design software and don’t rely on default settings. Accordingly, you need to get the actual constraints from your manufacturer and apply them downstream during the early stages.

Mistake #2: Poor Component Placement

Finally, this critical error disrupts the way the current flows through the PCB board due to traces being too thin or placed too close together.

As a result, you will end in having signal interference, overheating, or even burned-out traces. Plus, you already know that these are not minor issues – they can hamper your hard work completely.

Besides, just imagine a network of brittle, tiny wires packed too closely together — no planning, and no breathing room at all. Well, that’s an impending catastrophe for sure.

So, coming to the solution now! Determine the appropriate trace width using tools based on your ongoing requirements. Then, observe IPC-2221 guidelines and, if necessary, simulate high-speed signals. Because, a reputable source in PCB design and layout services always calculate and confirm the processes instead of speculating.

Mistake #3: Inadequate Trace Spacing and Width

Finally, this critical error disrupts the way the current flows through the PCB board due to traces being too thin or placed too close together.

As a result, you will end in having signal interference, overheating, or even burned-out traces. Plus, you already know that these are not minor issues – they can hamper your hard work completely.

Besides, just imagine a network of brittle, tiny wires packed too closely together — no planning, and no breathing room at all. Well, that’s an impending catastrophe for sure.

So, coming to the solution now! Determine the appropriate trace width using tools based on your ongoing requirements. Then, observe IPC-2221 guidelines and, if necessary, simulate high-speed signals. Because, a reputable source in PCB design and layout services always calculate and confirm the processes instead of speculating.

Bottom Line

Summing up, every dollar matters in any of such product development. Likewise, after completing the entire PCB designing process, a $5 design error can become a $5,000 catastrophe.

Now, to avoid these costly mistakes, working with seasoned PCB design experts is highly crucial. As, they help you avoid expensive redesigns, plan ahead, and identify hidden problems early.

Therefore, always choose a vendor who prioritizes quality, testing, and manufacturability while investing in PCB layout and design services. Consequently, the ideal partner will protect your budget and schedule in addition to building your board.

Moreover, for a free consultation and to learn how we can future-proof your PCB designs, contact us at info@gighz.net.

Afterall, you can lower risks drastically, save money, and build more intelligently with just one click.

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.