5 Amazing Ideas of PCB Design for Automobiles

The story of automobiles started with the clever idea of using steam power to make a vehicle move back in the 17th century.

This was the very beginning of what we now know as cars.

It’s like a big adventure that’s still ongoing today, with cars becoming smarter and more connected all the time.

The story of automobiles started with the clever idea of using steam power to make a vehicle move back in the 17th century.

This was the very beginning of what we now know as cars.

It’s like a big adventure that’s still ongoing today, with cars becoming smarter and more connected all the time.

Category :

Published Date :

April 11, 2024

Category :

Published Date :

April 11, 2024

Category :

Published Date :

April 11, 2024

From the early days of steam power, automobiles have evolved to incorporate advanced technologies like printed circuit boards, showcasing the incredible journey of innovation and progress.

Basically, PCBs are like the electronic nervous system of a car. They’re used in lots of different parts of the vehicle to help things run smoothly and to power all sorts of electronic features.

Imagine PCBs as the super-smart brains behind the car’s electronics. They make sure everything from the GPS and brakes to the engine and safety systems work properly.

In the past, cars were simple machines, but now, thanks to PCBs, they can do really cool things like drive more efficiently, keep you safe on the road, and even entertain you with fancy infotainment systems.

So, PCBs are like the behind-the-scenes heroes that help make our cars smarter, safer, and more fun to drive!

We’ve successfully crafted the layout designs for printed circuit boards (PCBs) tailored to numerous automotive applications.

Now, its time to share our experience and give you the hints with car PCBs in this blog post.

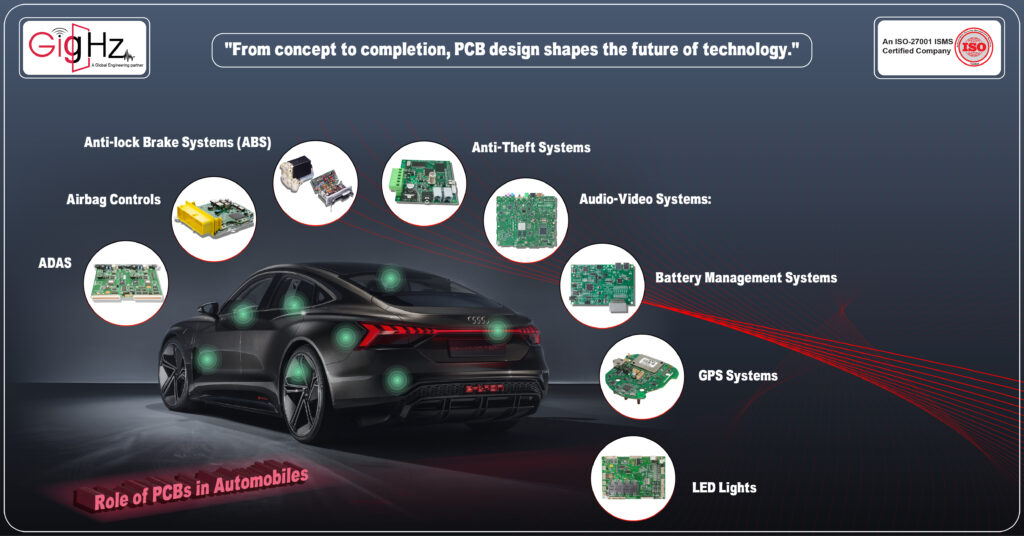

Role of Printed Circuit Boards in Automobiles

Printed circuit boards (PCBs) are extensively utilized in various parts of automobiles to power and control a wide range of electronic systems and components.

Here’s a detailed breakdown of the areas where PCBs are commonly employed within vehicles:

Airbag Controls: PCBs in airbag control systems manage sensor data, ensuring accurate deployment during safety events to protect occupants. PCBs are used in the control systems for airbags, ensuring timely and accurate deployment during vehicle safety events.

Anti-lock Brake Systems (ABS): PCBs play a crucial role in the electronic control units of ABS, enabling precise regulation of braking performance to prevent wheel lock-up.

Anti-Theft Systems: The electronic components of anti-theft and immobilizer systems rely on PCBs for their functionality, providing security features for the vehicle.

Audio-Video Systems: PCBs support the operation of entertainment and infotainment systems, including audio amplifiers, digital displays, and video components within the vehicle.

Climate Control: PCBs are used in the control panels and sensors of the climate control systems, regulating heating, ventilation, and air conditioning functions.

LED Lights: Both exterior and interior LED lighting systems in automobiles are powered and controlled by PCBs, ensuring efficient and reliable operation.

Engine Management: PCBs are integral to engine control modules (ECMs), managing fuel injection, ignition timing, and other critical engine functions.

GPS Systems: The electronic components of GPS and navigation systems rely on PCBs to process and transmit location data, contributing to accurate navigation within the vehicle.

Transmission Controls: PCBs are utilized in the electronic control units of automatic transmissions, enhancing shifting performance and efficiency.

Dashboard Electronics: Various electronic components within the dashboard, such as instrument clusters, infotainment interfaces, and driver information displays, are equipped with PCBs for their operation.

Power Relay Systems: PCBs are employed in power relay modules, managing electrical distribution and control within the vehicle’s power system.

Comfort Control Systems: PCBs contribute to the functionality of comfort features such as power windows, mirrors, seats, and other electronic convenience systems.

ADAS (Advanced Driver-Assistance Systems): PCBs are essential for the operation of ADAS components, including sensors, cameras, and control units that enable advanced safety and driver assistance functionalities.

Battery Management Systems: PCBs play a key role in battery management units, monitoring and managing the performance and health of the vehicle’s battery system.

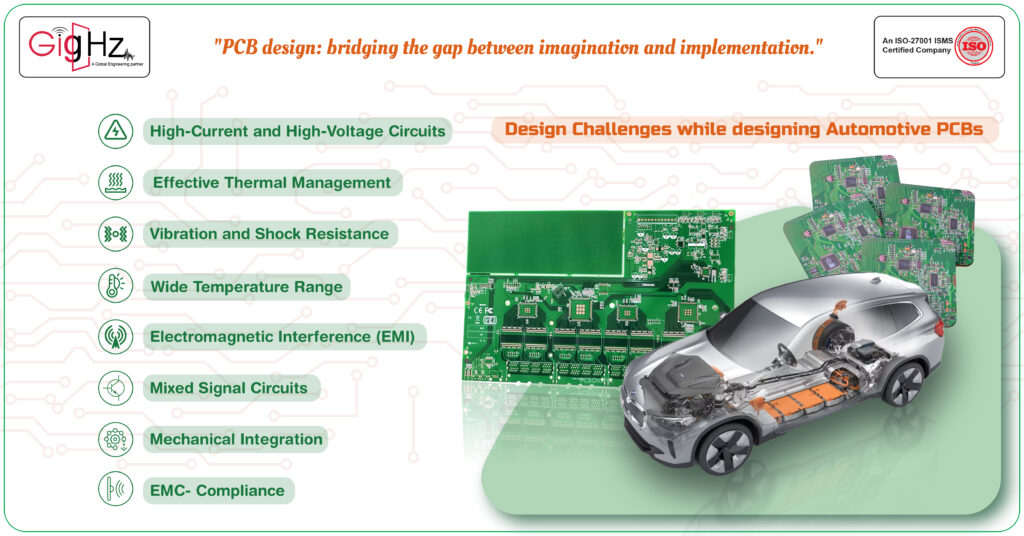

Design Challenges while designing Automotive PCBs

Designing printed circuit boards (PCBs) for automotive applications is no easy task.

There are several challenges that we need to navigate to ensure these PCBs can meet the demands of the automotive environment.

Let’s break it down:

High-Current and High-Voltage Circuits: Okay, so first off, you’ve got to consider those high-current and high-voltage circuits. These PCB designs need to handle some serious power, so the components, layout, and thermal management all need careful attention.

Effective Thermal Management: Imagine the heat under the hood of a car – PCBs need to be able to handle that heat effectively. It’s all about making sure the electronic components can perform well and have a long lifespan.

Vibration and Shock Resistance: Cars experience a lot of bumps and shakes while on the road. Designing PCBs that can withstand all that vibration and shock without missing a beat is definitely a challenge.

Wide Temperature Range: From freezing cold to scorching heat, automotive PCBs need to work reliably across a wide temperature range. Choosing the right materials and managing heat becomes crucial here.

Electromagnetic Interference (EMI): With so many electronic systems in a vehicle, managing electromagnetic interference is a big deal. PCB designs have to find ways to minimize interference and keep those signals clean.

Mixed Signal Circuits: Think analog and digital signals coming together. Designing for these mixed signal environments calls for real attention to detail in terms of signal isolation and noise reduction.

Mechanical Integration: These PCBs have to fit within the mechanical framework of the vehicle. That means thinking about the size, how they’re mounted, and making sure they can take a bit of rough handling.

EMC (Electromagnetic Compatibility) Compliance: Ensuring that PCB designs meet electromagnetic compatibility standards is a big deal. We’ve got to make sure these designs play nice with the vehicle’s electronic systems and the world around them.

It’s a complex set of challenges, but mastering them is key to creating PCBs that can deliver the performance and reliability needed in today’s vehicles.

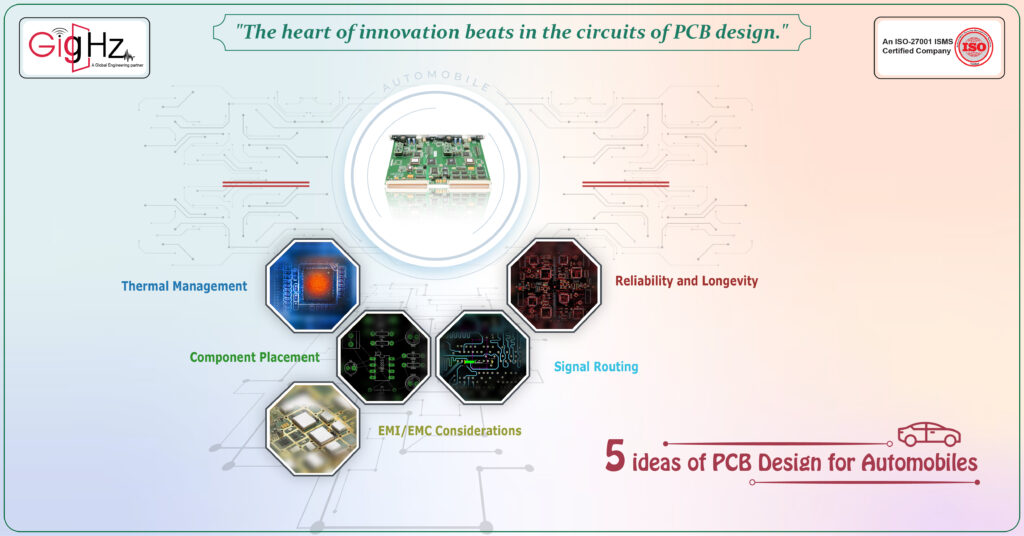

5 ideas of PCB Design for Automobiles

“So, let’s now explore ideas for effective design, considering the challenges.”

Thermal Management:

So, to keep things cool, we need to make sure the PCB can effectively handle the heat generated by its components. This means using smart heat dissipation techniques, adding thermal vias to improve heat transfer, and choosing materials with high thermal conductivity. By doing this, we can really boost the durability and reliability of automotive electronics.

Component Placement:

When we’re putting components on the PCB, it’s not just about finding space for them. We’ve got to be strategic, thinking about how to minimize unwanted effects, optimize signal paths, and make sure there’s enough room for high-voltage components. We also pay special attention to critical components like microcontrollers and power devices to reduce noise and interference.

Signal Routing:

It’s not just about connecting the dots. Signal routing involves using controlled impedance traces for high-speed signals, setting up differential pairs routing, and carefully planning the layer stackup to keep the signals clean and clear. We can also use simulation tools to fine-tune the routing for minimal signal distortion.

Environmental Factors:

We need to think about where these PCBs will be living – in cars, that means dealing with moisture, contaminants, vibration, shock, and temperature changes. To handle this, we can apply conformal coating, choose tough components and materials, and make sure the PCB can handle all the challenges that come with being in a vehicle.

Compliance with Industry Standards:

Meeting industry standards in automotive PCB design is crucial. It means understanding specific regulations such as AEC-Q100 for electronic components, the ISO 26262 functional safety standard, and the IPC-6012 automotive addendum for PCBs. Following these standards is key to making sure our automotive PCBs are reliable and safe.

Reliability and Longevity:

Want these PCBs to last?

Design for manufacturing (DFM) principles are the way to go.

This means paying attention to things like pad and trace sizes, solder mask expansion, and test point placement to make testing during production easy. All of these factors contribute to a long-lasting, reliable PCB.

EMI/EMC Considerations:

Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are big deals in automotive PCB design. We need to use shielding techniques, smart ground plane design, and EMI filters to control electromagnetic interference and meet EMC requirements, keeping the PCB working smoothly within the complex electronic system of the vehicle.

By considering these technical aspects during the PCB design process, we can create strong and reliable circuit boards tailored specifically for the demanding requirements of automotive applications.

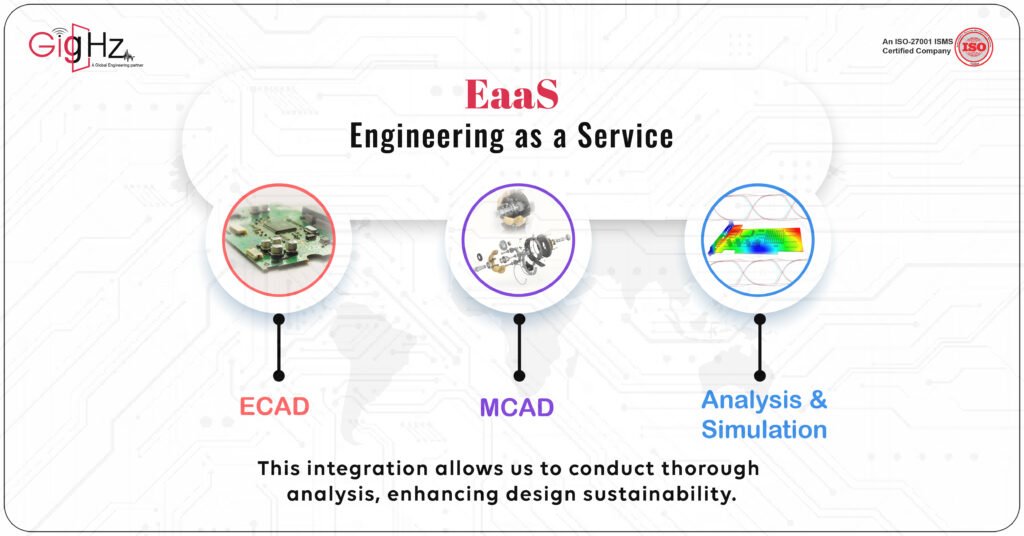

Our Notable Upgrade: Engineering as a Service (EaaS)

Absolutely!

The engineering landscape is constantly evolving, and it’s incredible to see how Engineering as a Service (EaaS) is rising to meet the industry’s growing demands.

By tapping into the power of ECAD, MCAD, and Analysis & Simulation, we’re able to deliver end-to-end solutions that cover every facet of the engineering process.

It’s truly remarkable how far we’ve come in integrating various engineering disciplines. With EaaS, we seamlessly combine electronic design, mechanical design, and analysis and simulation—all under one roof.

This approach not only streamlines workflows but also boosts efficiency and enhances collaboration across teams.

Conclusion

When it comes to pcb layout design, there are a plethora of design guidelines and best practices to follow for a successful design. Choosing the right pcb manufacturer is crucial, especially when designing pcbs for automotive use in the fast-paced automotive industry.

Utilizing the right pcb design software can make a significant difference in the circuit design process, whether you are working with surface mount or through-hole components.

Paying attention to power and ground connections, signal integrity, and coupling is essential for a reliable design.

PCB design tips, such as incorporating heat sinks and power planes, can also greatly impact the performance of the electronics design.

As you navigate the complexities of pcb layout and design, remember that it’s easy to get overwhelmed, but with the right design tools and design rules, creating a successful pcb layout is achievable.

To Discover our Specialities. Visit our Services Page. https://gighz.net/services/