When we talk about PCB (Printed Circuit Board) design,

We know it’s a crucial part of almost every electronic system.

But when it comes to the automotive industry, the stakes are even higher.

Automotive PCB designs aren’t just about making sure everything works—

They have to meet tough standards for safety, reliability, performance, and durability, all while navigating strict environmental regulations.

So, if you’re diving into automotive PCB design, you’ve got to be on top of your game.

This isn’t just about basic design principles—it’s about mastering advanced concepts and cutting-edge technologies.

Whether you’re working on ADAS (Advanced Driver Assistance Systems), Battery Management Systems (BMS), or electrification components, each of these systems presents its own set of challenges.

As an automotive PCB design expert, you need to be well-versed in the methodologies and tools that ensure the success of these critical automotive systems.

From ensuring high-speed signal integrity in ADAS to managing the power needs of EV battery systems, your designs will play a huge role in making vehicles safer, smarter, and more efficient.

Ready to take your expertise to the next level and tackle these challenges head-on?

Let’s explore what it takes to be an expert in automotive PCB design!

PCB Design for Today’s Advanced Improvements

PCB design is essential for the success of advanced technologies such as 5G, electric vehicles (EVs), and AI systems, all of which require high performance and reliability. Here’s how key aspects of PCB design are connected:

Signal Integrity in High-Speed Applications: As data speeds increase in 5G and AI, maintaining clean signals becomes critical. Effective signal integrity management ensures that high-speed signals are not degraded by noise or interference, enabling fast, reliable data transmission.

Power Integrity for Stability: Proper PCB design also ensures stable power integrity, which is key to preventing noise and interference in high-speed signals. This is especially important in power-sensitive applications like electric vehicles, where consistent power delivery impacts both performance and safety.

In essence, optimizing signal integrity and power integrity in PCB design ensures reliable, efficient operation of advanced systems, helping meet the stringent demands of modern technologies.

In EVs, maintaining a stable power distribution network (PDN) is critical. Good power integrity ensures smooth signal transmission, helping thermal management in compact designs like wearables and autonomous vehicles.

The push for smaller, more efficient devices, like wearables, relies on HDI PCBs. These designs require 3D modeling for optimal component placement, ensuring space efficiency and better thermal management. For wearable tech and automotive applications, rigid-flex PCBs provide durability and flexibility, meeting space and reliability needs.

As devices become more interconnected, managing electromagnetic interference (EMI) is vital. Effective shielding and grounding reduce noise, ensuring optimal performance.

AI-powered tools automate component placement and routing, improving design efficiency and addressing challenges in signal integrity, power integrity, and thermal management.

How Much of an Automotive PCB Design Expert Are You? Let’s Find Out!

Automotive PCB design is a specialized field that requires advanced knowledge of signal integrity, power integrity, thermal management, and manufacturing requirements.

Experts in this area must not only design boards that work effectively but also ensure they are durable and meet strict industry standards.

Let’s dive into the technical specifications that every expert should know to design reliable automotive PCBs,

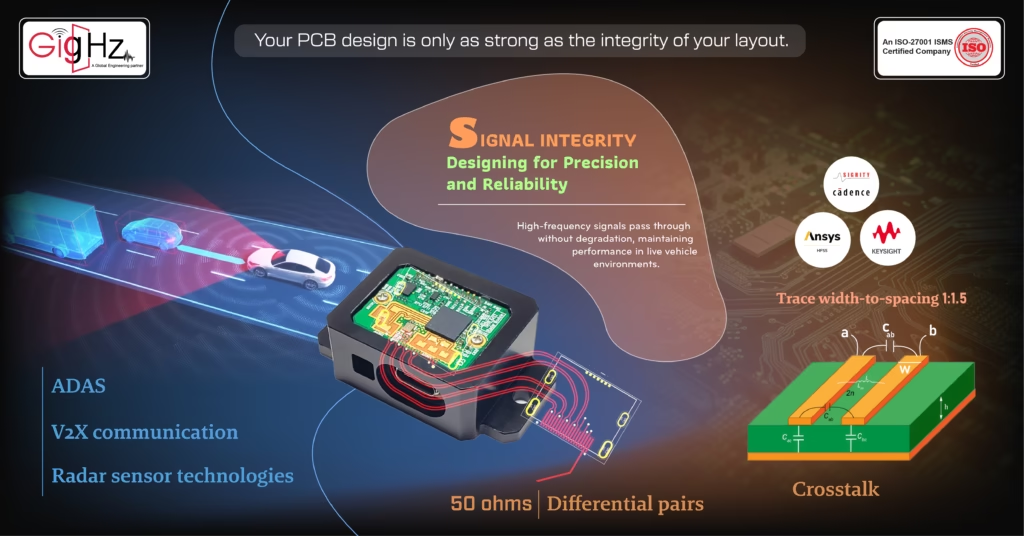

1. Signal Integrity: Designing for Precision and Reliability

In automotive systems like ADAS (Advanced Driver Assistance Systems), V2X communication, and radar/sensor-based technologies, signal integrity is crucial. Here’s how an expert ensures that automotive PCBs meet the highest standards:

Target impedance of 50 ohms for differential pairs (for high-speed signals) and 100 ohms for single-ended lines.

To ensure minimal signal reflection and transmission loss, maintaining signal clarity for real-time data applications in vehicles.

Crosstalk Minimization:

Trace width-to-spacing ratio to maintain adequate isolation, typically aiming for 1:1.5 or higher.

Prevent unwanted interference between closely spaced signal traces, ensuring high signal fidelity for safety-critical applications like autonomous driving.

Use of simulation tools like Cadence Sigrity, Keysight ADS, or Ansys HFSS to model high-speed signal paths and check for potential issues such as reflection, resonance, and noise.

Ensure that high-frequency signals pass through without degradation, maintaining performance in live vehicle environments.

1. Power Integrity: Ensuring Stable Power for High-Performance Systems

Automotive PCB designs must handle high power densities, especially in electric vehicles (EVs) and autonomous driving systems.

Here’s how experts address power integrity:

PDN Design:

Use of power planes with a low impedance to ensure stable voltage delivery.

To ensure that components such as battery management systems (BMS), electric motors, and inverters receive stable, uninterrupted power even under high load.

Current Density:

Specification: Calculate trace width based on Joule’s Law to ensure the PCB traces can handle the maximum current required without excessive heating. For example, 0.5mm traces might be used for currents of up to 5A, but for higher currents, wider traces are needed.

Thermal Management:

Thermal vias and copper pours to spread heat and maintain temperatures below component tolerances (typically < 125°C for most components).

Prevent thermal damage, especially in power-intensive systems like charging circuits and motors.

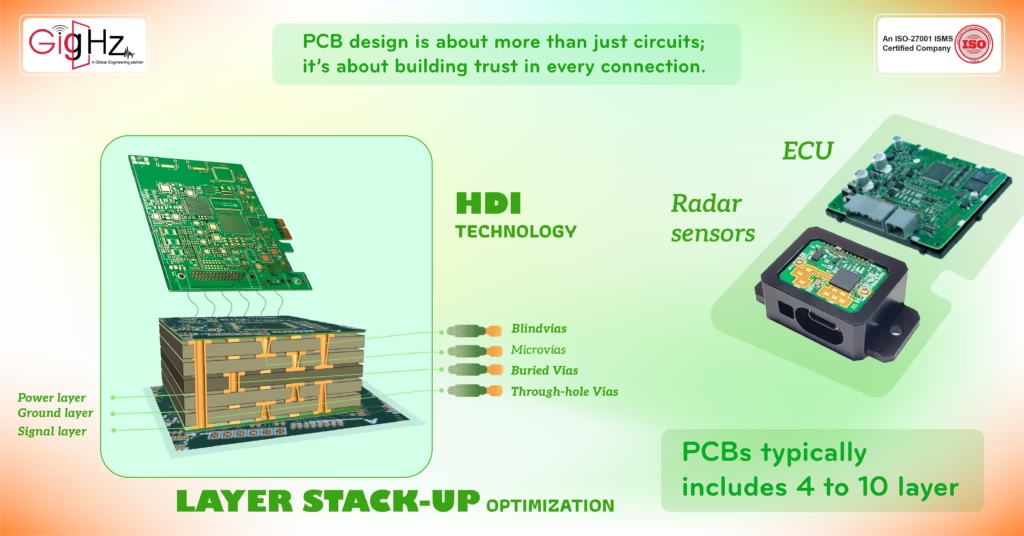

3. Compact and Efficient Design: Mastering HDI for Small Spaces

With the increasing complexity of automotive systems, PCB designs need to be both compact and powerful. High-Density Interconnect (HDI) techniques are essential for this:

HDI Technology:

Use of microvias (typically < 150µm in diameter) and blind vias to achieve high layer density.

To reduce the footprint of the PCB while maintaining the performance of critical components, like radar sensors, ECUs, and battery controllers.

Layer Stack-Up Optimization:

An optimal stack-up for automotive PCBs typically includes 4 to 10 layers, with internal ground and power planes for optimal signal routing.

Reduce noise and provide efficient power distribution, all while minimizing the PCB size.

4. Designing for Safety: Adhering to Industry Standards

Automotive PCB design involves strict safety standards and compliance to ensure the system operates correctly and safely

EMI Shielding:

The PCB must have ground planes and shielding that comply with ISO 11452 and IEC 61000-4 standards for electromagnetic immunity and emissions.

Prevent interference between sensitive electronics (e.g., radar, LIDAR, and cameras) while meeting EMC (electromagnetic compatibility) standards.

Redundant Circuit Design:

Use of redundant power supplies and failover circuits for safety-critical systems, with watchdog timers and error detection protocols.

Provide safety for critical systems like steering, brakes, and powertrain, which need to operate reliably even if one component fails.

5. Manufacturing and Assembly Considerations

The ability to scale up production while maintaining quality is essential. Automotive PCB designers must consider:

DFM (Design for Manufacturability):

Design traces with a minimum trace width of 4 mils for standard PCB manufacturing processes and ensure component placement allows for automated assembly.

To reduce manufacturing costs, improve the assembly process, and avoid issues such as component misalignment.

Automated Test Points:

PCB designs should include test pads and boundary scan capabilities for in-circuit testing (ICT).

To simplify quality control and minimize defects during mass production.

Summary

Are You Ready to Be an Automotive PCB Design Expert?

Automotive PCB design is a highly specialized skill that combines signal integrity, power integrity, thermal management, and safety standards.

By following the specifications and practices outlined here, you can ensure that your designs will meet the demands of the automotive industry while maintaining safety, reliability, and performance.

Make automotive PCB design easy – follow our simple guidelines post for expert results https://www.linkedin.com/in/chandra-thimma/recent-activity/all/

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.