LED PCB Schematic Design

When I first started out in PCB design, I didn’t fully grasp just how critical the schematic design stage was.

I thought it was just a simple matter of placing components and connecting them together, but I quickly learned that the schematic is the foundation of everything that comes later.

It’s where the heart of your design lives—

The relationships between components, the signal paths, and the power distribution.

All of which determine how well your PCB will perform in the real world.

As I progressed, the need for more advanced designs arose.

I began working with multi-LED PCBs for larger applications, like automotive lighting or LED signage.

This required not just a few components but a structured design that could handle multiple LEDs efficiently while preventing excessive heat build-up.

The next challenge was designing for RGB LEDs.

These required more precise current control and a more complex power circuit.

The schematic design for RGB LEDs involved a more intricate connection of red, green, and blue LED pins to their respective drivers, as well as integrating PWM (pulse width modulation) for color mixing and brightness control.

Here, I also began adding components for voltage regulation and protection diodes to safeguard against power surges.

My 5-Step Solution for the Best PCB Schematic Design

Importance of Schematic Design

When I first ventured into the world of PCB design, developing schematic diagrams was a daunting task.

It wasn’t just about wiring up components—there was a lot more involved in creating a design that would be both functional and manufacturable.

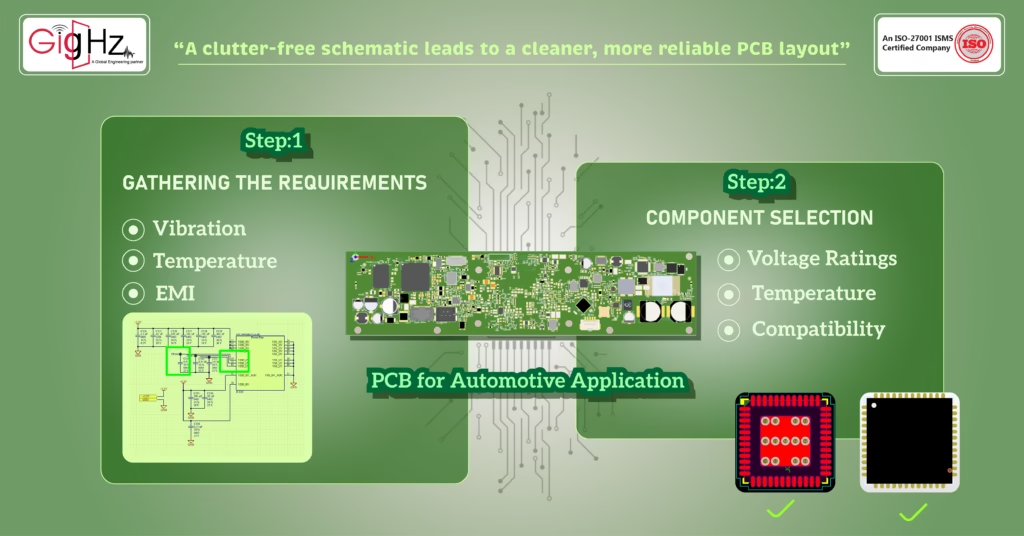

Step 1: Gathering the Requirements

The first stage in any PCB design begins with understanding the project requirements.

When I began my journey, I would often rush this phase, assuming I understood the purpose of the PCB and its function. However, I quickly learned that digging deeper into the specifications and collaborating with the design team is critical.

When I first worked on a PCB for an automotive application, I didn’t initially ask enough questions about environmental conditions like vibration, temperature ranges, or electromagnetic interference (EMI) that could impact the design. These requirements need to be incorporated from the start, as they will affect every aspect of the schematic design—from component choice to routing considerations.

Step 2: Component Selection

Once the project requirements are understood, the next task is selecting the right components. Early on, I often went with what was easily available or what I thought would work. However, as I gained more experience, I learned that choosing the wrong components can create issues down the line—issues that could delay the project or even make the final product unreliable.

In my more recent projects, I’ve been meticulous about component selection. Factors such as the component’s voltage ratings, temperature tolerance, and mechanical compatibility with other parts have become crucial considerations. I also ensure that components are readily available in the quantities needed, as a component shortage can throw off the entire project timeline.

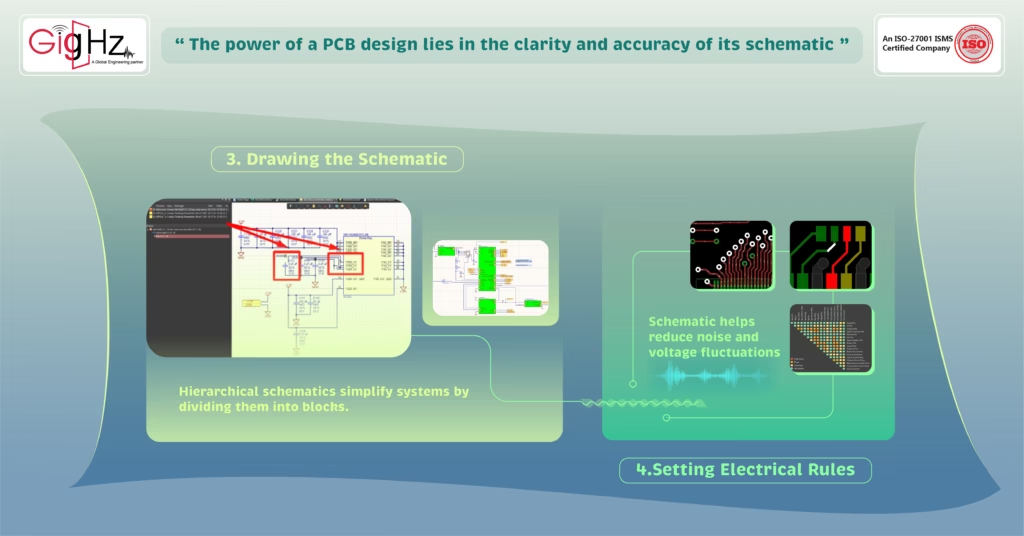

Step 3: Drawing the Schematic

After selecting components, I began drawing the schematic itself. In the beginning, I didn’t fully appreciate how important an organized schematic could be. I’d rush through this process, placing components randomly and connecting them haphazardly. This resulted in more time spent correcting mistakes later on.

Today, I focus on creating clear, organized schematics. I use tools like hierarchical schematics for complex systems, which break the design down into manageable blocks. This makes it easier to track connections and understand the overall flow. Every signal and power line is drawn with intention, and I keep a close eye on minimizing cross-talk and ensuring clean, noise-free signals.

One key piece of advice I can give here: always label components clearly and consistently. This avoids confusion later, especially when debugging or handing off the design to another engineer. You’ll be thankful for it when you return to the project after some time away!

Step 4: Setting Electrical Rules

I didn’t fully appreciate the significance of electrical rules at the start. In my early designs, I ignored certain constraints like power integrity or signal integrity, thinking they would be addressed during the layout phase. However, I quickly learned that establishing these rules early on is essential for creating a reliable design.

Ensuring that power and ground planes are well-defined early in the schematic helps reduce noise and voltage fluctuations. Signal integrity also needs to be planned at the schematic level, especially when designing for high-speed circuits. Including impedance control and high-frequency routing specifications right in the schematic reduces issues down the line.

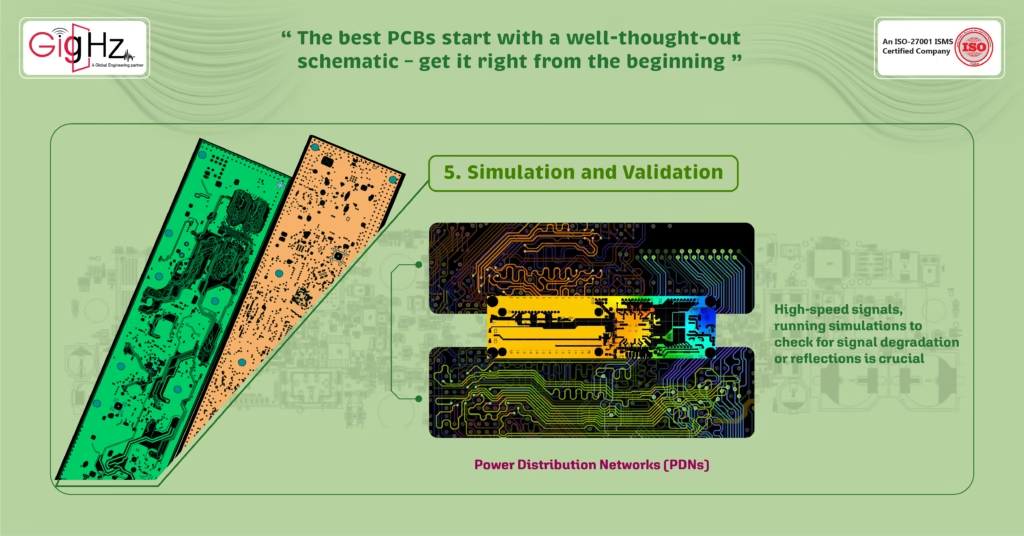

Step 5: Simulation and Validation

One of the best decisions I made as I progressed in schematic design was adopting simulation tools. Initially, I was hesitant to simulate circuits, believing the schematic was sufficient. However, as the designs became more complex, I realized the immense value of simulation.

When designing a PCB with high-speed signals, running simulations to check for signal degradation or reflections is crucial. I use tools to simulate power distribution networks (PDNs) and ensure that all power rails are stable. Simulations for thermal analysis, electromagnetic interference (EMI), and cross-talk have also become an essential part of my workflow.

Validating the schematic against design rules (DRC) and running functional simulations helps catch issues that might not be visible at a glance, saving hours of troubleshooting later on.

Final Review and Documentation

Once the schematic design is complete, it’s time to review everything carefully. In the past, I used to skip the final check, thinking I had covered all the bases. But now, I ensure that the schematic is double-checked, especially for critical errors such as incorrect component values or missed connections.

I also document the design thoroughly. Each schematic sheet includes a detailed bill of materials (BOM), component placement information, and any special considerations for future revisions. This makes it easier to communicate the design to other engineers or manufacturers and ensures smooth transitions from design to production.

Summary

In the world of electronics, a well-structured and error-free design is crucial, particularly when it comes to circuit board design.

The schematic diagram serves as a logical drawing of the circuit board, detailing the electronic components and their connections through wires.

Utilizing schematic design software like Altium Designer, designers can create a pcb schematic diagram that adheres to standard specifications for PCB schematics.

The netlist generated during this design process helps in verifying signal flow while performing a design rule check to catch any design errors.

Each component, from capacitors to integrated circuits, has a specific footprint that must be accurately placed within a grid.

A good schematic not only includes reference designators but also follows standard schematic guidelines to ensure clarity and functionality.

See How We Can Help You Achieve More https://calendly.com/gighz/30min

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.